forklift

A technology for forklifts and fork tines is applied in the direction of lifting devices, which can solve the problems of wasting manpower and working time, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

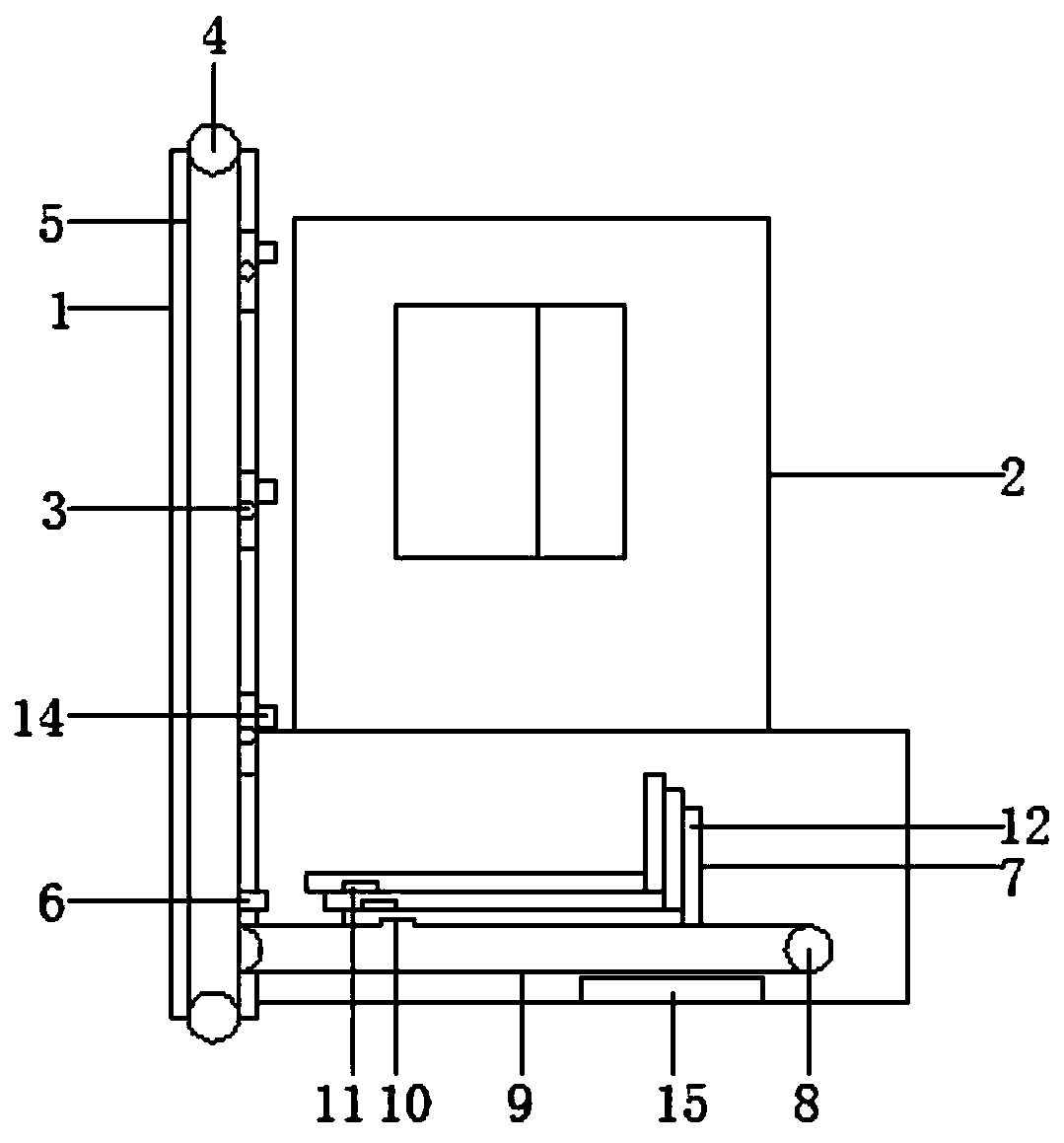

[0042] Such as Figure 1 to Figure 3 As shown, the forklift includes:

[0043] Car body 2, the bottom of car body 2 is provided with a gravity sensor 15, which is used to measure the change of car body gravity;

[0044] The door frame 1, the door frame 1 is installed on the car body 2, the rotatable supporting plate 3 is arranged equidistantly between the beams on both sides of the door frame 1, the lifting wheels 4 are arranged at both ends of the door frame, and the lifting chains are arranged on the lifting wheels 4 5. There is a lifting hook 6 on the lifting chain 5;

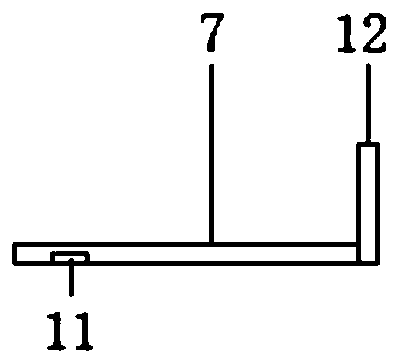

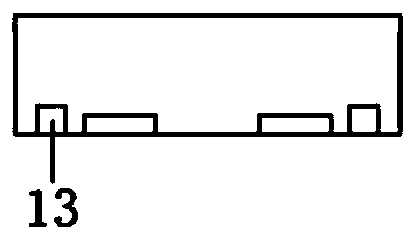

[0045] Forklift structure, the forklift structure is located at the bottom of the car body 2, including a plurality of fork tines 7 and a conveying structure, a plurality of fork tines 7 are stacked on the conveying structure, and can move with the conveying structure, and the roots of the fork tines 7 are provided with supports Plate 12, the support plate 12 forms an included angle with the fork 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com