Wood block and wood floor

A wood floor and board technology, applied in the field of wood boards, can solve problems such as difficult to remove, easy to accumulate dust and dust, and affect the overall appearance of the wood board surface, so as to achieve the effect of avoiding dust accumulation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

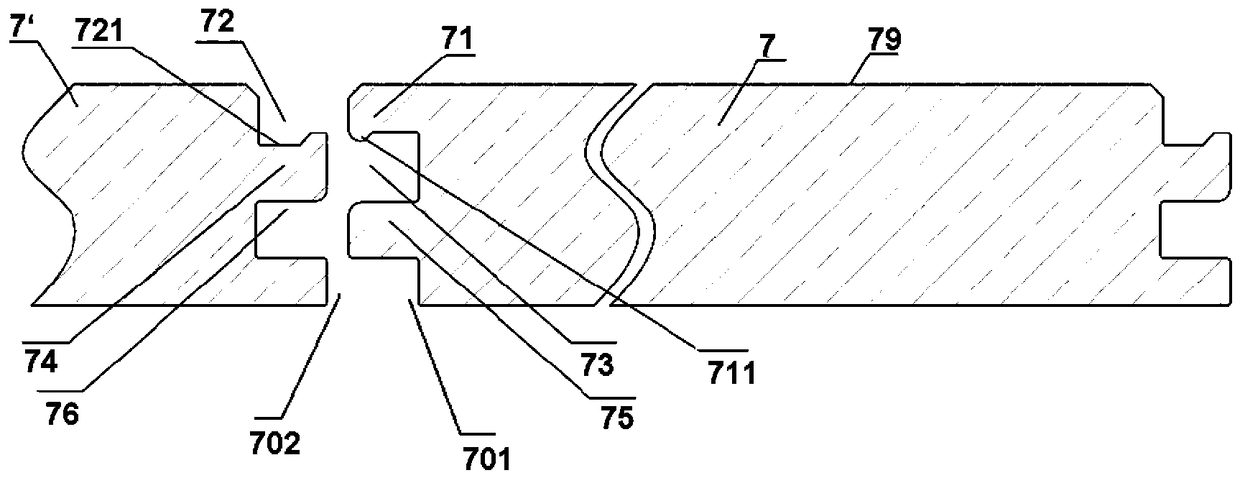

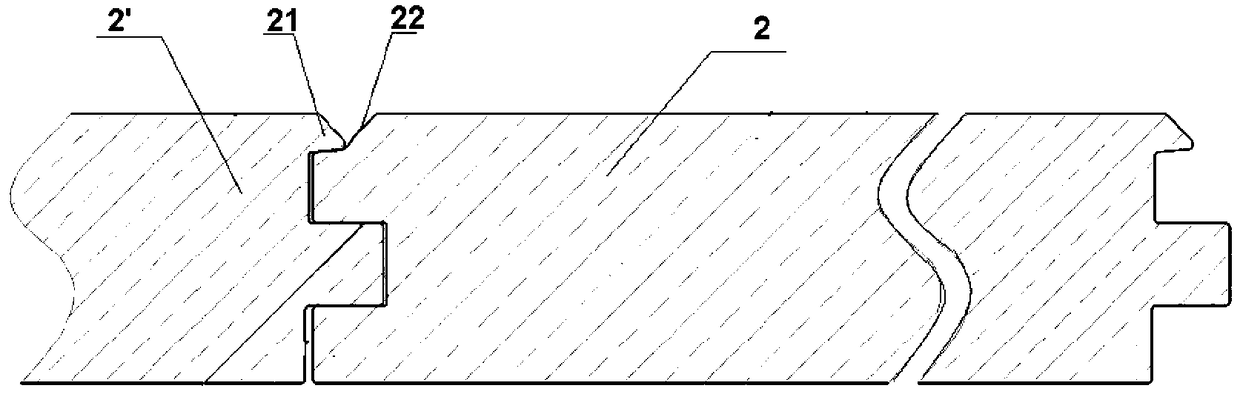

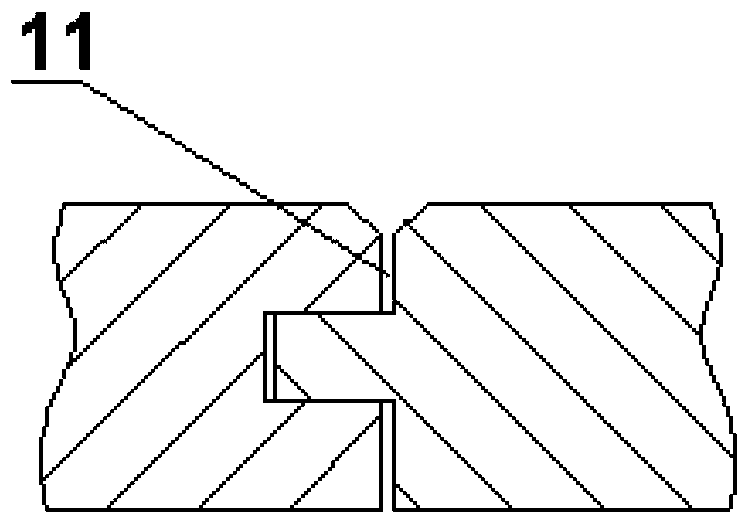

[0033] It should be understood that in the present invention, the term "transverse" is used to indicate the splicing direction of the wood panels, which is parallel to the plane of use of the wood panels, and the term "vertical" is used to indicate the direction perpendicular to the plane of use of the wood panels or the thickness direction of the wood panels. In the case of wooden boards laid horizontally as a floor, the transverse direction corresponds to the horizontal direction and the vertical direction corresponds to the vertical direction. As the way the boards are laid changes, the meaning of the terms "transverse" and "vertical" changes accordingly.

[0034] In particular, when a solid wood floor with a conventional tongue-and-groove structure is used in a floor heating environment, due to a greater degree of drying shrinkage of the wooden boards, a larger gap between the wooden floors will be caused, and even the tongue and groove will be completely separated. One so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com