Vibrating screen with high screening efficiency

A vibrating screen, high-efficiency technology, applied in the field of vibrating screen, can solve the problems affecting the working efficiency and screening quality of the screening machine, and the chips are easy to block the screening machine, etc., and achieves the effect of good self-cleaning effect, simple structure and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

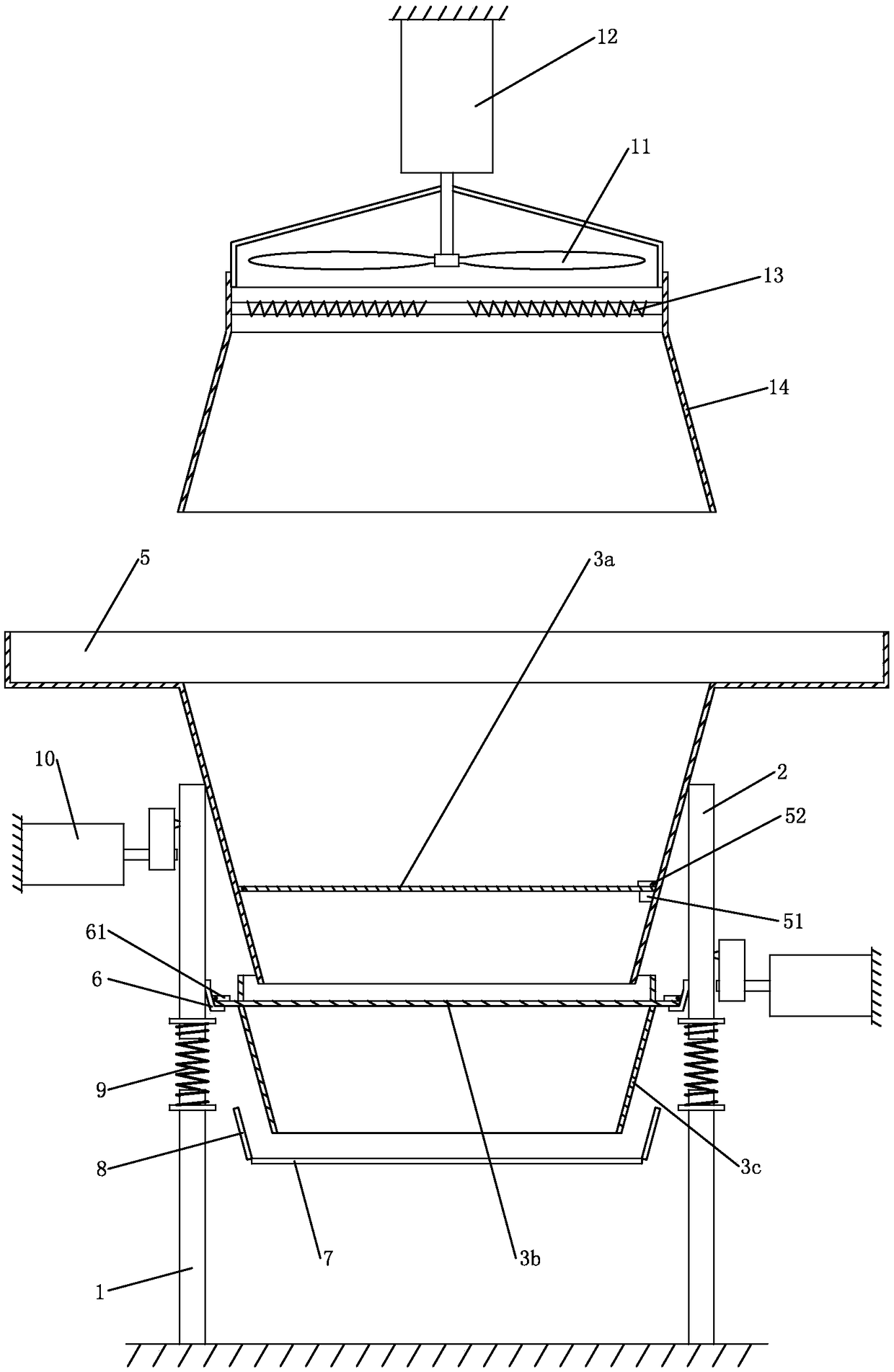

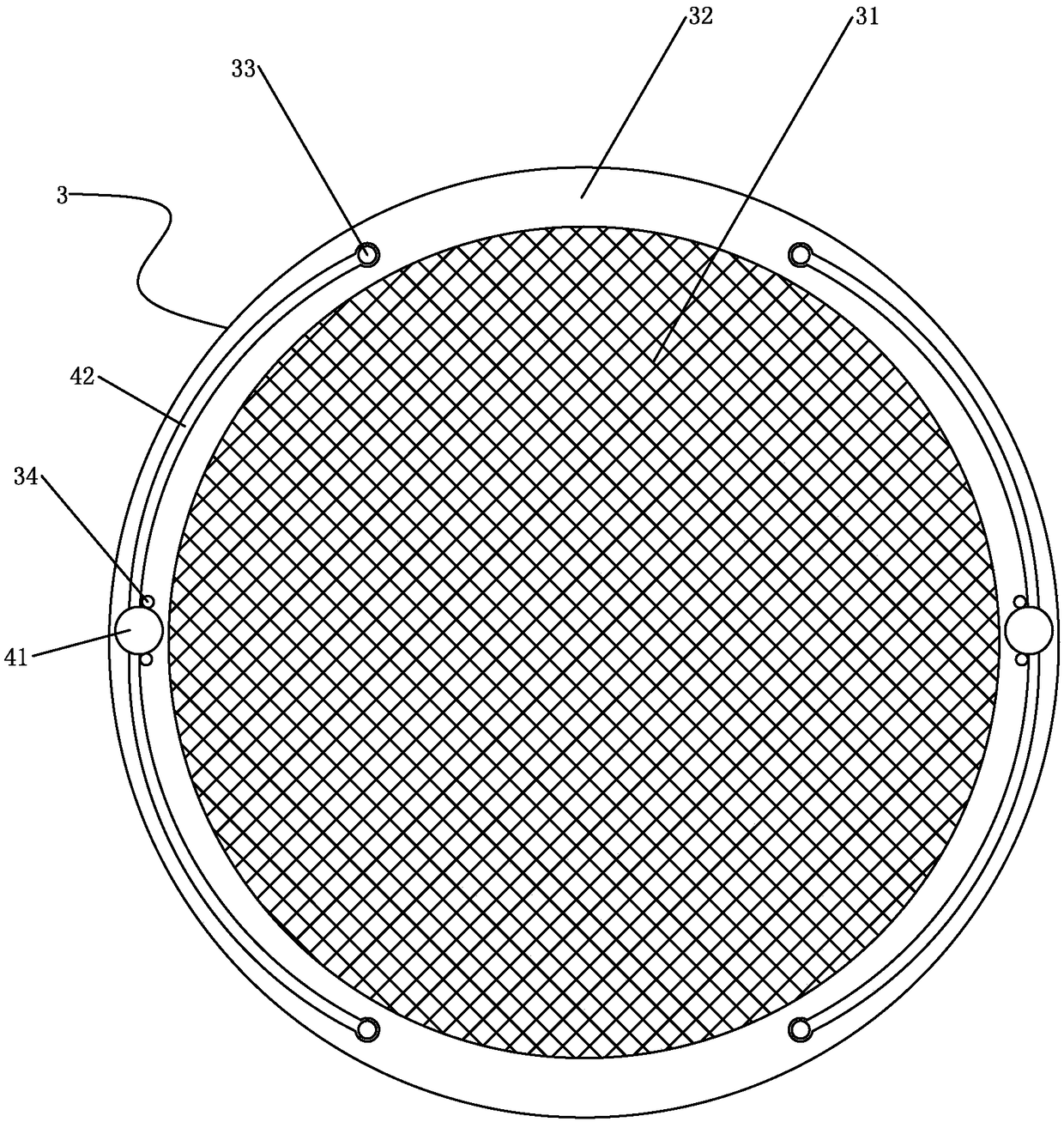

[0020] like figure 1 , figure 2 As shown, the vibrating screen with high screening efficiency provided by the first embodiment of the present invention includes a column 1 fixed on the ground, a column 2 floating on the top of the column, a screen 3 connected to the column, and a screen for driving the column to vibrate. Vibration motor 10 . In addition, it also includes a hot air device arranged above the screen. The hot air device includes a blade 11, a rotary motor 12 for driving the blade, and a heating element 13 arranged below the blade. The heating element includes a bracket and a heating wire wound around the bracket. .

[0021] When the vibrating screen sieves the material, the heating wire generates heat, and the rotating motor drives the blades to rotate to form a hot air flow. When the hot air flow flows down, it can heat the material on the screen, reduce the moisture content of the material, improve the dryness of the material, and make the agglomeration. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com