Thermoplastic polyurethane (TPU) film slitter guide roller mechanism

A slitter and guide roller technology, applied in metal processing, sending objects, thin material processing, etc., can solve the problems of inability to limit, unable to adjust the limit, difficult to adjust the tension of the guide rod, to avoid re-adjustment , The effect of preventing deviation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

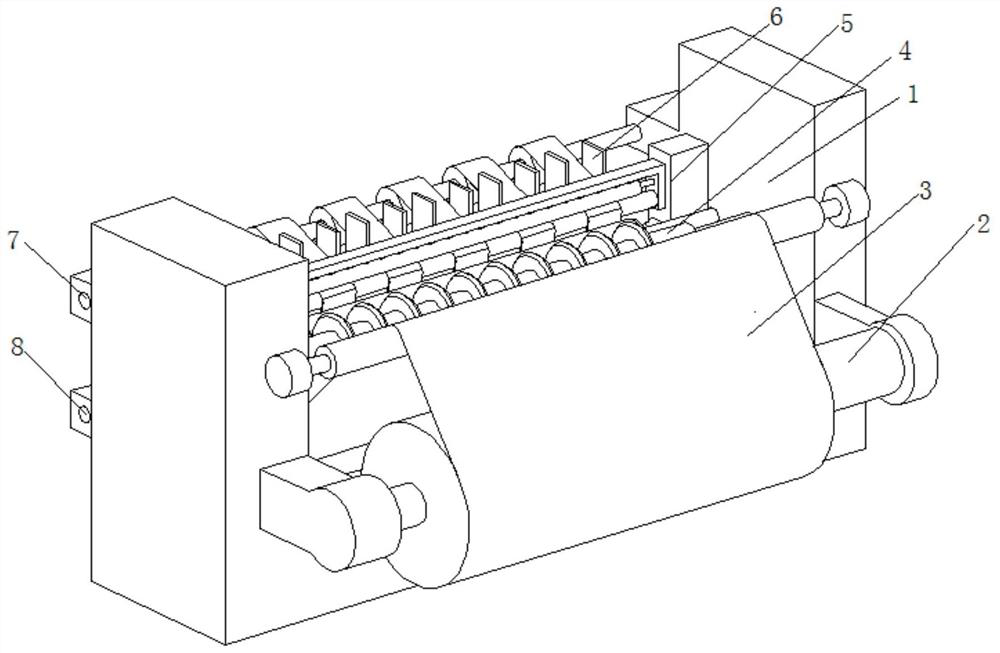

[0031] A TPU film slitting machine guide roller mechanism, such as Figure 1-Figure 5 As shown, it includes a body 1, the front of the body 1 is rotatably connected to a feed roller 2, the surface of the feed roller 2 is fixedly connected to a film roll body 3, and the inside of the body 1 is rotatably connected to a knife roller 4, and the body 1 is located on the knife roller The rear part of 4 is provided with adjusting mechanism 5, and the surface of adjusting mechanism 5 is provided with guiding mechanism 6, and body 1 is positioned at the rear portion of adjusting mechanism 5 and is respectively connected with upper receiving roller 7 and lower receiving roller 8, and upper receiving roller The roll 7 is located above the lower take-up roll 8 .

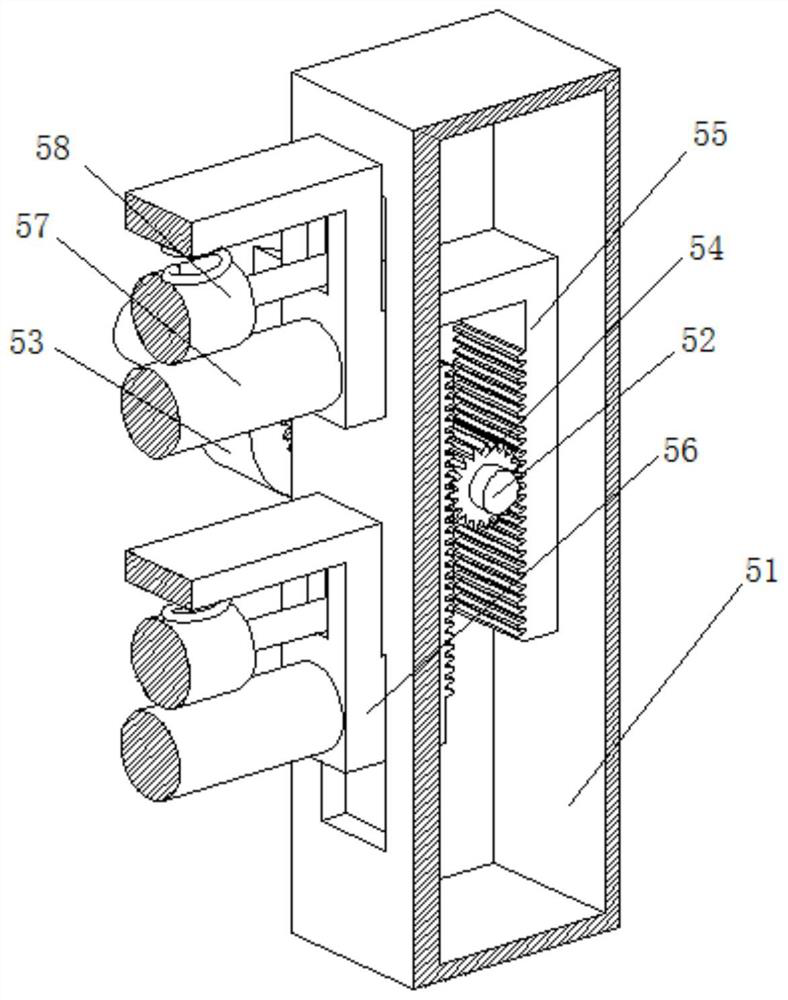

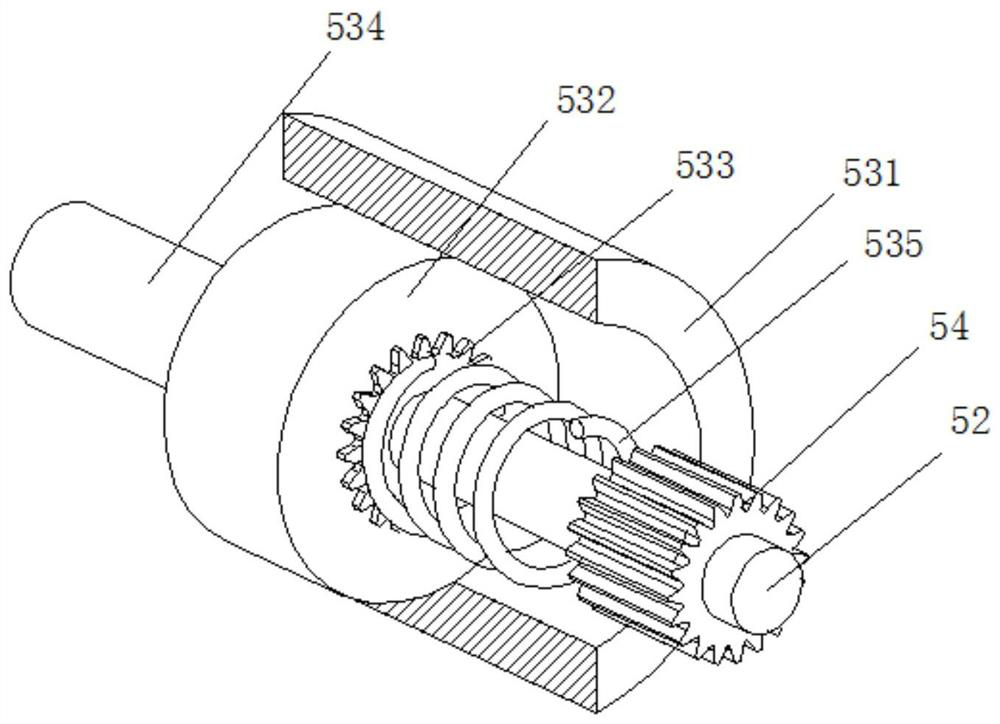

[0032] In this embodiment, the adjustment mechanism 5 includes an adjustment box 51, the right side of the adjustment box 51 is fixedly connected to the surface of the body 1 by bolts, the inside of the adjustment box 51 is conn...

Embodiment 2

[0042] like Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the guide mechanism 6 includes a base 61, the top of the base 61 is welded and fixed to the surface of the lead roller 57, and the inner wall of the base 61 is rotatably connected to a shaft 62, the shaft The surface of 62 is welded with adjustment gear 63, and the surface of adjustment gear 63 is engaged with front tooth plate 64 and rear tooth plate 65 respectively, and the rear end of front tooth plate 64 and rear tooth plate 65 is welded with right guide plate 66 and left guide plate 67 respectively, And the bottoms of the front tooth plate 64 and the rear tooth plate 65 are all slidably connected with the bottom of the inner wall of the base 61, the inside of the base 61 is provided with an interlocking device 68, and the shape of the right guide plate 66 and the left guide plate 67 is set to Z.

[0043] The folding state achieves the effect of limiting the slitting film on the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com