A processing method of hemp ash wrapped yarn with intermediate color characteristics and hemp ash wrapped yarn

A processing method and technology of wrapping yarn, applied in the direction of yarn, textile and paper making, etc., can solve the problems of rough style, inferior to fiber grade, delicate color mixing, etc., and achieve the effect of adapting to a wide range of raw materials and vivid style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

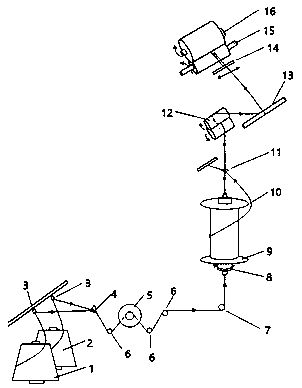

Method used

Image

Examples

Embodiment 1

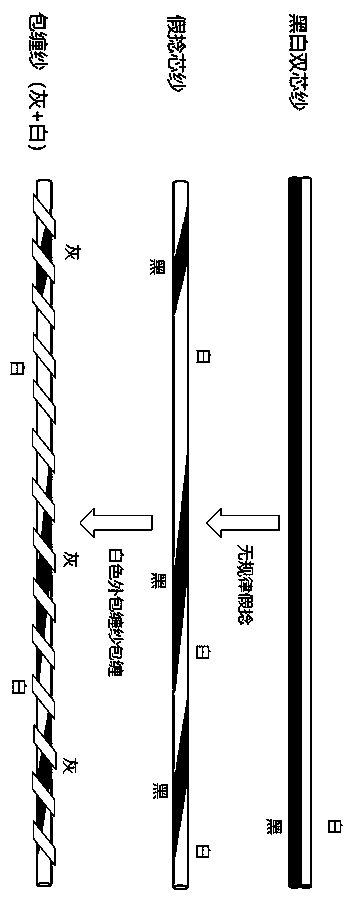

[0088] Example 1: Polyester / brocade filament wrapping composite hemp gray intercolored yarn

[0089] Design the spinning principle and technology according to this patent, use 70D / 24F nylon DTY (Drawn Textured Yarn) twisted filament yarn (twist 120 twist / m) as the core yarn each of black and white, white 70D / 36F polyester DTY non-twisted filament yarn is wrapped yarn, spinning "(white+black)+white" intermediate color hemp gray yarn. The hollow spindle speed is 15435r / min, the yarn drawing speed is 23.6m / min, the wrapping twist is 654 twists / m, and the wrapping twist direction is Z twist.

[0090] The appearance of the spun yarn is as follows Figure 4 Yarn blackboard diagram shown. It can be seen from the figure that the false twist of the black and white two-color core yarn forms an irregular black-white segment color effect. After being wrapped and fixed by the white outer wrapping yarn, the composite yarn is distributed with white segments of different lengths along its le...

Embodiment 2

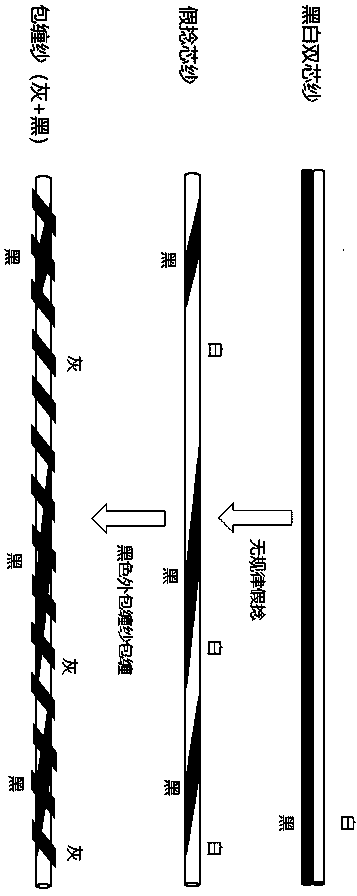

[0092] Embodiment 2: tencel / nylon inter-colored heather gray yarn

[0093] Design the spinning principle and technology according to this patent, use 70D / 24F black nylon 6 DTY filament yarn and natural color 60S (English count) Tencel (Tencel fiber) ring yarn (spun yarn) to form a double-core yarn, 70D / 24F The black nylon 6 DTY filament yarn is wrapped yarn, and it is spun into "(white+black)+black" intermediate color hemp gray yarn. The hollow spindle speed is 15435r / min, the yarn drawing speed is 21.0m / min, the wrapping twist is 735 twists / m, and the wrapping twist direction is S twist.

[0094] The appearance of the spun yarn is as follows Figure 5 and Figure 6 Yarn blackboard diagram shown. It can be seen from the figure that the false twist of the black and white two-color core yarn forms an irregular black-white segment color effect. After being wrapped and fixed by the black outer wrapping yarn, the composite yarn is distributed along its length with black segments...

Embodiment 3

[0096] Embodiment 3: tencel / nylon / polyester-cotton intercolored heather gray yarn

[0097] Design the spinning principle and technology according to this patent, use 70D / 24F black nylon 6 DTY filament yarn and natural color 60S (English count) Tencel (Tencel fiber) ring yarn (spun yarn) to form a double-core yarn, 60S natural color polyester / Cotton blended combed ring spun yarn is wrapped yarn, spinning "(white+black)+white" intermediate color hemp gray yarn. The hollow spindle speed is 15435r / min, the yarn drawing speed is 21.0m / min, the wrapping twist is 735 twists / m, and the wrapping twist direction is S twist.

[0098] The appearance of the spun yarn is as follows Figure 7 and Figure 8 Yarn blackboard diagram shown. It can be seen from the figure that the black-and-white two-color core yarn false-twisting effect forms an irregular black-white segment color effect. After being wrapped and fixed by the black outer wrapping yarn, the composite yarn is distributed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com