Composite coating and preparation method and application thereof

A composite coating and composite liquid technology, used in coatings, anti-corrosion coatings, natural resin coatings, etc., can solve problems such as unfavorable corrosion protection of metal substrates, affecting the uniformity and compactness of film layers, and achieve the scope of application of monomers The effect of wide, high density and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

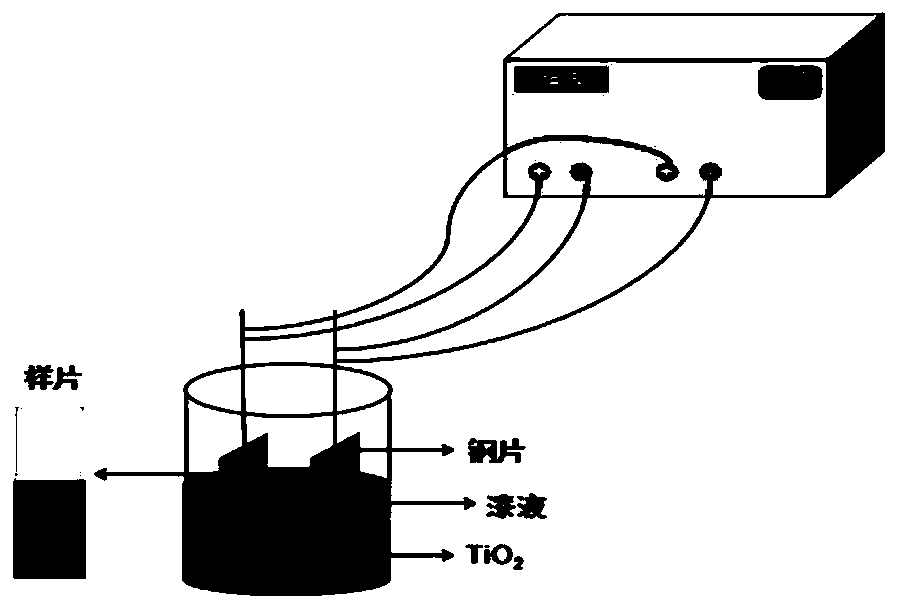

Embodiment 1

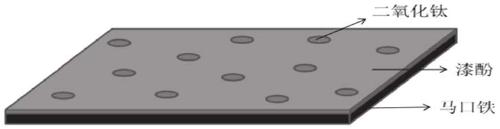

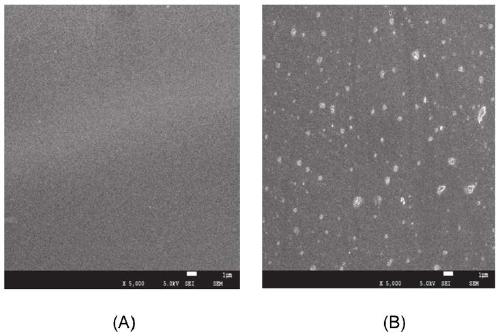

[0048] Component A: Dissolve 10 g of urushiol in absolute ethanol (90 g), and component B: add 20 g of distilled water to absolute ethanol (90 g). Slowly add all the above component B to the above component A, stir well for 20min, then add 10g TiO2 dropwise 2 The aqueous sol was stirred at room temperature for 2h 15min, and prepared into urushiol / nano-TiO 2 compound fluid. The prepared composite liquid is poured into a 100ml beaker for electrochemical polymerization (constant voltage about 130V) experiment, and the electrochemical polymerization device is as figure 1 As shown, get as figure 2 Nano-TiO with the structure shown 2 Polyurshiol / TiO with a mass fraction of 0.2% 2 Composite coating, recorded as UT0.2.

Embodiment 2

[0050] Component A: Dissolve 10 g of urushiol in absolute ethanol (90 g), and component B: add 20 g of distilled water to absolute ethanol (90 g). Slowly add component B to component A dropwise, stir well for 20min, then add 15gTiO2 dropwise 2 The aqueous sol was stirred at room temperature for 2h 15min, and prepared into urushiol / nano-TiO 2 compound fluid. Pour the prepared composite solution into a 100ml beaker for electrochemical polymerization (constant voltage about 130V) experiment to obtain nano TiO 2 Polyurshiol / TiO with a mass fraction of 0.5% 2 Composite coating, recorded as UT0.5.

Embodiment 3

[0052]Component A: Dissolve 10 g of urushiol in absolute ethanol (90 g), and component B: add 20 g of distilled water to absolute ethanol (90 g). Slowly add component B to component A dropwise, stir well for 20min, then add 20g TiO2 dropwise 2 The aqueous sol was stirred at room temperature for 2h 15min to prepare urushiol / nano-TiO 2 compound fluid. Pour the prepared composite solution into a 100ml beaker for electrochemical polymerization (constant voltage about 130V) experiment to obtain nano TiO 2 1% poly urushiol / TiO 2 Composite coating, recorded as UT1.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com