Mold locating device accurate in locating

A mold and positioning wheel technology, applied in packaging, transportation and packaging, manufacturing of rigid/semi-rigid containers, etc., can solve the problem of inapplicability of the bottom structure of the buckle, and achieve the effect of reducing position deviation and ensuring production accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

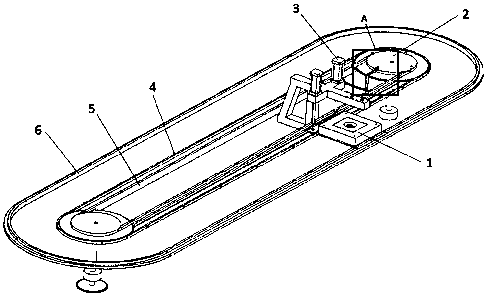

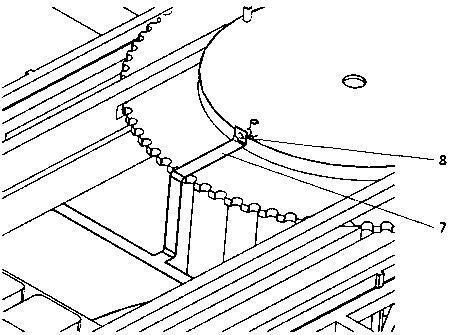

[0026] The present invention is a mold positioning device with accurate positioning, such as Figure 1-6 , including mold 1, positioning wheel 2, deviation correction device 3, non-standard chain 4, inner guide rail 5, outer guide rail 6, sensor bracket 7, proximity sensor 8;

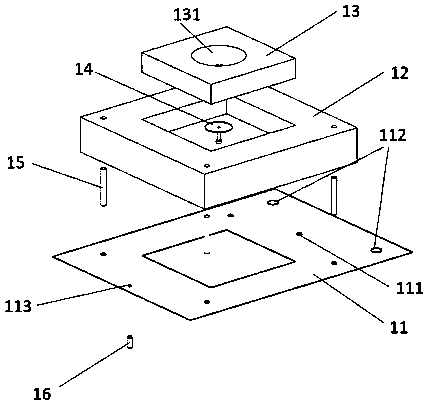

[0027] Described mold 1 comprises mold bottom plate 11, put mold groove 12, mold cavity body 13, discharge mechanism 14, assembly pin 15, roller 16, and described mold put groove 12 is fixed on the mold bottom plate 11 by assembly pin 15, so The mold cavity 13 is placed in the mold slot 12, and fits with the inner wall 121 of the mold slot;

[0028] The mold bottom plate 11 has a mold installation hole 111, a mold positioning hole 112, and a square hole 113, and the mold installation hole 111 is connected to the non-standard chain 5 by bolts;

[0029] The mold cavity 131 on the mold cavity body 13 is the same size as the cylinder body of the packaging box, the cylinder body of the packaging box is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com