A ring synthetic structure of gem-grade diamond and its preparation method and application

A diamond and ring-shaped technology, which is applied in the field of gem-grade diamond ring synthesis structure and its preparation, can solve the problems of difficult to achieve high-quality and high-efficiency synthesis of gem-grade diamond, uneven particle size of diamond synthesis, and large temperature difference in the growth zone. Commercial application, strong market advantage, solving the effect of small growth area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

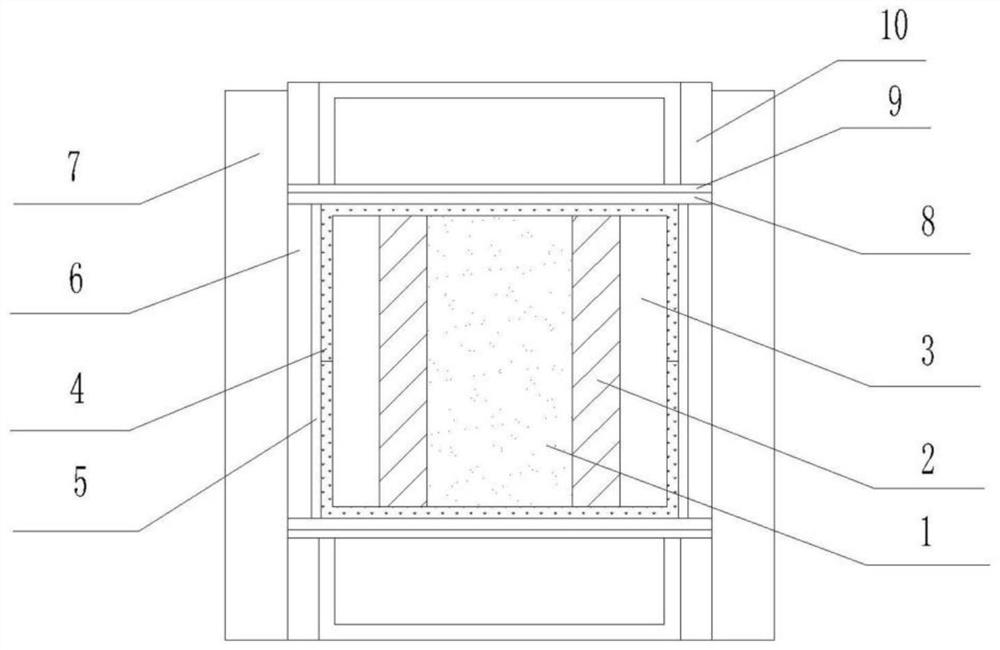

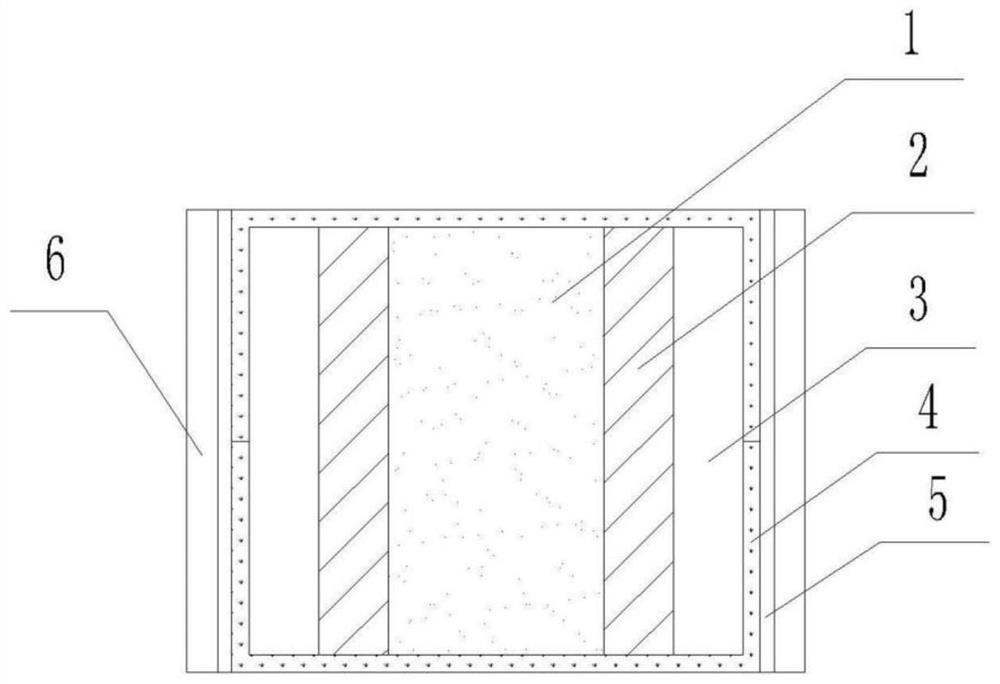

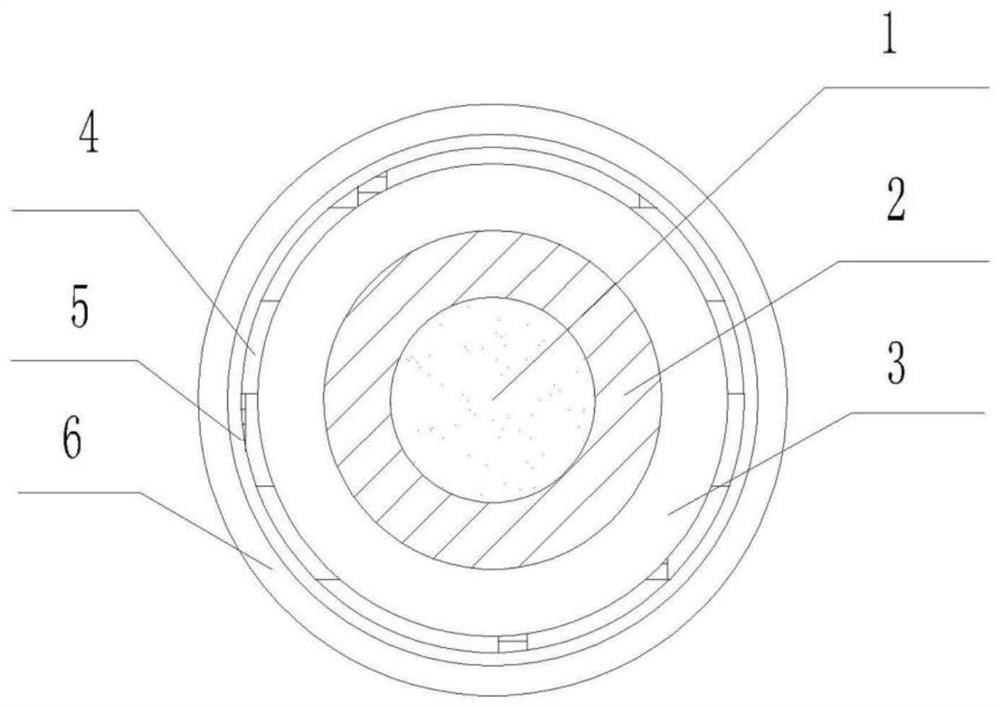

[0042] See Figure 1-3 The gem-level diamond synthesis structure of the present invention includes a gratis compound block 7, a heating sheet 8, a copper sheet 9, a conductive plug 10, and a synthetic cavity assembly, and the synthetic cavity assembly is sequentially provided with a cylindrical crystal bed. 1, the annular catalysis 2, the annular carbon source 3, the insulating cup 4, the heating tube 5 and the transfer tube 6; the cylindrical bed 1, the annular catalyst 2 and the annular carbon source 3 are sequentially placed in the insulating cup 4, insulating cup 4 is parallel to the heating tube 5; the heating tube 5 is equal to the height of the transfer tube 6; the synthetic cavity assembly is sleeved into the outer container composite block 7, the annular synthesis structure, from the center, down two The end sequentially is a cylindrical bed 1, an insulating cup 4, a heating sheet 8, a copper sheet 9, and a conductive 10 electrojection, and the heating sheet 8 is connected...

Embodiment 2

[0047] The preparation method of the preparation method of the preparation method is as follows:

[0048] A, prepared by a cylindrical crystal bed: Take 100 mesh, purity> 99% analysis of pure magnesium oxide as raw materials, using four column hydraulics at 20 MPa pressure to press the raw material to press the cylindrical crystal bed substrate, the resulting cylinder The diameter of the adted bed substrate was 20 mm; the obtained cylindrical crystal bed substrate was baked under 800 ° C for 10 h, cooled to room temperature to obtain a cylindrical crystal bed substrate; the resulting cylindrical crystal bed substrate was punched, then in the well Implanted 1.0 mm diamond to get a cylindrical bed;

[0049] B. Preparation of the annular catalyst: The raw material group of the annular catalyst has become Fe 70%, Ni 25%, CO 3.0%, Al0.2%, Ti 0.3%, Zr 1.0%, Si 0.3% and Cu 0.2%, various The amount of the material mass is 100%; the various alloy components are formulated according to the ...

Embodiment 3

[0060] The preparation method of the preparation method of the preparation method is as follows:

[0061] a, prepared by a cylindrical crystal bed: Take 100 mesh, purity> 99% analysis of pure magnesium oxide is a raw material, using a four-column hydraulic press to calculate the raw material to a cylindrical crystal bed substrate under 30 MPa pressure, the resulting cylinder The diameter of the collar base is 15 mm; the resulting cylindrical crystal bed base is baked at 1000 ° C for 8 h, cooled to room temperature to obtain a cylindrical crystal bed substrate; the resulting cylindrical crystal bed substrate is punched, then in the well Implanted 1.5 mm diamond to get a cylindrical bed;

[0062] B. Preparation of the annular catalyst: The raw material group of the annular catalyst is Fe 70%, Ni27%, CO 1%, Al0.5%, Ti 0.2%, Zr 0.5%, Si 0.5% and Cu 0.3%, various raw materials. The sum of the percentage of mass is 100%; the various alloy components are formulated according to the raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com