A Composite Actuator for Numerical Control and Intelligent Polishing

A kind of executive mechanism and composite technology, applied in the direction of grinding/polishing equipment, grinding machine parts, metal processing equipment, etc., can solve complex and cumbersome disassembly and installation problems, and achieve the goal of improving efficiency, reducing costs, and rapid production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings.

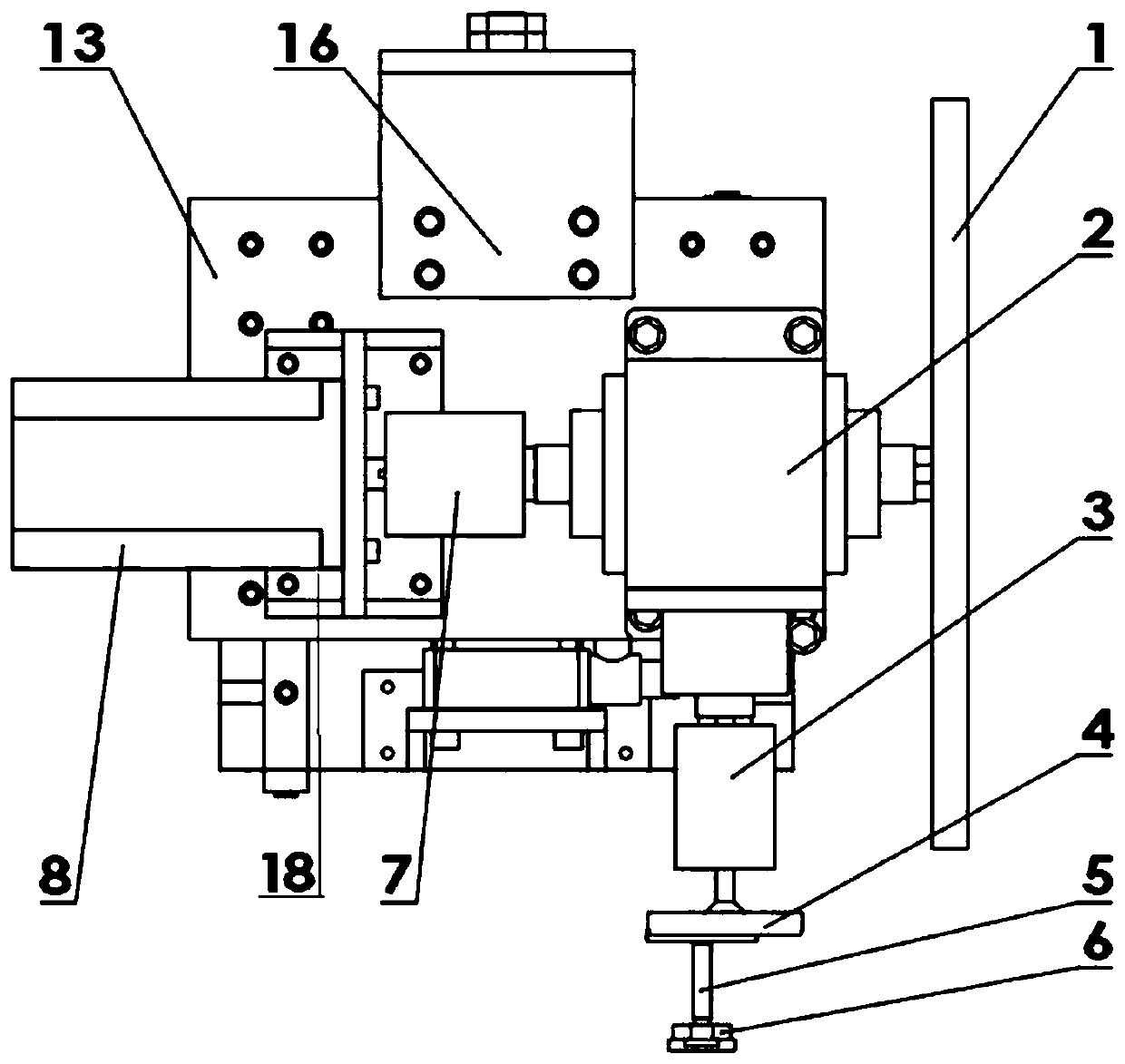

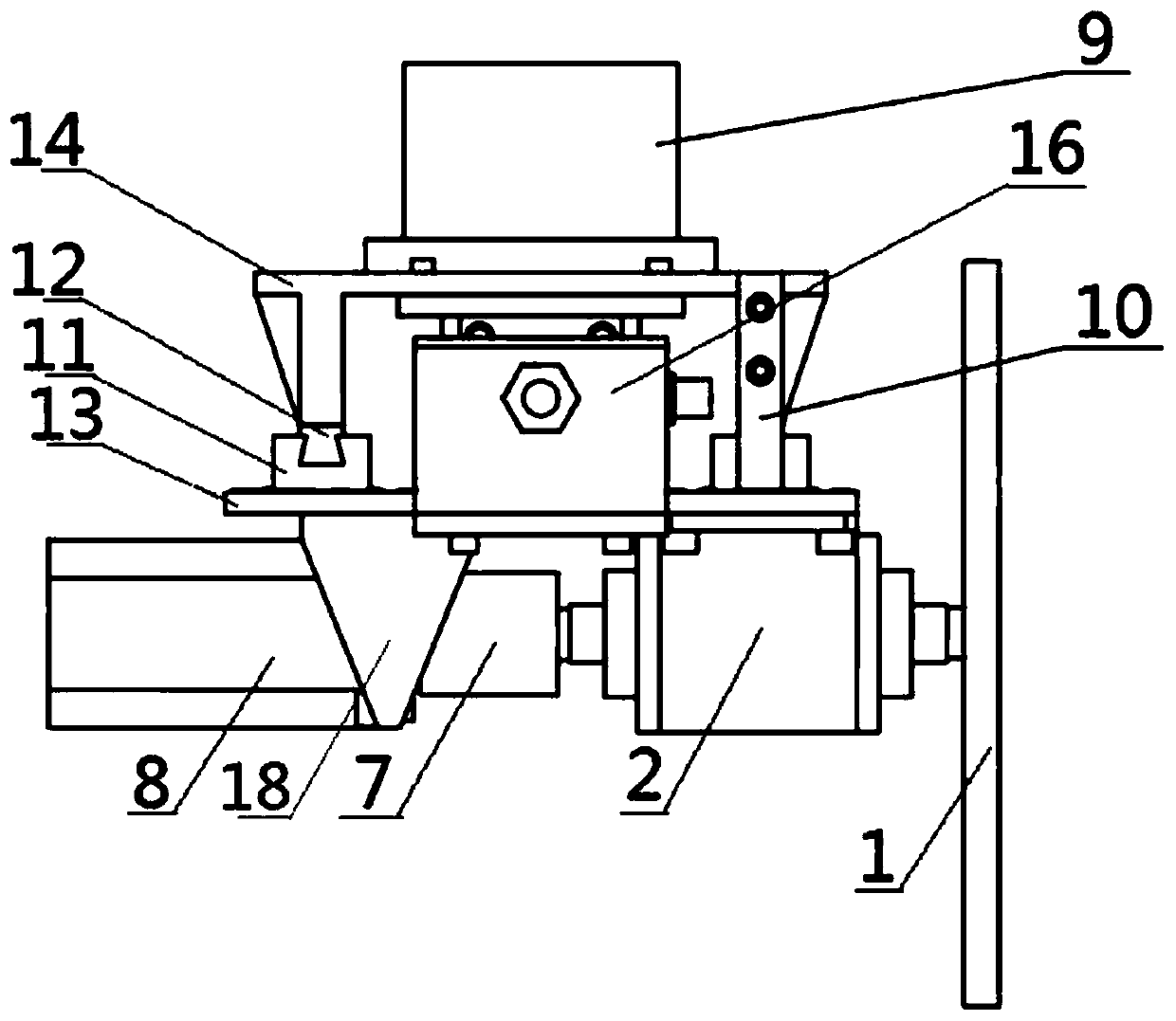

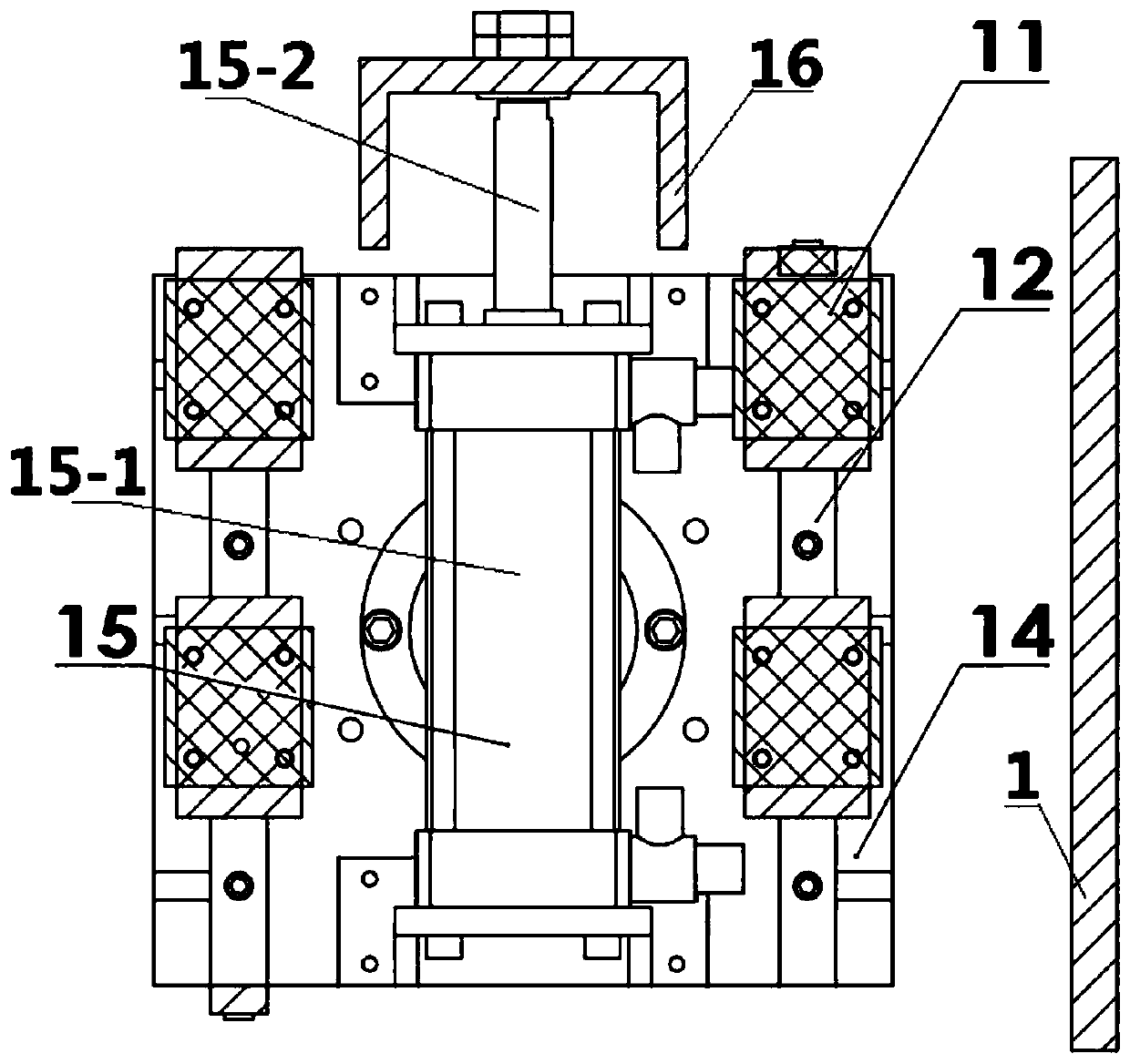

[0025] Such as figure 1 As shown, a composite actuator for numerical control and intelligent polishing includes a polishing wheel 1, a one-to-two transmission 2, a rigid coupling 3, an eccentric disk 4, a polishing rod 5, a polishing disk (6), a flexible coupling Shaft device 7, stepper motor 8, limit block 10, slide block 11, guide rail 12, actuator base plate 13, actuator base plate 14, bidirectional precision adjustment cylinder 15 and cylinder adapter 16.

[0026] The one-to-two transmission 2 is fixed on the actuator substrate 13, and the polishing wheel 1 is fixed on the one-to-two transmission 2 through the cooperation of the key and the keyway to transmit torque, and the polishing wheel 1 can be used to polish the workpiece.

[0027] One end of the rigid coupling 3 is connected to one shaft of the one-to-two transmission 2. By adjusting the bolt at one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com