OLED substrate and manufacturing method thereof, and display device

A manufacturing method and substrate technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as easy color shift of images, redness of displayed images, poor display effect of AMOLED panels, etc. Achieve the effect of ensuring display effect and improving OLED color cast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

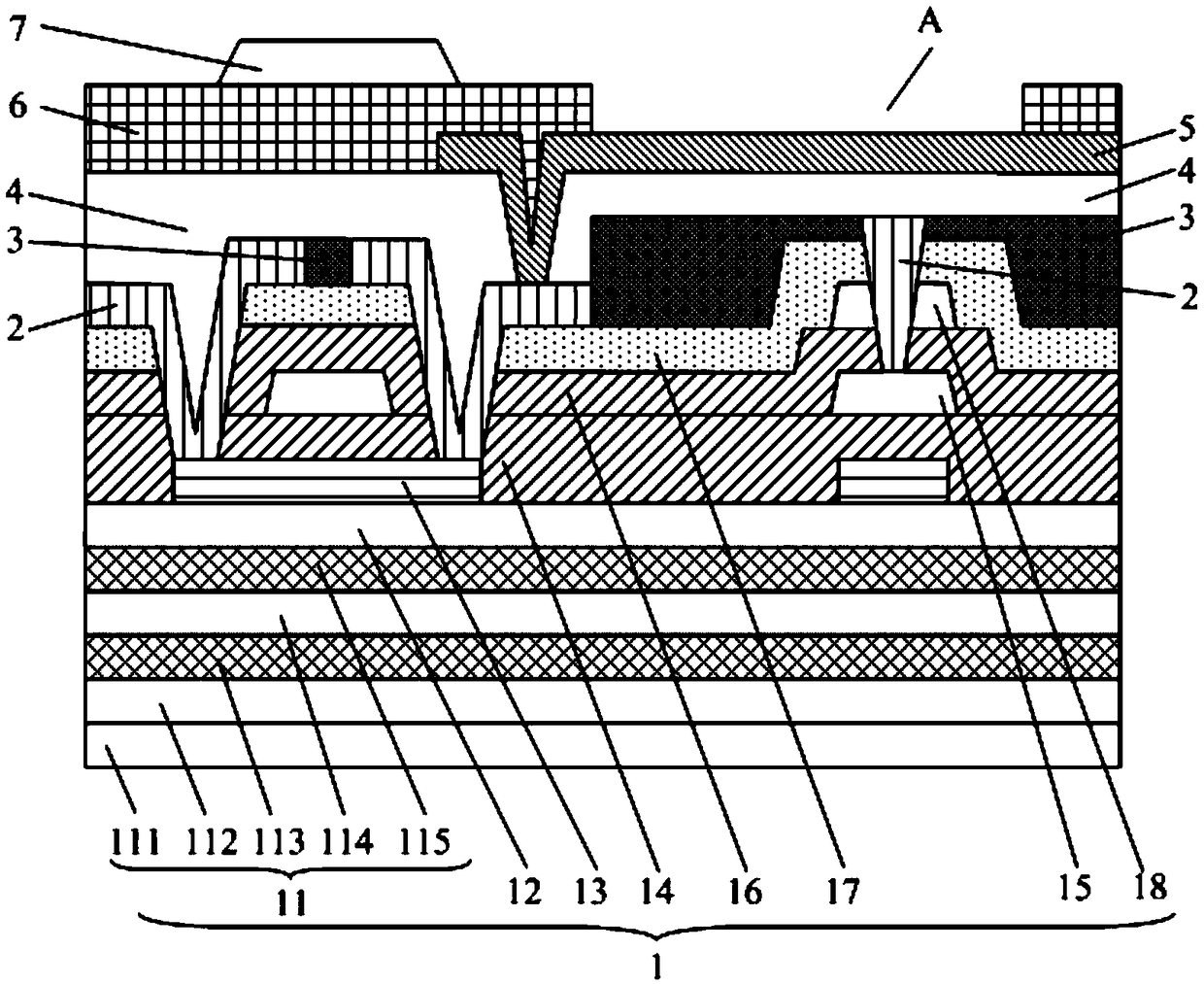

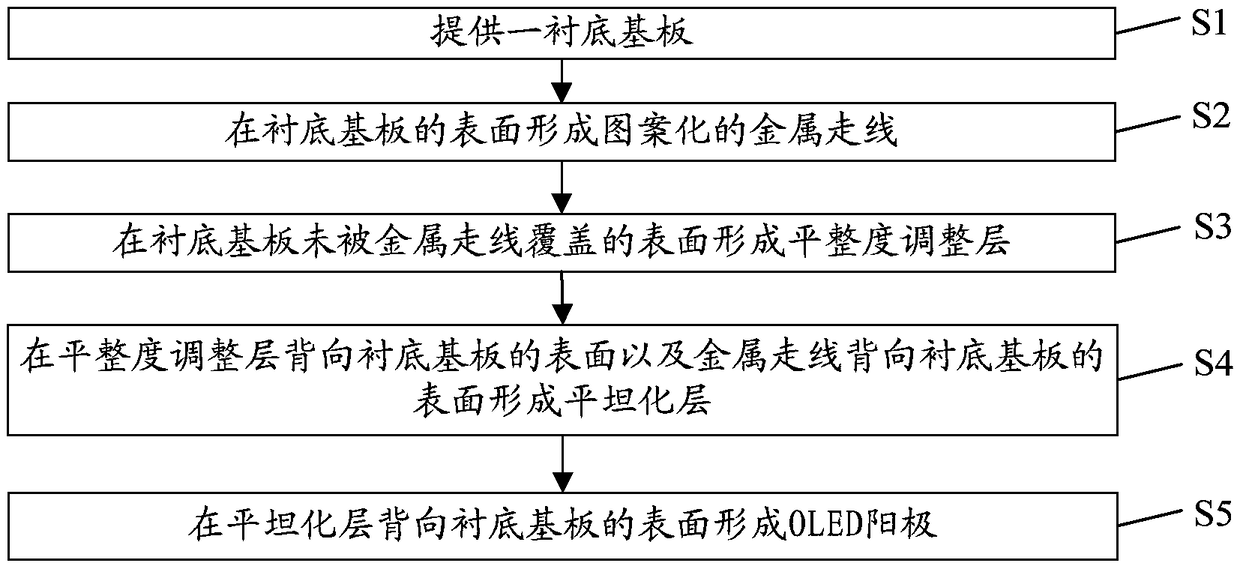

[0026] In order to further illustrate the OLED substrate, manufacturing method, and display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

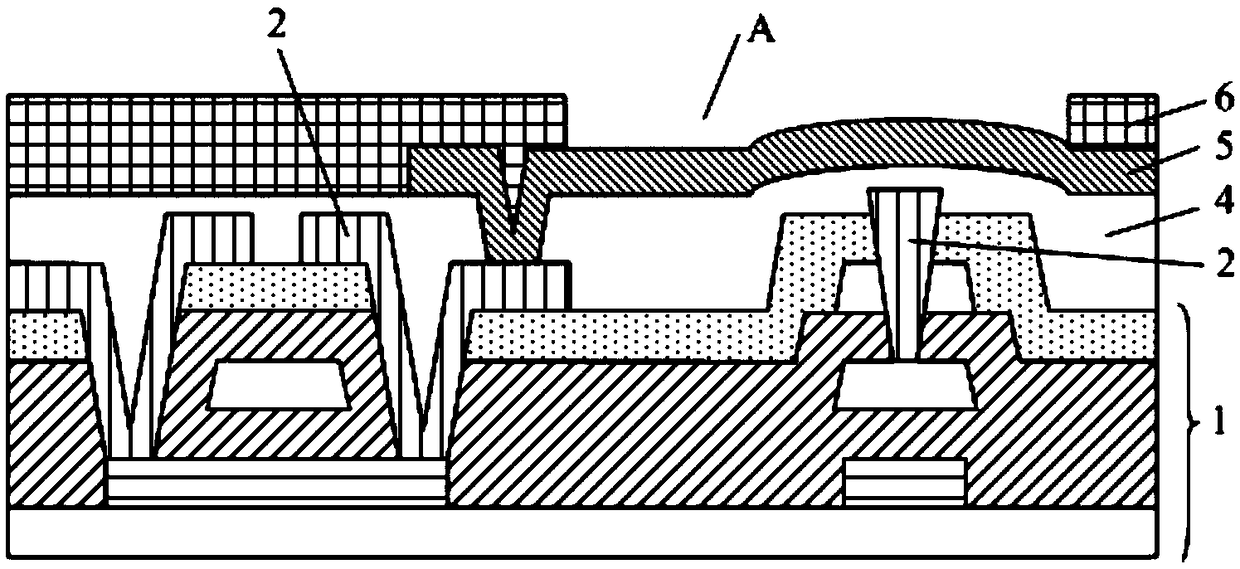

[0027] see figure 1 , a common OLED substrate includes a base substrate 1 and a metal wiring 2 fabricated on the surface of the base substrate 1 by FFM technology; the surface of the base substrate 1 not covered by the metal wiring 2 and the metal wiring 2 facing away from the base substrate 1 is formed with a planarization layer 4, and the surface of the planarization layer 4 facing away from the base substrate 1 is respectively formed with an OLED anode 5 and a pixel defining layer 6, and the area of the pixel defining layer 6 opposite to the OLED anode 5 is provided with a pixel hole A .

[0028] However, since the bottom of the pixel hole A in the OLED substrate, that is, the bottom of the OLED anode 5 is inevitably formed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com