Transmission assembly and biscuit conveying equipment

A technology for transmission components and conveying equipment, which is applied in the directions of packaging biscuits and food packaging, can solve the problems of low production efficiency, difficult control, and high noise, and achieve the effects of high production efficiency, simple structure and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

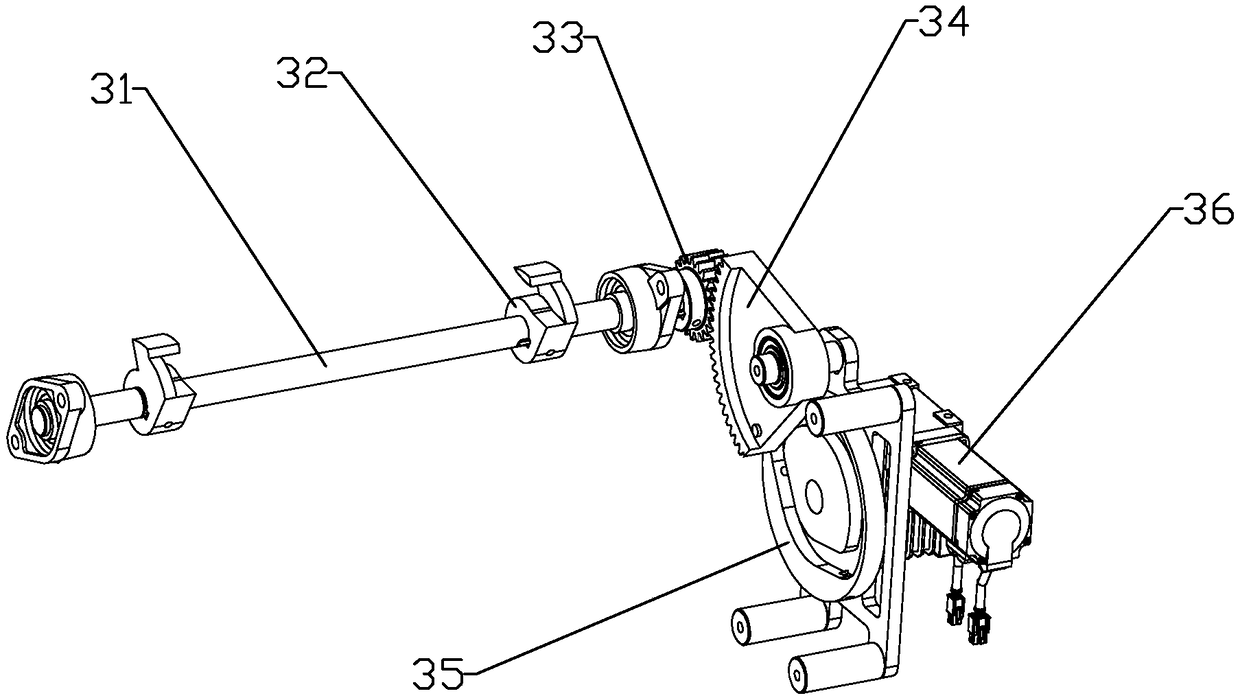

[0022] A transmission assembly, characterized in that it includes a rotating shaft 31, a lane changing member 32 fixed on the rotating shaft 31, a lane changing gear 33 fixed on the rotating shaft 31, a swing gear 34 and a cam mechanism, the swing gear 34 and the lane changing gear 33 meshes, the cam mechanism drives the swing gear 34 to rotate, and the lane-changing member 32 is provided with a lane-changing groove.

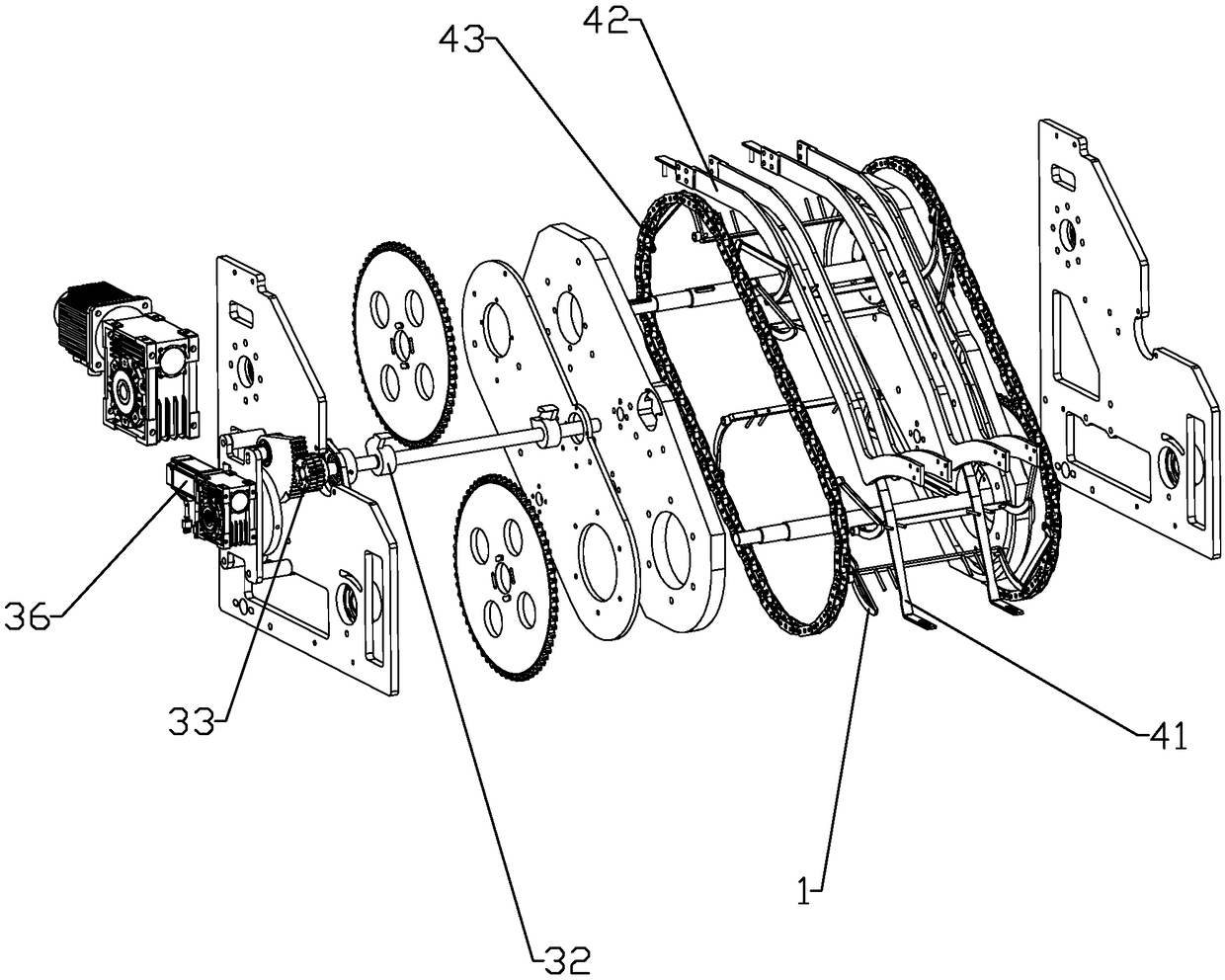

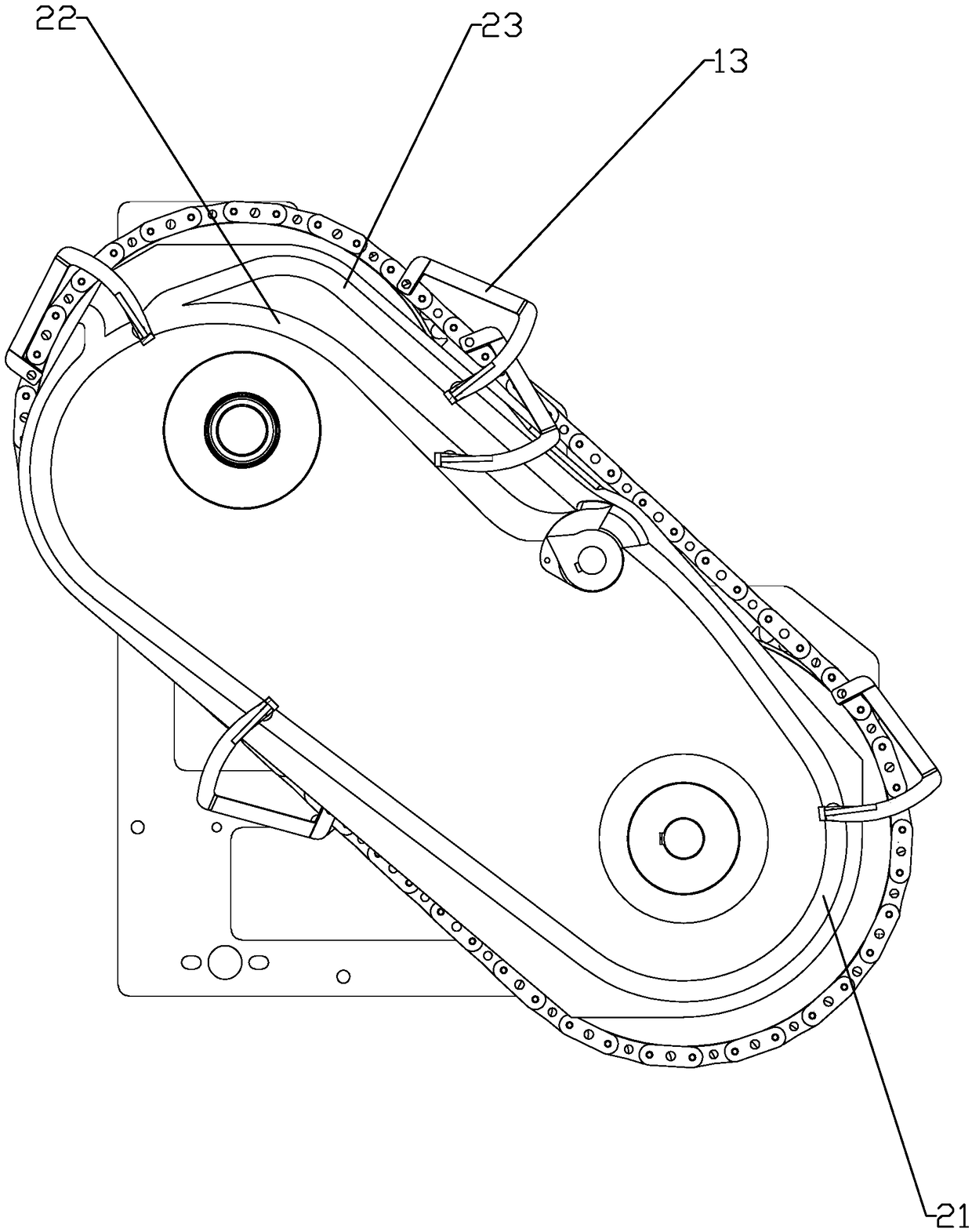

[0023] Such as Figure 1-Figure 5 As shown, a biscuit conveying equipment includes a frame, a cake pushing assembly 1 movably arranged on the frame, a transmission assembly arranged on the frame and a side plate vertically arranged on the frame. An annular guide groove for guiding the cake pushing assembly 1 is provided on the plate, the annular guide groove includes a rail-joining section 21 and a rail-dividing section, and the rail-dividing section includes a first branch section 22 and a second branch section 23, so One end of the rail fitting section 21 is ...

Embodiment 2

[0029] Such as Figure 6 As shown, the swing gear 34 includes an arc-shaped rack 341 and a swing rod 342 matched with the lane-changing gear 33. One end of the swing rod 342 is hinged on the frame, and the other end is fixedly connected to the arc-shaped rack 341. The cam mechanism includes a second cam 5 and a third power device that drives the second cam 5 to rotate. The second cam 5 is arranged between two ends of the swing rod 342 and drives the swing rod 342 to swing. The third power unit drives the second cam 5 to rotate, so that the swing rod 342 swings around one end hinged on the frame, and then the arc-shaped rack 341 reciprocates around the center of the circle, and is fixed on the rotating shaft 31 through the lane change gear 33 The channel-changing member 32 realizes forward and reverse rotation, and alternately guides the cake pushing assembly 1 on the rail joint section 21 into the first branch section 22 or the second branch section 23 . Refer to Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com