Packaging line of combined stuffing filling machine

A filling machine, packaging line technology, applied in packaging, packaging machines, transportation packaging and other directions, can solve the problems of multi-space, dirty food, unsanitary and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

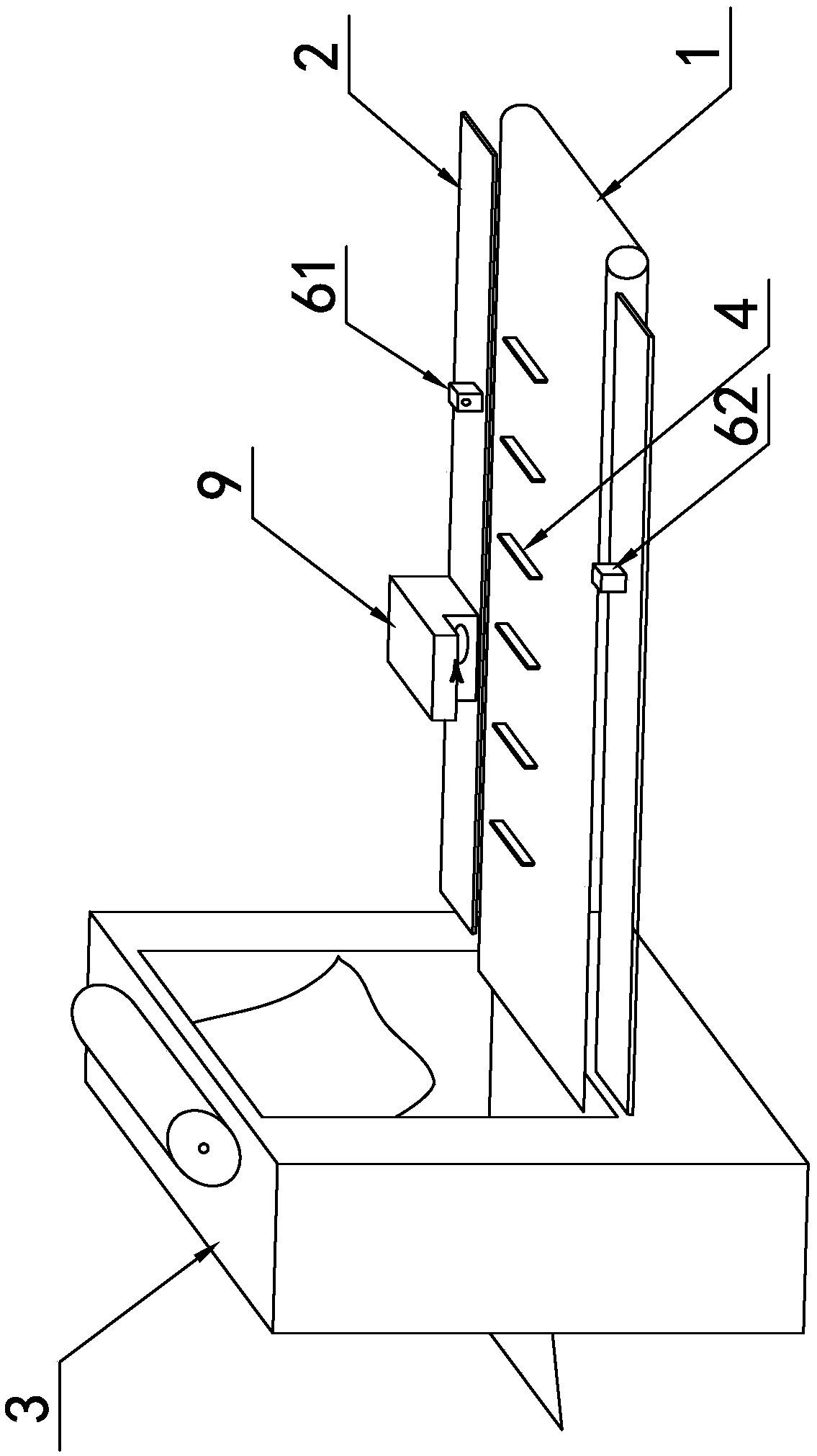

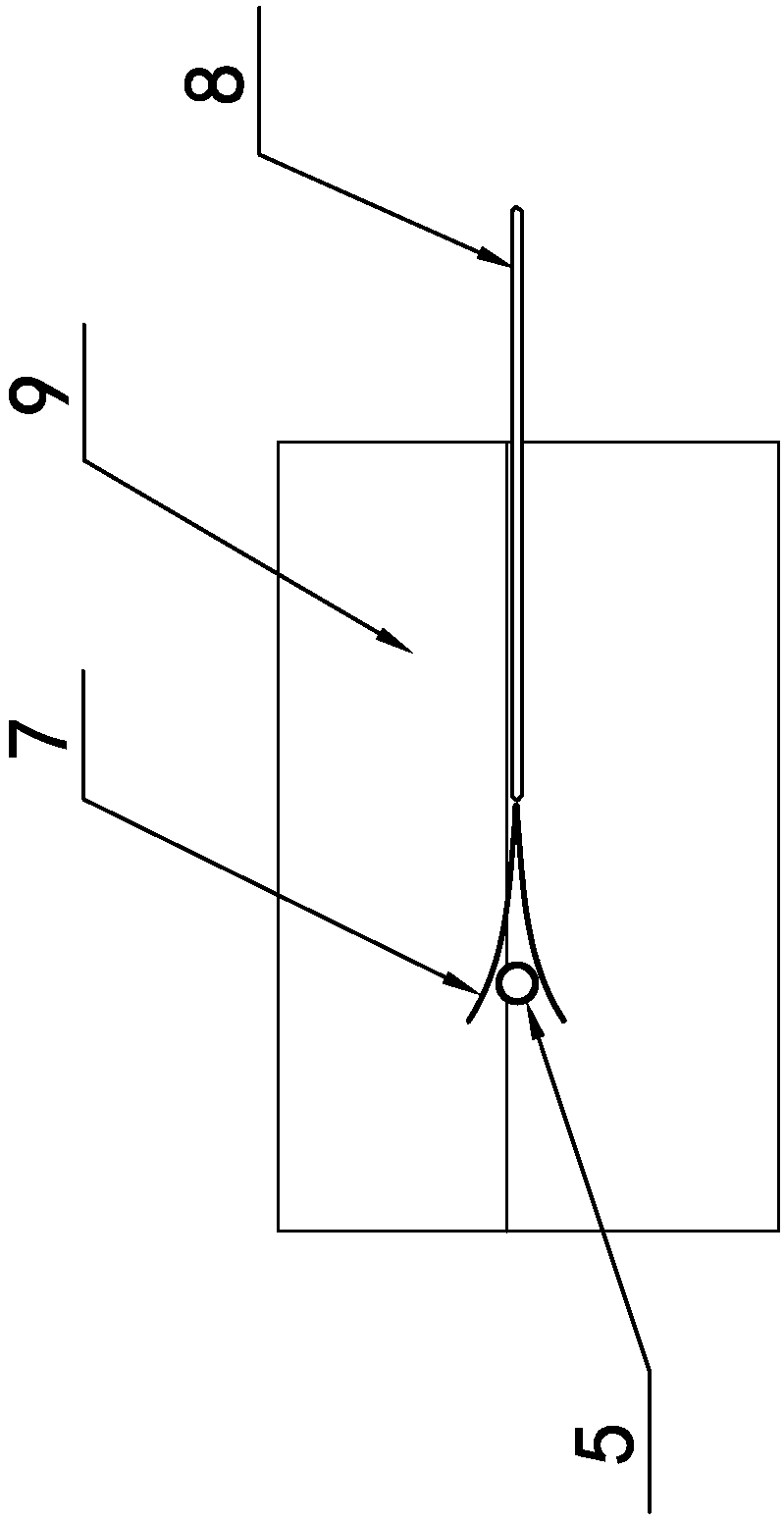

[0014] refer to figure 1 and figure 2 , the present invention is a packaging line for a combined stuffing machine, which mainly processes strip-shaped bread, including a conveyor belt 1, worktables 2 on the left and right sides of the length direction of the conveyor belt 1, and a packaging machine 3 located at the end of the conveyor belt 1, the conveyor belt 1. A number of baffles 4 are provided along the length direction for pulling the bread to move, and a filling machine is provided on one side of the work surface 2. The filling machine includes a discharge port 5, and the stuffing machine pours the filling into the bread. There are several rolls of packaging bags on the packaging machine 3. During use, the machine tears the packaging bags and winds them on the bread. The stuffing machine itself includes a stirring mechanism for stirring materials and a pushing device for pushing materials to the discharge port 5, Figure 1 Only the filling port is drawn in the figure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com