Coaxial linear speed changing mechanism

A speed change mechanism and coaxial technology, applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve problems such as stuck joints, irregular sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

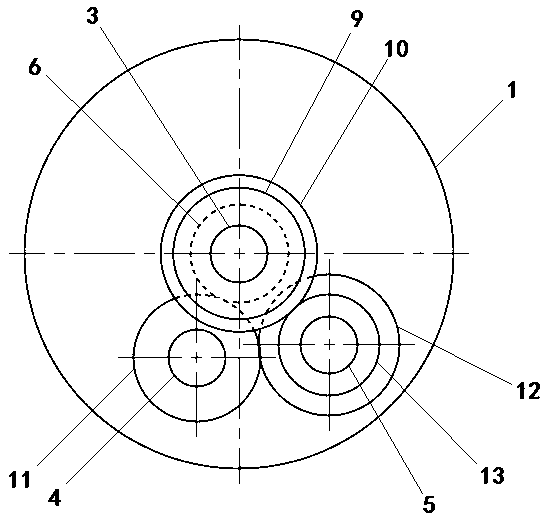

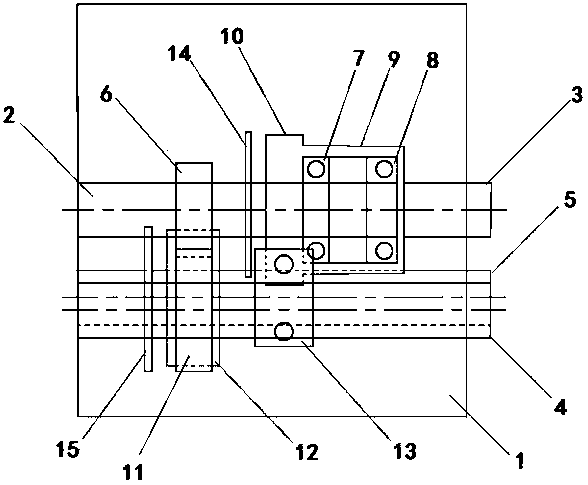

[0039] see figure 1 and figure 2 As described above, a coaxial linear transmission mechanism includes a housing 1, an input shaft 2, an output shaft 3, a transition shaft 4 and a low-speed transmission shaft 5, and the input shaft 2, the transition shaft 4 and the low-speed transmission shaft 5 are in pairs are arranged parallel to each other in the housing 1 .

[0040] The input shaft 2 is connected to the motor, and can rotate counterclockwise or clockwise with the motor. The input shaft 2 is provided with a first transmission gear 6 and a one-way conjoined gear. The first transmission gear 6 It is fixedly connected with the input shaft 2. The one-way conjoined gear is composed of a bearing inner ring and a gear casing sheathed together. The bearing inner ring includes a supporting bearing 7 and a one-way bearing 8 arranged side by side. The gear casing includes a front casing connected together. Gear 9 and rear gear 10 of the outer casing.

[0041] The front end of the...

Embodiment 2

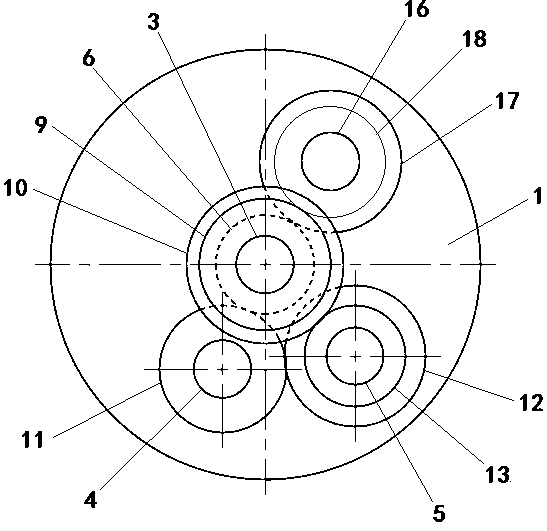

[0048] see image 3 and Figure 4 As shown, in order to meet the reverse gear requirements of four-wheel electric vehicles, on the basis of Embodiment 1, a reverse transmission shaft 16 parallel to the input shaft 2 is also provided in the housing 1, and the reverse gear The transmission shaft 16 is sleeved with a third transmission gear 17 and a fourth transmission gear 18, the third transmission gear 17 is movably connected with the reverse transmission shaft 16, the fourth transmission gear 18 is connected with the reverse transmission The shaft 16 is fixedly connected. The third transmission gear 17 is meshed with the first transmission gear 6 , and the fourth transmission gear 18 is meshed with the front gear 9 of the one-way conjoined gear. The diameter of the third transmission gear 17 is larger than the diameter of the first transmission gear 6, the diameter of the fourth transmission gear 18 is smaller than the diameter of the third transmission gear 17, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com