Arrangement method of semi-continuous process middle bridge in open pit coal mine

An open-pit coal mine, semi-continuous technology, applied in the field of mining technology, can solve problems such as affecting the normal advancement of the mobile help, increasing the inner discharge and transportation distance of the stripped material, and increasing the inner discharge and transportation distance of the stripped material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

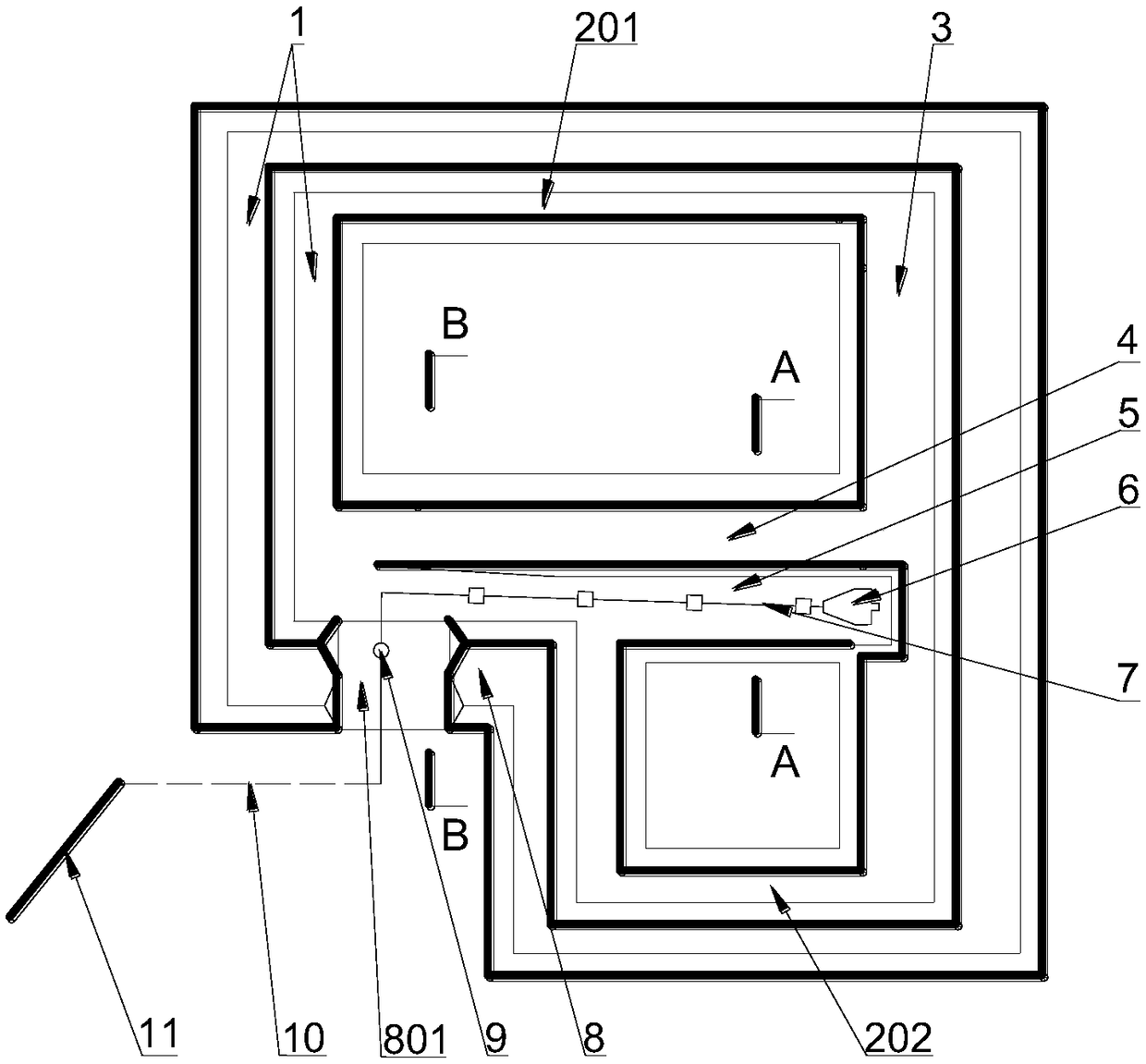

[0023] Such as figure 1 and figure 2 As shown, the layout of the semi-continuous process intermediate bridge in the open-pit coal mine of the present invention includes a crushing station 6, a bottom belt conveyor 7, a lifting belt conveyor 9, a connecting belt conveyor 10 and a ground belt conveyor 11; It is characterized in that the steps are as follows:

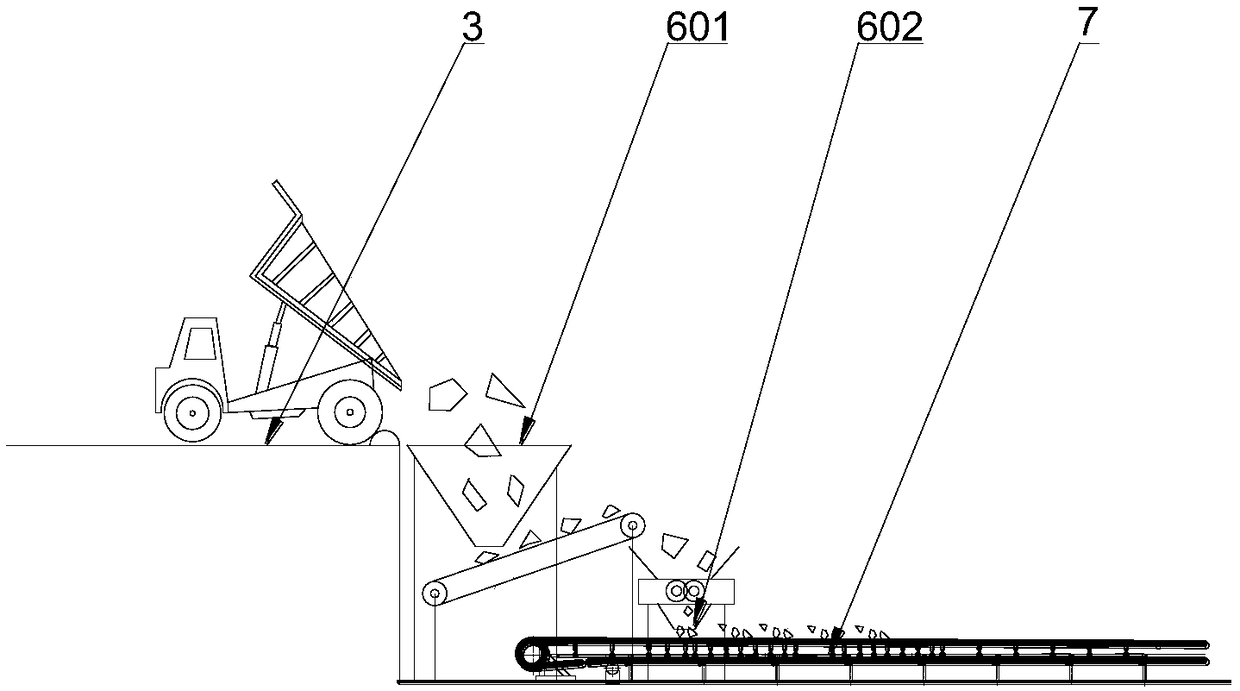

[0024] A groove is dug down at the middle point of the connection line between the left end side 201 and the right end side 202 on the uppermost coal mining step 3 platform of the open-pit coal mine, and the crushing station 6 is arranged in the groove, and the crushing station 6 includes the crushing station The material inlet 601 and the crushing station outlet 602, the crushing station material inlet 601 is at the same level as the coal seam roof;

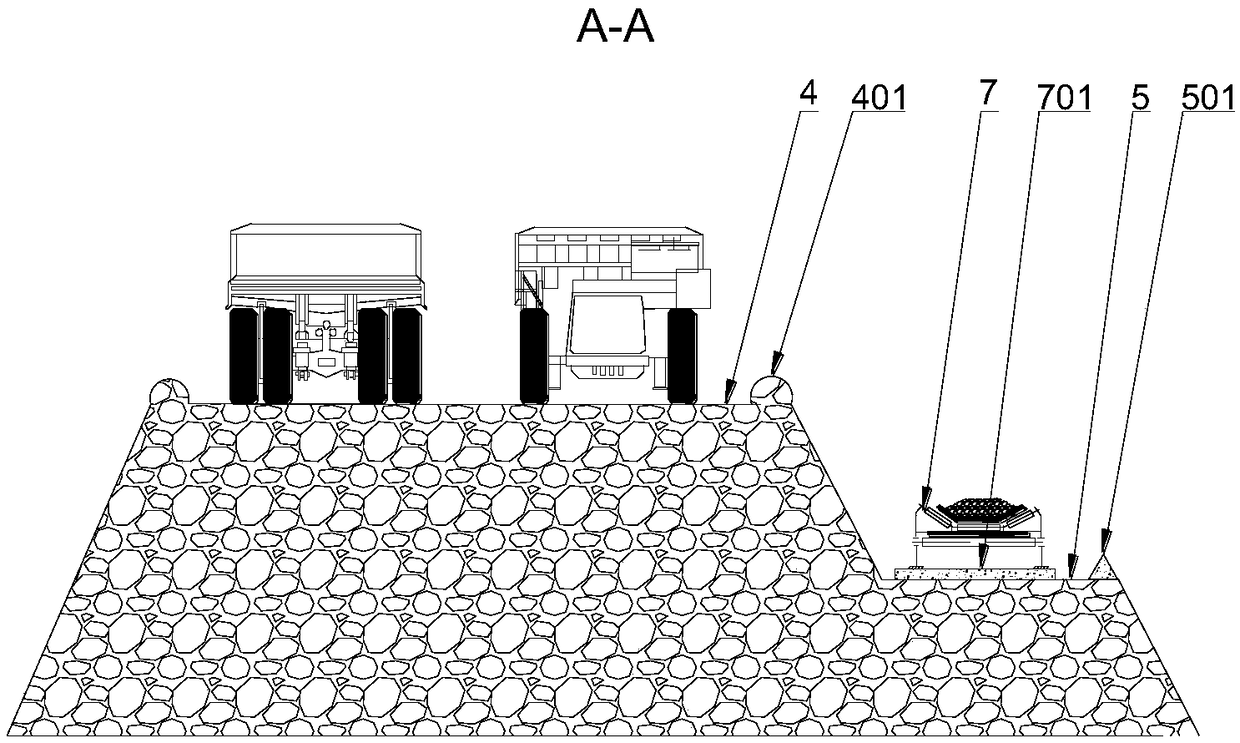

[0025] Such as image 3 and Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com