Inductively controlled circuit board fixing structure of automobile model

A car model and induction control technology, applied in the direction of support structure installation, clamping/extracting device, etc., can solve the problems of low efficiency of bolt fixing and locking, inconvenient maintenance, and structural scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

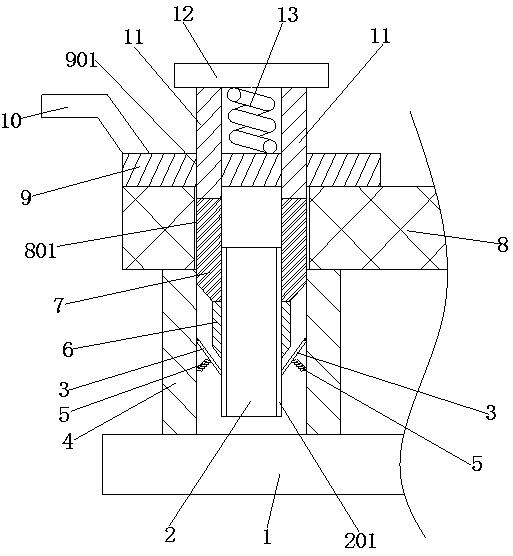

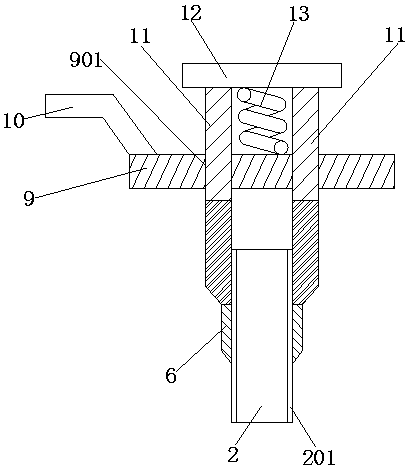

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as Figures 1 to 2 As shown, a circuit board fixing structure of an induction-controlled car model according to the present invention includes an outer fixing sleeve 4 and a locking device; the locking device includes a fixed shaft 2 and a pressing plate 12; the fixing The top of the shaft 2 is fixed with an upper limit plate 9; the outside of the fixed shaft 2 is covered with a retaining sleeve 6 and a positioning sleeve 7; the surface of the upper limit plate 9 is provided with several through holes 901; the through holes 901 The interior of the straight rod 11 is provided with a straight rod 11; the straight rod 11 is slidably connected with the through hole 901; one end of the straight rod 11 is fixedly connected with the top of the positioning sleeve 7; the other end of the straight rod 11 passes through the through hole 901 from bottom to top Afterwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com