Low-water pressure sealing performance test method and system for high-water pressure solenoid valve

A test method and test system technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve problems such as water trouble and property loss for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

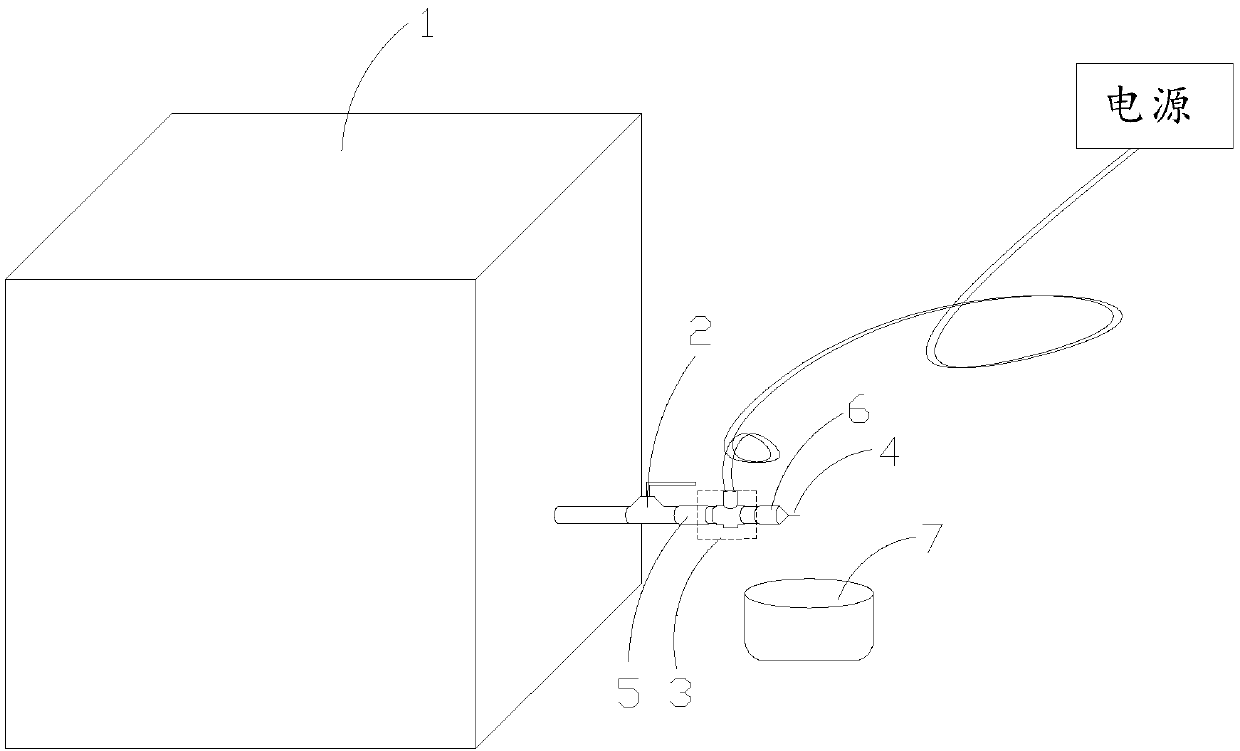

[0027] In order to fully understand the technical content of the present application, the technical solution of the present application will be further introduced and explained below in conjunction with schematic diagrams, but not limited thereto.

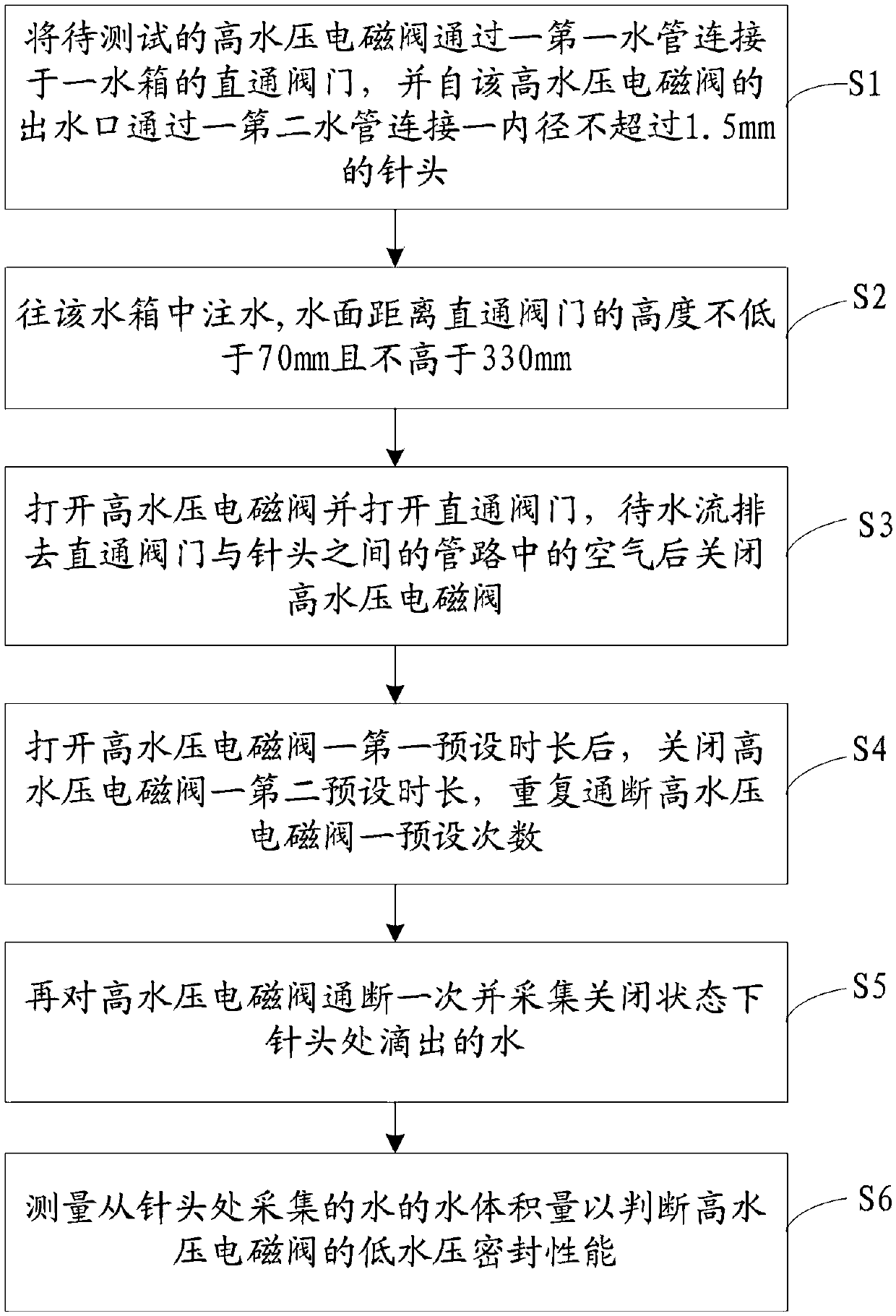

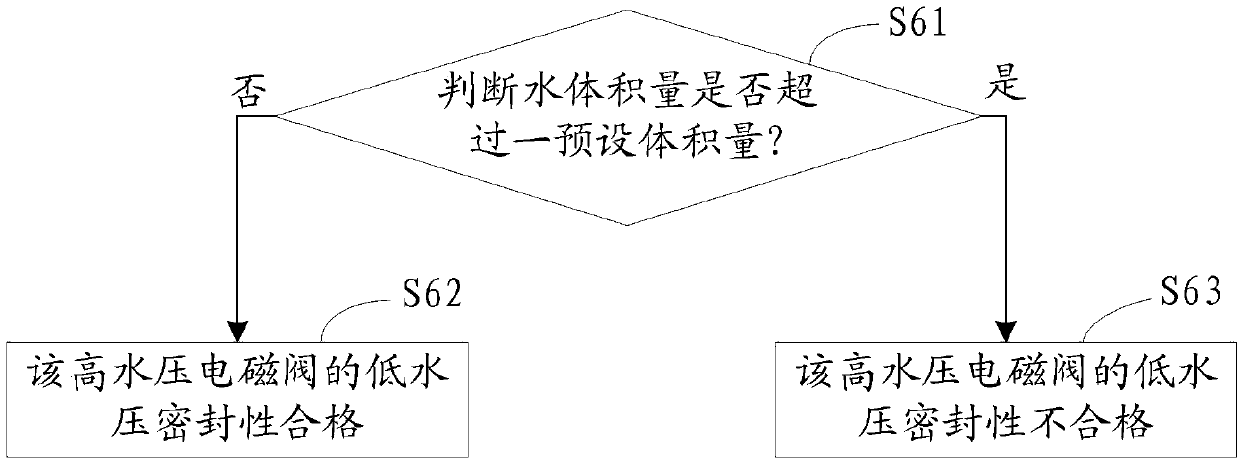

[0028] Such as figure 1 and image 3 As shown, in an embodiment of the present application, the low water pressure tightness test method of the high water pressure solenoid valve 3 includes steps:

[0029] S1, the high water pressure solenoid valve 3 to be tested is connected to the straight-through valve of a water tank 1 through a first water pipe 5, and the water outlet of the high water pressure solenoid valve 3 is connected to a second water pipe 6 with an inner diameter not larger than 1.5mm needle 4;

[0030] S2, inject water into the water tank 1, the height of the water surface from the through valve 2 is not less than 70mm and not higher than 330mm;

[0031] S3, open the high water pressure solenoid valve 3 and open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com