Building self-heat insulation wall and corner building block and collar beam building block

A self-insulation and block technology, which is applied in construction, building materials, building components, etc., can solve problems such as uncontrollable mortar joints in wall masonry, poor energy saving effect, and difficult to deal with reinforced concrete thermal bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

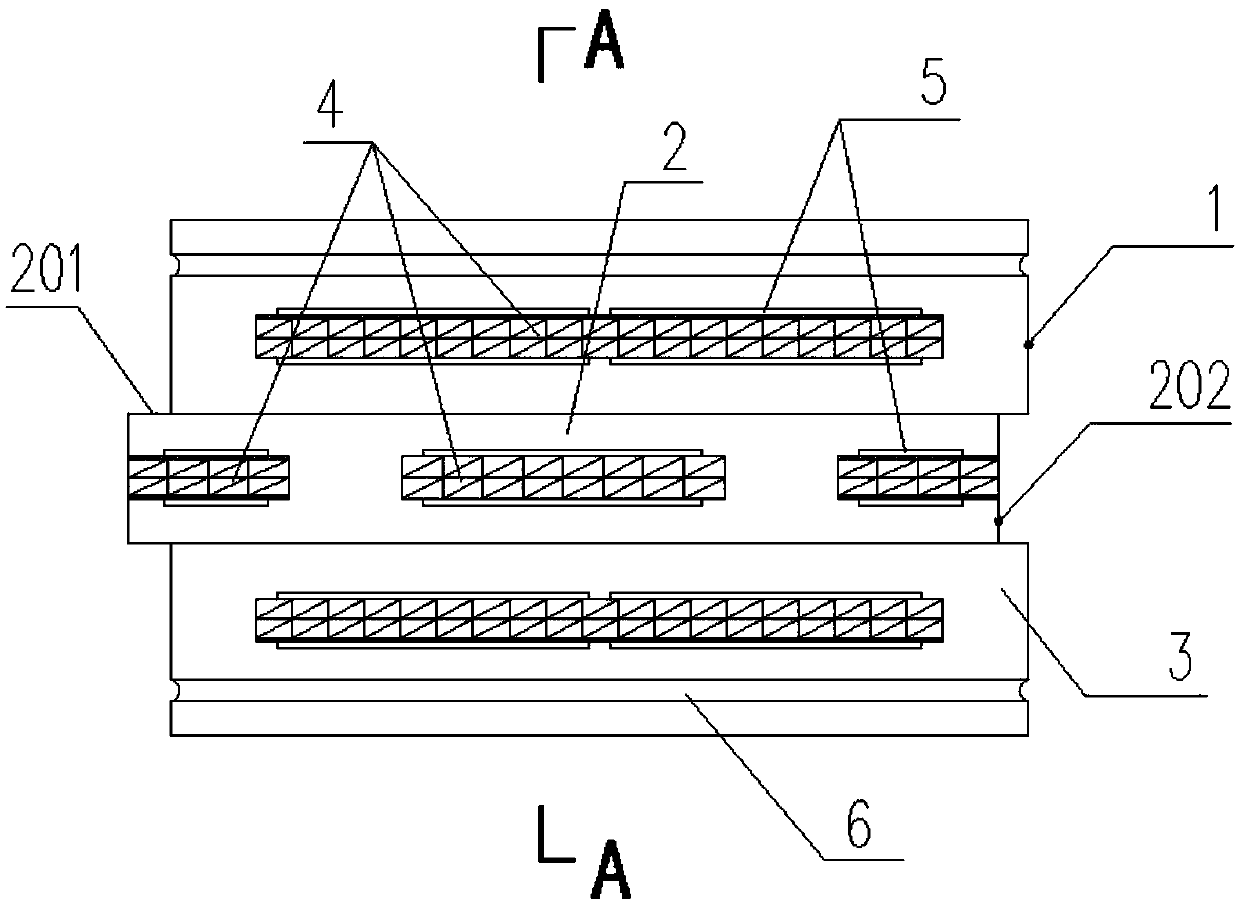

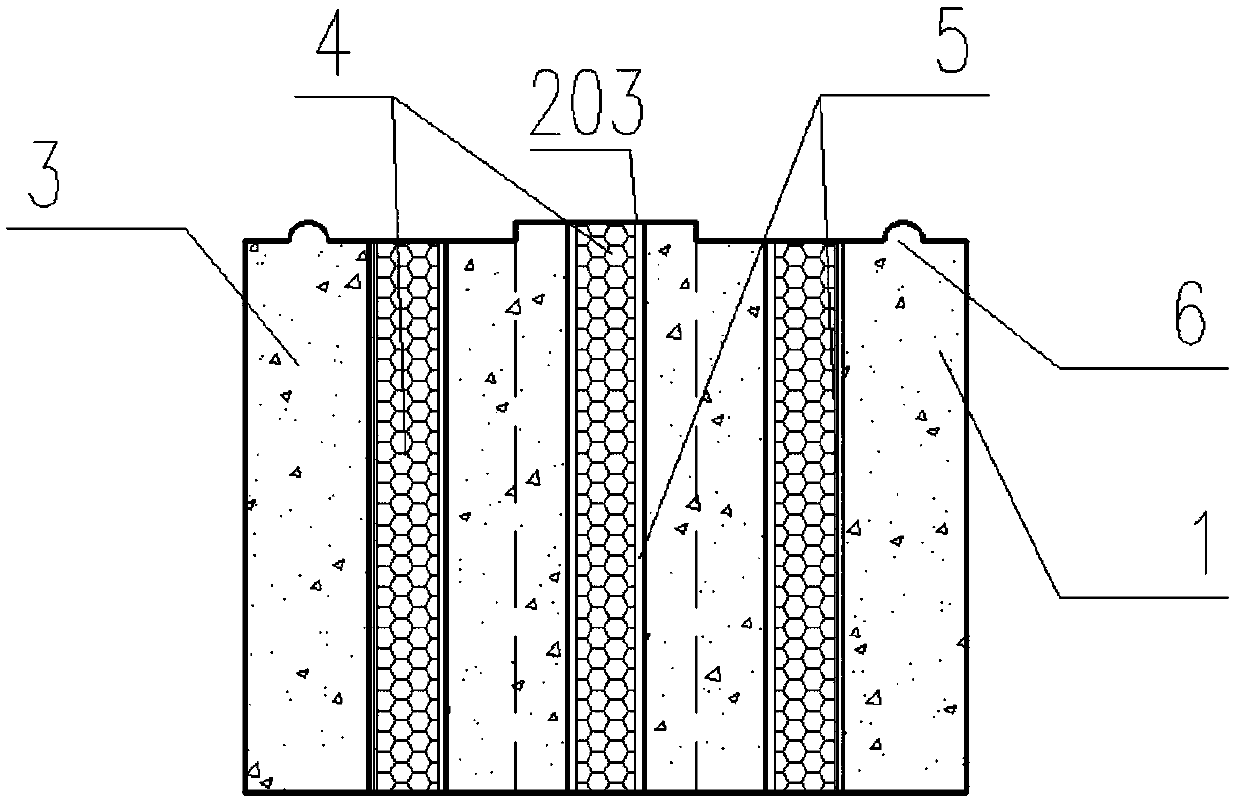

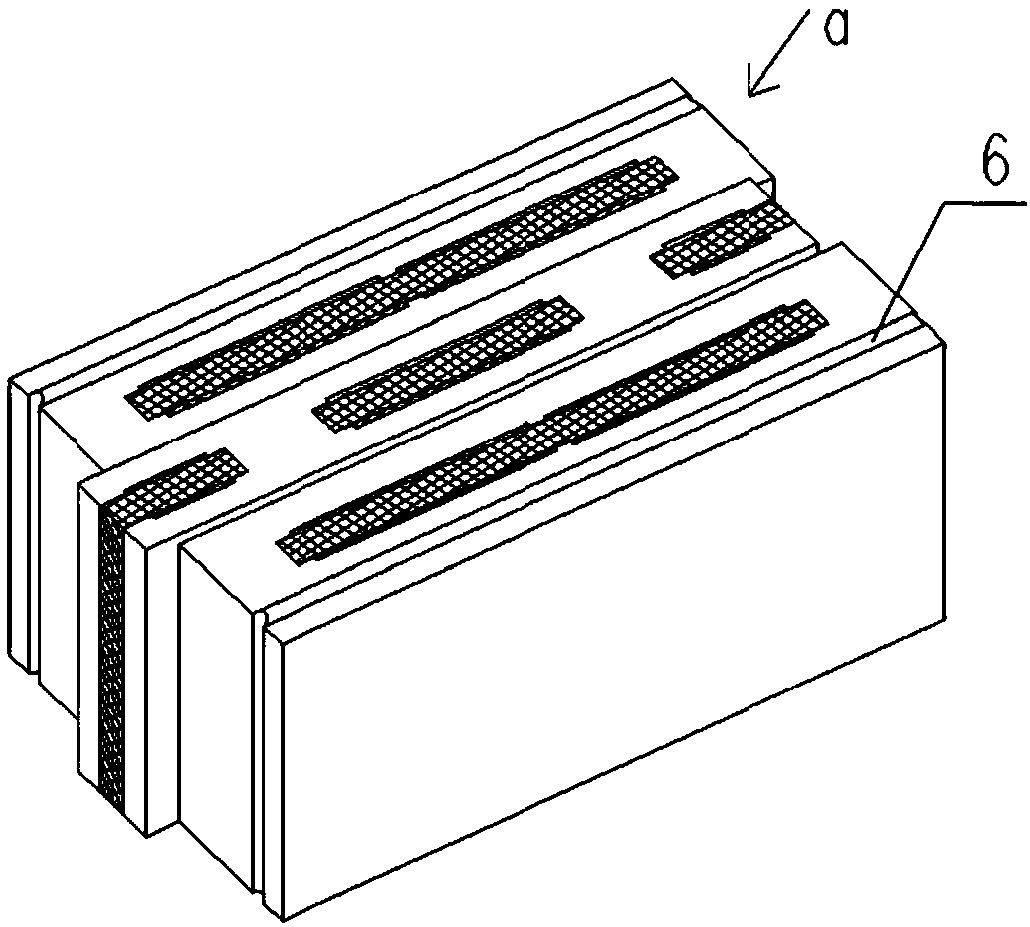

[0068] The building self-insulation wall of the present invention is composed of a main block a, a first auxiliary block b, a second auxiliary block c, a first structural column block d, a second structural column block e, and a first hole side block f, the second hole side block g, the first corner block h, the second corner block i and the tie beam block j are piled up.

[0069] Such as Figure 1-5 As shown, the main block a, the first auxiliary block b, and the second auxiliary block c have the same structure, the length of the auxiliary block is shorter than that of the main block, and the length of the first auxiliary block b is shorter than that of the second The length of the auxiliary block c is long, and the main block a, the first auxiliary block b, and the second auxiliary block c all include a block body, a thermal insulation layer 4, a reflective heat insulation layer and an air thin layer.

[0070] The block body is sequentially composed of three layers of block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com