Centrifugal Casting Method of Large Size Double Flange Copper Alloy Bushing or Copper Alloy Bearing Pad

A centrifugal casting and copper alloy technology, applied in the field of casting and centrifugal casting technology, can solve the problems of inability to meet high requirements, excessive machining time, poor ventilation effect of sand core, etc., to reduce the investment of machining time and overcome the uneven crystal , the effect of reducing the input of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

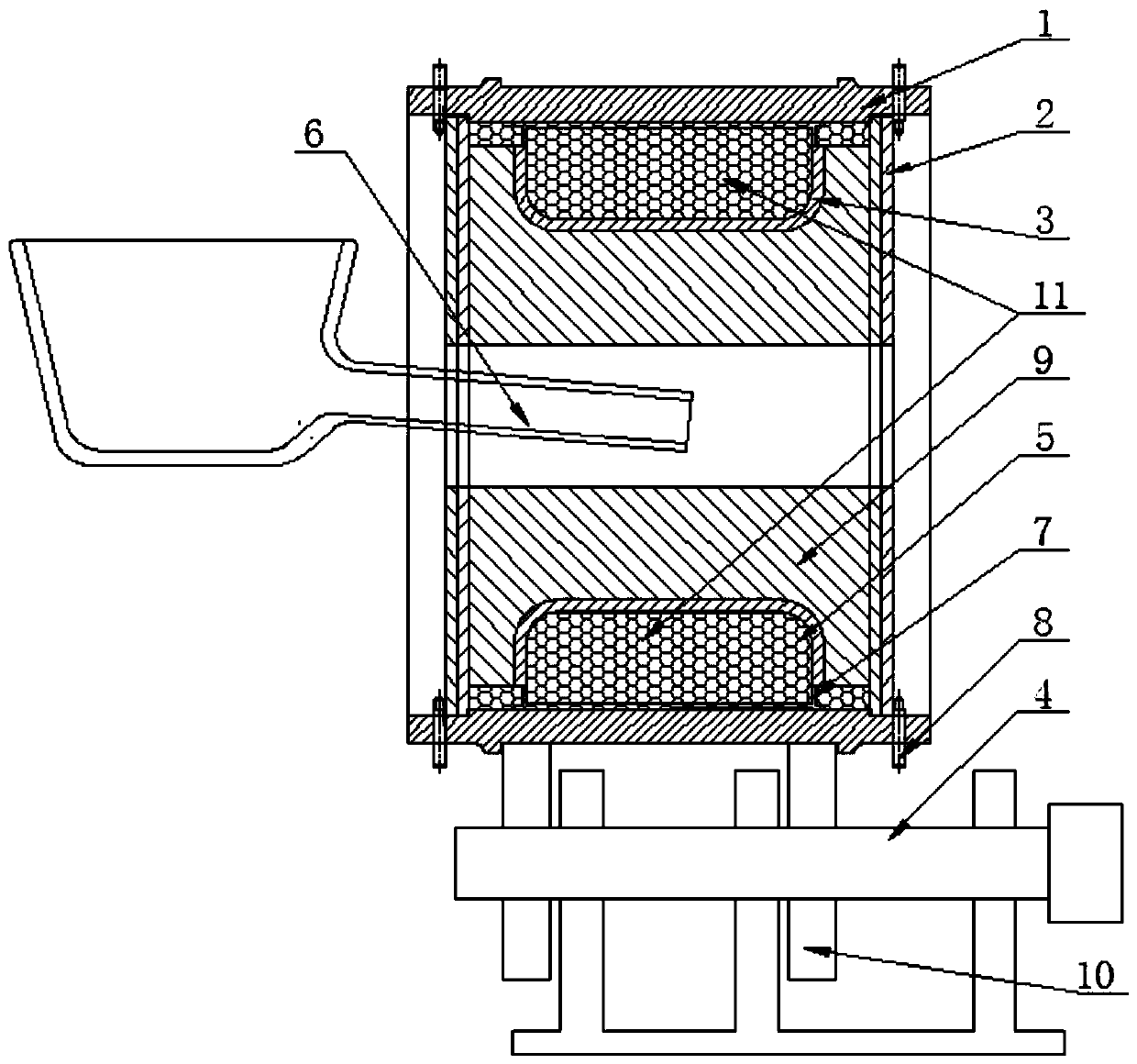

[0071] Now take the application of the method of the present invention to the processing of the double-flange copper alloy bushing of the open bridge half hub in Malaysia as an example to describe in detail, and it also has guidance for the invention to be applied to the centrifugal casting of other large-scale double-flange copper alloy bushings (tiles) effect.

[0072] 1) The finished size of the semi-hub double-flange copper alloy bushing is φ1100×φ735×φ625×800, double S=50mm, the weight of the finished product is 1250kg, and the material is ZCuPb10Sn10; according to the process design, the size of the centrifugal casting blank is φ1130×φ765×φ585× 824, double S=74mm, casting weight (R=90 at the flange) 2186kg;

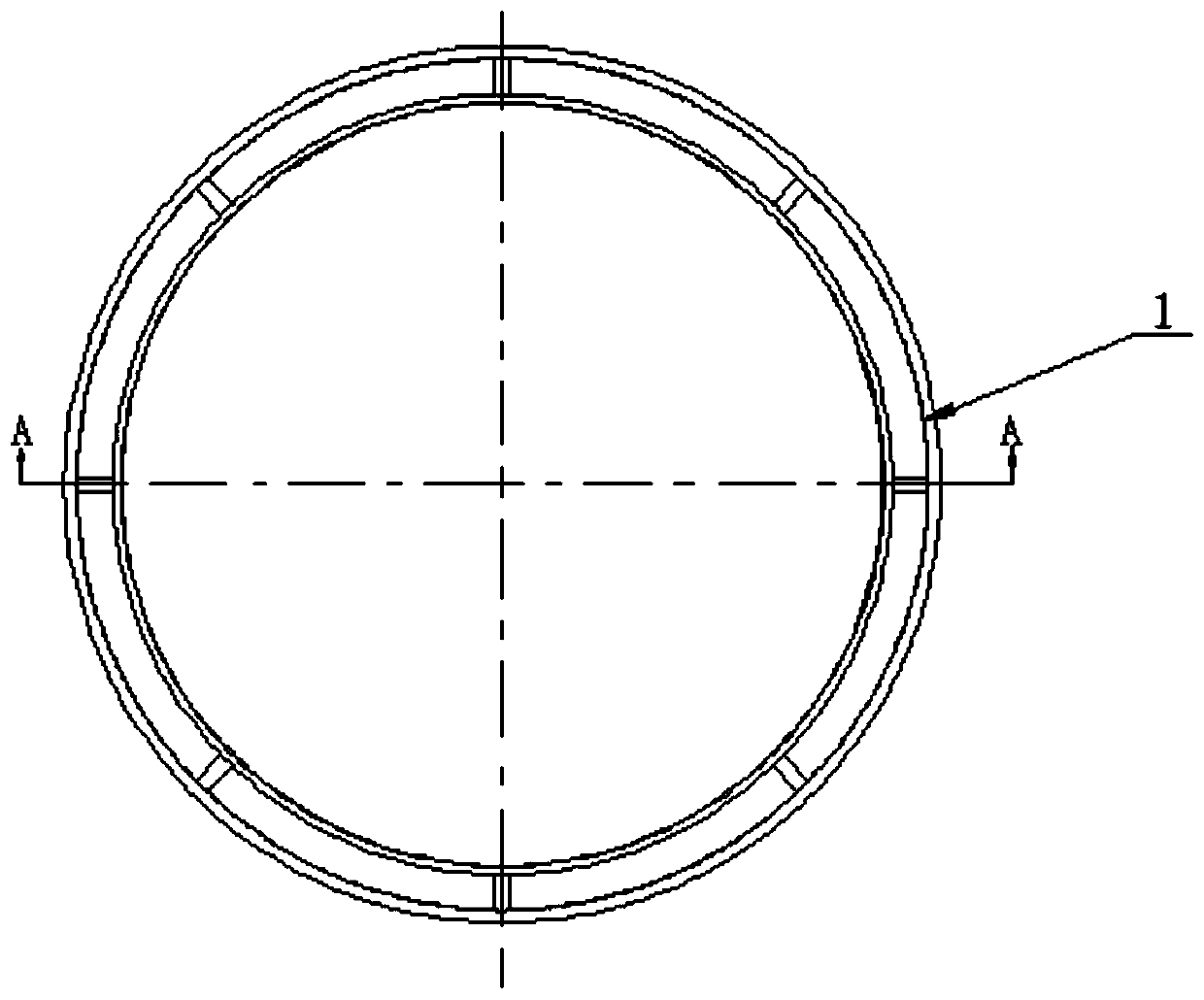

[0073] 2) External mold (such as figure 2 The size shown) is: the diameter of the outer circle is 1420mm; the diameter of the inner circle is 1237mm, and the length is 1052mm;

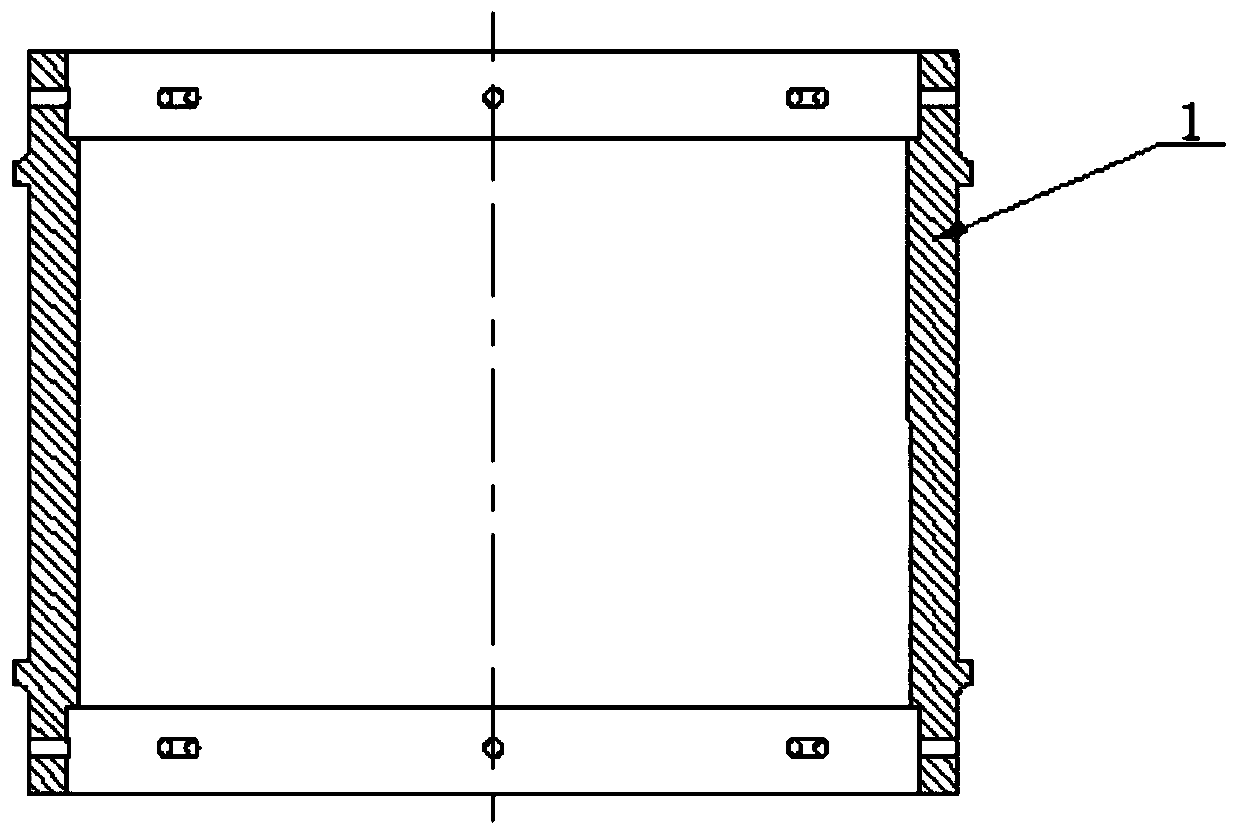

[0074] 3) Inner mold (such as image 3 The dimensions shown) are: the diameter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com