Labor-saving wooden door clamp

A fixture and wooden door technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of low production efficiency, inconvenient clamping, and laborious, etc., to achieve the goals of improving production efficiency, convenient manual adjustment, and shortening the time spent on clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

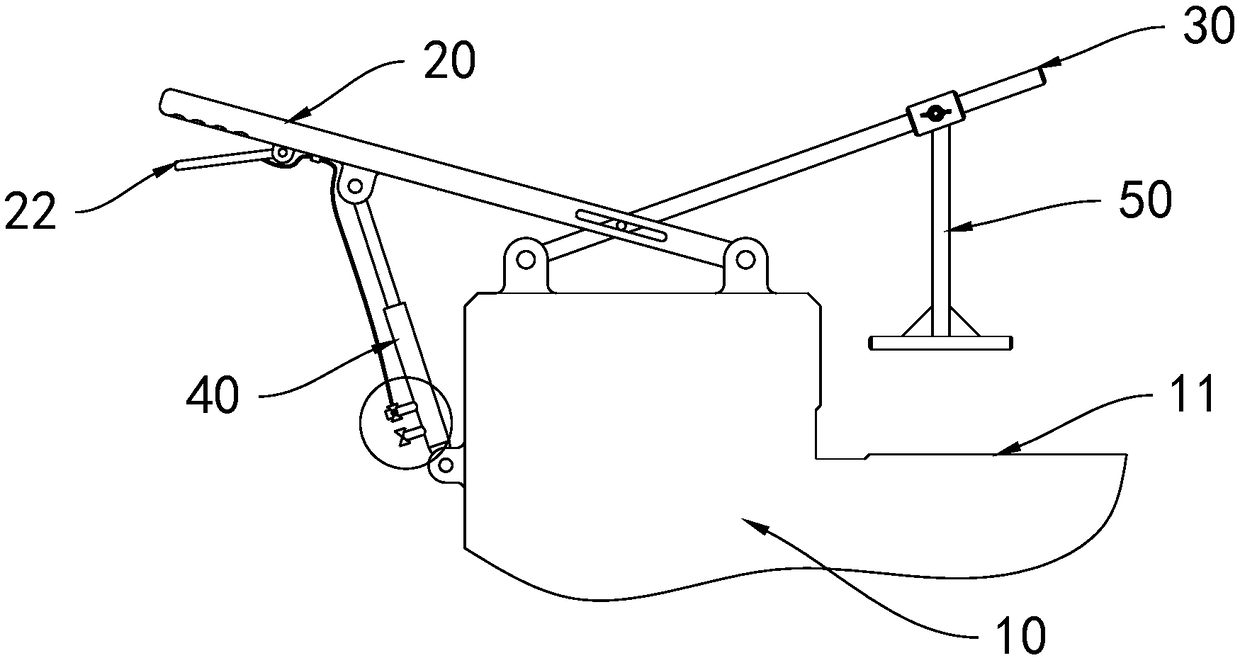

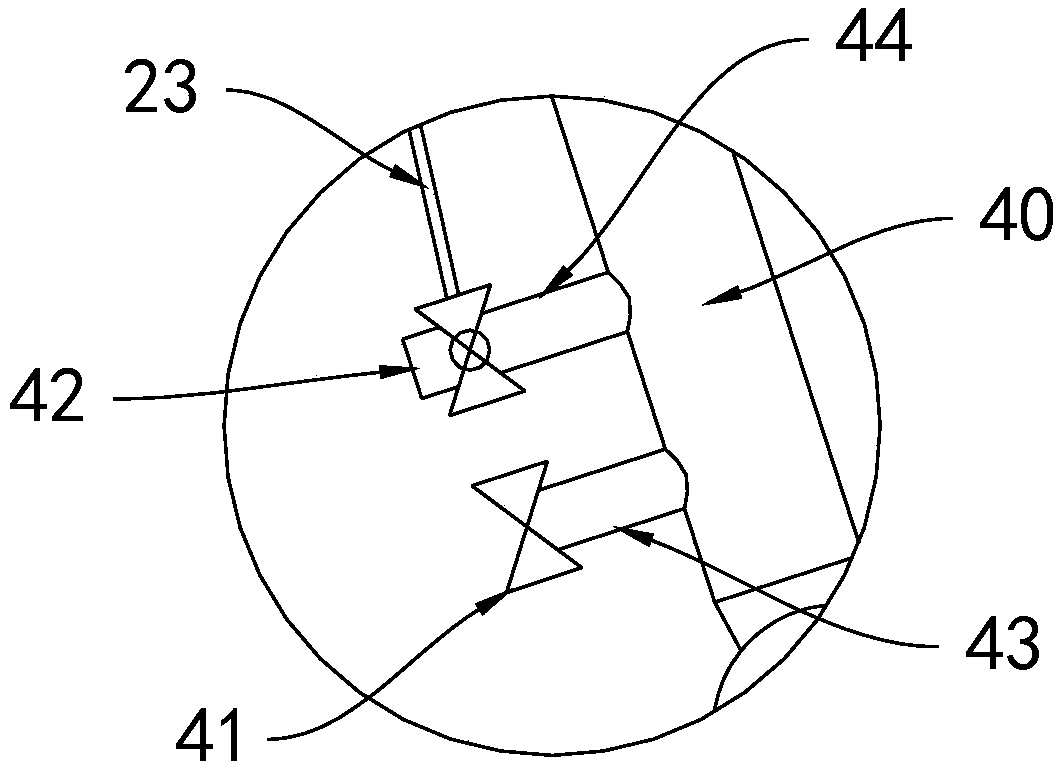

[0017] Embodiment: a labor-saving wooden door fixture, including a base 10 with a placement platform 11, on which the base 10 is hinged with an operating rod 20 and a pressing rod 30, the operating rod 20 and the pressing rod 30 are arranged crosswise, and the operating rod 20 is provided with a chute, and the pressure rod 30 is provided with a sliding column sliding in the chute; a piston rod 40 is also hinged between the operating rod 20 and the base 10, and a pressure relief valve is also hinged on the operating rod 20. The handle 22 and the piston rod 40 are provided with a one-way exhaust valve 41 and an automatic reset intake valve 42, and the automatic reset intake valve 42 is connected with the pressure relief handle 22 through the gate line 23; There is a sliding platen 50 .

[0018] A torsion spring is provided at the hinge of the pressure relief handle 22 and the operating rod 20 .

[0019] The pressing plate 50 is connected with the pressing rod 30 via a wing nut....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com