An anti-friction flat gate valve

A flat gate valve, anti-friction technology, applied to valve details, valve devices, sliding valves, etc., can solve the problems of increased cost, short service life, enlarged external drive device, etc., and achieve the effect of preventing jamming and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

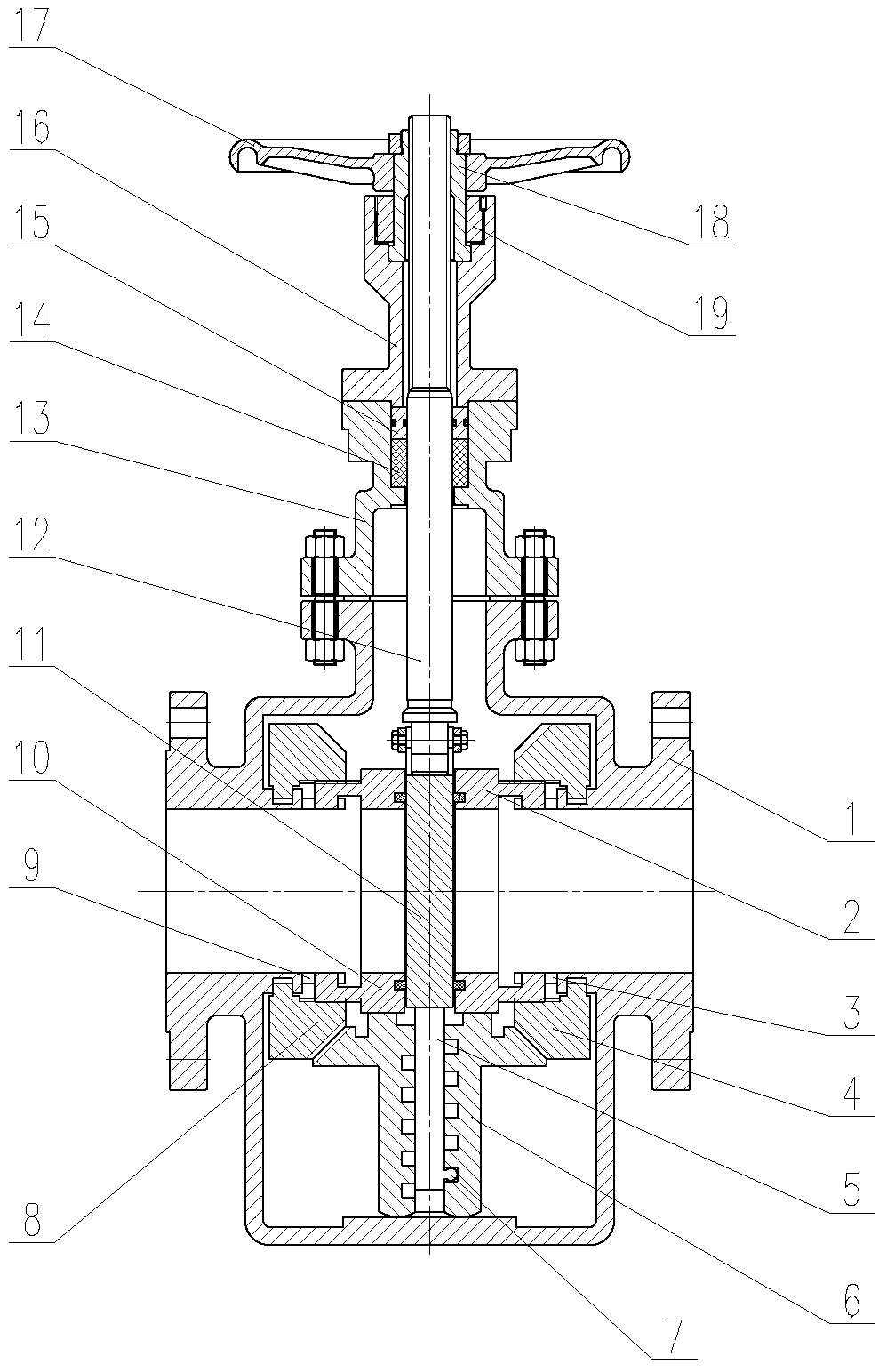

[0012] according to figure 1 It can be seen that the anti-friction flat gate valve includes: valve body 1, left valve seat 10, right valve seat 2, gate plate 11, valve cover 13, valve stem 12, packing 14, packing pad 15, bracket 16, hand wheel 17. Stem nut 18 and nut gland 19. The valve cover 13 is arranged at the upper end of the middle part of the valve body 1. The upper end of the valve cover 13 is provided with a downwardly concave packing groove. The packing 14 is fixed and installed in the packing groove by the packing pad 15. The bracket 16 is fixedly installed on the upper end of the bonnet 13, and a concave groove is provided at the upper end of the bracket 16, and the lower part of the valve stem nut 18 is placed in the concave groove, and the nut gland 19 is installed in the concave groove by threads, and the nut gland 19 Limit the upward and downward movement of the valve stem nut 18, the valve stem nut 18 is provided with a trapezoidal internal thread, the handwhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com