A pulseless s-valve wet spray machine

A non-pulse, wet spraying machine technology, applied in shaft equipment, wellbore lining, mining equipment, etc., can solve the problems of increasing the chance of pipe plugging, pulse, rebound, etc. during the pumping process, achieve compact structure, and reduce pump pressure loss , Conducive to the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] combine Figure 1 to Figure 8 As shown, the specific implementation of a non-pulse S-valve wet spraying machine according to the present invention is as follows.

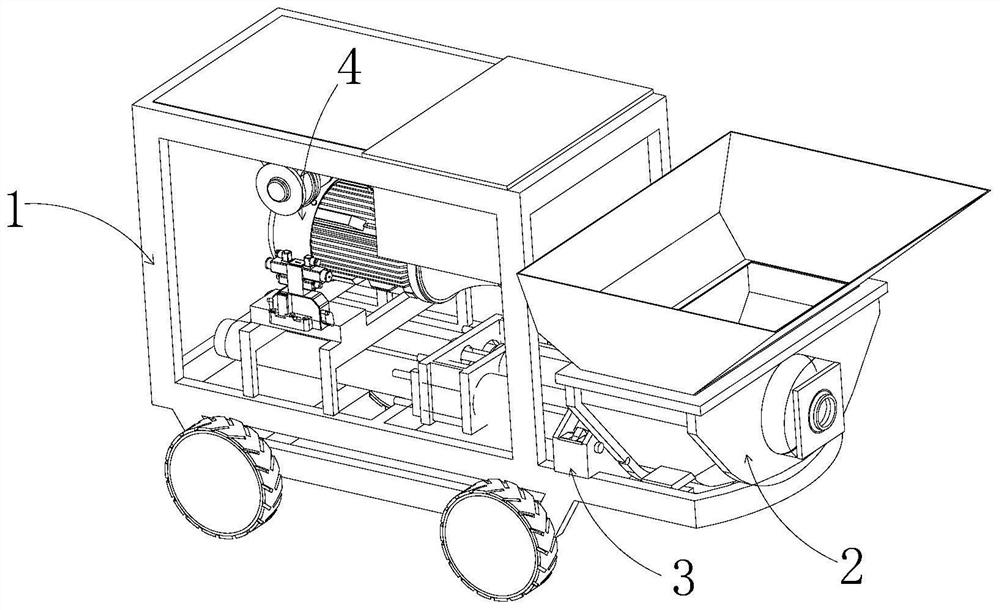

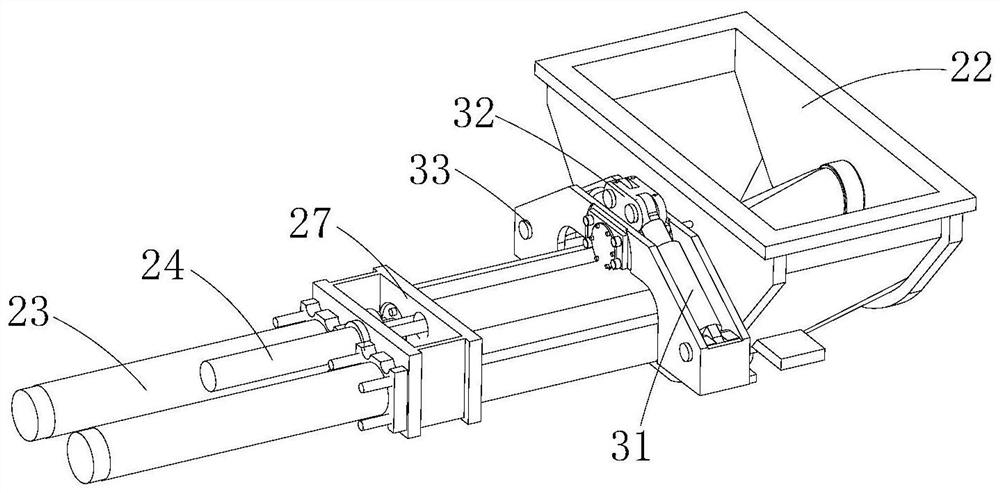

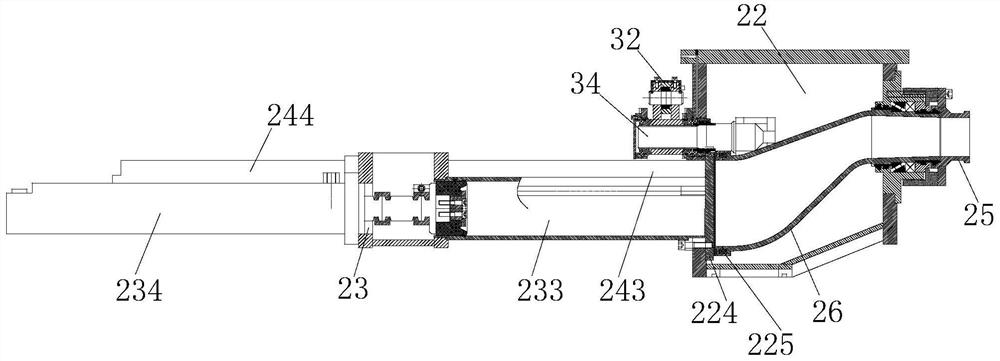

[0024] A non-pulse S-valve wet spray machine such as figure 1 As shown, it specifically includes a frame 1, a pumping mechanism 2, a swing mechanism 3, a motor and a hydraulic system 4. Frame 1 is provided with organic wheels to facilitate the movement of the wet spraying machine; the motor and hydraulic system 4 includes a hydraulic oil tank and a motor. , the output power of this structure is stable, safe and reliable; the swing mechanism 3 and the pumping mechanism 2 are installed together, the concrete feeding mechanism 23 of the pumping mechanism 2 is set at the bottom of the frame 1, and the hopper 21 of the pumping mechanism 2 is set at the front of the frame Above, the pumping mechanism 2 realizes the pumping of materials, and the swing mechanism 3 drives the distribution valve 26 to swing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com