Manual cleaning device for writing brush cleaning

A cleaning device and cleaning technology, which is applied to devices for removing pen nibs, printing and writing utensils, etc., can solve the problem of soiling the user's fingers, etc., and achieve the effect of speeding up the drying speed and improving the drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

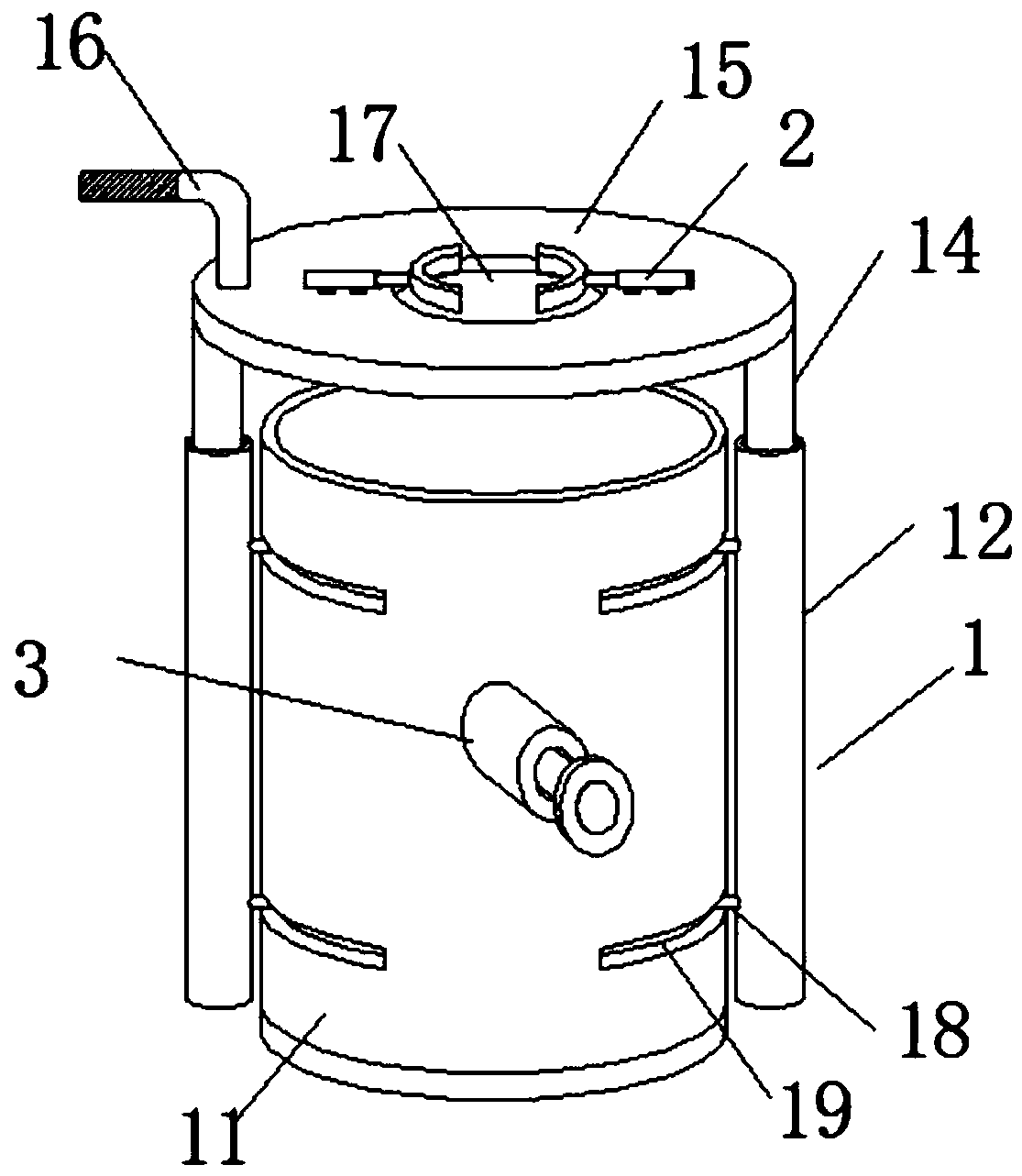

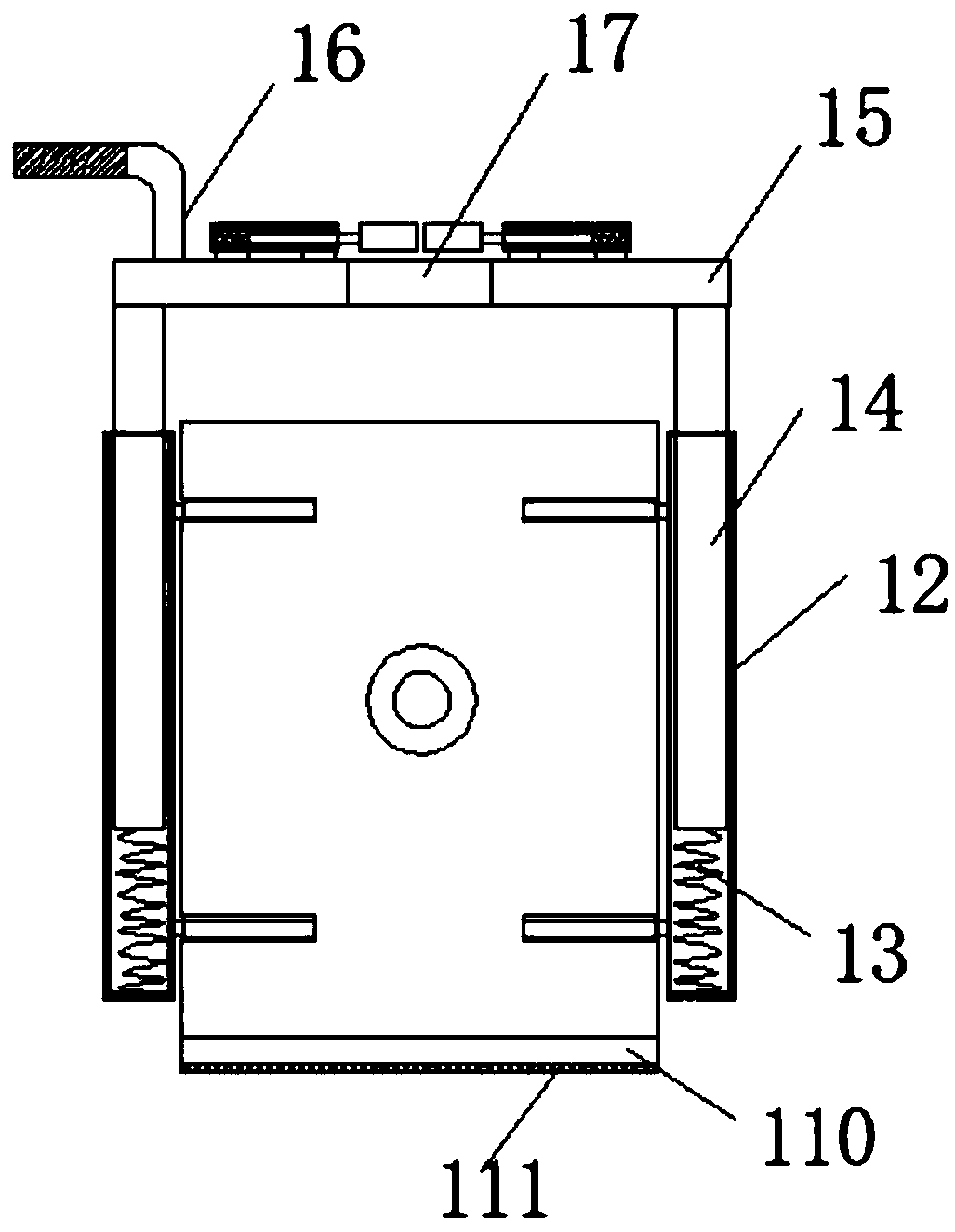

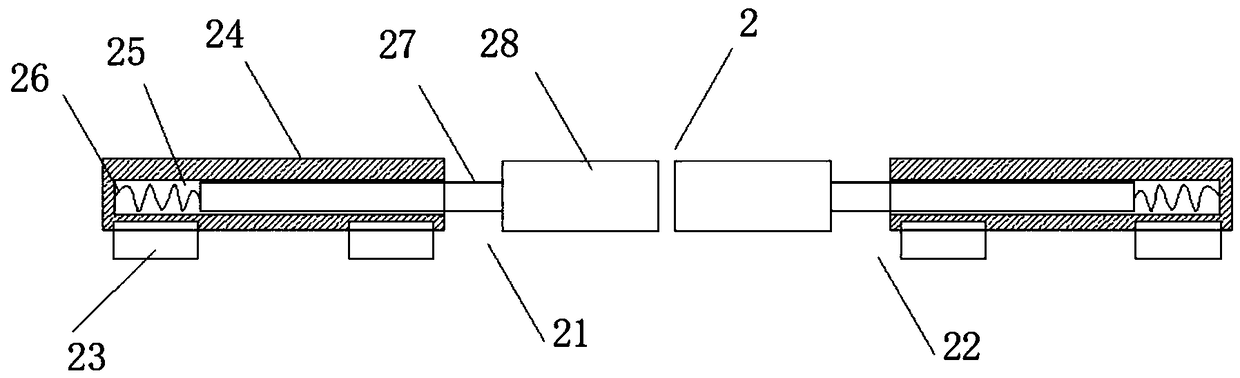

[0023] like figure 1 As shown, a kind of manual cleaning device that the present invention proposes is used for brush cleaning, comprises cleaning mechanism 1, the clamping mechanism 2 that is arranged on cleaning mechanism 1 top and the clamping mechanism 3 that is fixed on cleaning mechanism 1 both sides, and cleaning mechanism The function of 1 is to clean the brush, the function of the clamping mechanism 2 is to fix the brush, the function of the clamping mechanism 3 is to squeeze out the water absorbed on the tip of the brush, and the cleaning mechanism 1 includes a glass with cleaning liquid inside Cylinder 11, the outer walls of both sides of the glass cylinder 11 are provided with arc-shaped chute 19, the inside of chute 19 is engaged with slide rod 18, one end of slide rod 18 is engaged inside chute 19, and the other end of slide rod 18 is The sleeve 12 is welded, the first spring support 13 is arranged inside the sleeve 13, the bottom of the first spring support 13 i...

Embodiment 2

[0025] In addition, please continue to refer to Figure 2-5, different from the above embodiment, the chute 19 has an arc-shaped structure, the number of chute 19 is four, the left side wall of the glass cylinder 11 is provided with two chute 19, and the right side of the glass cylinder 11 is provided with two chute 19, and the two chutes 19 on the same side of the glass cylinder 11 are arranged in parallel, each chute 19 is engaged with a slide bar 18, and the slide bar 18 and the chute 19 slide, so that the chute 19 can be used The sliding rod 18 fixes the sleeve 12, and the sleeve 12 can be moved to slide back and forth on the chute 19. The handle 16 is vertically arranged on the top of the fixed table 15, and the left end of the handle 16 is wrapped with a sweat-absorbing belt, so that it can be absorbed by the sweat-absorbing belt. Sweat on the hands of the user improves the comfort of the user. A base 110 with a circular structure is provided at the bottom of the glass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com