Indexing chuck

A collet and indexing technology, which is applied in the direction of metal processing machinery parts, precision positioning equipment, metal processing equipment, etc., can solve the problems of increasing structural complexity and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

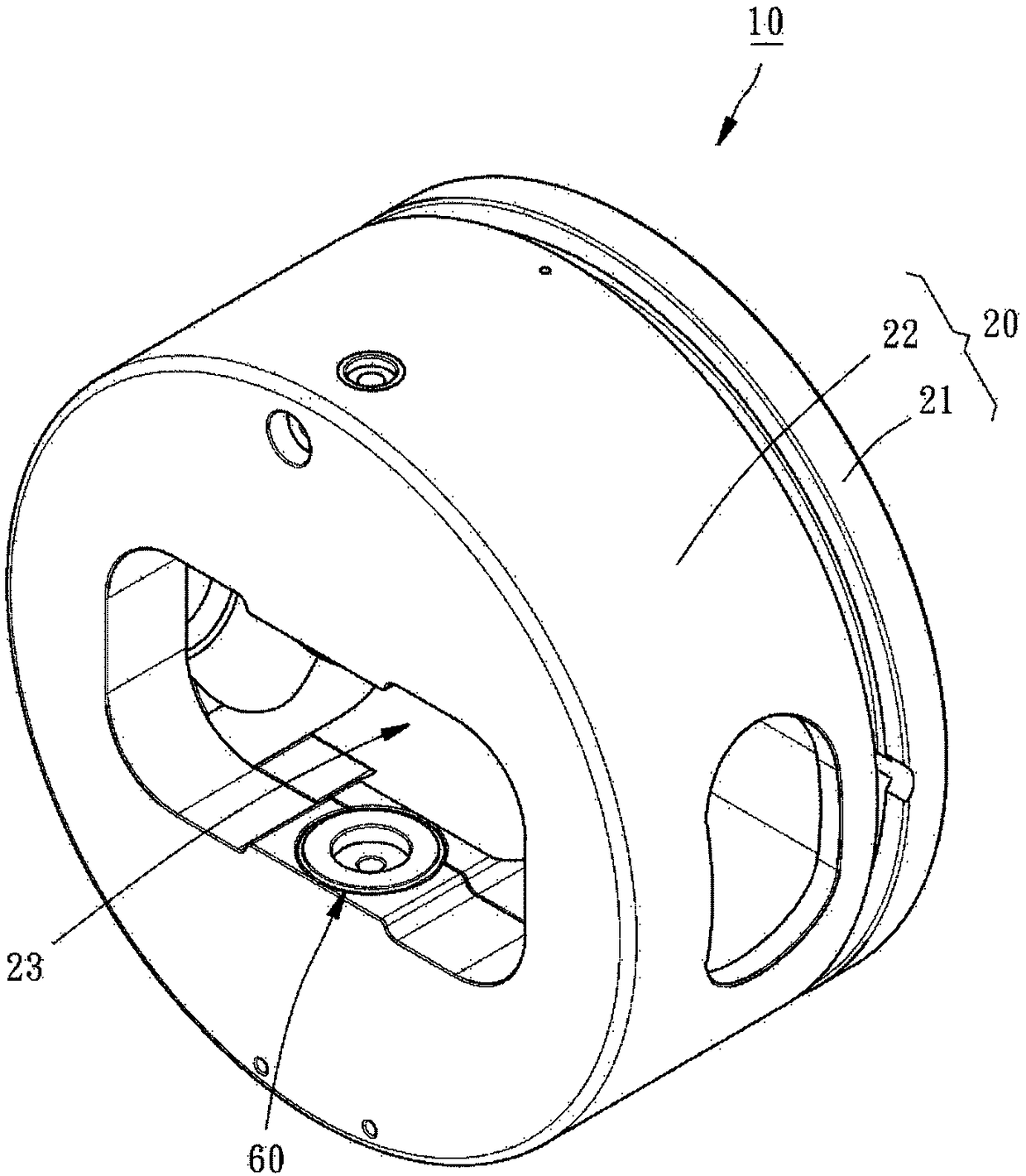

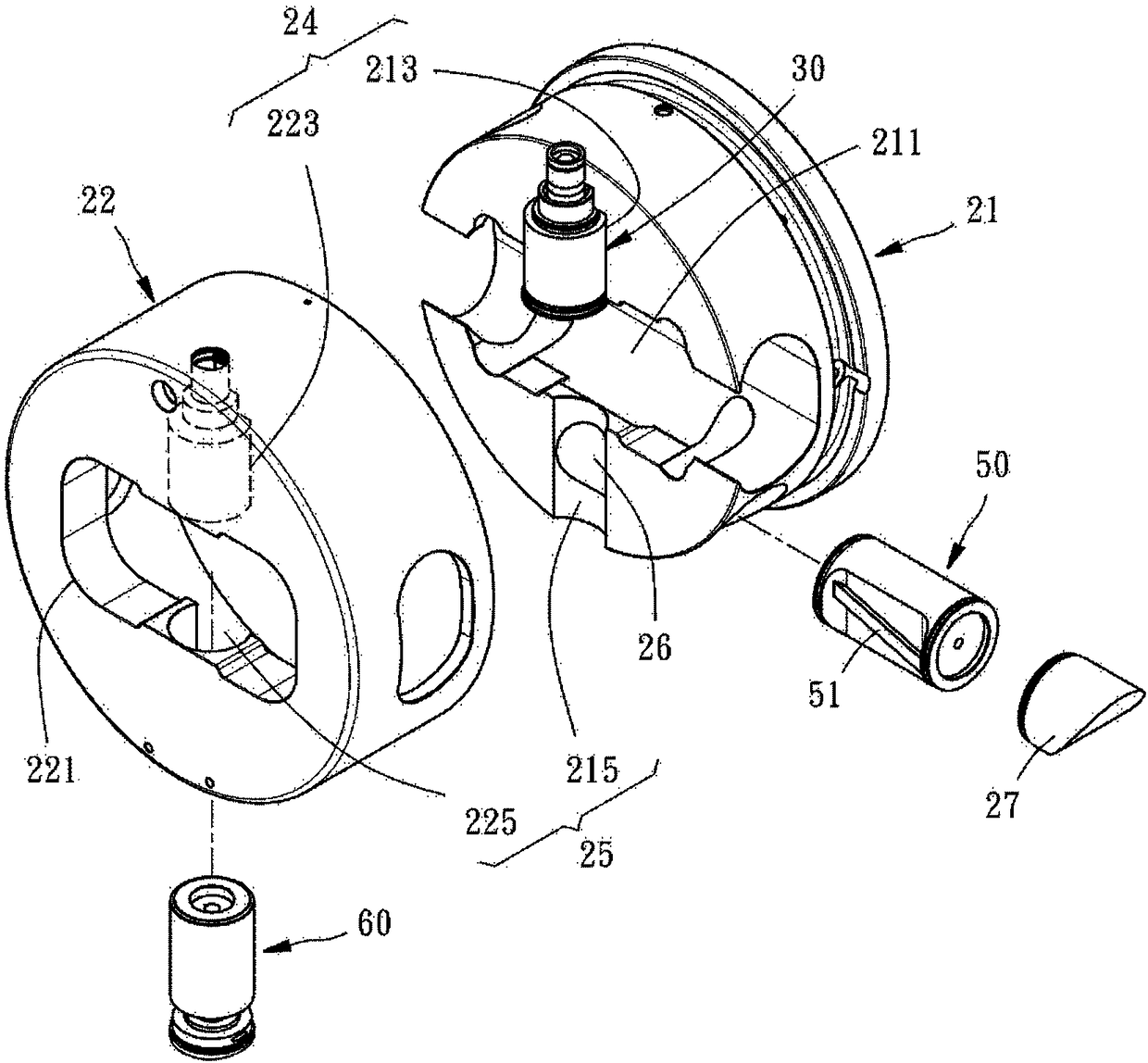

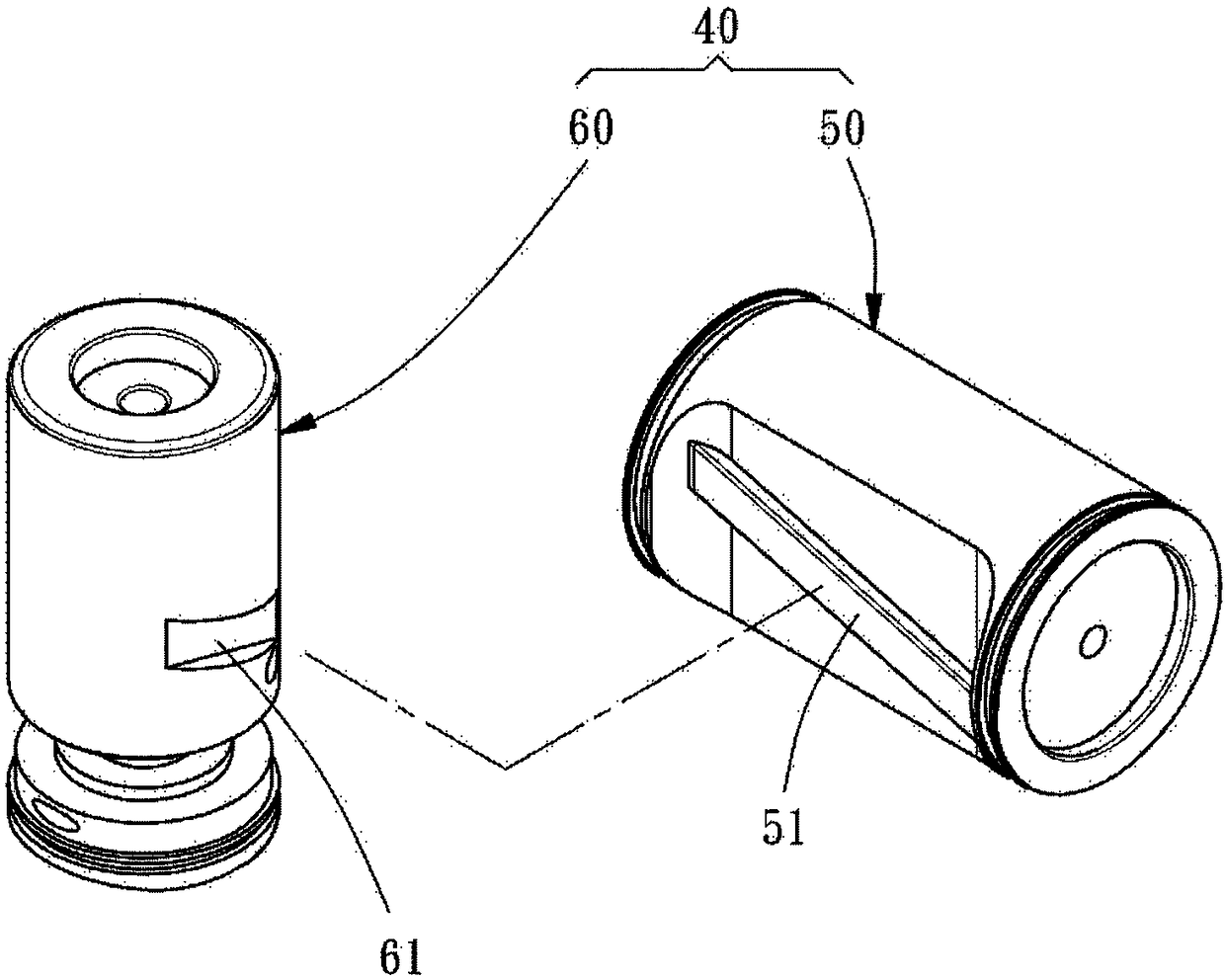

[0029] Please see first Figure 1 to Figure 3 , The indexing chuck 10 of the present invention includes a clamp seat 20 , an indexing shaft 30 , and a positioning assembly 40 .

[0030] The clamp seat 20 has a seat body 21 and a cover body 22 covering the seat body 21. The center of the seat body 21 has an elongated groove 211. The cover body 22 has an opening 221. The opening 221 of the cover body 22 is correspondingly connected to the seat body. 21 of the elongated groove 211, so that both together form the workpiece accommodating groove 23. The seat body 21 has a first arc groove 213 communicating with the elongated groove 211 and a second arc groove 215 communicating with the elongated groove 211 on two opposite sides of the elongated groove 211, and the cover body 22 is Two opposite sides of the opening 221 respectively have a third arc groove 223 communicating with the opening 221 and a fourth arc groove 225 communicating with the opening 221, the first arc groove 213 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com