Patents

Literature

34results about How to "Avoid readjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

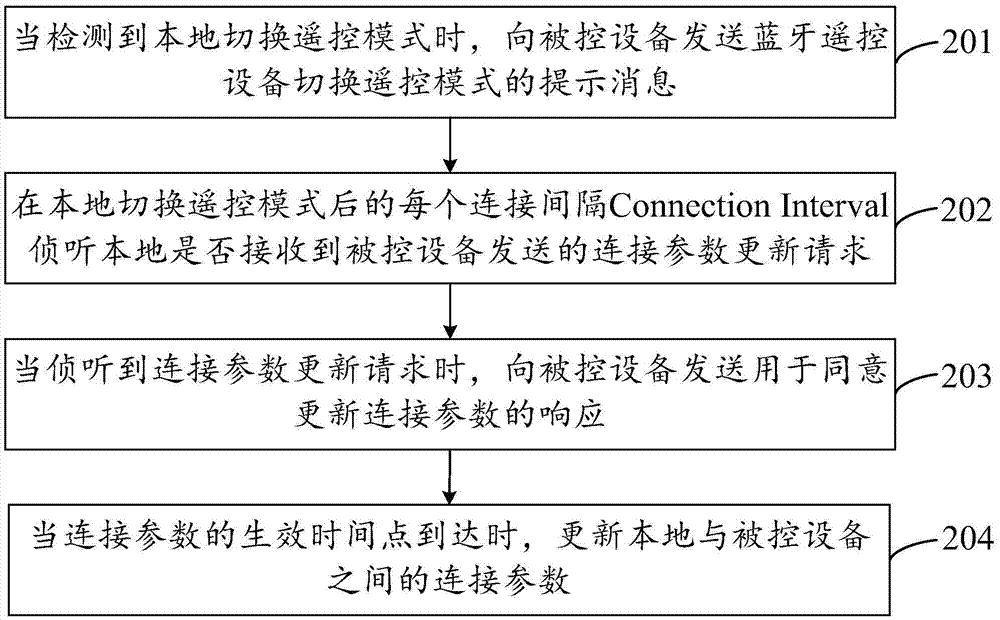

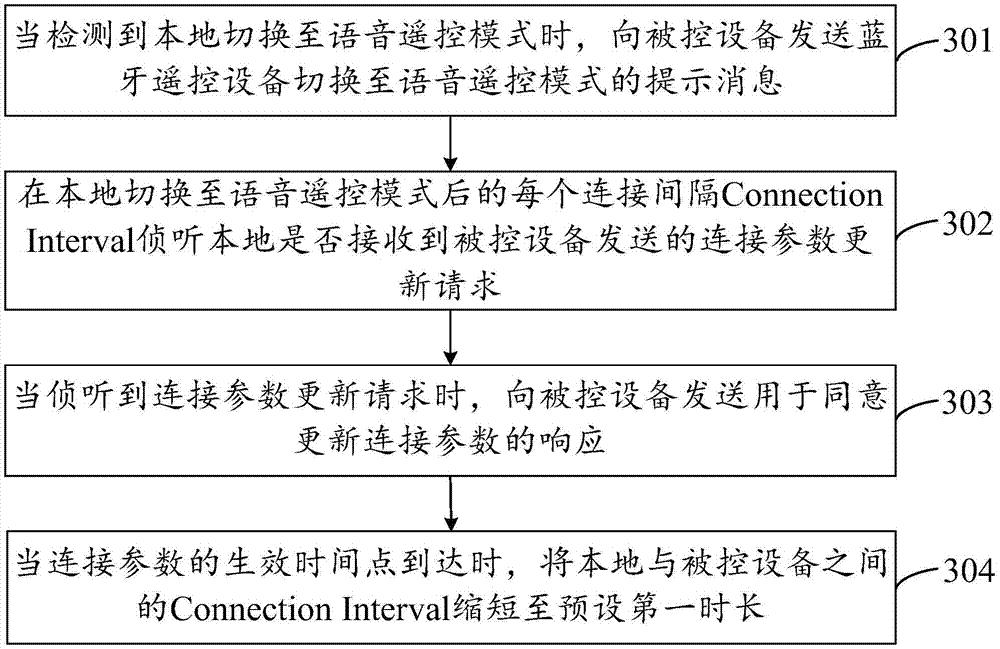

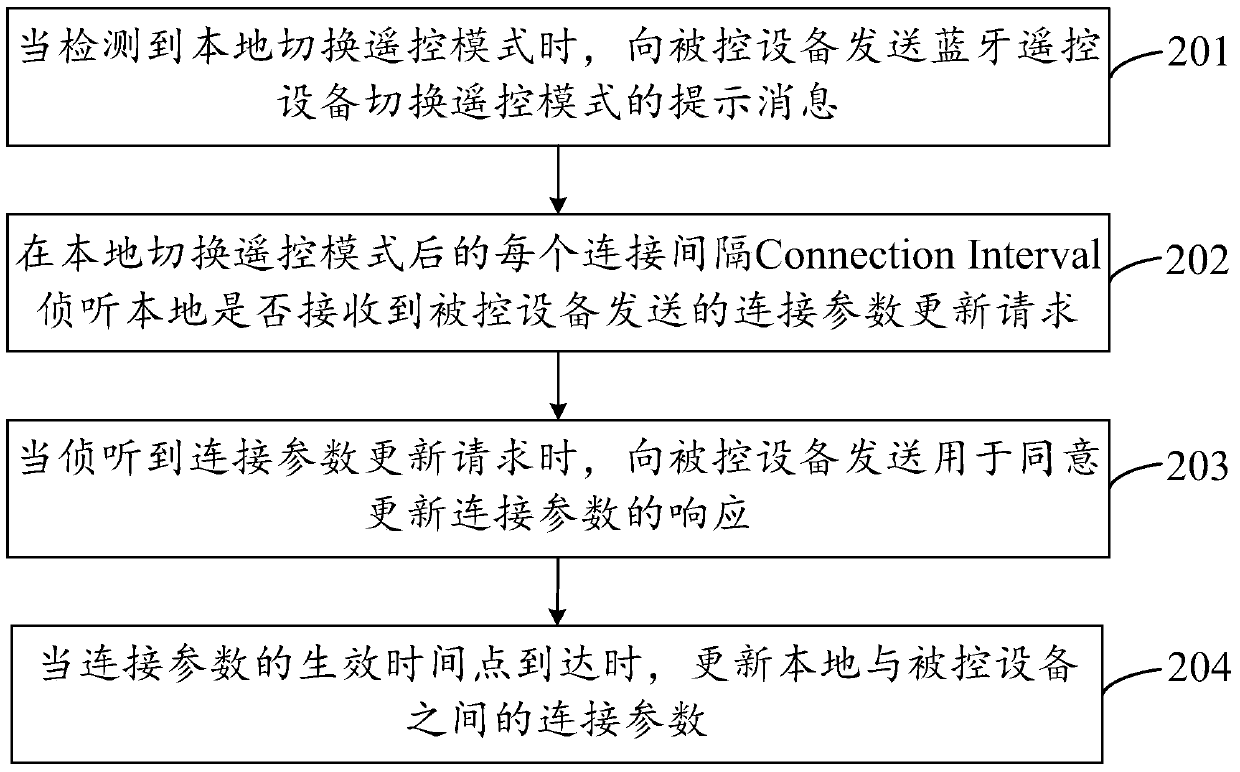

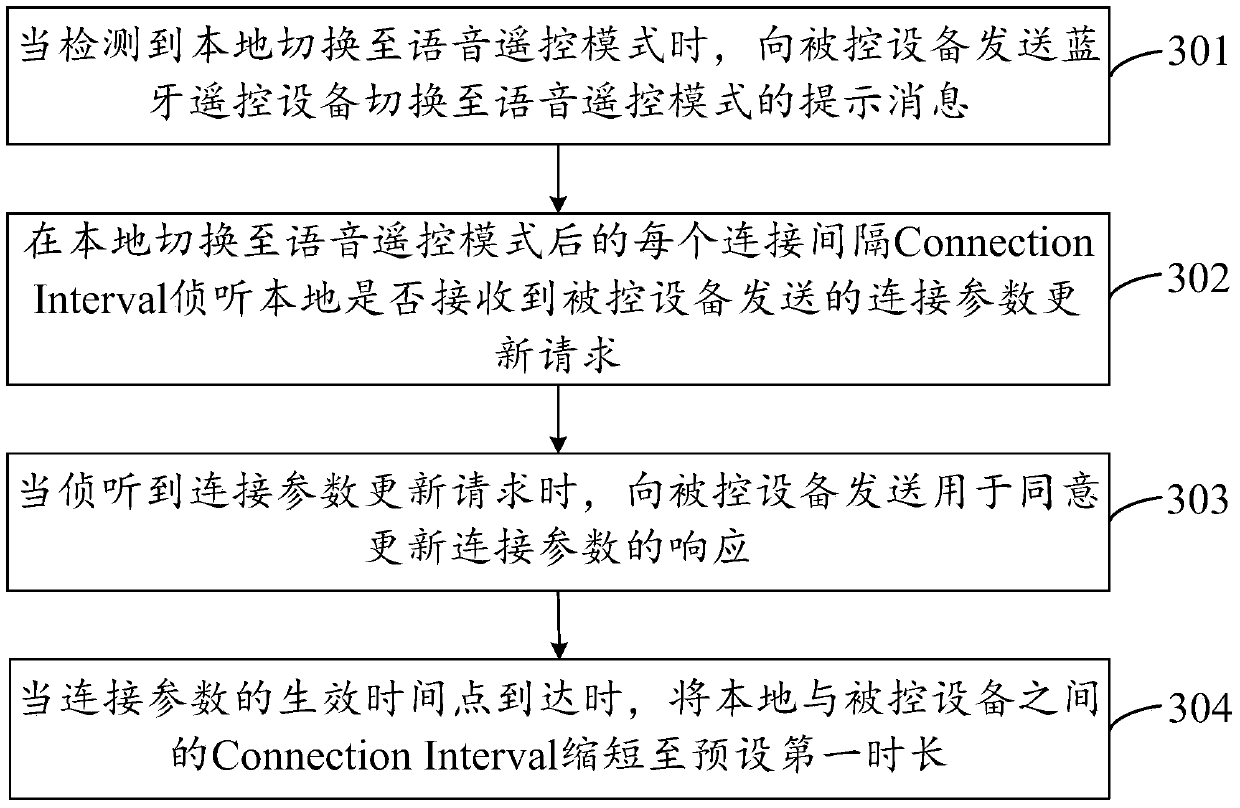

Method and apparatus for updating connection parameter of Bluetooth device with low power consumption

ActiveCN105451369AQuick responseFast updateTransmission systemsNetwork topologiesRemote controlEffective time

The invention provides a method and an apparatus for updating a connection parameter of a Bluetooth device with low power consumption. The method comprises the following steps: when detecting that aremote control mode is switched locally, sending a prompt message indicating that a Bluetooth remote control device switches the remote control mode to a controlled device, for enabling the controlled device to generate a connection parameter updating request according to the prompt message and send the connection parameter updating request to the Bluetooth remote control device, wherein the connection parameter updating request carries an effective time point of the connection parameter, and the effective time point is prior to a default effective time point; monitoring whether the connection parameter updating request sent by the controlled device is received locally at each connection interval after the remote control mode is switched locally; when monitoring the connection parameter updating request, sending response used for agreeing to update the connection parameter to the controlled device; and when reaching the effective time point of the connection parameter, updating the connection parameter of the local and the controlled device. In summary, the method and the apparatus provided by the technical scheme of the invention can be used for improving the updating speed of the connection parameter by improving the response speed of the Bluetooth remote control device.

Owner:XIAOMI INC

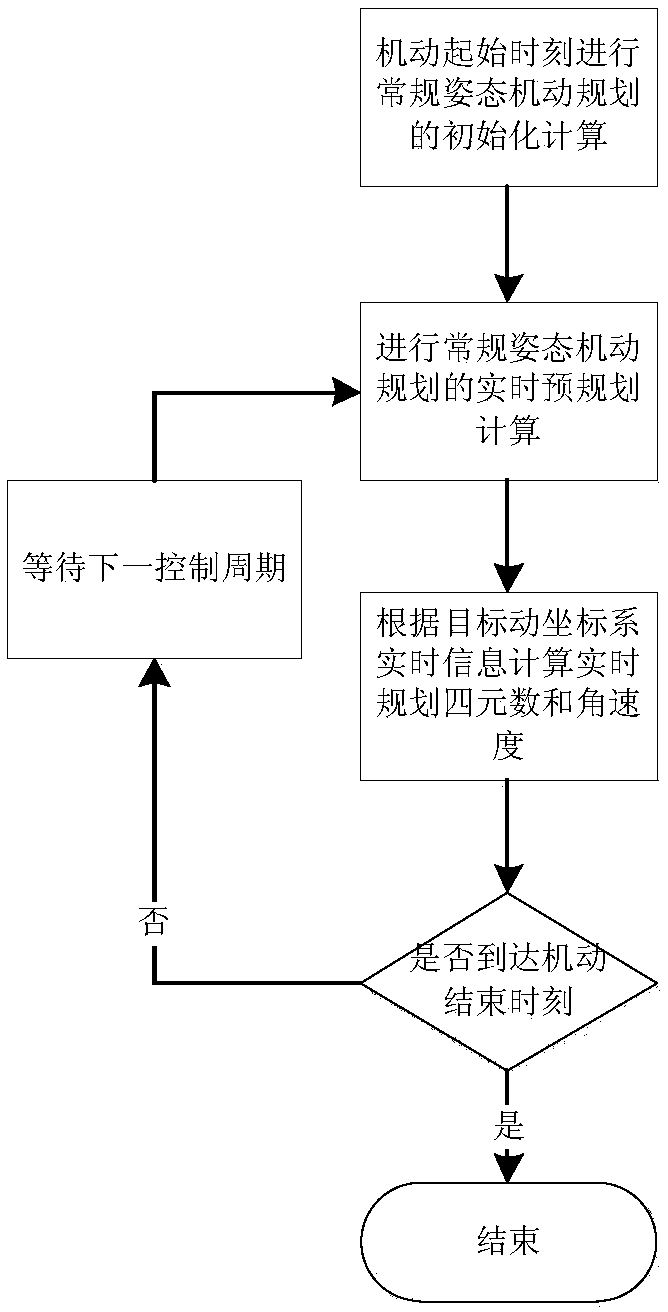

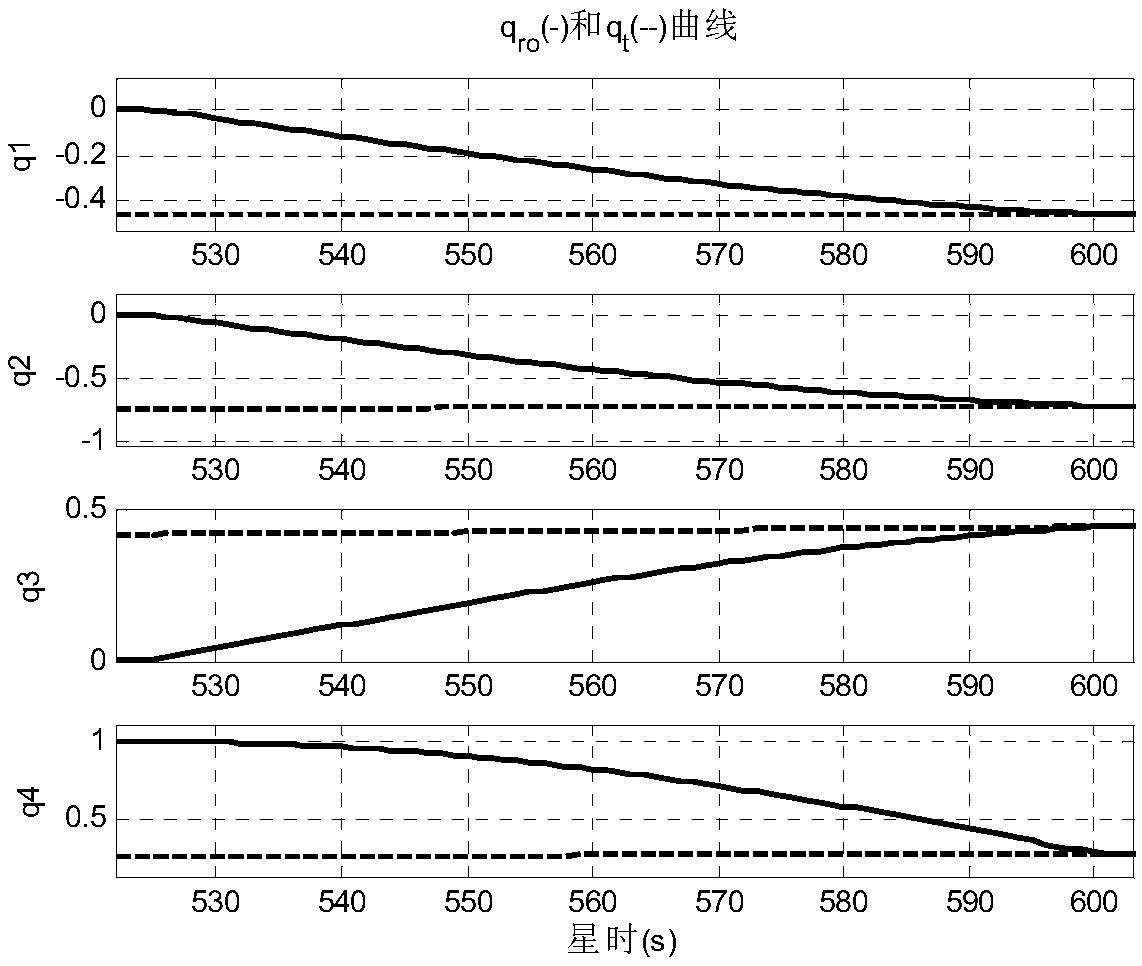

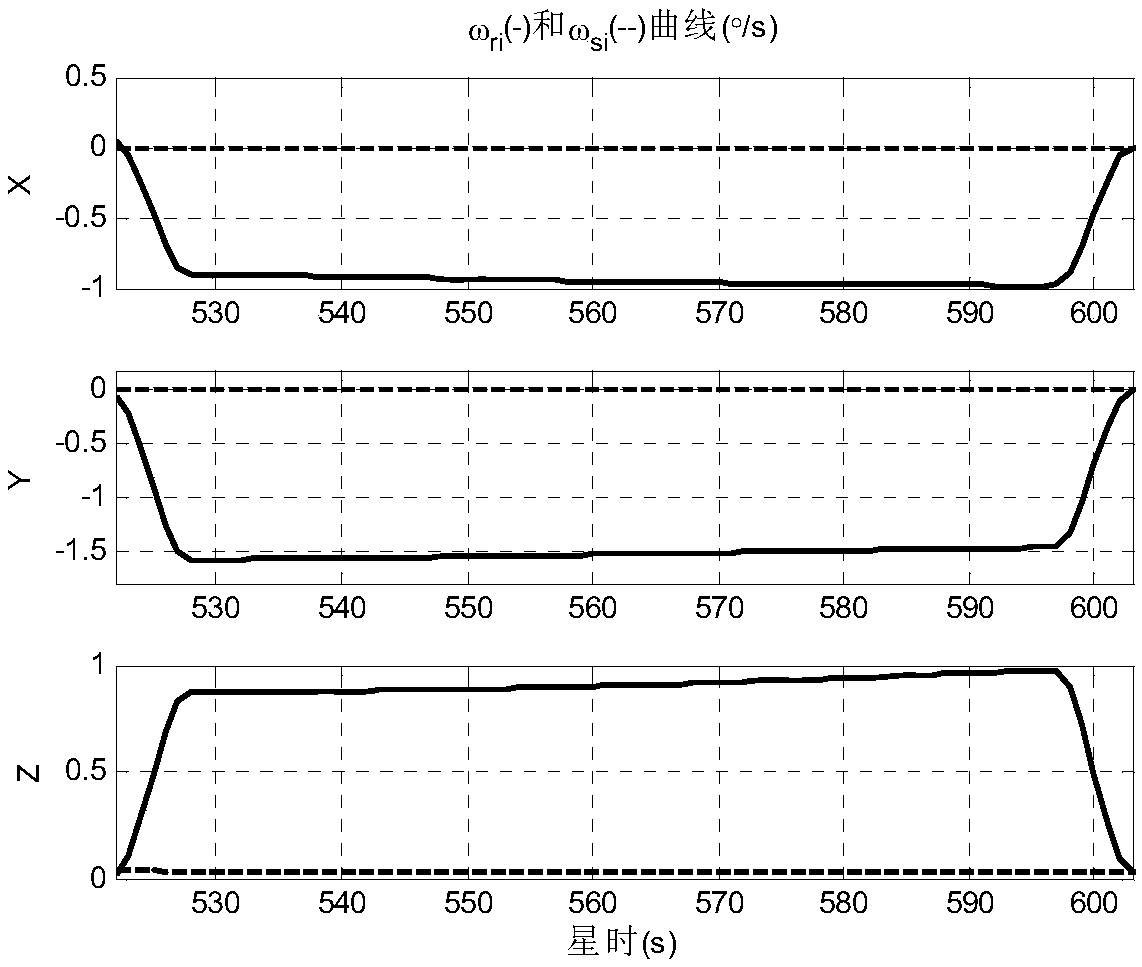

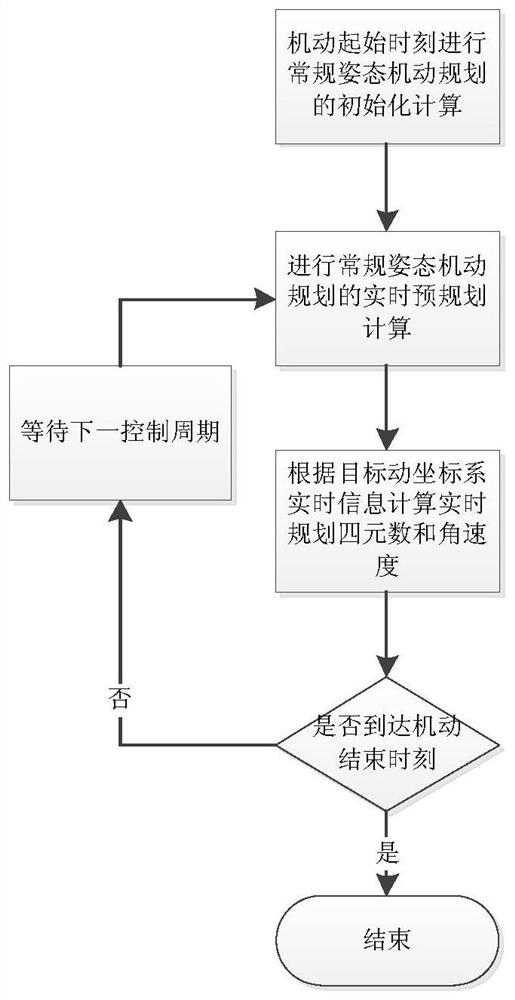

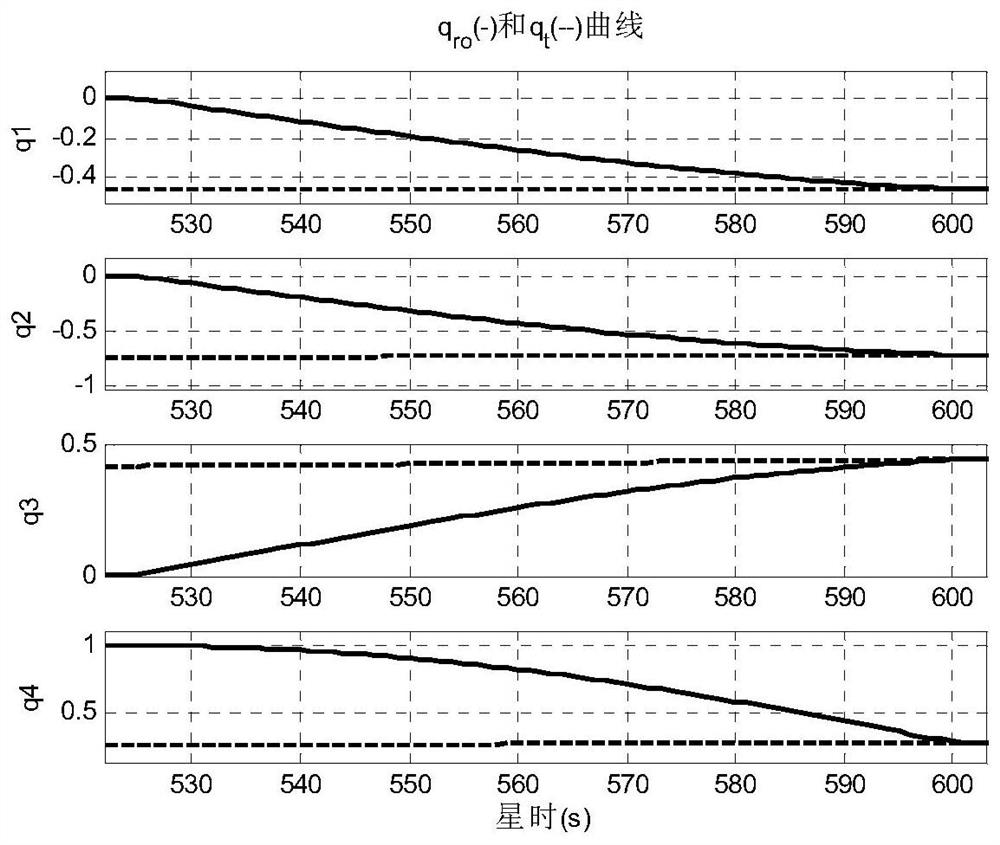

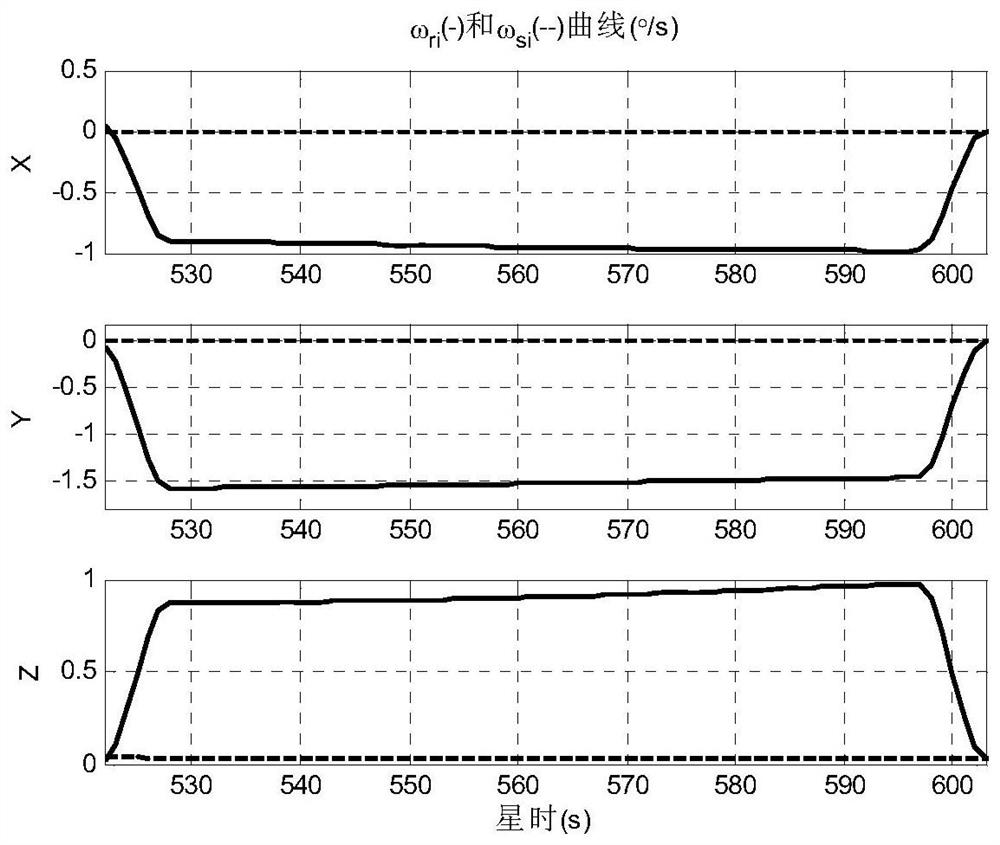

Real-time planning method of moving coordinate system maneuvering target by spacecraft

ActiveCN108319143AAvoid readjustmentAddress constant motionAdaptive controlQuaternionSatellite orbit

A real-time planning method of a moving coordinate system maneuvering target by a spacecraft comprises the steps of: performing conventional attitude maneuvering planning initialization calculation, and obtaining an initial quaternion and a maneuvering planning parameter of a target moving coordinate system relative to a satellite orbit system; performing real-time planning pre-calculation of theconventional attitude maneuvering planning according to the maneuvering planning parameter information in each control cycle, and obtaining a pre-calculation result; and finally, calculating an attitude quaternion of real-time planning relative to an inertial system and an angular speed of real-time planning relative to the inertial system according to a real-time direction cosine matrix of the target moving coordinate system relative to an orbit system and the angular speed of the target moving coordinate system relative to the inertial system in each control cycle in the maneuvering process,and completing the moving coordinate system maneuvering target real-time planning by the spacecraft.

Owner:BEIJING INST OF CONTROL ENG

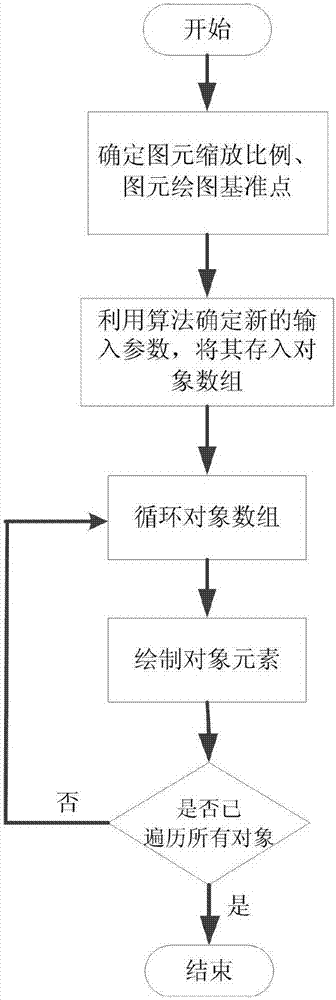

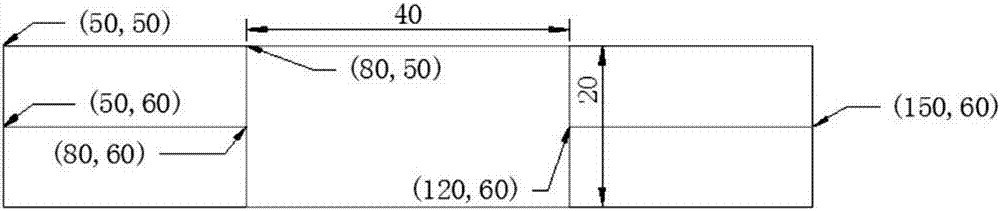

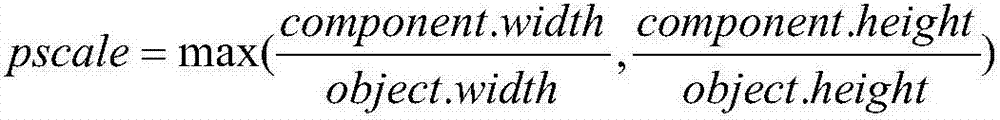

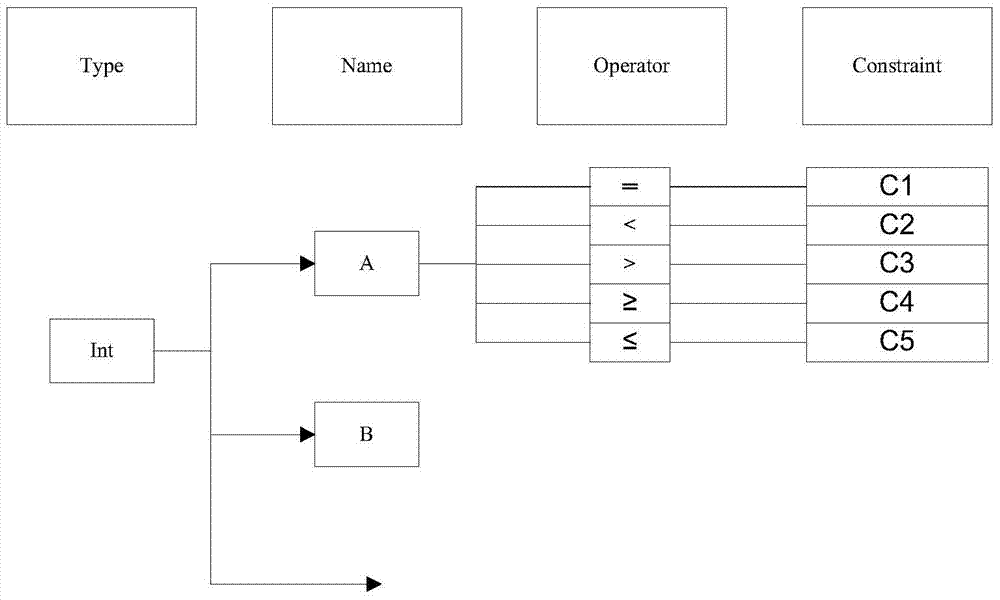

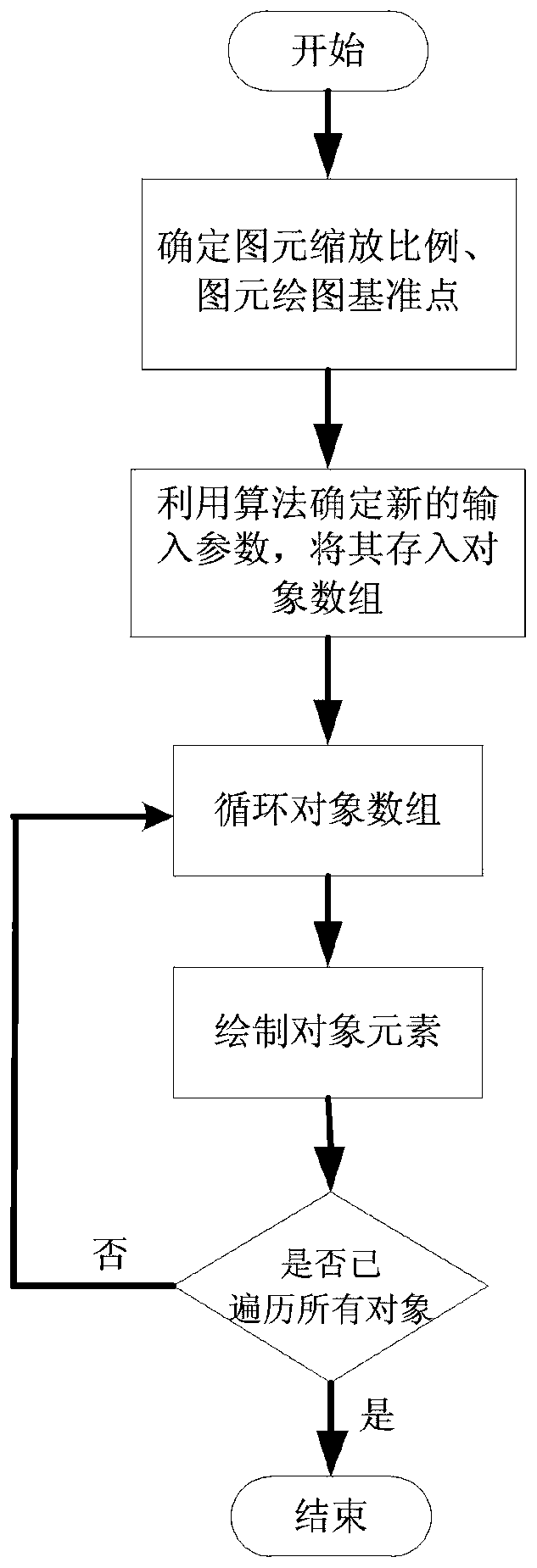

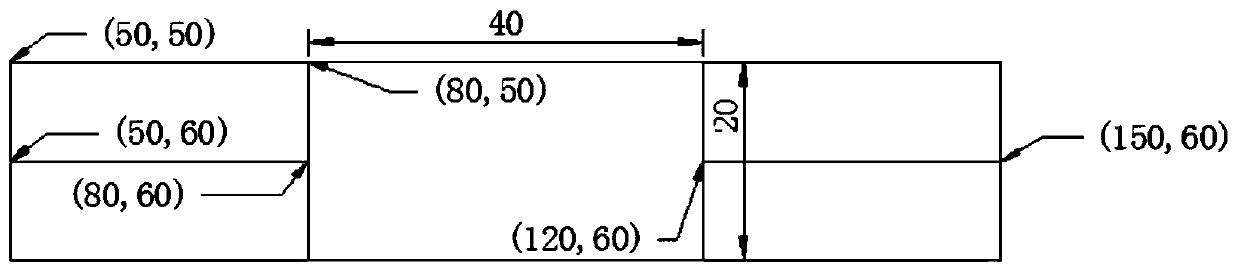

Drawing method for power distribution wiring diagram of energy utilization information collection system

ActiveCN107450906AAvoid error-prone modification of graphicsImprove loading speedDrawing from basic elementsSemi-structured data retrievalCollection systemArray data structure

The invention relates to a drawing method for a power distribution wiring diagram of an energy utilization information collection system. The method comprises the steps of 1, analyzing an XML document to obtain original data of each graphic primitive, recording graphic data of zooming or rotation operation, performing comparative calculation on the original data of the graphic primitives and the graphic data to obtain a zooming coefficient of the graphic primitives, and performing geometric calculation to obtain drawing center point coordinates of the graphic primitives; 2, based on a canvas API, if a graphic primitive rotation angle is 0, calculating absolute coordinates of the graphic primitives; if the graphic primitive rotation angle is not 0, calculating relative coordinates of the graphic primitives; storing new graphic primitive input parameters obtained by calculation in an object array; and 3, traversing the object array, and drawing graphic primitive object elements one by one. According to the method, the defects of high error probability of graph modification, low page loading speed and the like of an existing drawing method are overcome; the page loading speed is increased; and convenience is brought for system maintenance personnel to draw and modify the graph.

Owner:INTEGRATED ELECTRONICS SYST LAB

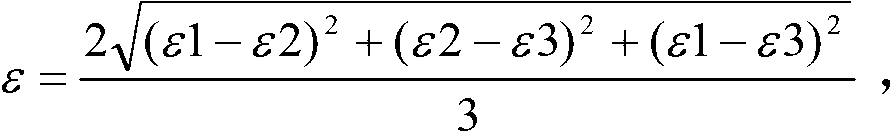

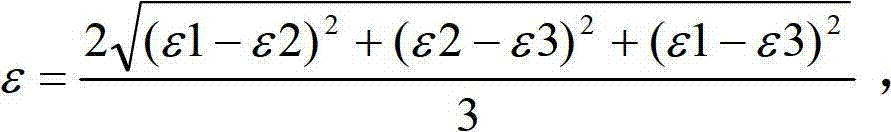

Production process for PSL-2 grade non-tempered N80 steel grade oil casing pipes

InactiveCN102703838AAvoid bendingAvoid deformationTemperature control deviceMetal rolling arrangementsMetallurgyRoom temperature

The invention relates to a production process for PSL-2 grade non-tempered N80 steel grade oil casing pipes, comprising the following processing steps: step (1) of heating pipe blanks in an annular furnace at 1200-1280 degrees centigrade for 3-3.5 h; step (2) of punching the heated pipe blanks with a puncher, and rolling to obtain coarse pipes with required specification, wherein temperature of coarse pipes is not less than 1150 degrees centigrade; step (3) of rolling coarse pipes obtained by punching on a retained mandrel pipe mill until required specification is obtained, wherein final rolling temperature for continuous rolling is not less than 1000 degrees centigrade; and putting rolled coarse pipes on an extracting mill to separate pierced pipes from core rods; step (4) of processing pierced pipes obtained by rolling and detaching with a sizing mill to obtain required outside diameter, wherein inlet temperature of the sizing mill is not less than 880 degrees centigrade, temperature of pierced pipes after sizing is not less than 820 degrees centigrade, and an equivalent dependent variable in a sizing process is not less than 0.4; step (5) of cooling sized pierced pipes in air at 820-800 degrees centigrade for 10-15 s, then atomizing and cooling at 650-800 degrees centigrade, and cooling to room temperature in the air at the last. The process provided by the invention meets demand of API standard PSL-2 grade on impact properties, and prevents pipes bending, deforming and cracking in a re-tempering process.

Owner:WUXI SEAMLESS OIL PIPE

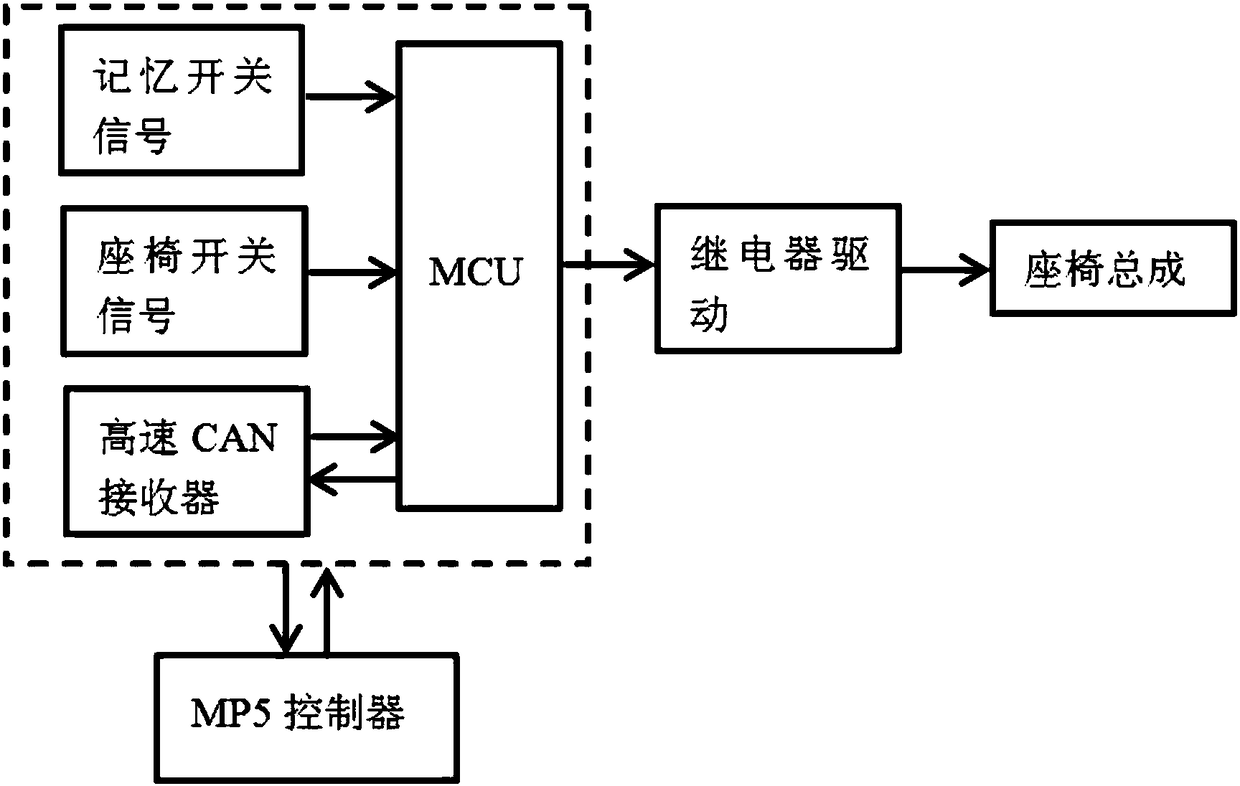

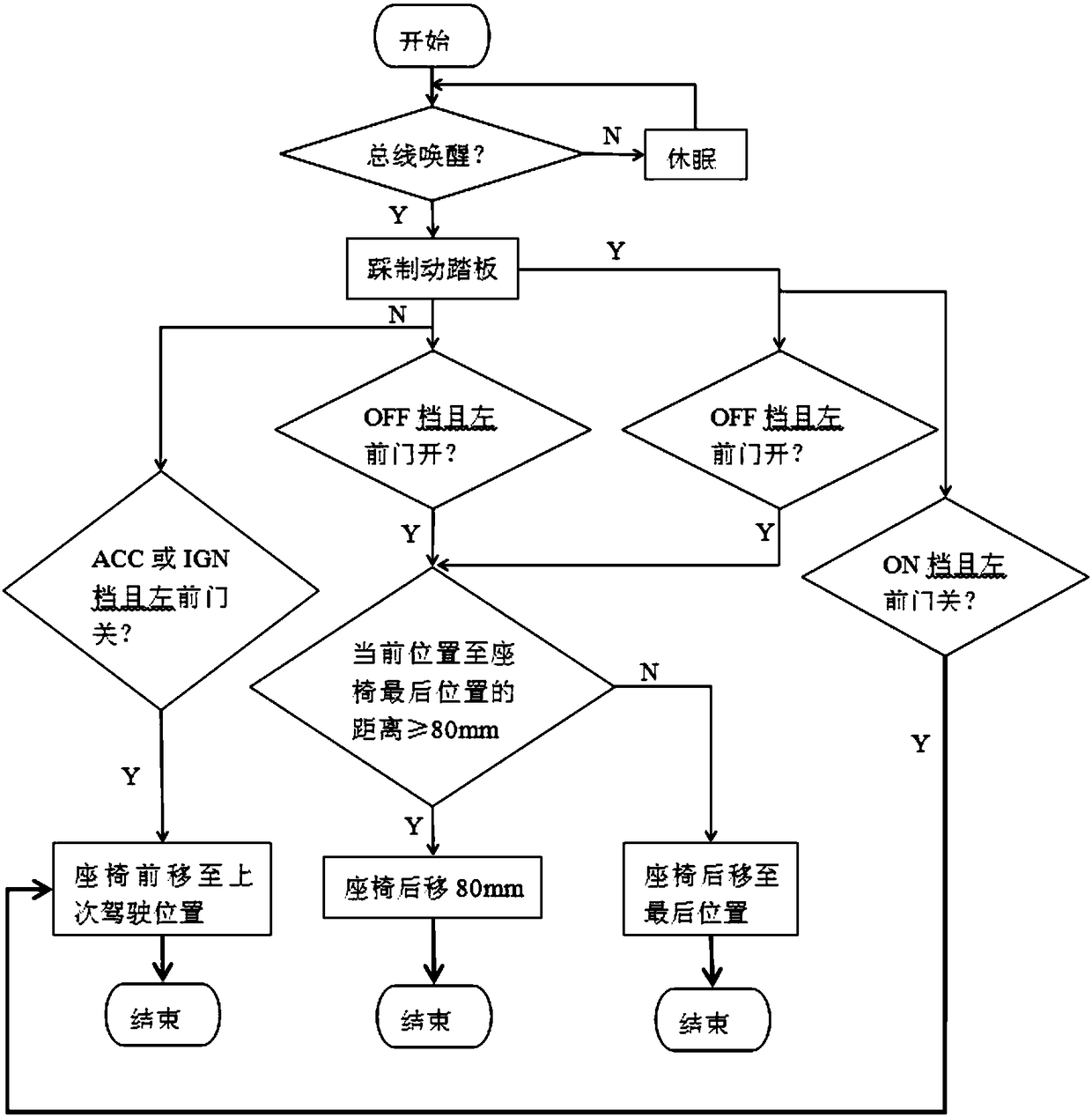

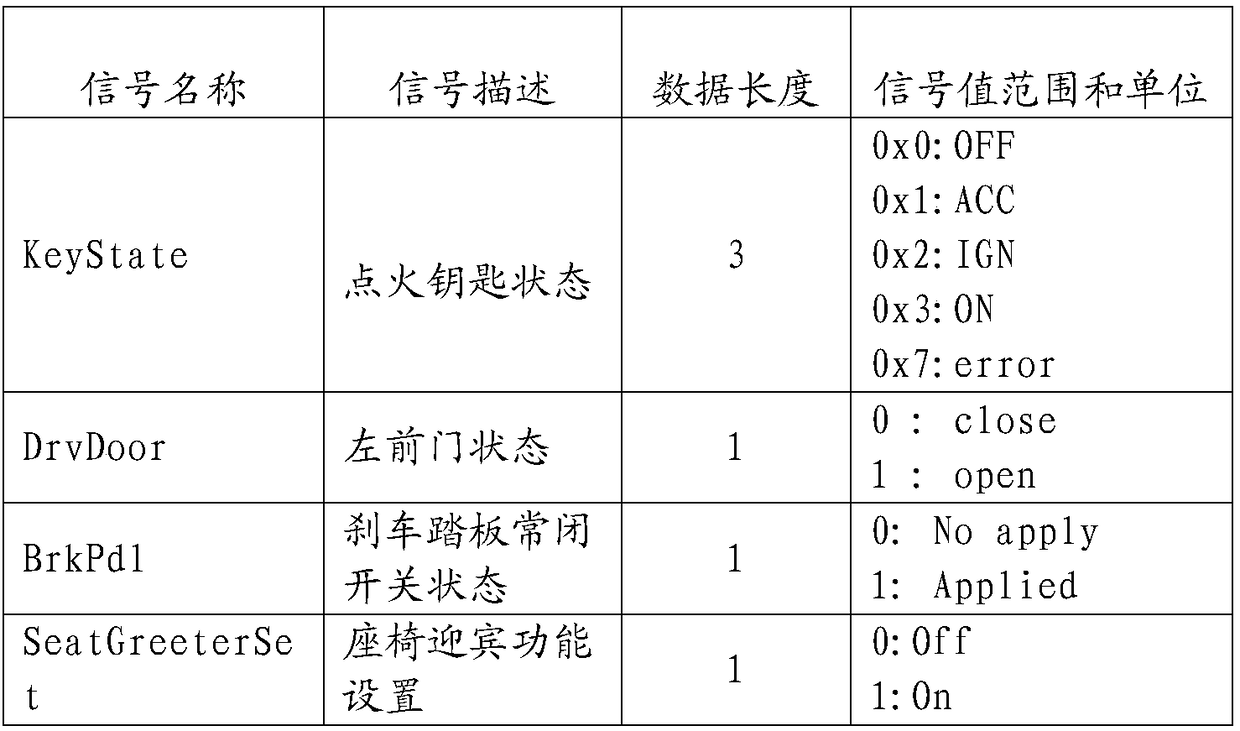

Seat with comity function and control method thereof

InactiveCN108544989AAvoid readjustmentCourtesy function realizedMovable seatsElectric/fluid circuitEmbedded systemControl system

The invention discloses a seat with a comity function. The seat with the comity function comprises a seat assembly; a seat control system is also arranged for the seat with the comity function; the seat control system comprises a micro control unit, a seat memory switch, a seat adjusting switch and a bus receiver; and the micro control unit is used for controlling the position adjustment of the seat assembly according to digital information obtained by the bus receiver, a seat position signal transmitted by the seat memory switch and a seat adjusting signal transmitted by the seat adjusting switch. The invention further discloses a seat comity function control method. The seat comity function control method comprises the steps of judging whether a bus is awakened or not; judging whether abrake pedal is stepped or not, judging the gear of an ignition key and judging whether an opening and closing state of a left front door; and judging whether to execute the comity function or not according to whether the brake pedal is stepped or not, the opening and closing state of the left front door and the gear of the ignition key. According to the seat with the comity function, the get-on and get-off intentions of drivers can be sufficiently identified to accurately execute the comity function; and the seat does not execute the comity function when an engine is started under remote control.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

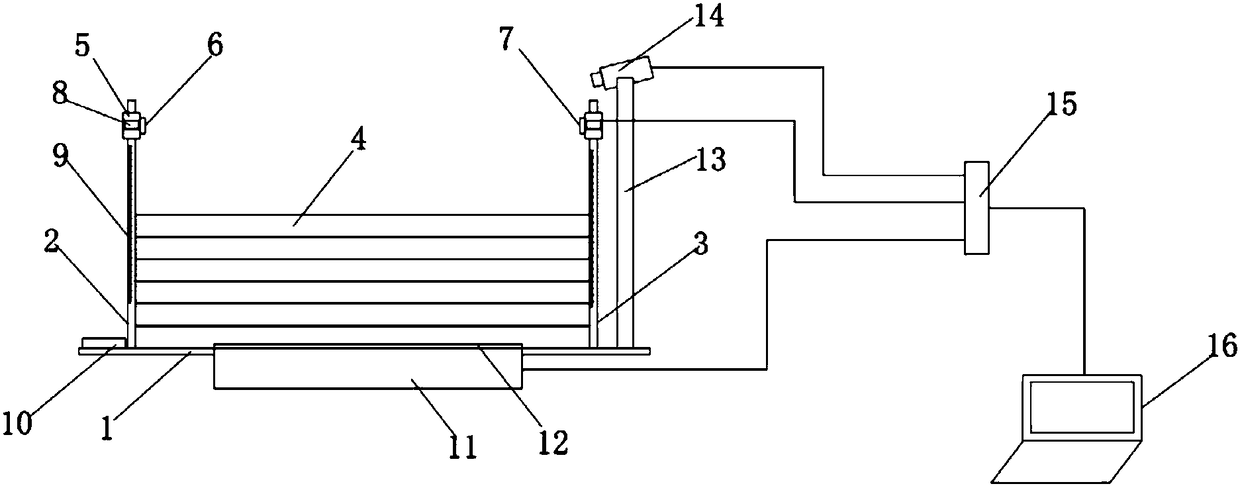

High jump trainer for sports teaching

InactiveCN108211194AControl and trainingImprove technologyJumping apparatusEngineeringElectronic equipment

The invention discloses a high jump trainer for sports teaching. The trainer mainly comprises a trainer body, the trainer body mainly comprises a supporting base plate, and the supporting base plate is of a horizontally placed flat plate structure; a left marking rod and a right marking rod which are vertically arranged on the left and right sides are welded to the supporting base plate and both sleeved with a sliding sleeve, each sliding sleeve is of a round tubular structure, anti-slip rubber strips are bonded to the inner walls of the sliding sleeves and tightly abut against the outer wallof the left marking rod or the outer wall of the right marking rod, and an infrared radiation alarm is arranged between the sliding sleeves. An electronic device is used for simulating the traditionalhigh jump sport, and meanwhile the motion force of a trainee is collected. No real rods are adopted in the overall design so that the damage caused by hitting rods during training cannot occur, and the safety is higher.

Owner:YANGTZE UNIVERSITY

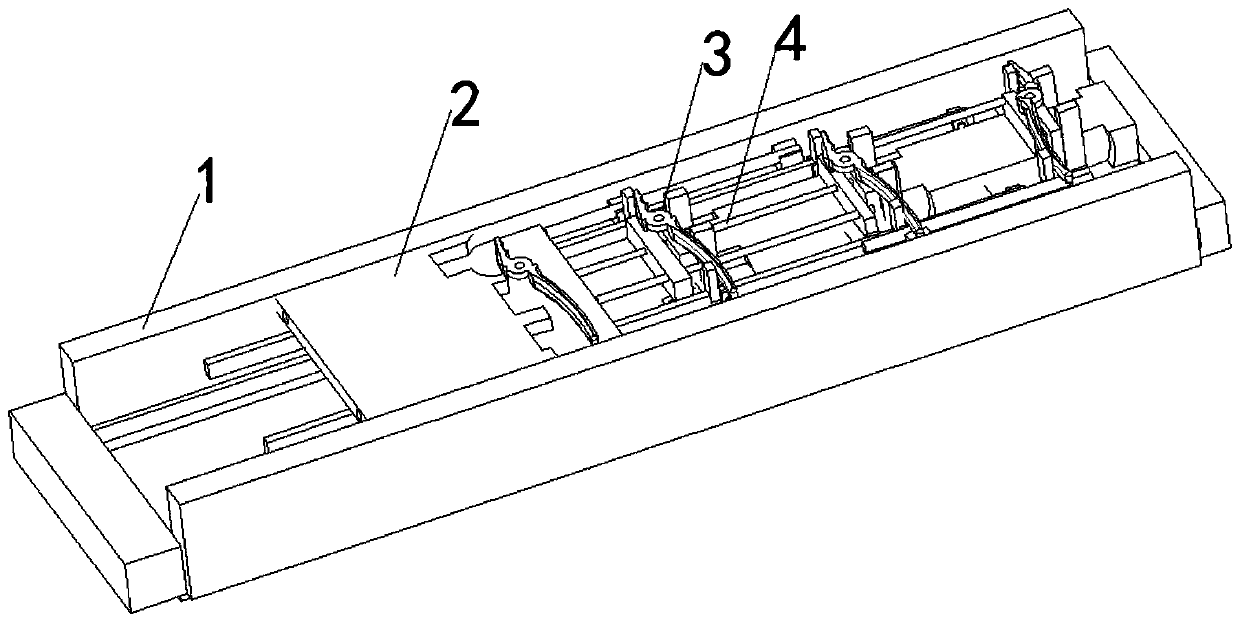

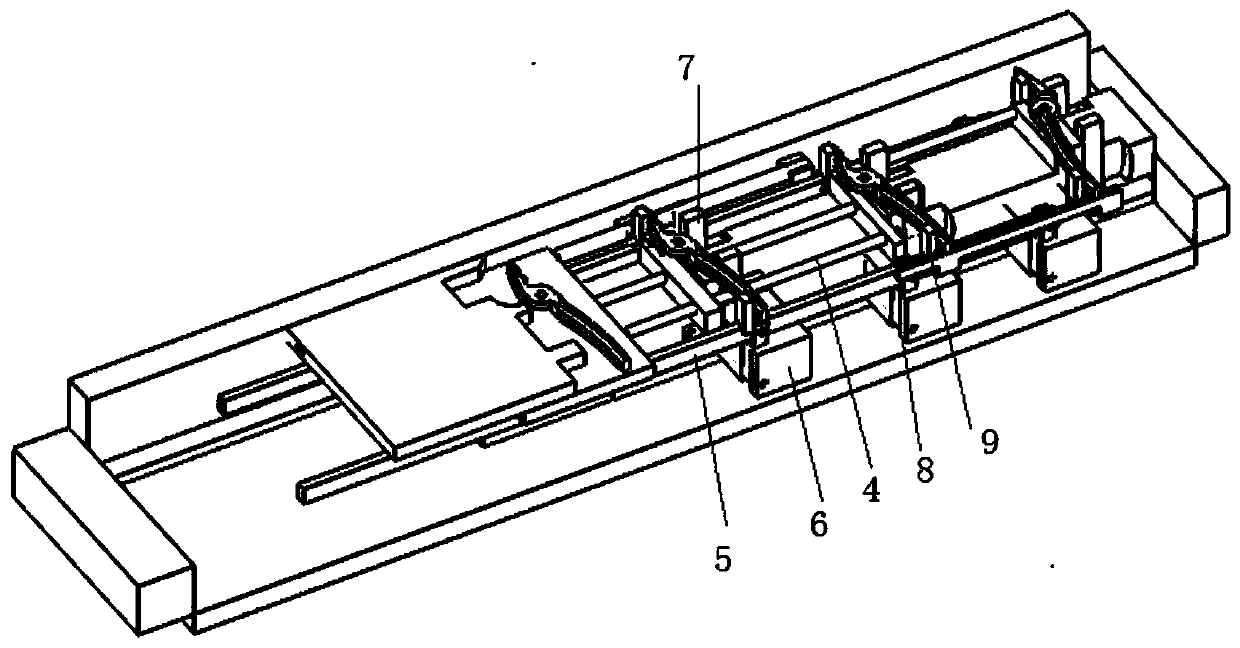

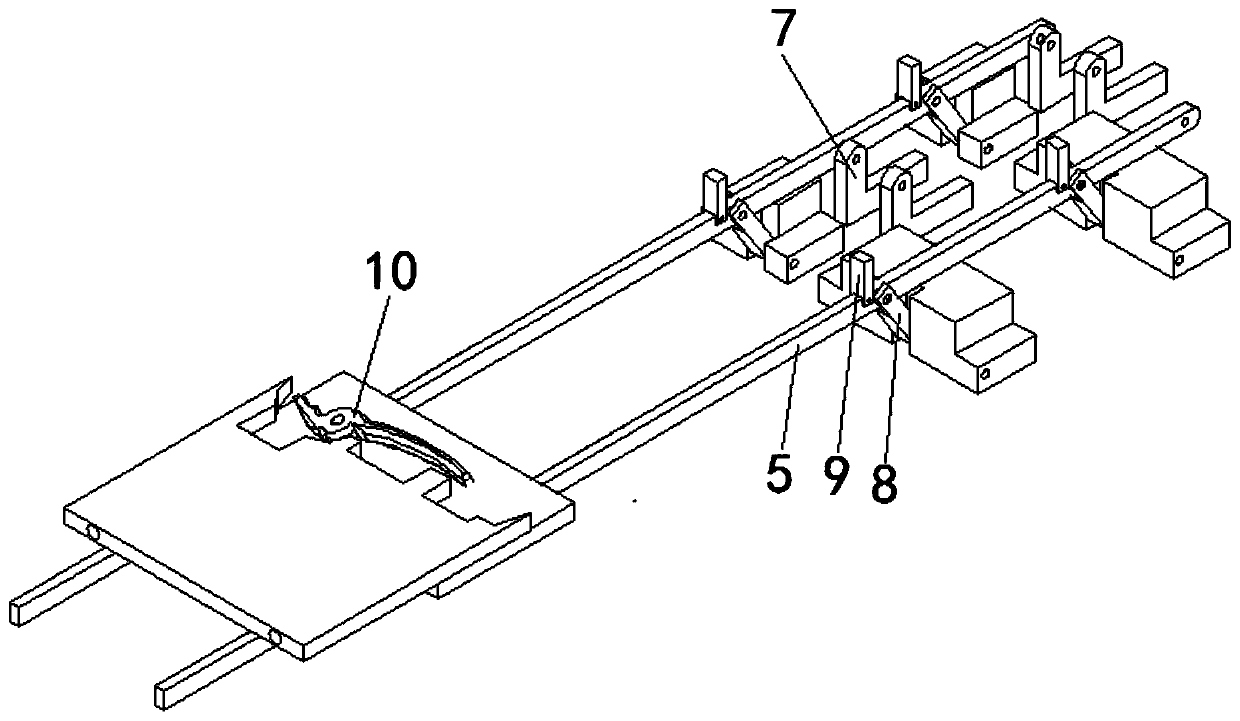

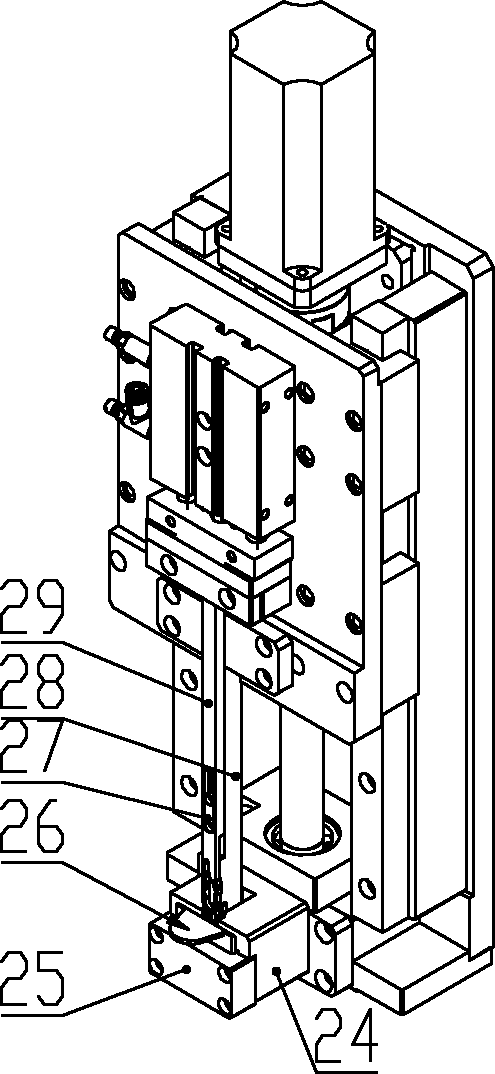

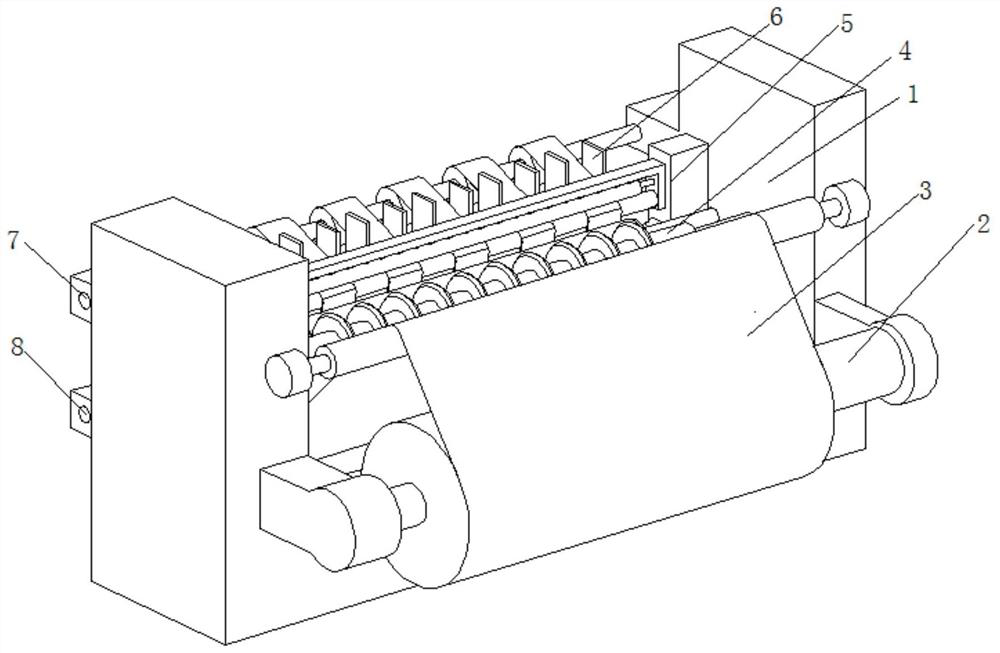

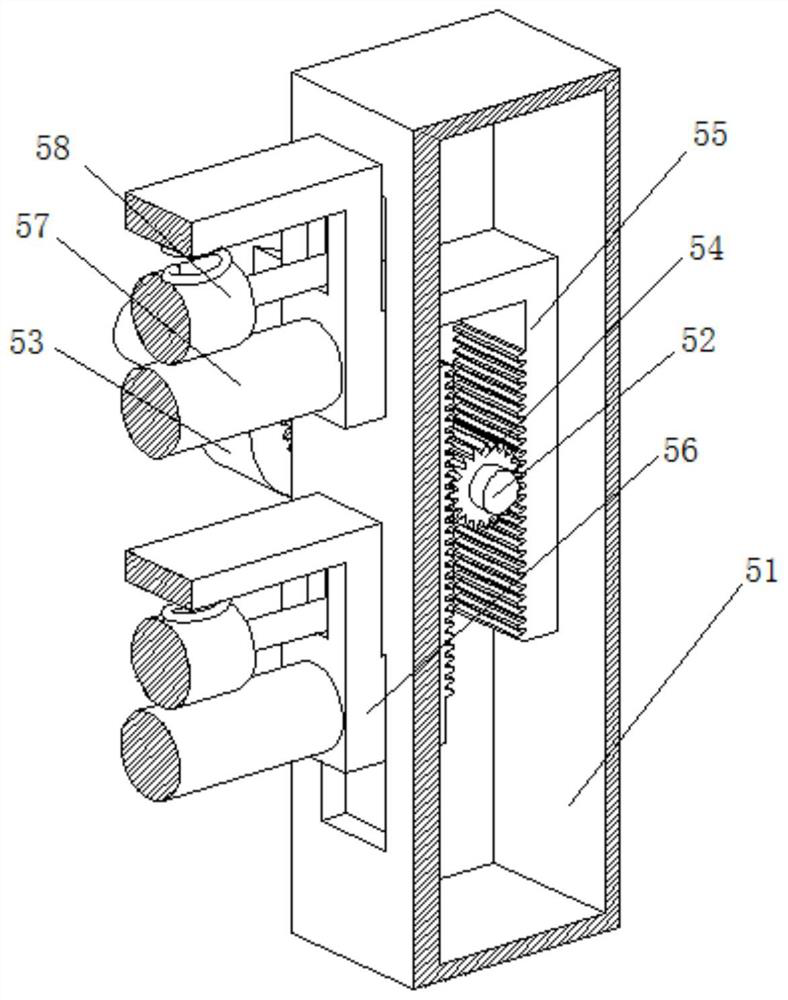

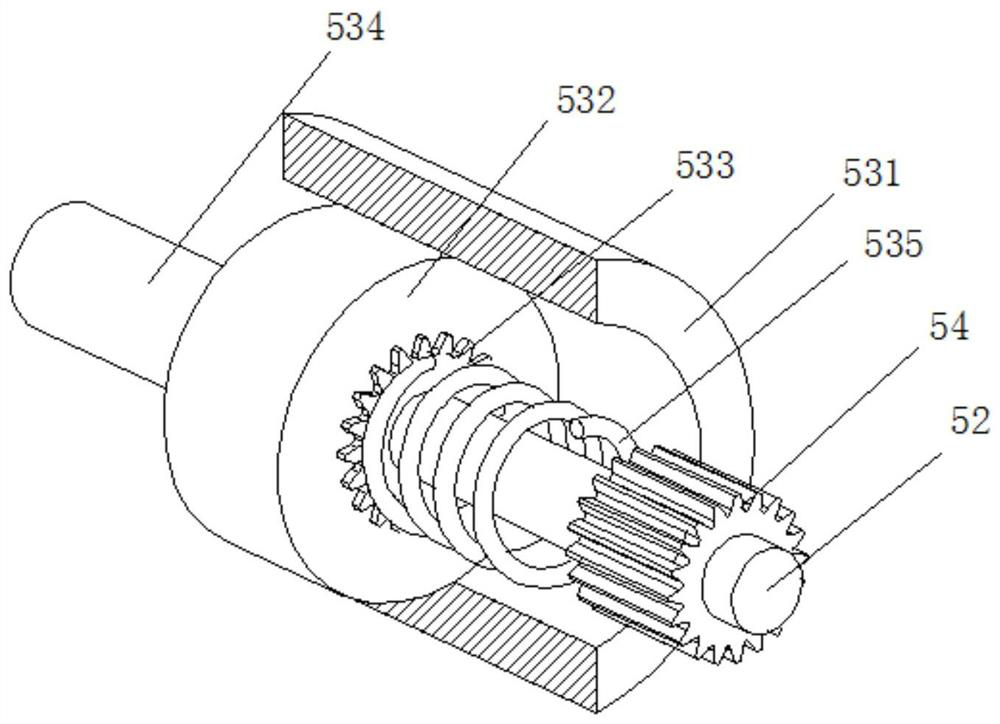

Adaptive adjustment machining platform for clamp body machining

PendingCN109968095AFacilitate subsequent processingSimple structureMetal working apparatusHardware toolEngineering

The invention belongs to the technical field of hardware tool manufacturing, and particularly relates to an adaptive adjustment machining platform for clamp body machining. The adaptive adjustment machining platform comprises a shell, transporting tracks are arranged on the inner walls of the pair of parallel edges of the shell and provided with machining stations, the ends of the transporting tracks are connected with falling devices, sliding blocks are slidably arranged on the inner walls of the other pair of parallel edges of the shell, the sliding blocks are connected with pushing rods through sliding block limiting devices, the pushing rods conduct reciprocating lifting movement along the sliding block limiting devices, clamp body limiting devices are arranged on the upper parts of the pushing rods, the sliding blocks are movably connected with positioning devices, the positioning devices conduct reciprocating lifting movement along with movement of the sliding blocks, the pushingrods are arranged on the lower parts of the transporting tracks, and the pushing rods are connected with reciprocating driving mechanisms. According to the adaptive adjustment machining platform, through mechanical linkage between the devices, falling, feeding and positioning are integrated, the structure is simple, the cost is low, the function is complete, and the adaptive adjustment machiningplatform is easily applied and promoted.

Owner:湖南精专自动化技术有限公司

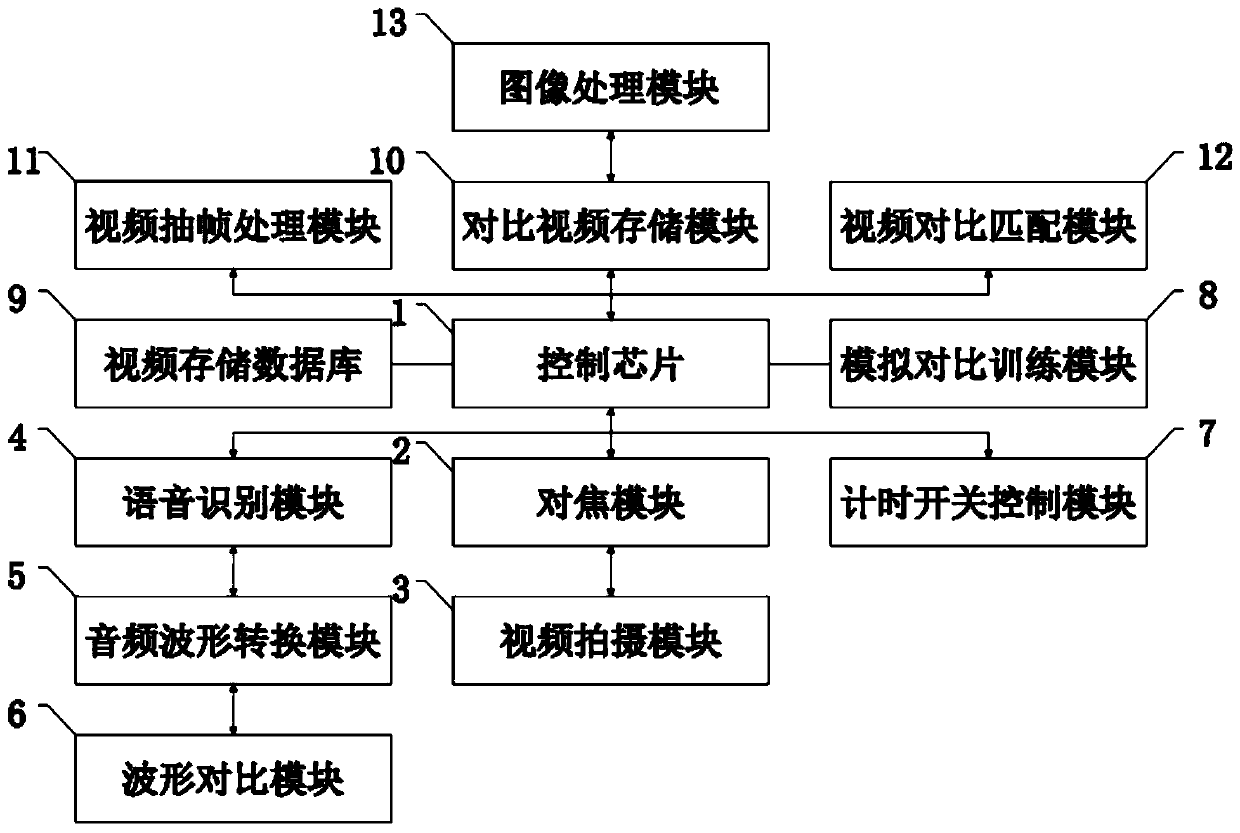

Automatic shooting system with auxiliary shooting function

InactiveCN111193864AHigh precisionReduce occupancyTelevision system detailsColor television detailsComputer hardwareSpeech sound

The invention belongs to the technical field of automatic shooting control, and specifically relates to an automatic shooting system with the auxiliary shooting function. The system comprises a control chip. The control chip is in electric bidirectional connection with a focusing module. The focusing module is electrically and bidirectionally connected with a video shooting module. The control chip is in electric bidirectional connection with a voice recognition module. The voice recognition module is in electric bidirectional connection with an audio waveform conversion module. The audio waveform conversion module is electrically and bidirectionally connected with a waveform comparison module. According to the invention, the beginning and the end of the live program are generally opened and ended in a fixed manner. When a matched statement or image is detected, the shooting function is started, so that the accuracy of the shot content is improved, the method is suitable for downloading and watching or online watching by a user outside, the problem that the shooting angle and position need to be readjusted after manual adjustment is avoided, and the system is fixed at a time and can be used for recording for a long time.

Owner:苏州狸猫旅游科技有限公司

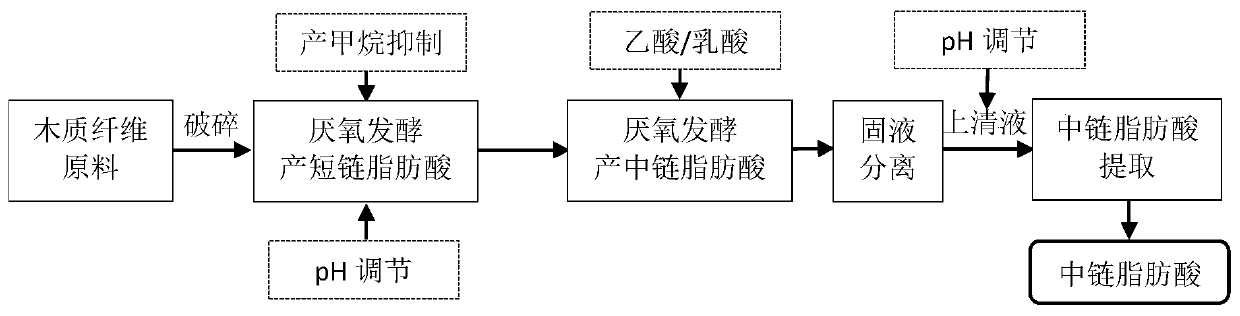

Method for producing medium-chain fatty acid through anaerobic fermentation of lignocellulosic material

The invention provides a method for producing a medium-chain fatty acid through anaerobic fermentation of a lignocellulosic material. The method for producing the medium-chain fatty acid through anaerobic fermentation of the lignocellulosic material comprises the following steps: (1) mixing the crushed lignocellulosic material and anaerobic digestion sludge according to a mass ratio ranging from 1:4 to 1:20, adjusting a pH value to be 9.0-11.0, adding a methanogenic inhibitor, and then conducting anaerobic fermentation to obtain first fermentation liquor containing a short-chain fatty acid; (2) continuing conducting anaerobic fermentation on the first fermentation liquor containing the short-chain fatty acid for 10-45 days at a fermentation temperature of 30-40 DEG C, and intermittently adding ethyl alcohol or lactic acid in the fermentation process to obtain second fermentation liquor containing the medium-chain fatty acid; and (3) conducting solid-liquid separation on the second fermentation liquor containing the medium-chain fatty acid to obtain supernate, adjusting a pH value of the supernate to be 3.0-6.0, and extracting the medium-chain fatty acid from the supernate. The method for producing the medium-chain fatty acid through anaerobic fermentation of the lignocellulosic material can not only consume the organic waste (lignocellulosic material), but also has a clean conversion process compared with a petrochemical-based technology, and thus is a clean green conversion technology.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

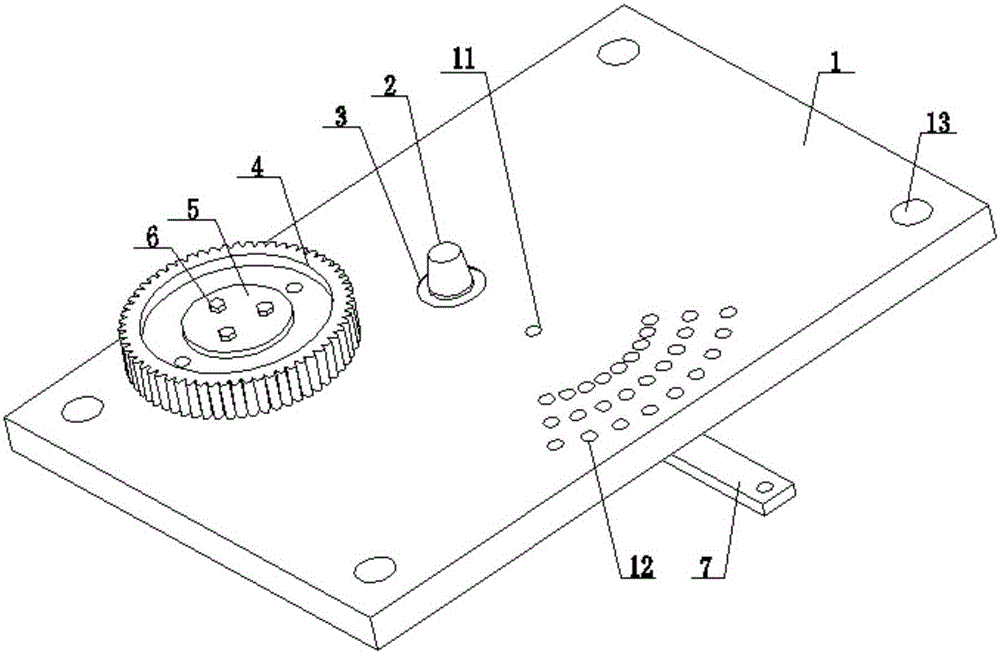

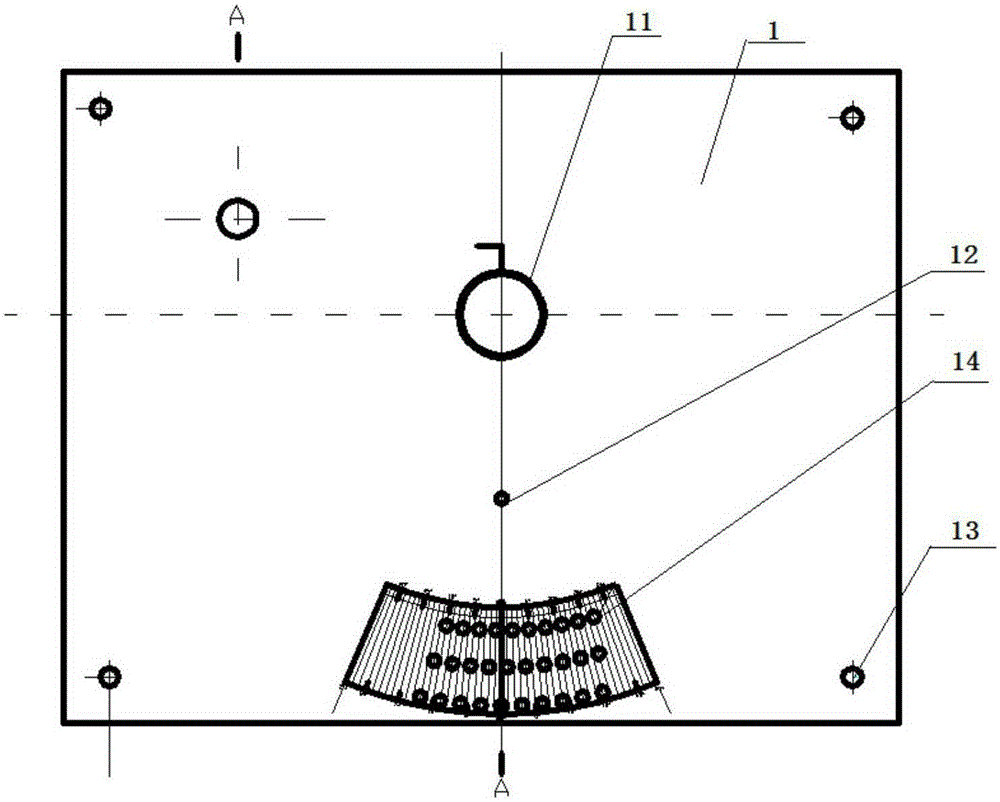

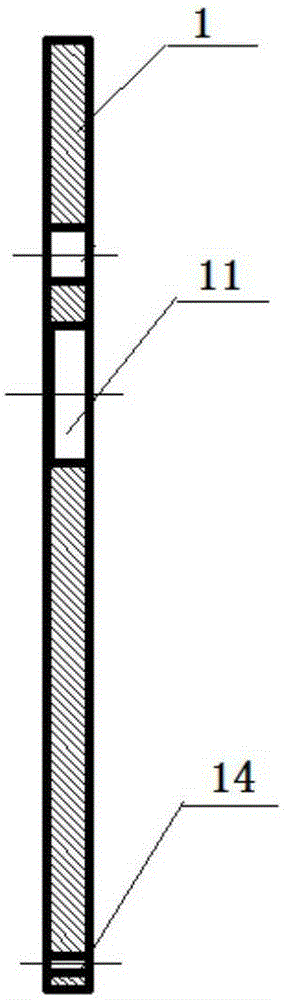

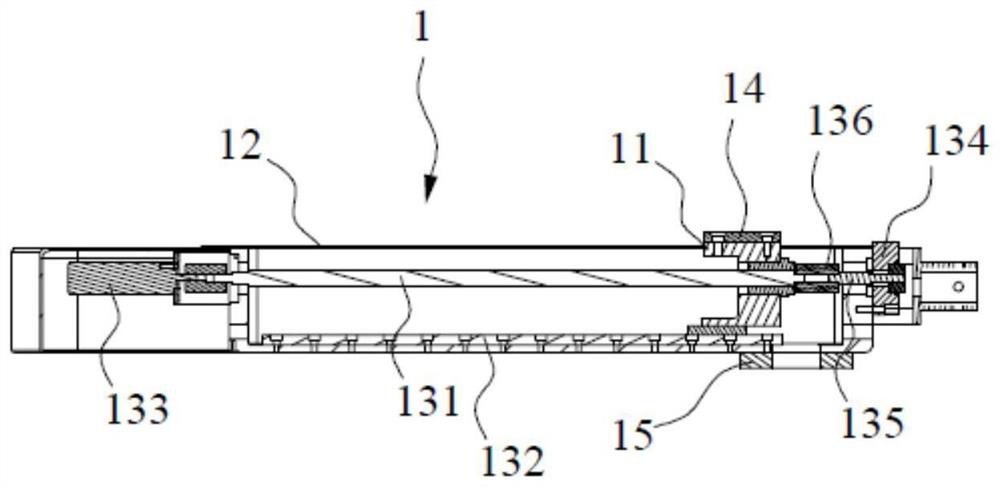

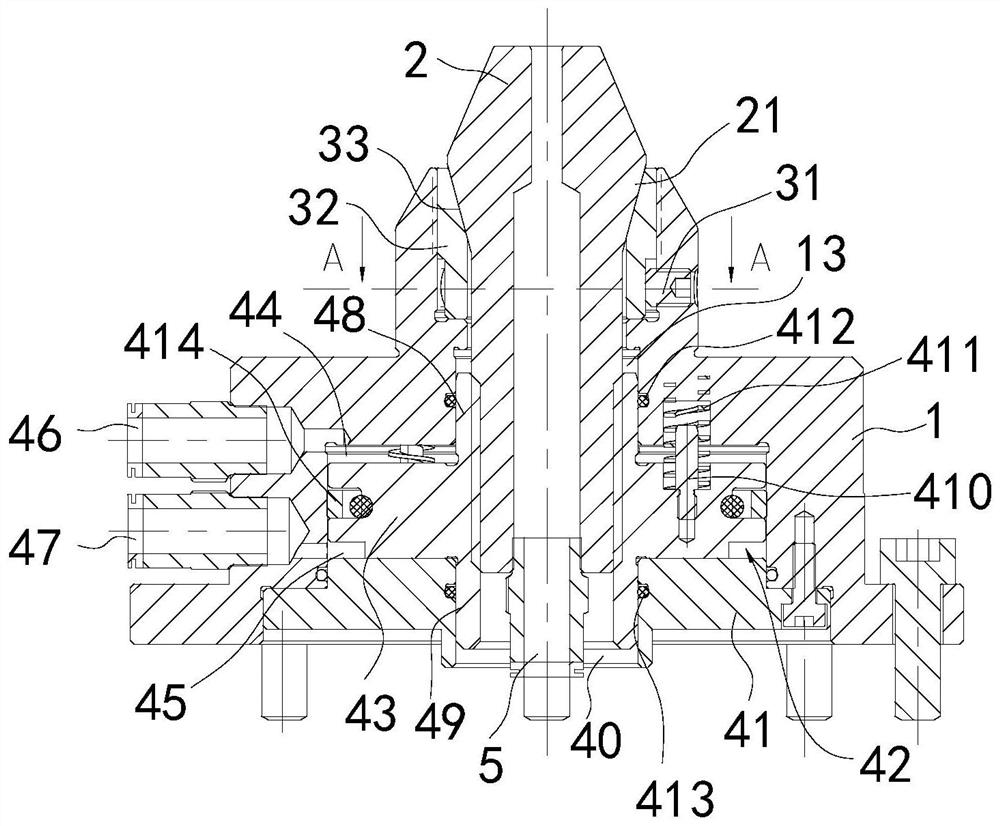

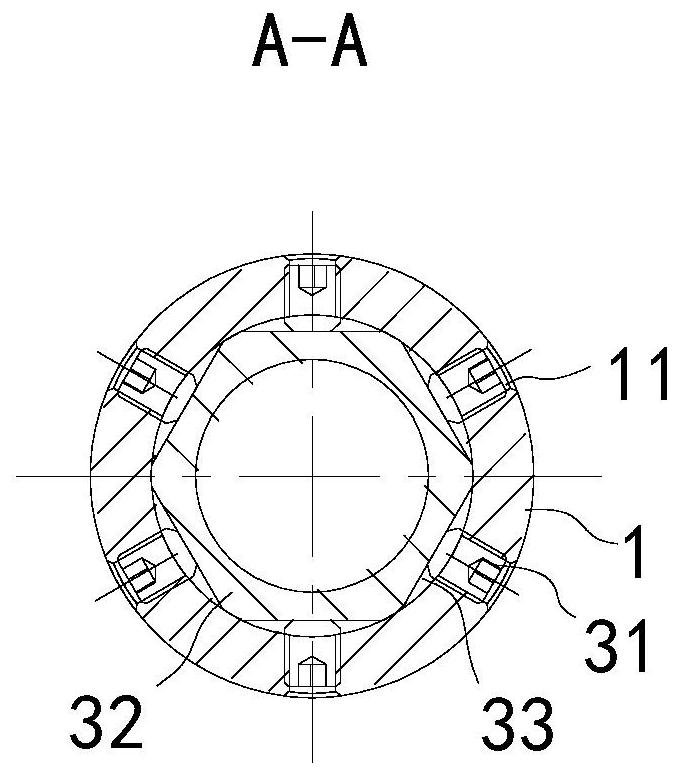

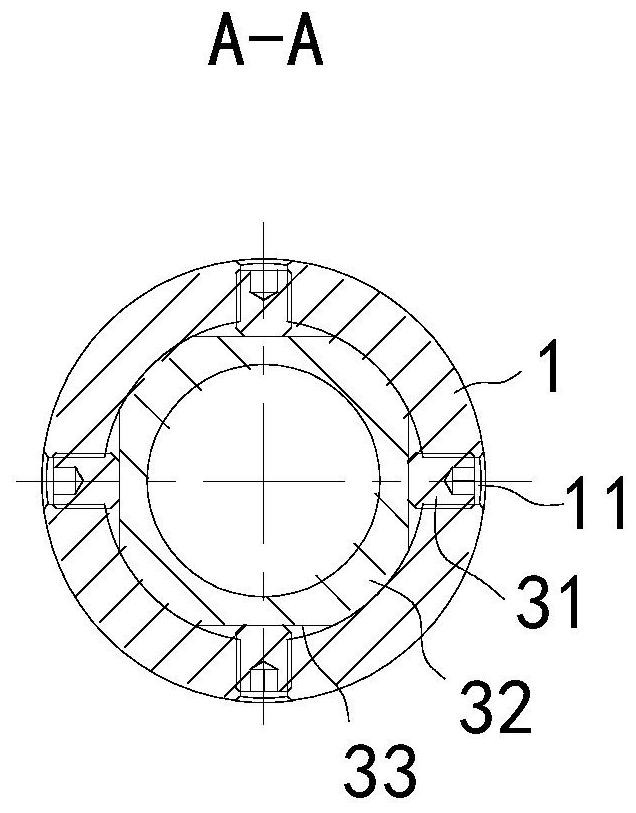

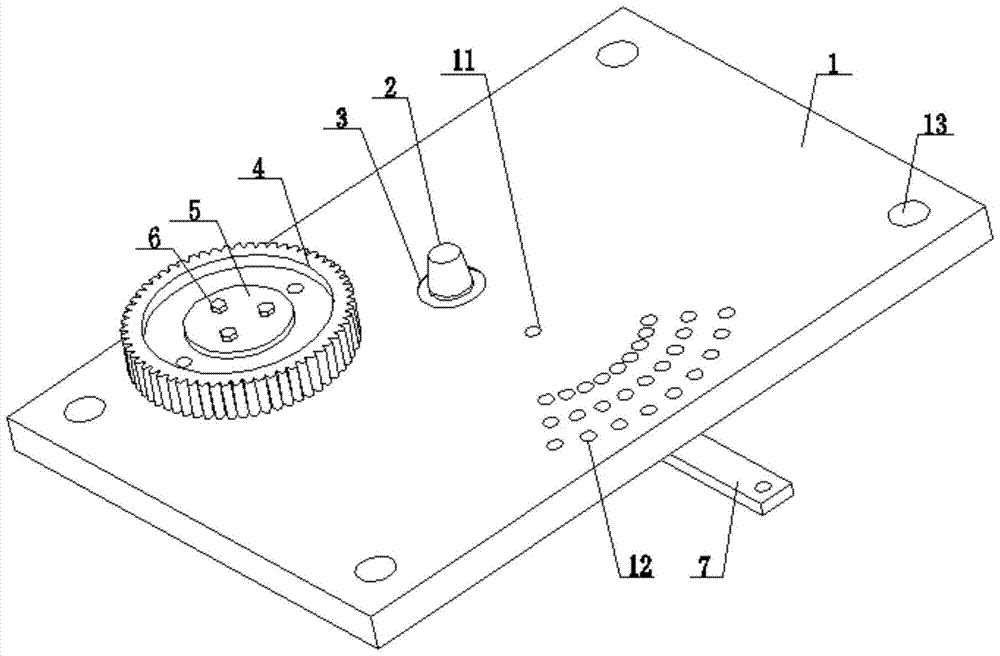

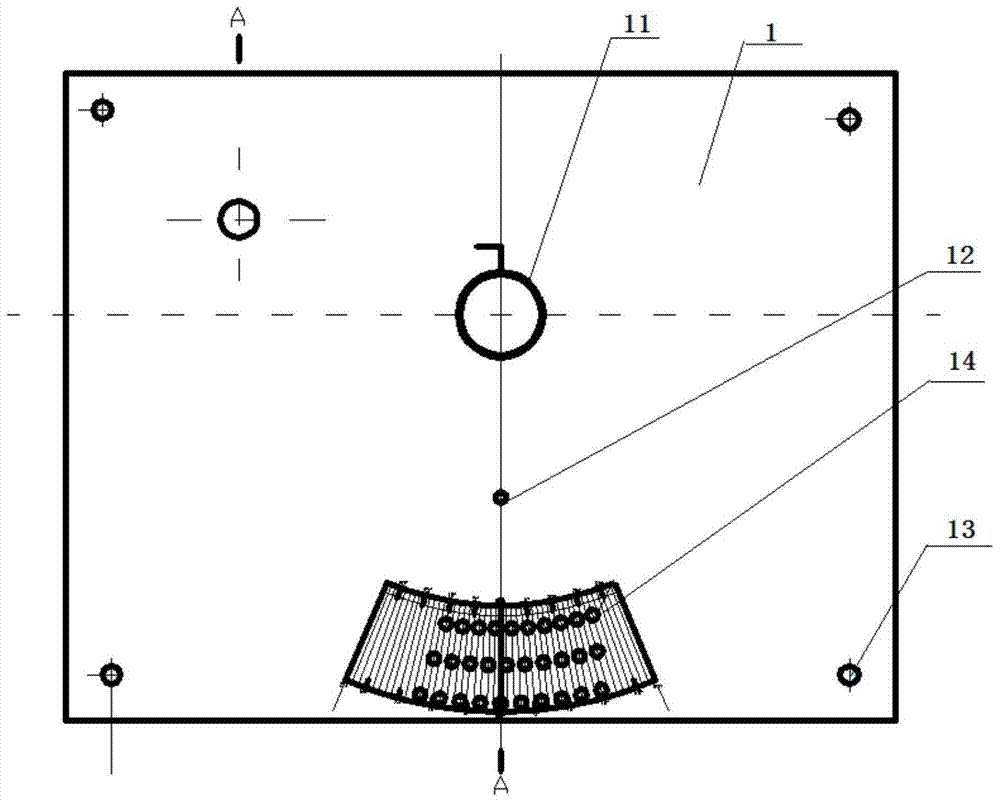

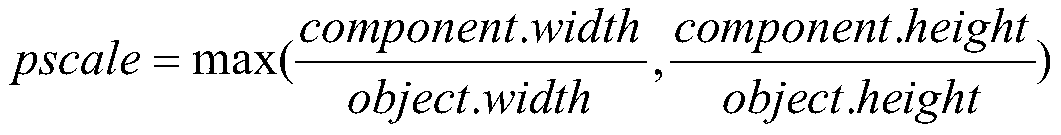

Fuel injection advance angle assembling tool of diesel engine fuel injector

ActiveCN105179133AAvoid readjustmentSolve low production efficiencyFuel injection apparatusMachines/enginesDiesel engineFuel injection

The invention discloses a fuel injection advance angle assembling tool of a diesel engine fuel injector. The fuel injection advance angle assembling tool of the diesel engine fuel injector comprises a base board on which an idle gear is fixed. The base board outside the idle gear is provided with a positioning shaft on which an oil pump gear connector is mounted. The positioning shaft is movably connected with the base board. The positioning shaft is provided with an adjusting handle. The base board at the periphery of the positioning shaft is provided with a reference hole. The base board at the periphery of the reference hole is provided with a plurality of angle positioning holes. The deflection angle of the positioning shaft is fixed through pins which are inserted between the angle positioning holes and the adjusting handle. According to the fuel injection advance angle assembling tool of the diesel engine fuel injector, a fuel injection pump advance angle can be preset according to a technological requirement for a diesel engine, and re-adjustment of the fuel injection pump advance angle in a thermal test is prevented. Not only is a problem of low production efficiency settled, but also consistency and reliability of a product are improved. Furthermore production cost is greatly reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

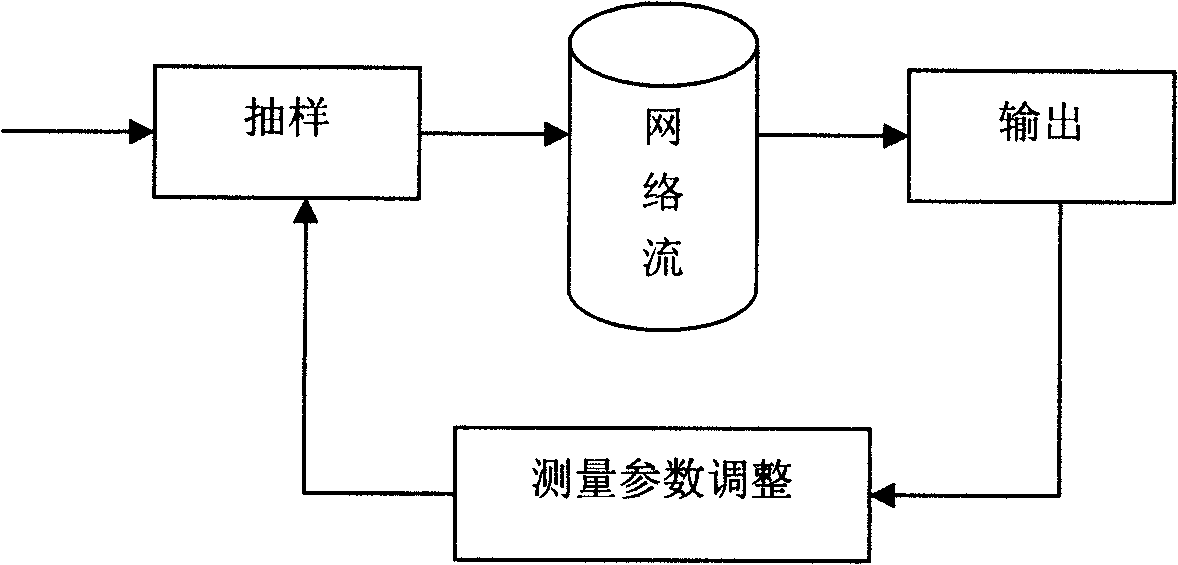

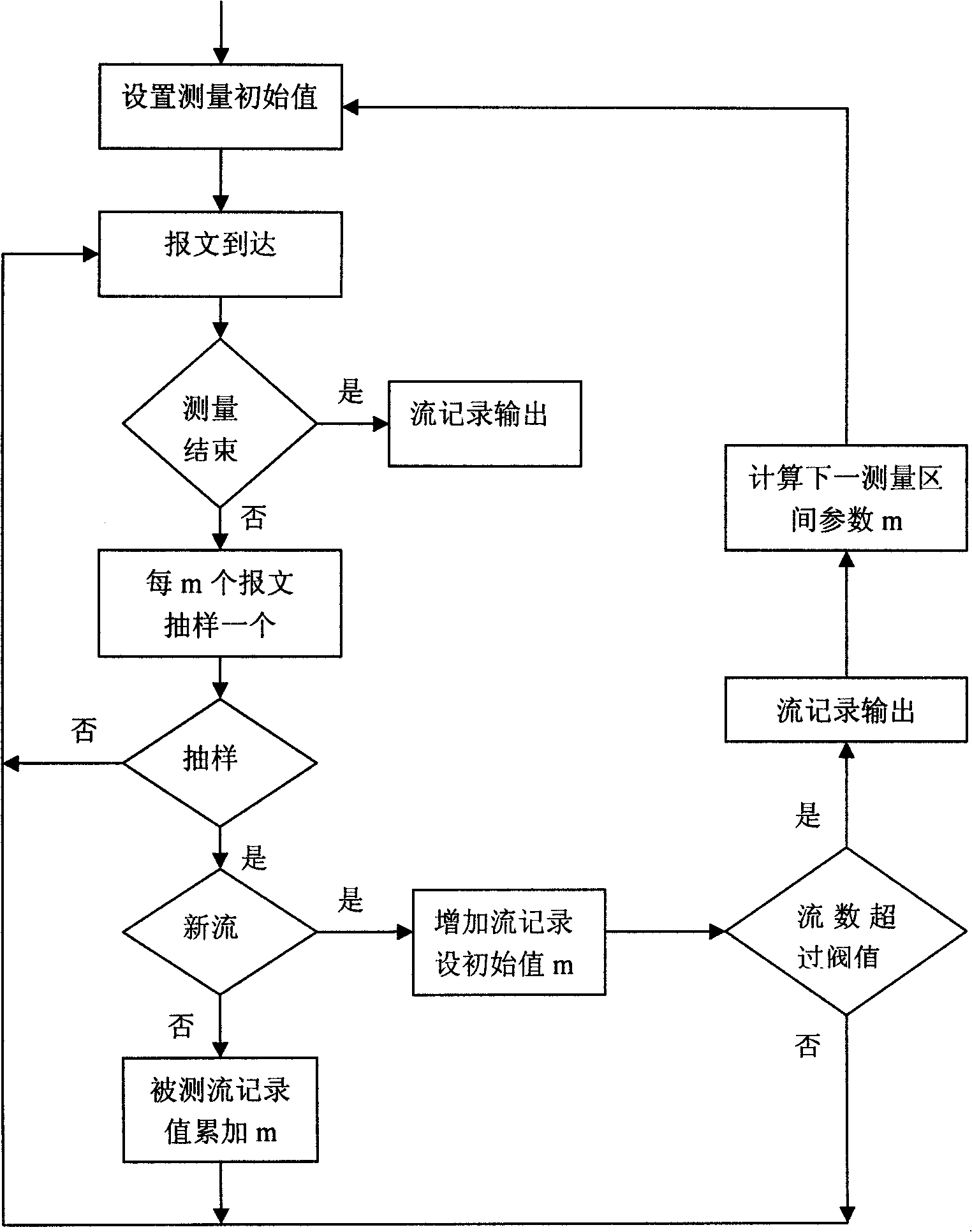

Network flow real time self-adapting measuring method based on fixed storage space

InactiveCN101257415AAvoid readjustmentReduce consumptionData switching networksSelf adaptiveSpace Network

Disclosed is a real time self-adapting measuring method based on the network flow in a permanent storage space, comprising: setting a duration of the interval to be measured, a network flow storage space and a sample measurement parameter; establishing a threshold for defining the storage space size of the network flow as a reference of measurement loop end in the measuring process, thus, if the fluxion of the storage space network flow exceeds the threshold, the present measurement interval is end, subsequently, outputting all the flow record information estimation value; calculating the sample measurement parameter of the next measurement interval according to the period of the present measurement interval, the duration of the interval to be measured and the present sample measurement parameter. The invention can save consumption of the measuring resources in the self-adapting process and maintain the accuracy of the network flow information; intercomparsion and calculation can be achieved directly in different measurement intervals by the measuring results of different sample parameters.

Owner:HAIAN CHANGDA TECH TRANSFER CENT +1

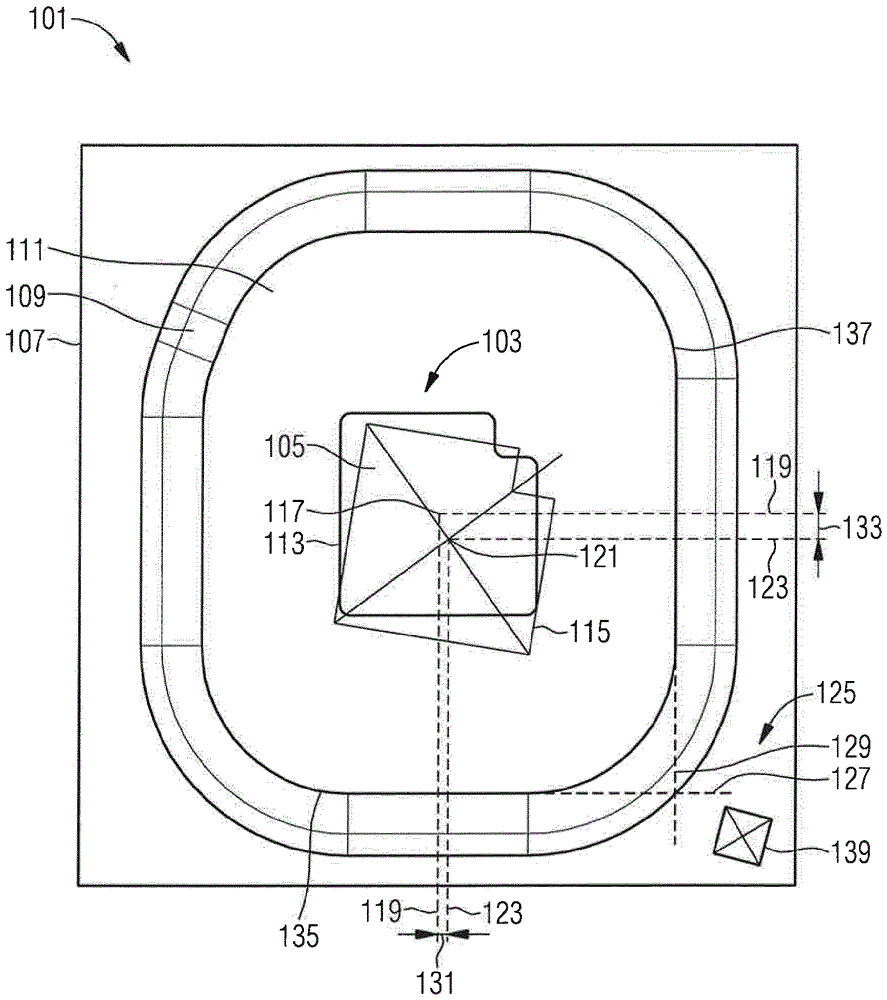

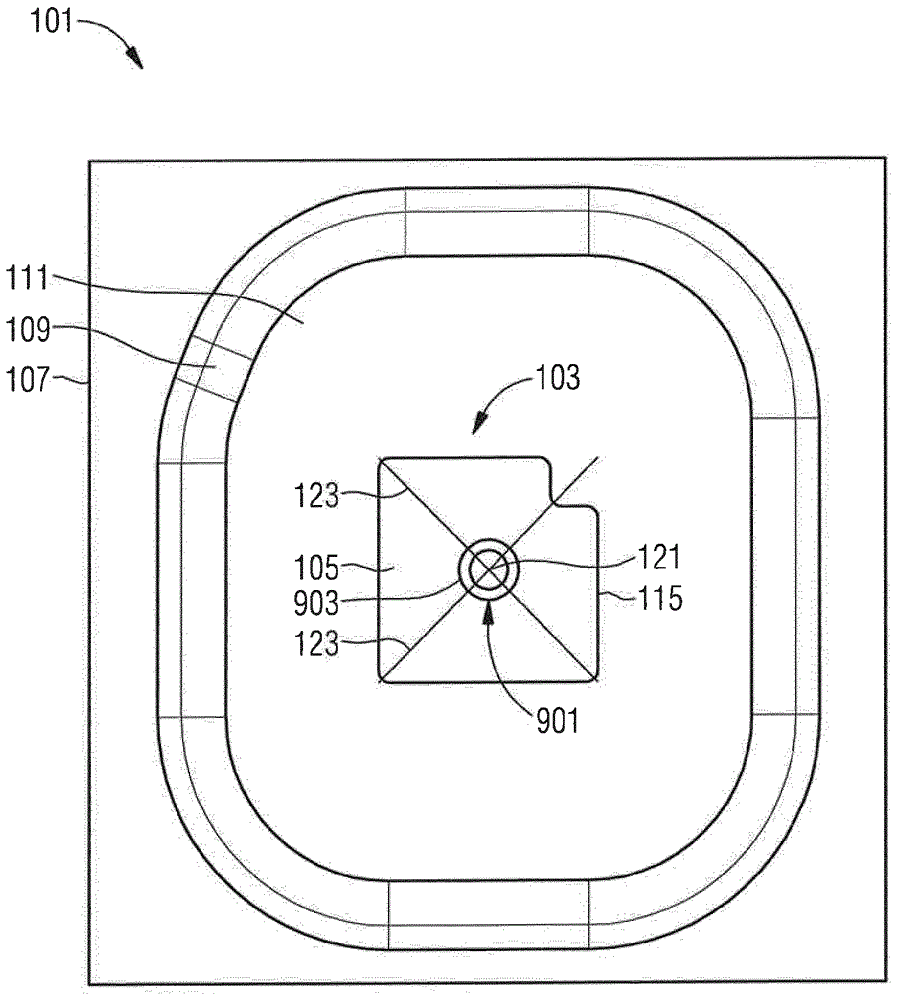

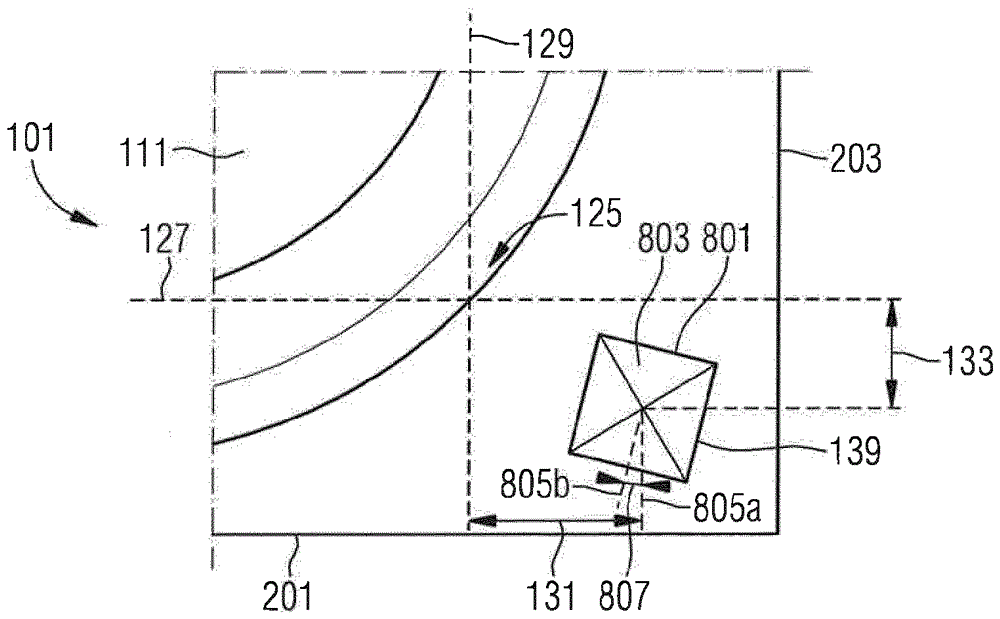

Method and apparatus for processing an optoelectronic component

InactiveCN105745770AAvoid readjustmentSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsOpto electronicLight source

The invention relates to a method for processing an optoelectronic component (101) comprising a light source (103), which has at least one luminous area (105) formed by one or a plurality of light emitting diodes, and a receptacle device (107) that receives the light source (103), comprising the following steps: determining (1101) a deviation of an actual position (115) of the light source (103) at the receptacle device (107) from a desired position (113) of the light source (103) at the receptacle device (107), forming (1103) at least one marking (139) at the receptacle device (107) which indicates the deviation. The invention furthermore relates to an apparatus (1201) for processing an optoelectronic component, to an optoelectronic component (101), to a method for equipping a carrier with an optoelectronic component, to an apparatus (1401) for equipping a carrier with an optoelectronic component, and to a computer program.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

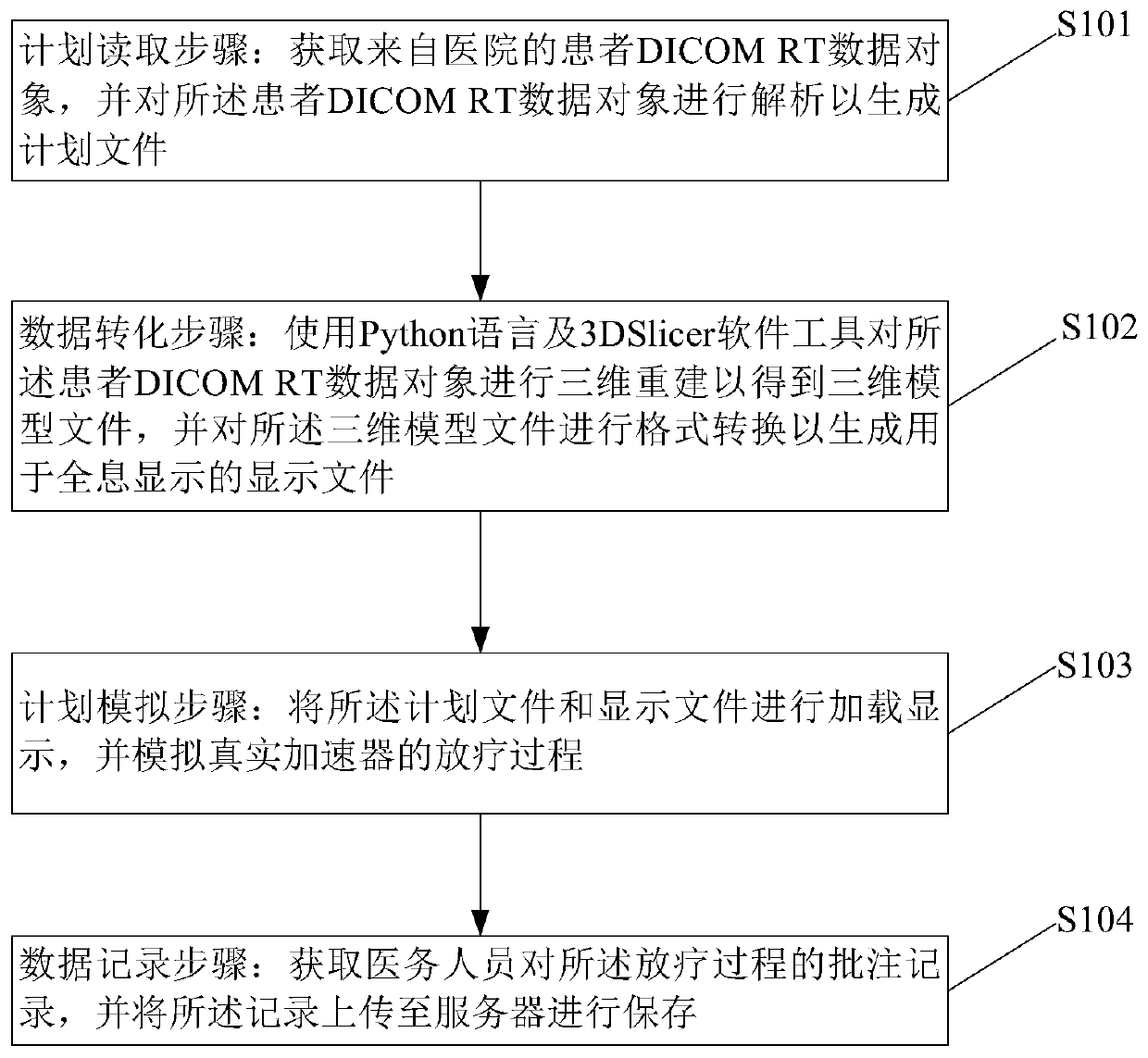

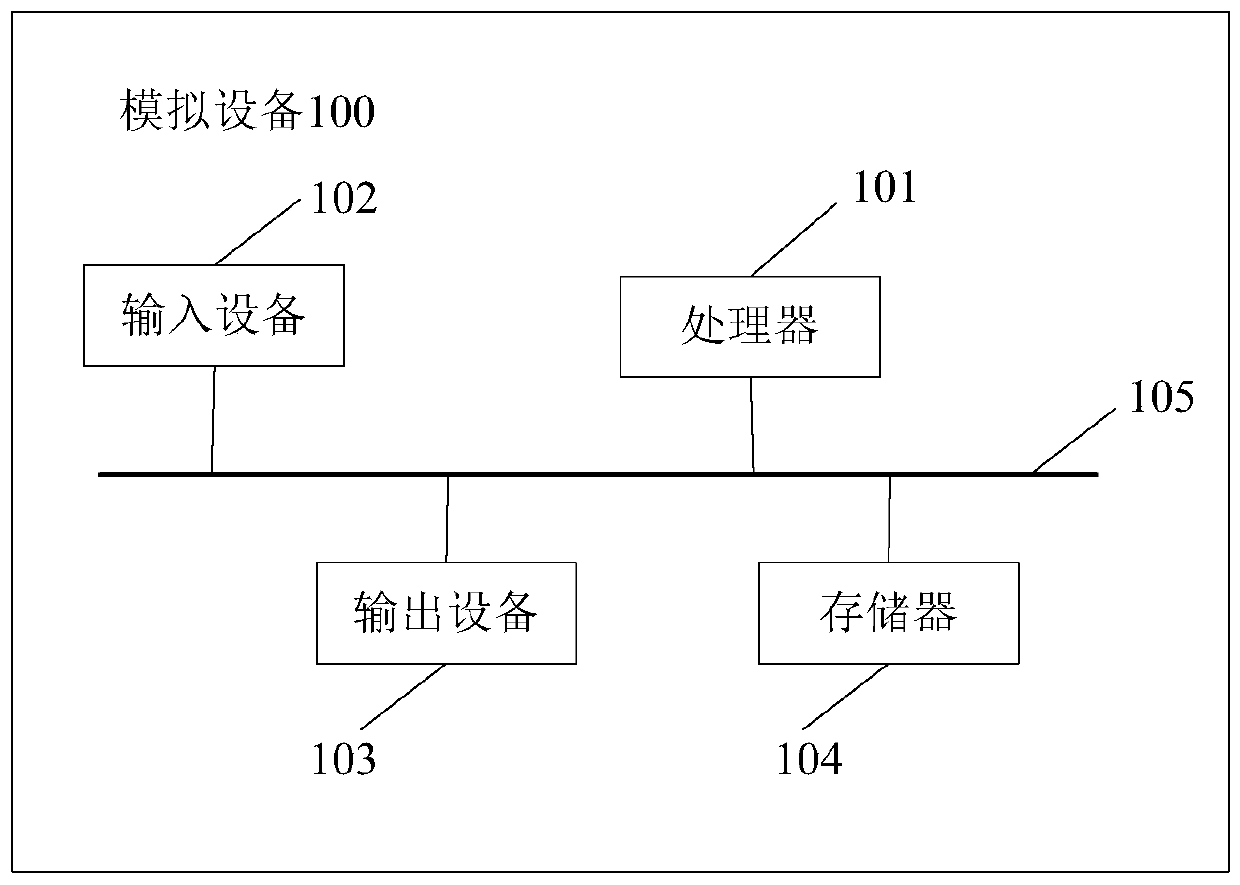

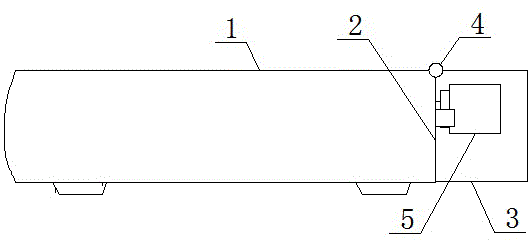

Radiotherapy plan simulation method and device based on virtual intelligent medical platform, and medium

PendingCN111243713AReduce workloadAlleviate pain and inconvenienceMedical simulationMedical imagesHolographic displayMedical physics

The embodiment of the invention discloses a radiotherapy plan simulation method, device and system based on a virtual intelligent medical platform, and the method comprises the steps: obtaining DICOMRT object data from a hospital, and analyzing the DICOM RT object data to generate a plan file; performing three-dimensional reconstruction by using Python and 3DSlicer software tools to obtain a three-dimensional model file, and performing format conversion to generate a display file for holographic display; and loading and displaying the plan file and the display file, and simulating a radiotherapy process of a real accelerator. According to embodiments of the present invention, the treatment plan implementation condition can be comprehensively simulated; problems possibly occurring in implementation of the treatment plan are predicted, the situation that a patient cannot be treated after being positioned in the treatment room is avoided, treatment room equipment is prevented from beingoccupied, the treatment plan is prevented from being readjusted, the workload of medical staff is reduced, and inconvenience and pain of the patient are also reduced.

Owner:于金明

External sound card with false contact prevention cover

InactiveCN104699442AOvercome the defect of not having an anti-mistouch coverAvoid parameter changesSound input/outputEngineeringSound card

The invention belongs to computer hardware, and provides an external sound card with a false contact prevention cover. The external sound card comprises a shell with a control panel, wherein a cover is arranged on the control panel, and a rotary knob is protected through covering, so that the parameter variation caused by false contact of the rotary knob is prevented, secondary adjustment is avoided, and the defect that an existing external sound card is free of a false contact prevention cover is overcome.

Owner:SHAANXI BOYUAN SCI & TECH DEV

Machining table for metal machining

InactiveCN109158902AEasy to processAvoid readjustmentLarge fixed membersPositioning apparatusGear wheelFixed frame

The invention relates to the technical field of metal machining, in particular to a machining table for metal machining. The machining table comprises a base and a fixing frame. A second fixing columnis vertically arranged on the top of the base, and a first fixing column is horizontally in sliding connection to the top of the base. A rotation mechanism is arranged in the fixing frame and comprises a first gear, a worm, a second gear, a first rotation motor and a third gear. A supporting table is arranged on the top of the fixing frame, and the top of the supporting table is rotationally connected with a fixing base. Displacement mechanisms are arranged at the two side positions of the top face of the base. The face, opposite to the fixing base, of the second fixing column is provided with a lifting mechanism. A rack and a third rotation motor are arranged on the top of the first fixing column. The face, deviating from the fixing frame, of the base is provided with a transmission mechanism. The provided machining table for metal machining has the advantages that operation is convenient, usage is flexible, and various parts of a workpiece can be conveniently machined.

Owner:嘉善敏达金属制品厂

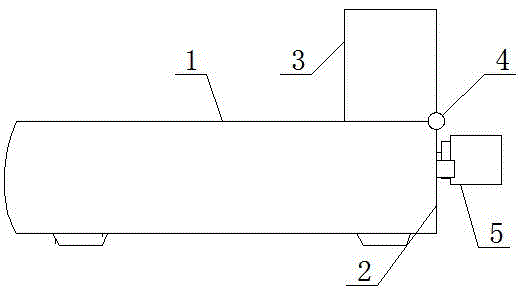

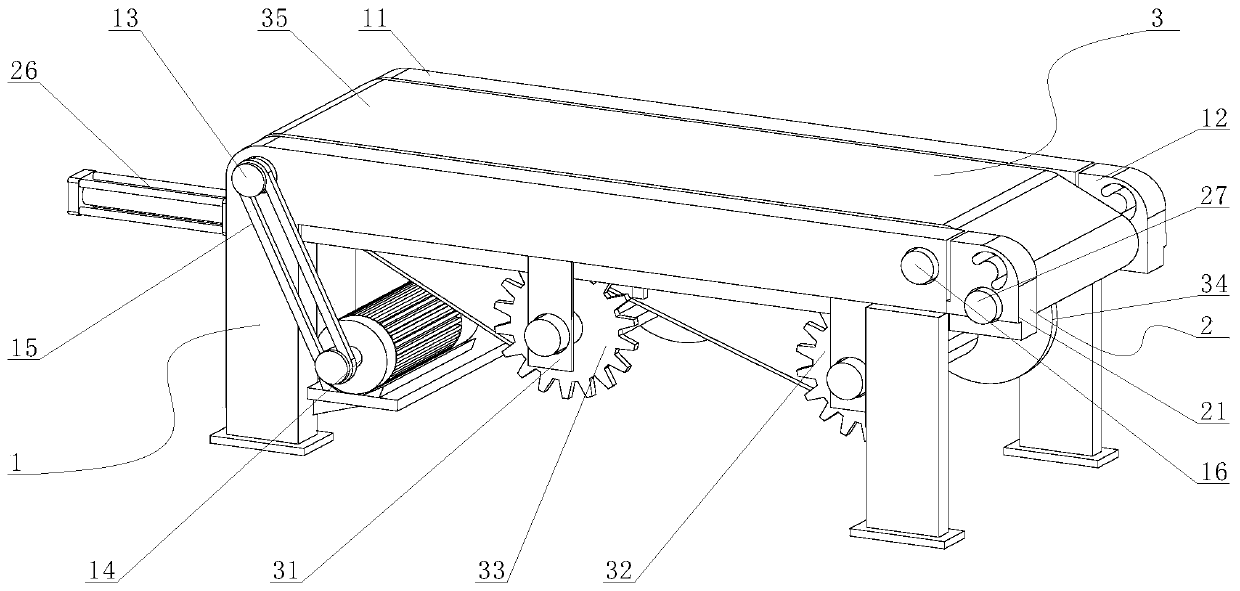

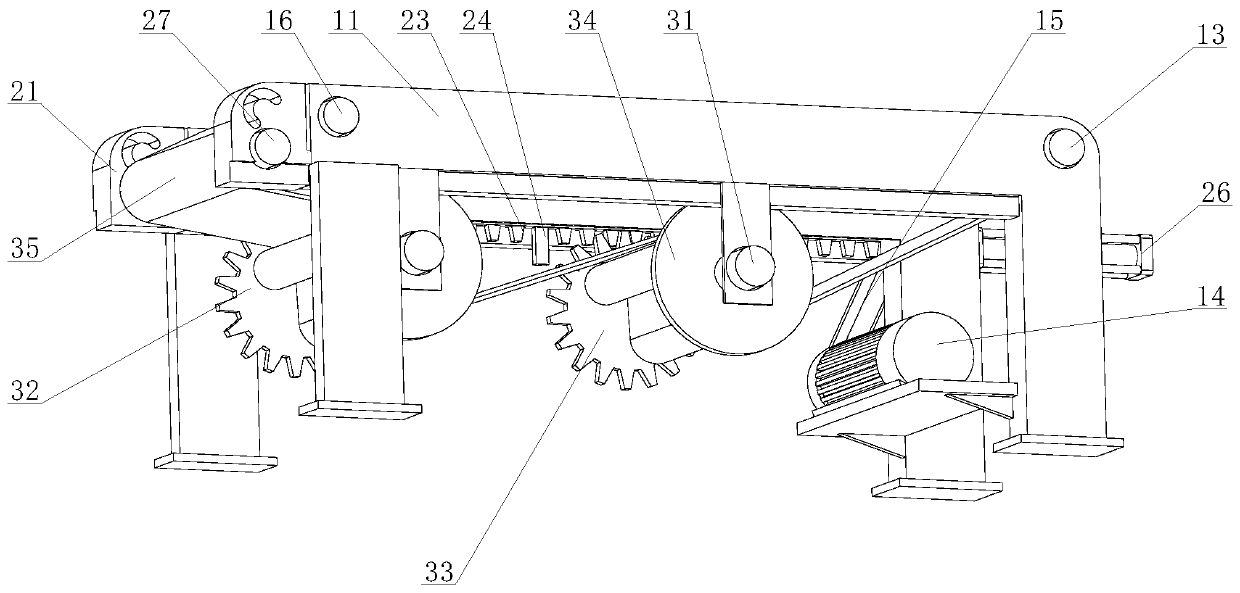

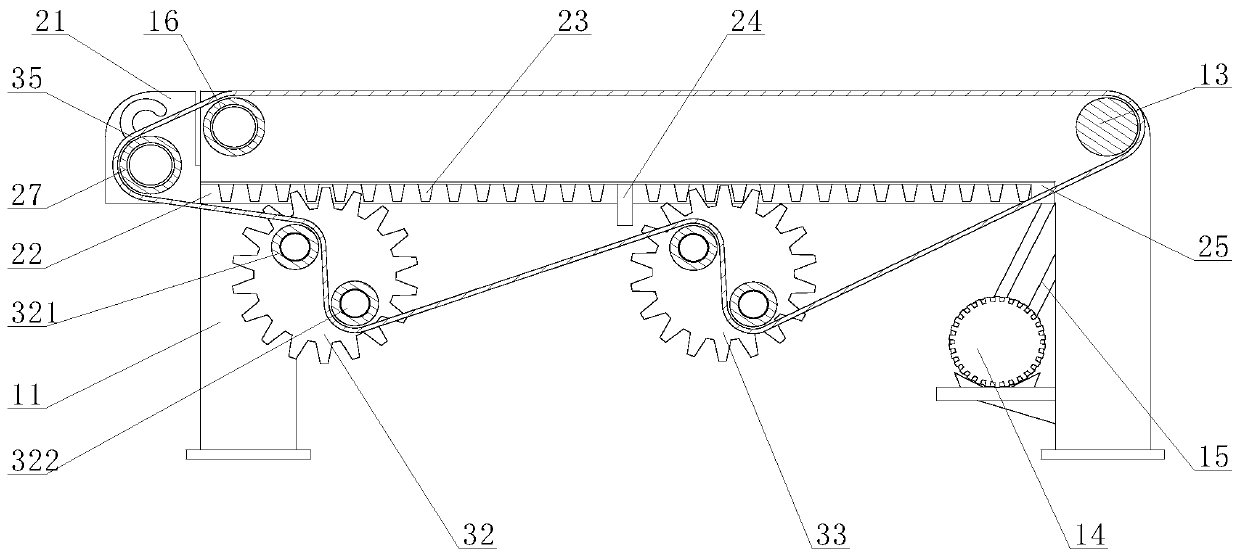

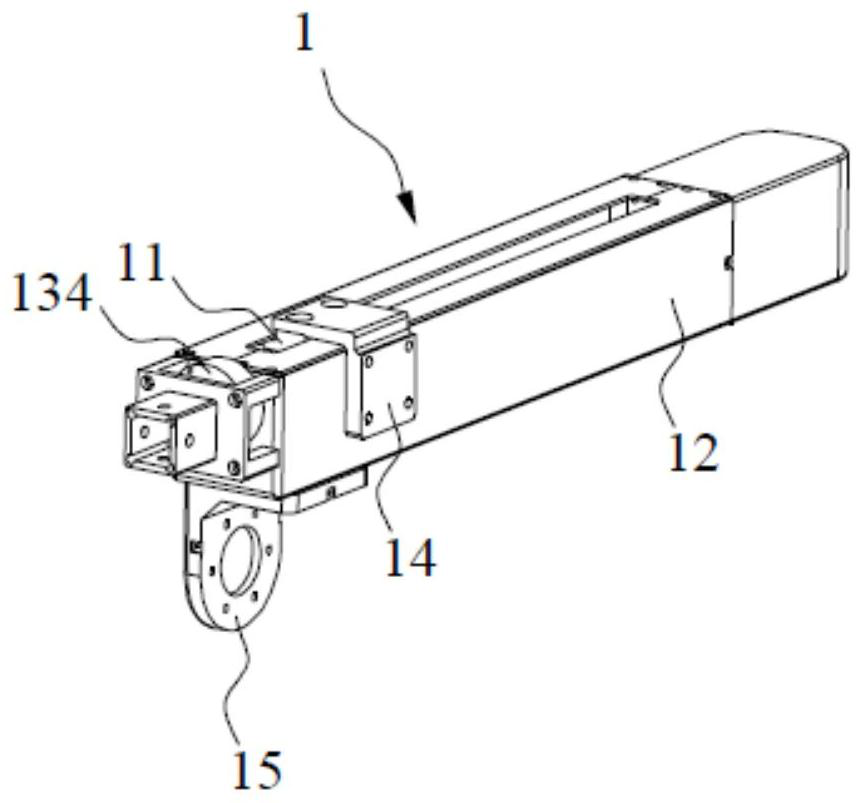

Telescopic conveyor with automatic belt length adjustment

The invention relates to a telescopic conveyor with automatic belt length adjustment. The telescopic conveyor includes a main frame, a telescopic frame is slidably accommodated inside the main frame,the lower part of the telescopic frame is connected to an adjustment assembly fixed on the surface of the main frame in a meshing mode, the telescopic frame telescopically slides inside the main frameand drives a winding wheel group in the adjustment assembly through a toothed plate to rotate to adjust the tightness of a conveyor belt automatically. A supporting arm is pushed to move outwards inan accommodating groove of a supporting frame by an air cylinder so as to enable the length of an entire conveyor to be extended, the supporting arm drives a first winding wheel and a second winding wheel to rotate through the toothed plate during the outward movement, a conveyor belt on the first winding wheel and the second winding wheel are released, so that when the conveyor is extended, the conveyor belt is further released, overall linkage and mutual cooperation are achieved, manual readjustment is avoided, fully automatic setting is achieved, the operation is convenient, and simplicityand practicality are achieved.

Owner:安徽芜湖宝丰输送机械有限公司

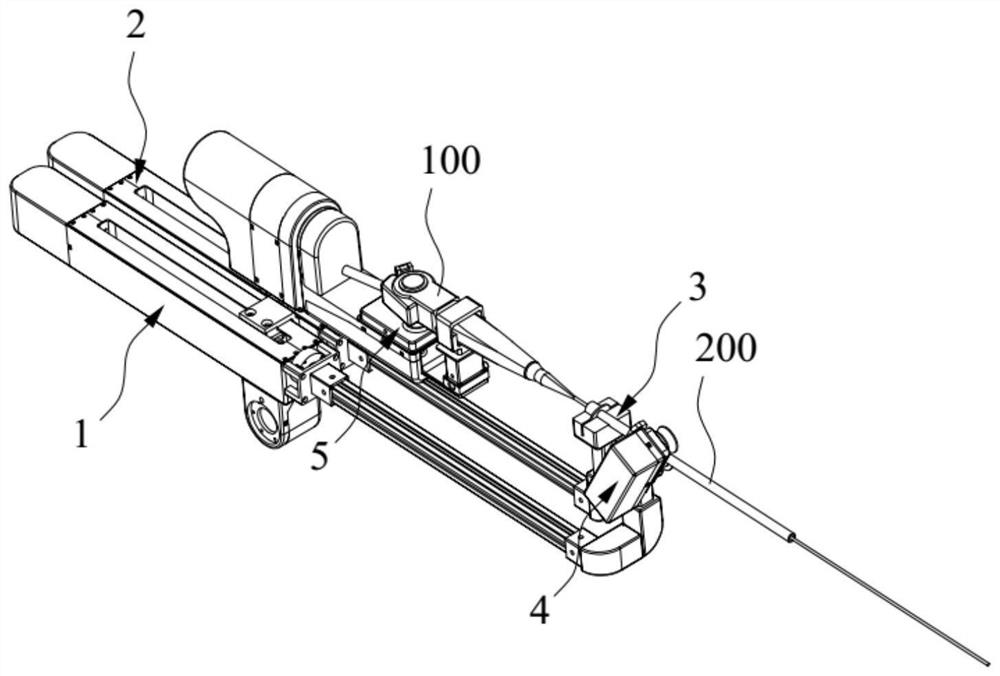

Tracheal intubation mechanism and tracheal intubation robot

PendingCN114588456AImprove practicalityReduce exposureTracheal tubesSurgical manipulatorsTube intubationPhysical medicine and rehabilitation

The invention relates to the technical field of medical instruments, and discloses a tracheal intubation mechanism and a tracheal intubation robot. The tracheal intubation mechanism comprises a first driving unit used for driving a second output unit to move in the first direction; the second driving unit comprises a second output part and a mirror bracket, the second output part can relatively move in the second direction, and the mirror bracket is connected to the second output part; the mounting assembly comprises a mounting frame connecting rod and a mounting frame, one end of the mounting frame connecting rod is connected to the second driving unit, and the mounting frame is vertically connected to the other end of the mounting frame connecting rod; the auxiliary assembly comprises a roller connecting rod and a roller frame, one end of the roller connecting rod is connected to the first driving unit, the other end of the roller connecting rod is connected to the roller frame, and a first roller and a second roller with parallel rotating axes are arranged on the roller frame; trachea intubation is achieved, medical workers do not need to make contact with a patient, the patient is rescued in time, the risk of cross infection is reduced, and the safety of the medical workers is guaranteed.

Owner:胡晓旻

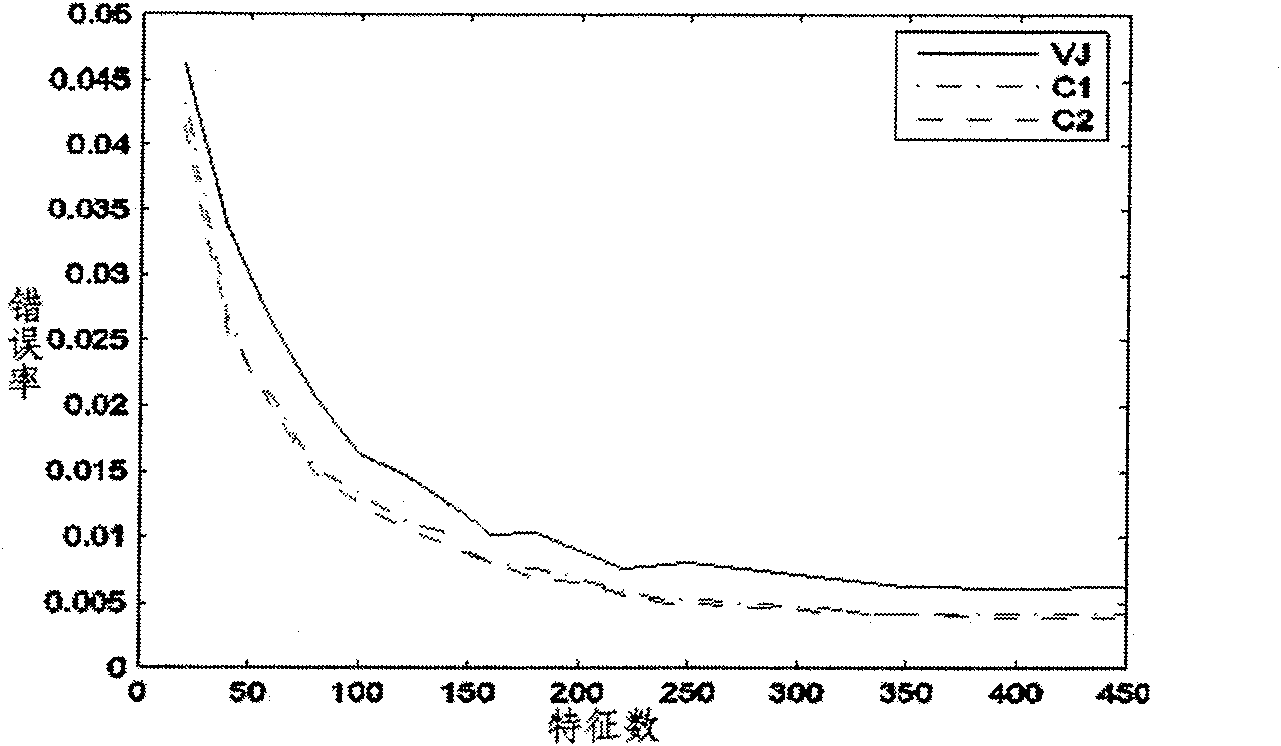

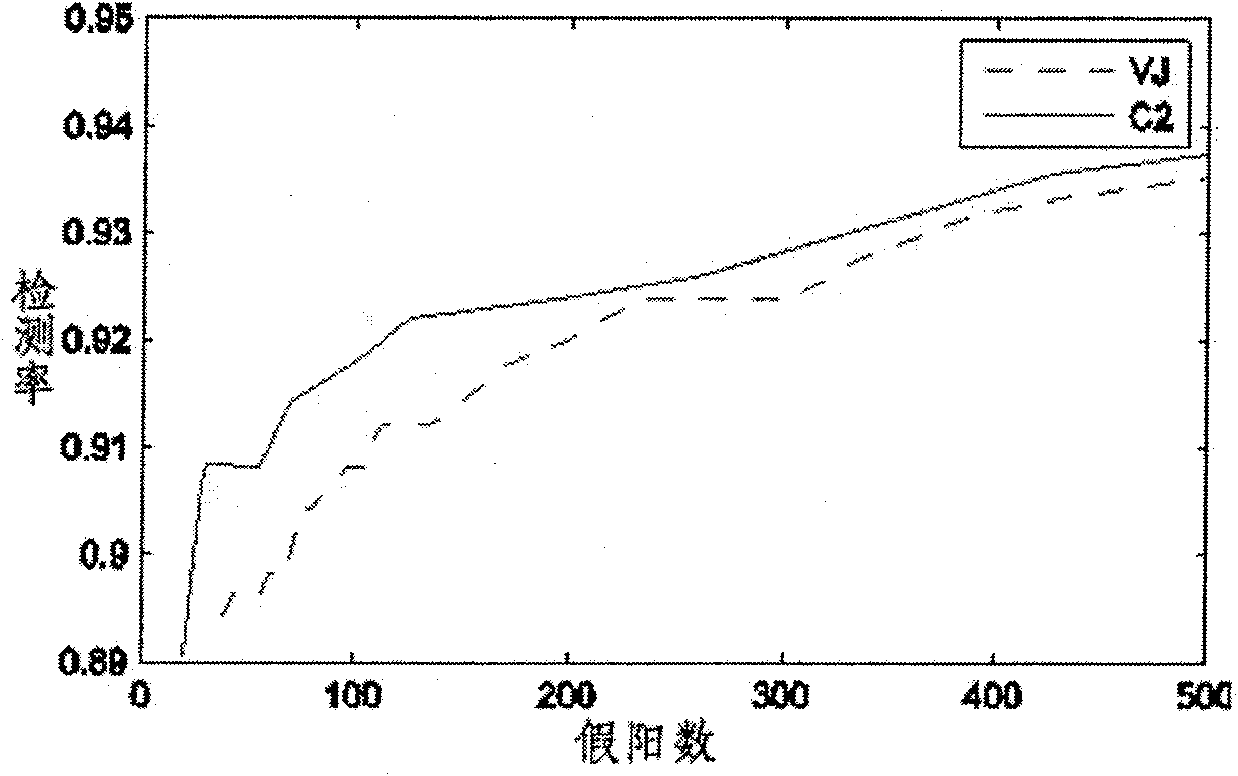

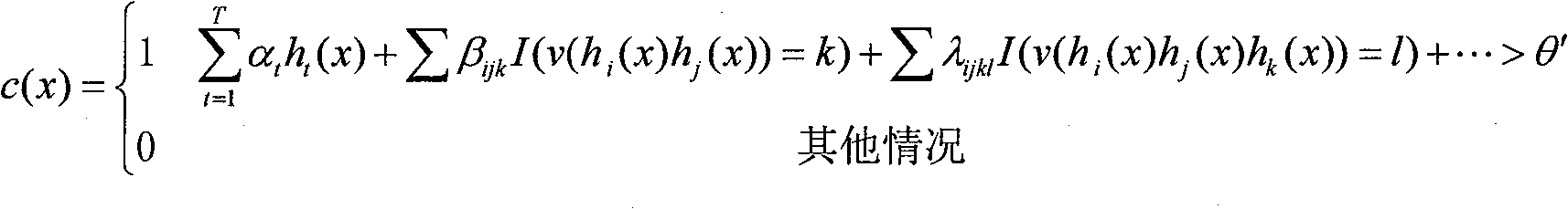

Method for detecting human face with weak sorter composite coefficient

InactiveCN100560025CImprove accuracyDetection speedPerson identificationCharacter and pattern recognitionFace detectionFeature vector

The present invention belongs to the field of image processing technology, and relates to a human face detection method with combination coefficient of weak classifier. Said method includes the following steps: first step: extracting characteristics of human face image, calling it human face image characteristic vector and forming sample set; second step; utilizing sample set to construct cascade detector; for every node of cascade detector adopting lifting method to select weak classifier based on characteristics and construct integrated classifier; for integrated classifier utilizing combination coefficient to further raise classification efficiency; and third step: finally, utilizing above-mentioned cascade detector to implement automatic human face detection.

Owner:SHANGHAI JIAO TONG UNIV

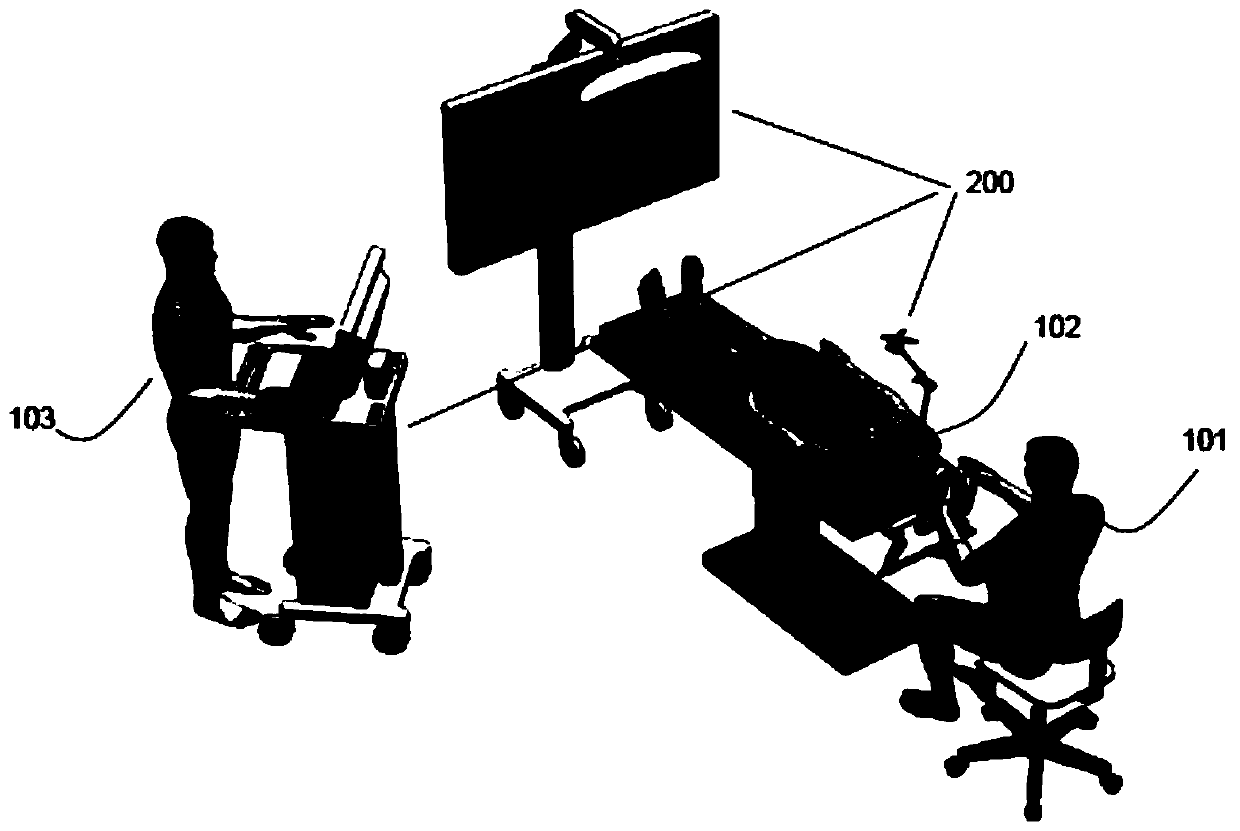

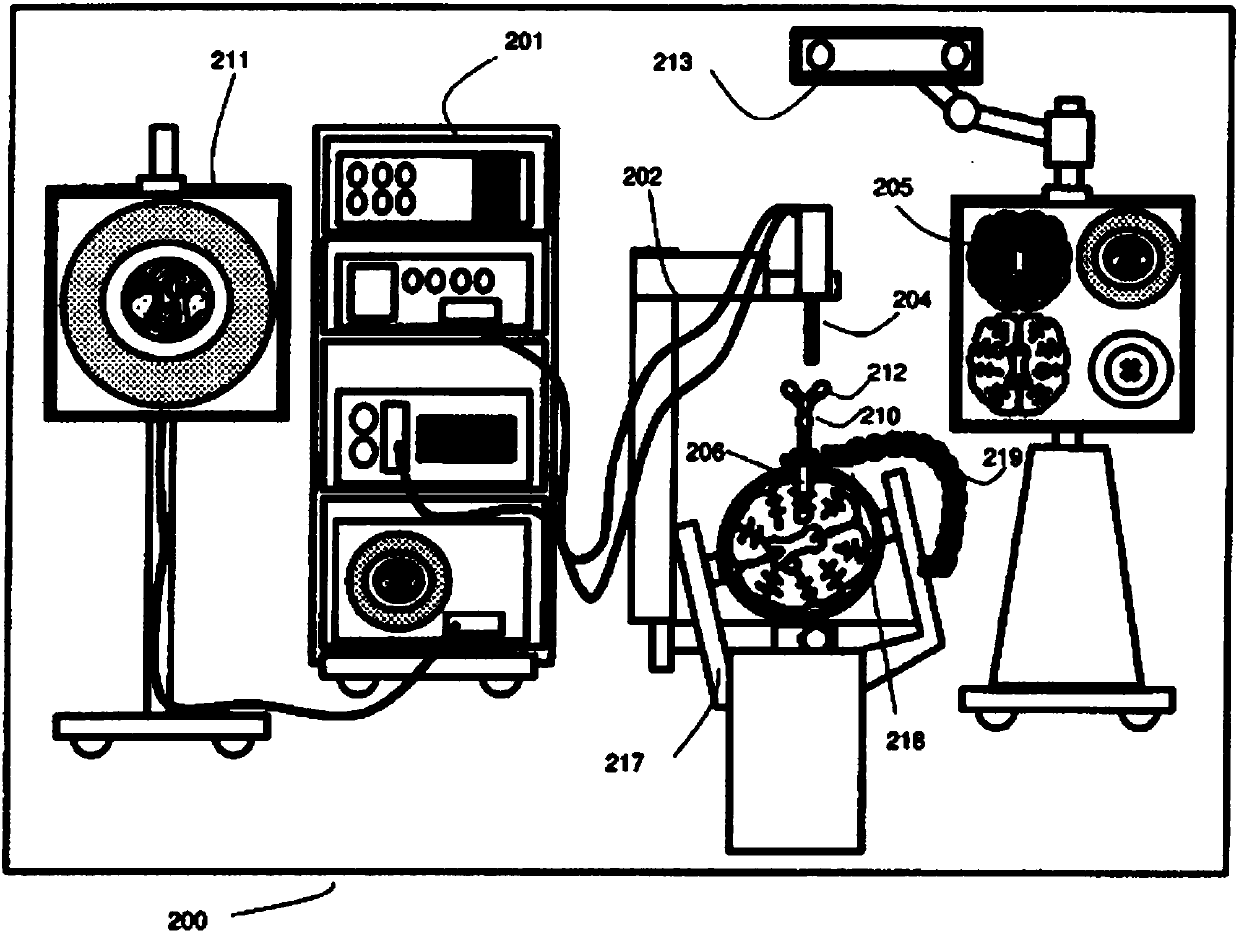

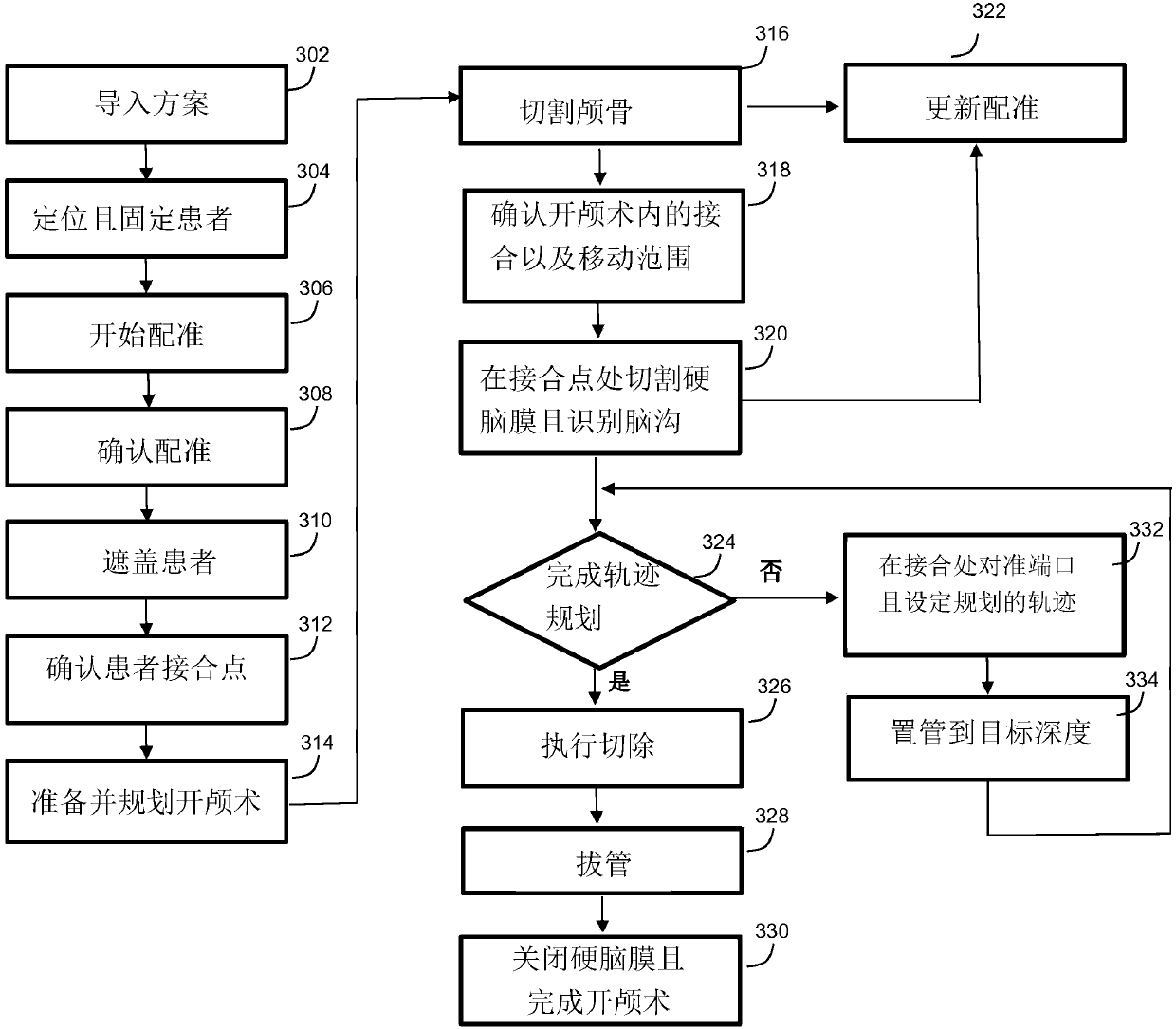

Systems and methods for navigation and simulation of minimally invasive treatments

Disclosed are navigation and simulation systems and methods for minimally invasive treatments, wherein the navigation system introduces a planning method using patient-specific pre-operative images. The navigation system uses intraoperative imaging to update preoperative images during the medical procedure and provides images of the tracked surgical tool along a surgical path prepared from the preoperative images.

Owner:SYNAPTIVE MEDICAL (BARBADOS) INC

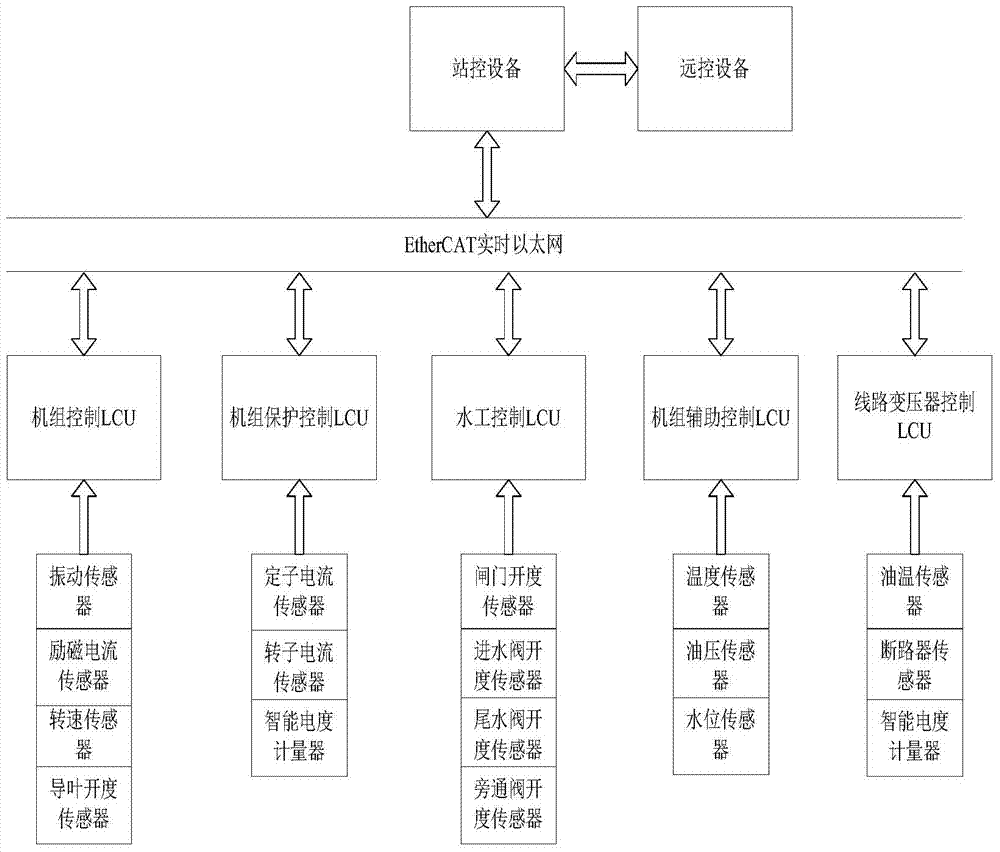

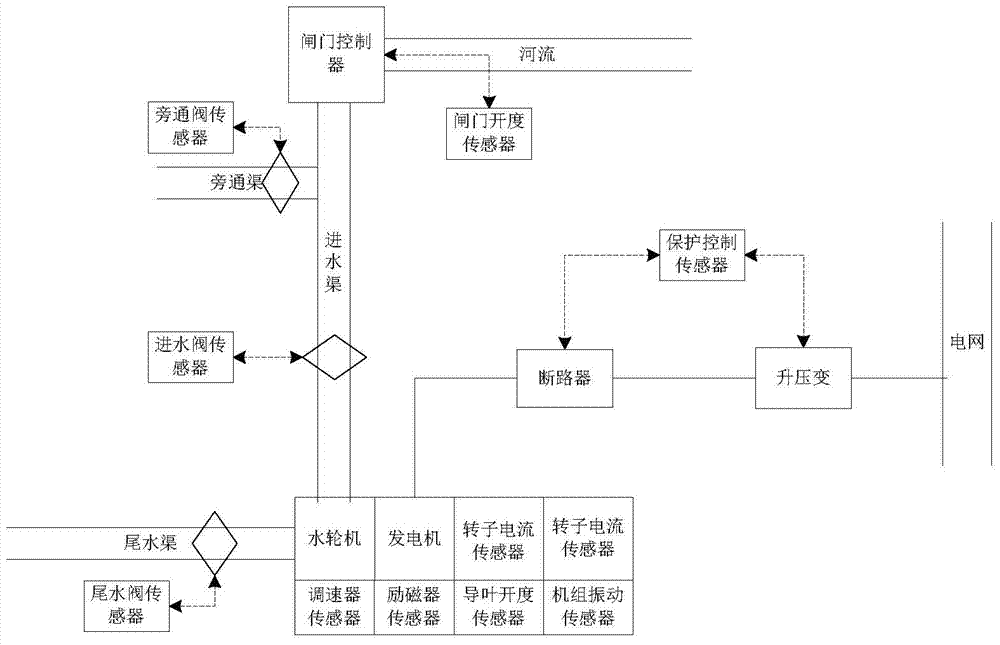

Intelligent control system and method for medium and small hydropower station

ActiveCN105182917BRealize remote controlEliminate "islands"Total factory controlProgramme total factory controlGroup controllerRemote control

The present invention is an intelligent control system and method for small and medium-sized hydropower stations. It is provided with a remote control layer, a station control layer, and at least one single unit control layer, wherein the single unit control layer is provided with an LCU layer and a sensor layer. The LCU layer is composed of at least two functional LCU controllers, each of which is connected to a sensor group at the input of the functional LCU controller. network, forming the LCU layer, the first communication end of the station control layer is connected to the EtherCAT real-time Ethernet, and the second communication end is connected to the remote control layer; the control method of the intelligent control system of the small and medium-sized hydropower station It is an intelligent control system for small and medium-sized hydropower stations that adopts a publish / subscribe mechanism to establish a unified information platform for the whole station to realize the sequential logic control and synchronous chain adjustment control functions of the intelligent hydropower station control system.

Owner:重庆新世纪电气有限公司 +1

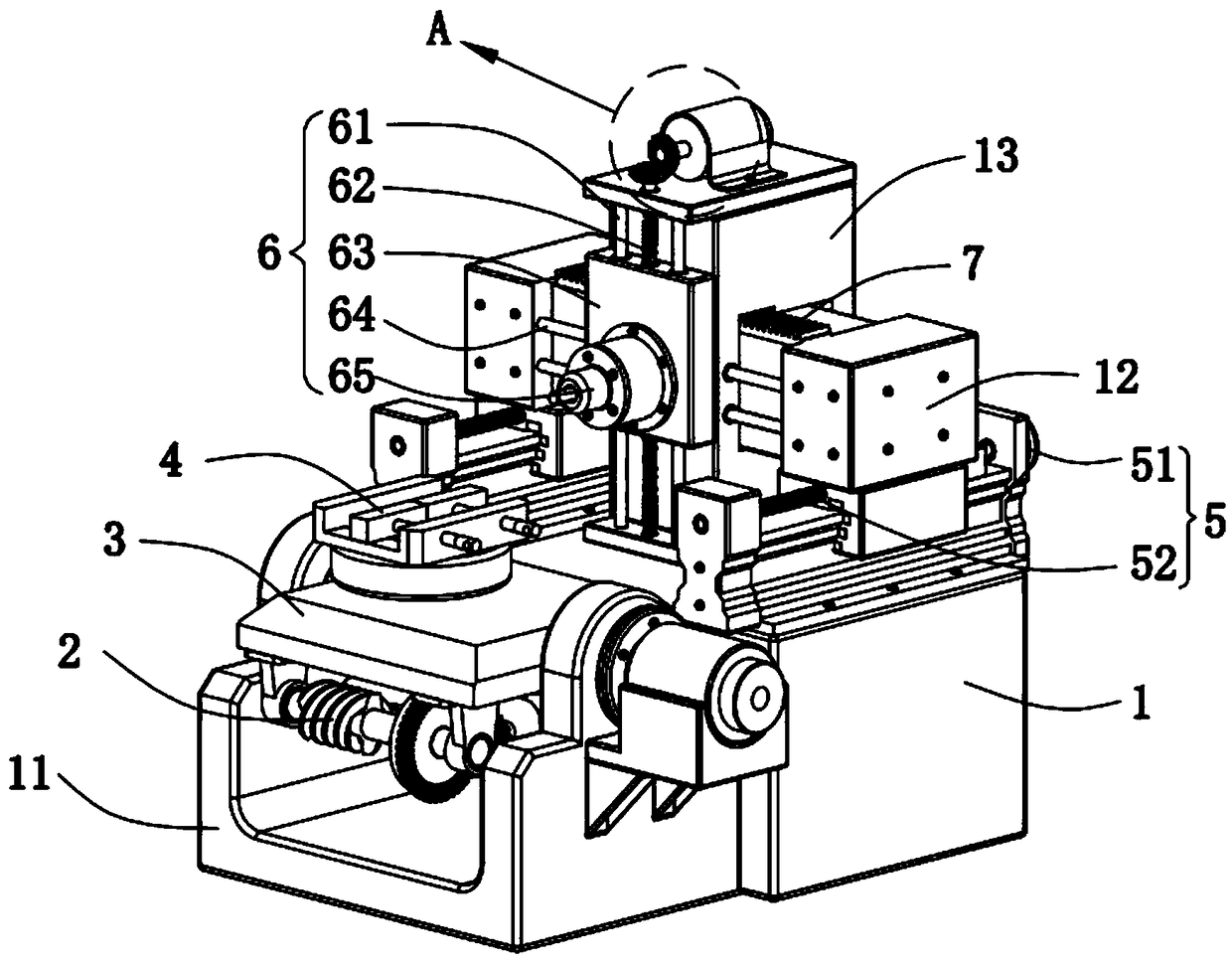

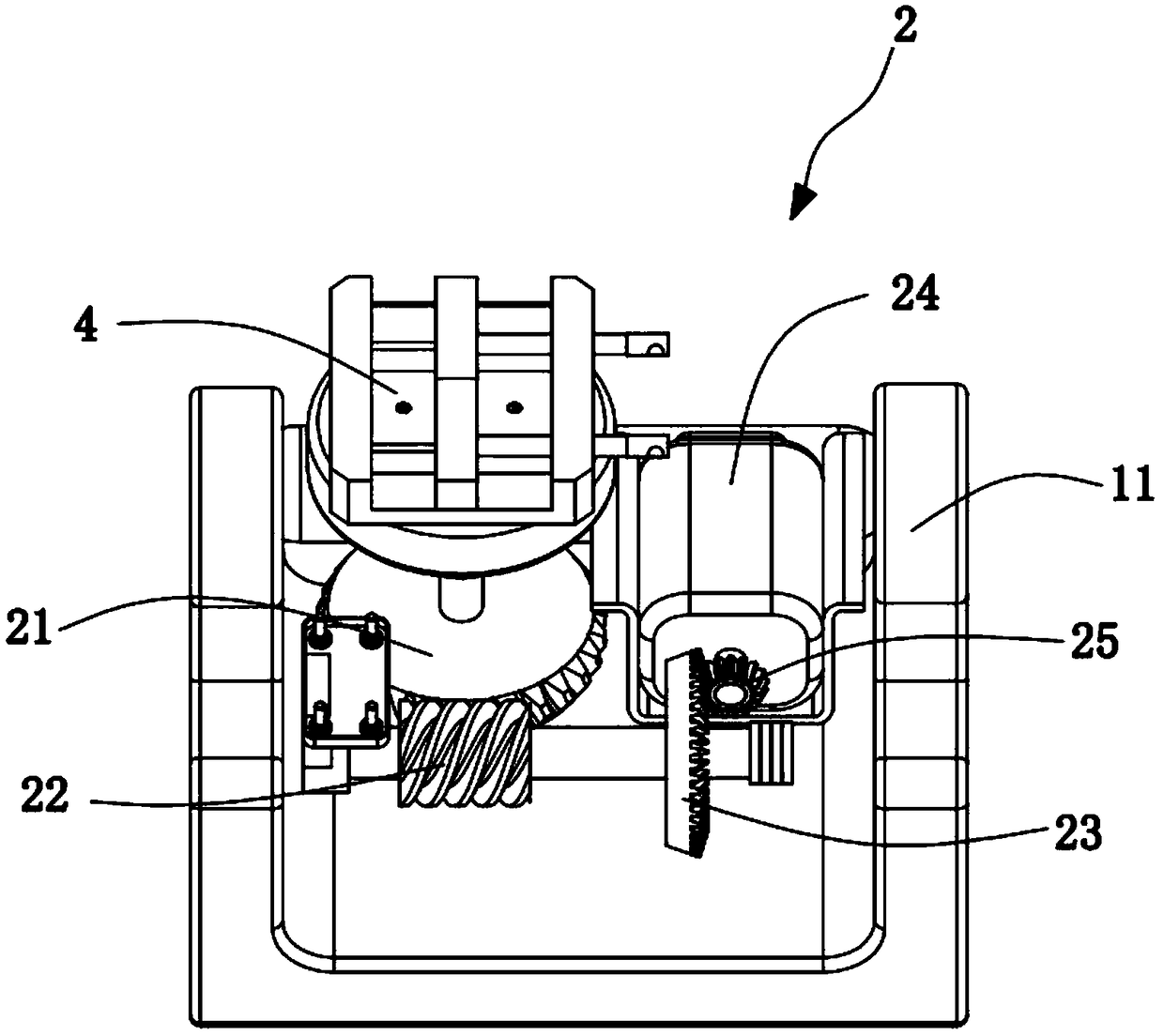

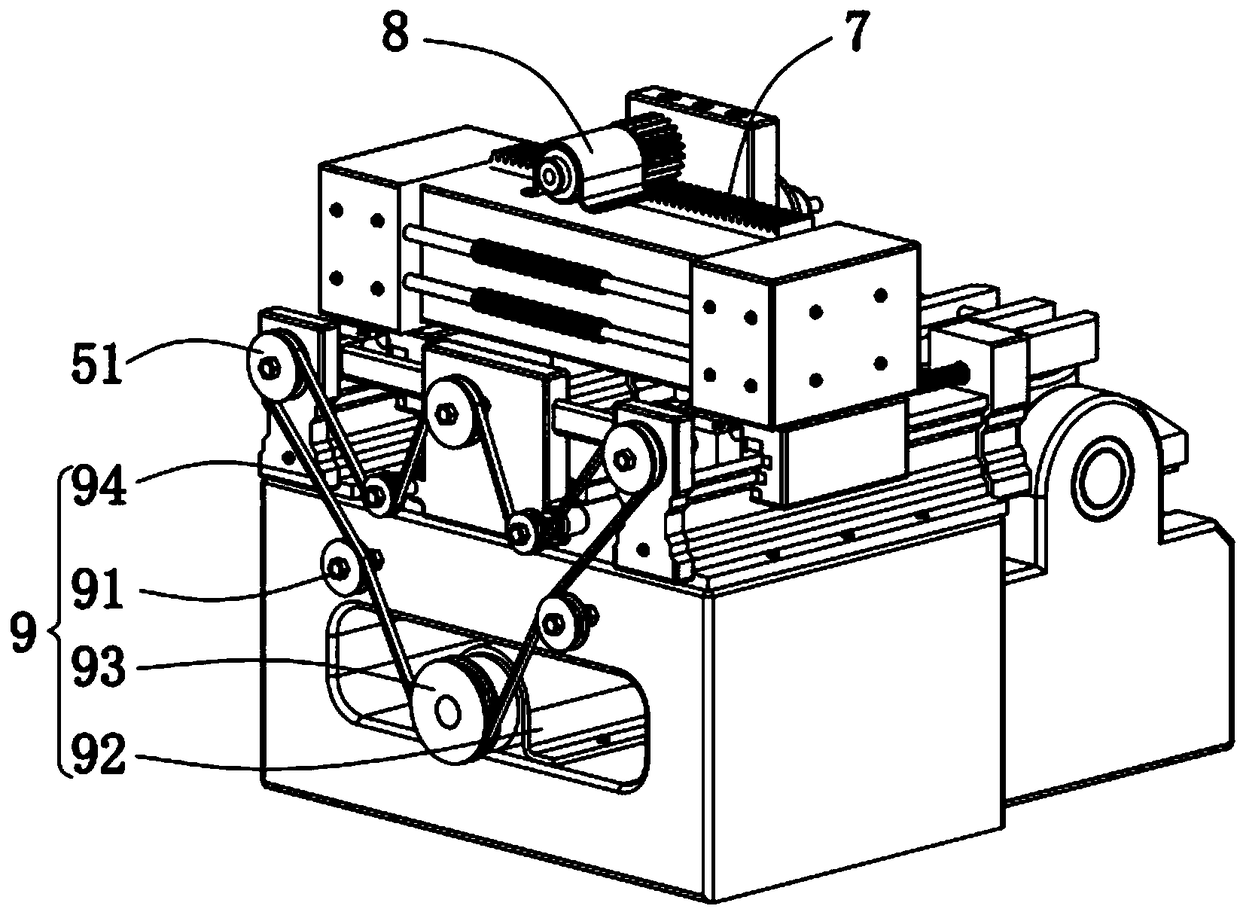

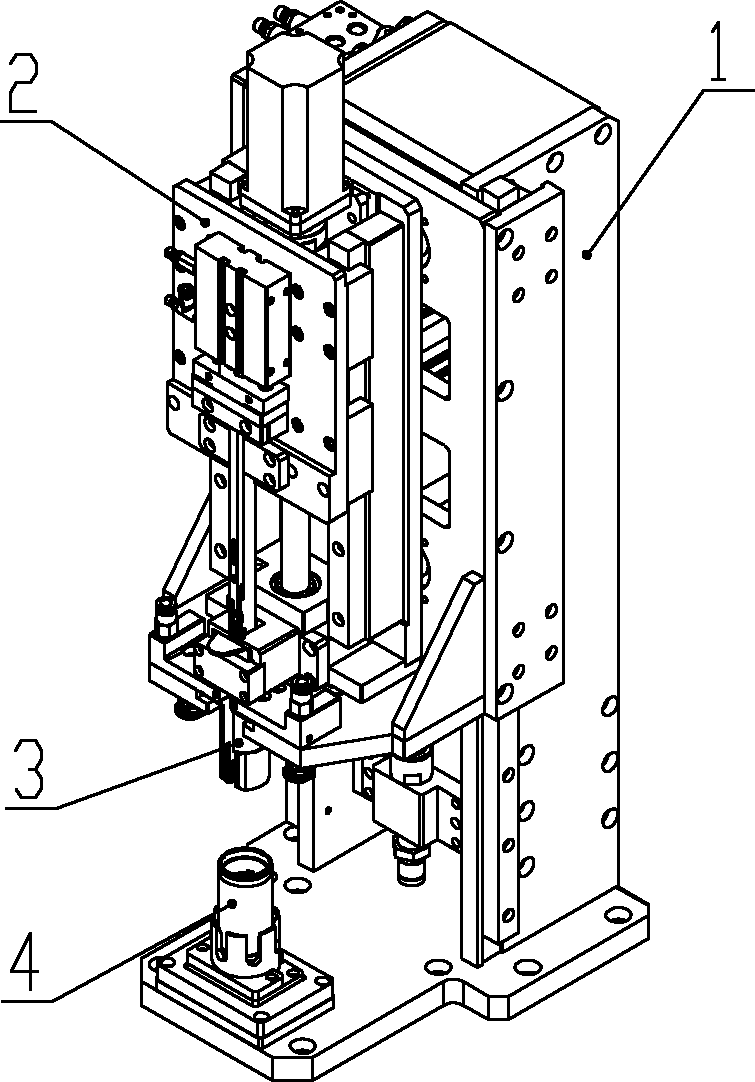

Workholding and sharpeners

ActiveCN110587480BEasy to upgradeImprove output accuracyOther manufacturing equipments/toolsGrinding work supportsPilot holeReciprocating motion

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

A Diesel Engine Fuel Injector Fuel Injection Advance Angle Assembly Tool

ActiveCN105179133BAvoid readjustmentSolve low production efficiencyFuel injection apparatusMachines/enginesDiesel injectorEngineering

The invention discloses a fuel injection advance angle assembling tool of a diesel engine fuel injector. The fuel injection advance angle assembling tool of the diesel engine fuel injector comprises a base board on which an idle gear is fixed. The base board outside the idle gear is provided with a positioning shaft on which an oil pump gear connector is mounted. The positioning shaft is movably connected with the base board. The positioning shaft is provided with an adjusting handle. The base board at the periphery of the positioning shaft is provided with a reference hole. The base board at the periphery of the reference hole is provided with a plurality of angle positioning holes. The deflection angle of the positioning shaft is fixed through pins which are inserted between the angle positioning holes and the adjusting handle. According to the fuel injection advance angle assembling tool of the diesel engine fuel injector, a fuel injection pump advance angle can be preset according to a technological requirement for a diesel engine, and re-adjustment of the fuel injection pump advance angle in a thermal test is prevented. Not only is a problem of low production efficiency settled, but also consistency and reliability of a product are improved. Furthermore production cost is greatly reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

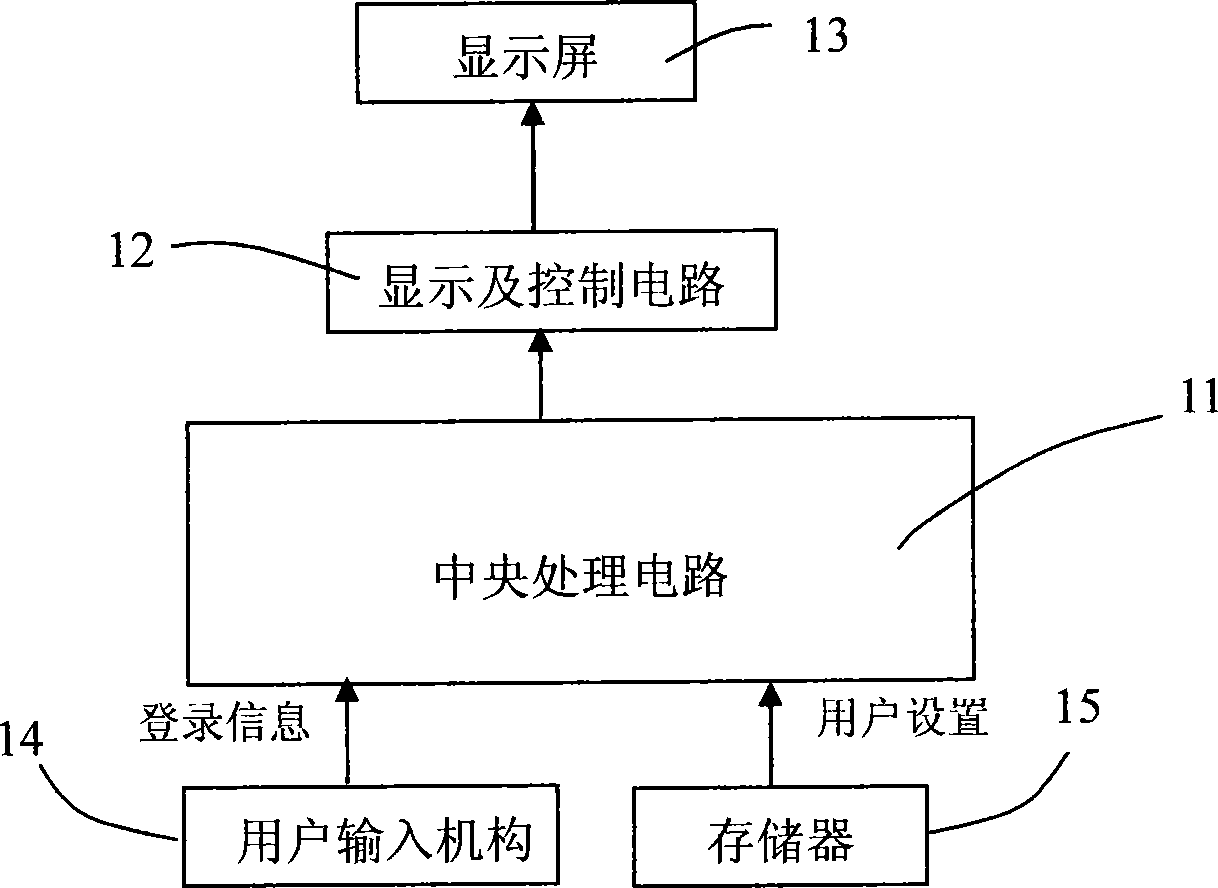

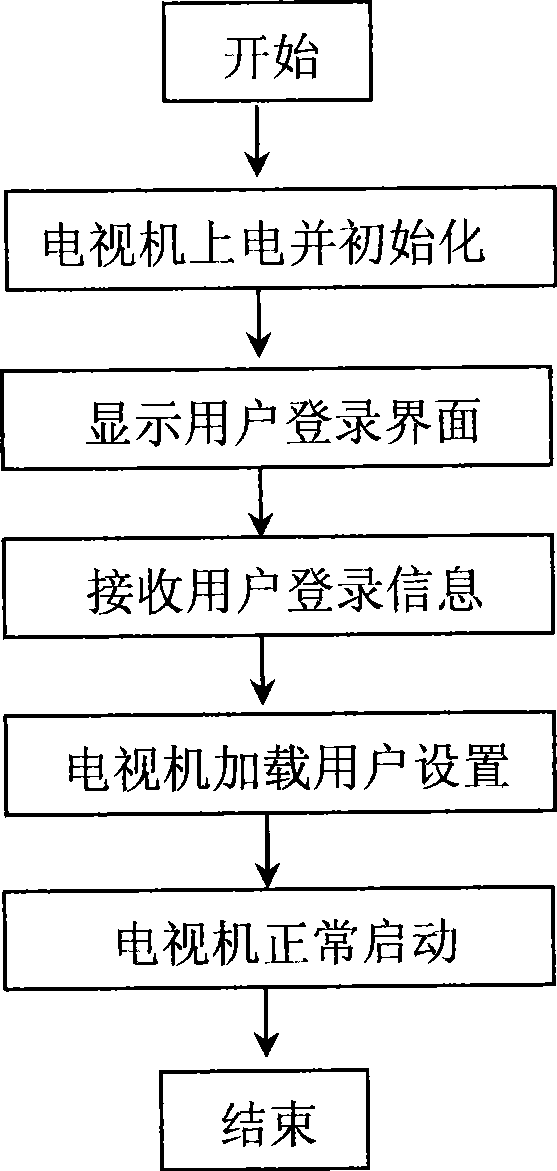

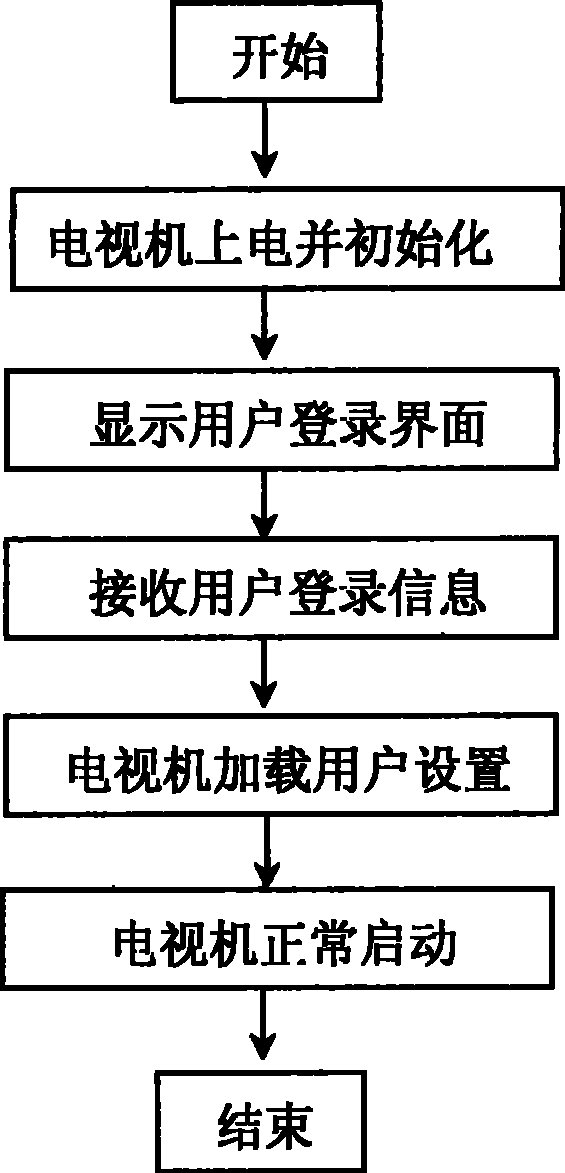

Multiuser television set and management method

ActiveCN101312488BEasy to manageAvoid readjustmentTelevision system detailsColor television detailsUser interfaceTelevision set

Owner:重庆市易平方科技有限公司

Production process for PSL-2 grade non-tempered N80 steel grade oil casing pipes

InactiveCN102703838BSave energyAvoid readjustmentTemperature control deviceMetal rolling arrangementsRoom temperatureContinuous rolling

The invention relates to a production process for PSL-2 grade non-tempered N80 steel grade oil casing pipes, comprising the following processing steps: step (1) of heating pipe blanks in an annular furnace at 1200-1280 degrees centigrade for 3-3.5 h; step (2) of punching the heated pipe blanks with a puncher, and rolling to obtain coarse pipes with required specification, wherein temperature of coarse pipes is not less than 1150 degrees centigrade; step (3) of rolling coarse pipes obtained by punching on a retained mandrel pipe mill until required specification is obtained, wherein final rolling temperature for continuous rolling is not less than 1000 degrees centigrade; and putting rolled coarse pipes on an extracting mill to separate pierced pipes from core rods; step (4) of processing pierced pipes obtained by rolling and detaching with a sizing mill to obtain required outside diameter, wherein inlet temperature of the sizing mill is not less than 880 degrees centigrade, temperature of pierced pipes after sizing is not less than 820 degrees centigrade, and an equivalent dependent variable in a sizing process is not less than 0.4; step (5) of cooling sized pierced pipes in air at 820-800 degrees centigrade for 10-15 s, then atomizing and cooling at 650-800 degrees centigrade, and cooling to room temperature in the air at the last. The process provided by the invention meets demand of API standard PSL-2 grade on impact properties, and prevents pipes bending, deforming and cracking in a re-tempering process.

Owner:WUXI SEAMLESS OIL PIPE

A method for drawing power distribution wiring diagram of energy consumption information acquisition system

ActiveCN107450906BImprove loading speedEasy to drawDrawing from basic elementsSemi-structured data retrievalAlgorithmCollection system

The invention relates to a drawing method for a power distribution wiring diagram of an energy utilization information collection system. The method comprises the steps of 1, analyzing an XML document to obtain original data of each graphic primitive, recording graphic data of zooming or rotation operation, performing comparative calculation on the original data of the graphic primitives and the graphic data to obtain a zooming coefficient of the graphic primitives, and performing geometric calculation to obtain drawing center point coordinates of the graphic primitives; 2, based on a canvas API, if a graphic primitive rotation angle is 0, calculating absolute coordinates of the graphic primitives; if the graphic primitive rotation angle is not 0, calculating relative coordinates of the graphic primitives; storing new graphic primitive input parameters obtained by calculation in an object array; and 3, traversing the object array, and drawing graphic primitive object elements one by one. According to the method, the defects of high error probability of graph modification, low page loading speed and the like of an existing drawing method are overcome; the page loading speed is increased; and convenience is brought for system maintenance personnel to draw and modify the graph.

Owner:INTEGRATED ELECTRONICS SYST LAB

Device for automatically and synchronously assembling magnetic shoes and U-shaped spring of direct-current motor

ActiveCN102594041BRealize synchronous automatic assemblyImprove yieldManufacturing dynamo-electric machinesCurrent meterEngineering

The invention provides a device for automatically and synchronously assembling magnetic shoes and a U-shaped spring of a direct-current motor. The device comprises a positioning device, a U-shaped spring closing device, a magnetic shoe vacuum suction device and a motor shell placing device, wherein the positioning device is provided with a vertical straight line main guide rail and a longitudinal supporting straight bearing; with the adoption of the U-shaped spring closing device, the U-shaped spring is forced to be closed through a guide groove of a U-shaped spring closing guide block, so that the closing state of the U-shaped spring is kept by a U-shaped spring closing rod driven by a closing air cylinder before mounting the U-shaped spring in the motor shell; the magnetic shoe vacuum suction device fixes magnetic shoes with an accurate standard at accurate positions; and the motor shell placing device is used for positioning and supporting the motor shell. With the adoption of the device provided by the invention, the U-shaped spring and the magnetic shoes can be automatically and synchronously assembled; furthermore, the U-shaped spring cannot scrap the lateral faces of the magnetic shoes in an assembling process; and a position distance of mounting the U-shaped spring between the two magnetic shoes is precisely controlled by using serve drive accurate positioning properties. Therefore, the operation labor intensity is effectively reduced, and the assembly operation efficiency and the assembly quality of the magnetic shoes and the U-shaped spring are improved.

Owner:SHANGHAI KELAI MECHATRONICS ENG CO LTD

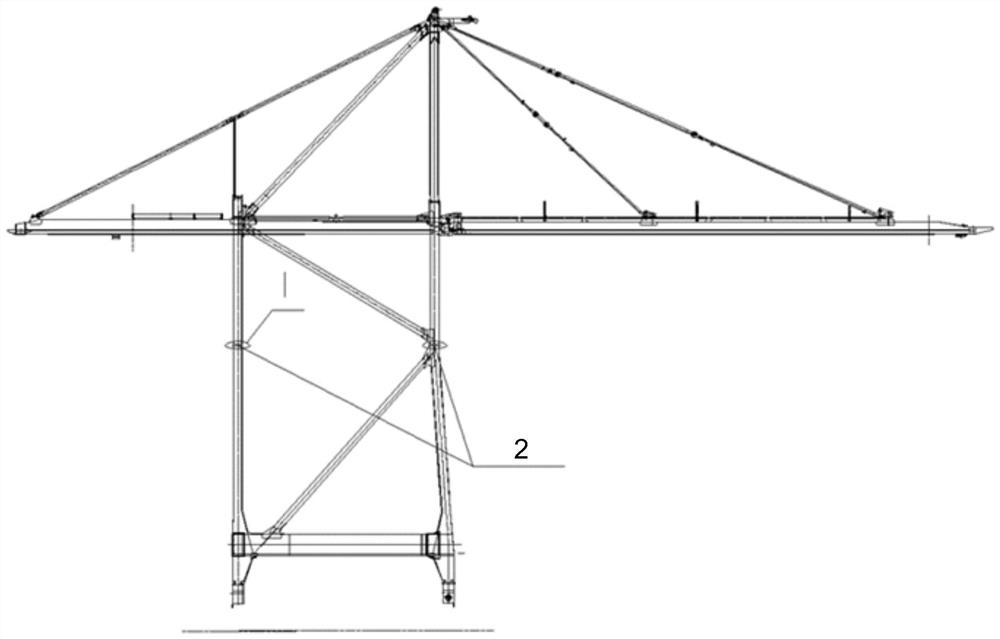

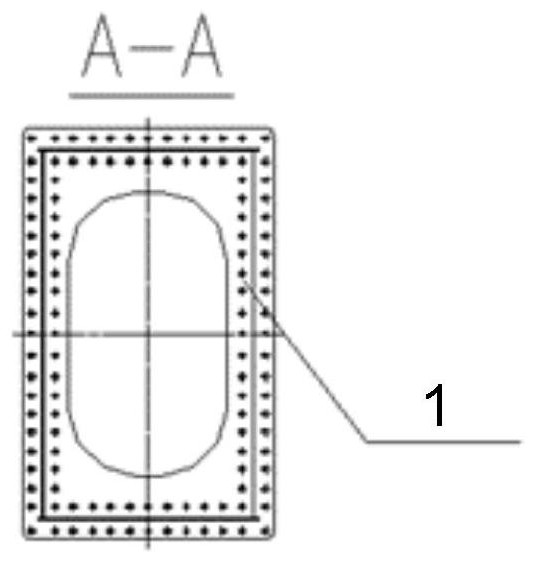

Machining method for stand column flange of quayside container crane

ActiveCN113909823AAvoid readjustmentLess adjustment workOther workshop equipmentContainer craneMachining

The invention discloses a machining method for a stand column flange of a quayside container crane, comprising: symmetrically leading out three reference points on webs on the upper side and the lower side of the flange by taking a binding surface before the flange is dismounted as a reference, so as to determine two completely parallel reference surfaces, and readjusting the states of upper and lower columns after the upper and lower columns are dismounted; and directly processing a flange binding surface by using a reference surface led out from the web plate. The method can reduce the difficulty of marking the thickness allowance of the flange.

Owner:SHANGHAI ZHENHUA HEAVY IND

Thermoplastic polyurethane (TPU) film slitter guide roller mechanism

PendingCN112589880AThe effect of preventing offsetThe effect of preventing deviationMetal working apparatusArticle deliveryThermoplastic polyurethaneMechanical engineering

The invention relates to the technical field of slitter guide rollers, and discloses a thermoplastic polyurethane (TPU) film slitter guide roller mechanism. The TPU film slitter guide roller mechanismcomprises a machine body; the front portion of the machine body is rotatably connected with a feeding roller; the surface of the feeding roller is fixedly connected with a film roll body; the interior of the machine body is rotatably connected with a knife roller; an adjusting mechanism is arranged at the position, located behind the knife roller, of the machine body; the surface of the adjustingmechanism is provided with a guide mechanism; an upper take-up roller and a lower take-up roller are rotatably connected to the portion, located on the rear portion of the adjusting mechanism, of themachine body; and the upper take-up roller is located above the lower take-up roller. According to the TPU film splitter guide roller mechanism, by installing the adjusting mechanism and the guide mechanism, the effect of adjusting the tension degree of the guide roller is achieved through mutual operation of all structures in the adjusting mechanism and the guide mechanism, and meanwhile, the effect that split film bodies different in thickness can be pressed is achieved when the tension degree is adjusted, thereby achieving the effect of guiding the film bodies different in cutting width tobe conveyed.

Owner:浙江长鸿纺织科技有限公司

A method for real-time planning of maneuvering targets in a moving coordinate system by a spacecraft

ActiveCN108319143BAvoid readjustmentAchieve smooth transitionAdaptive controlAngular velocitySatellite orbit

Owner:BEIJING INST OF CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com