Method for producing medium-chain fatty acid through anaerobic fermentation of lignocellulosic material

A technology for lignocellulosic raw materials and medium-chain fatty acids, which is applied in the field of waste recycling, can solve the problems of low energy density of small molecular acids, limited resource utilization, difficult separation and purification, etc., achieves high added value, reduces difficulty and cost, and increases Effect of acid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

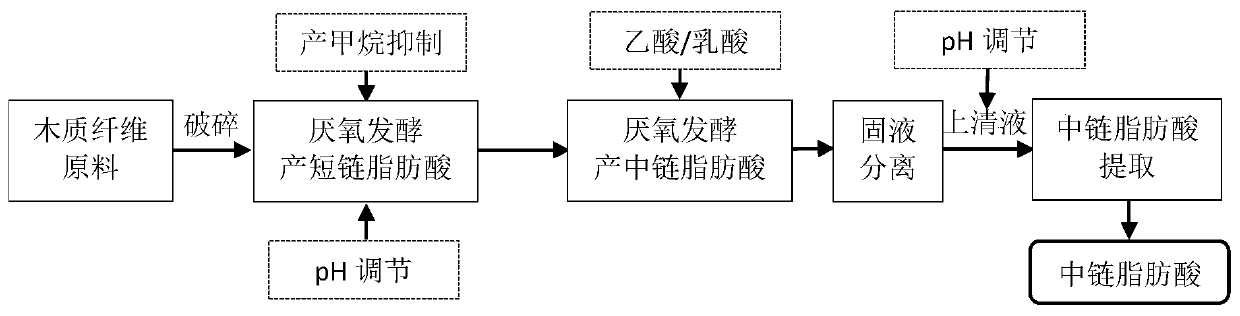

[0025] like figure 1 As shown, the method for preparing hexanoic acid by anaerobic fermentation of corn stalks comprises the following steps:

[0026] (1) Crush the corn stalks to less than 2cm, mix them with anaerobic digested sludge at a mass ratio of 1:20, use sodium hydroxide to adjust the pH to 11.0 to obtain a raw material solution, and add 20mmol of Add 2-bromoethylsulfonate sodium in a large amount, and then enter the anaerobic reactor for anaerobic fermentation. The fermentation temperature is 35°C, and the fermentation is continued for 15 days to obtain a fermentation broth with a short-chain fatty acid concentration of 6-8g / L. is about 5.5;

[0027] (2) Keep the fermented liquid obtained in step (1) for anaerobic fermentation for 20 days, control the fermentation temperature at 30°C, add ethanol in an amount of 1 g per 100 g of fermented liquid on the second day of fermentation, and obtain it after 15 to 20 days Fermentation broth rich in caproic acid, the concent...

Embodiment 2

[0030] like figure 1 Shown, the method for preparing hexanoic acid and octanoic acid by hybrid pennisetum anaerobic fermentation comprises the following steps:

[0031] (1) Crush fresh Pennisetum hybrida to less than 1cm, mix it with anaerobic digested sludge at a mass ratio of 1:10, adjust the pH to 10.0 with sodium hydroxide to obtain a raw material solution, and add 50mmol / L sodium 2-bromoethylsulfonate was added, followed by anaerobic fermentation at a fermentation temperature of 55°C for 10 days to obtain a fermentation broth with a short-chain fatty acid concentration of 10-12g / L;

[0032] (2) Continue anaerobic fermentation of the fermentation broth obtained in step (1), the fermentation temperature is 40°C, and ethanol is added every 2 days from the second day of fermentation, and the amount of ethanol is added per 100g of fermentation broth 0.5g of ethanol was added to the fermentation broth, and after 40 to 45 days, a fermentation broth rich in caproic acid and capr...

Embodiment 3

[0035] like figure 1 Shown, the method for preparing caproic acid by anaerobic fermentation of silage corn stalks comprises the following steps:

[0036] (1) Crush the silage corn stalks to less than 2 cm, mix them with anaerobic digested sludge at a mass ratio of 1:4, adjust the pH to 9.0 with potassium hydroxide to obtain a raw material solution, and add 50 mmol of per liter of raw material solution to the raw material solution Add sodium 2-bromoethylsulfonate in a large amount, then carry out anaerobic fermentation at a fermentation temperature of 30°C, and continue fermentation for 5 days to obtain a fermentation broth with a short-chain fatty acid concentration of 8-10 g / L;

[0037] (2) Continue anaerobic fermentation of the fermented liquid obtained in step (1), the fermentation temperature is 30°C, add lactic acid in the amount of 3 g of lactic acid per 100 g of fermented liquid on the second day of fermentation, and ferment for 10 to 15 days Obtain a fermented liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com