Patents

Literature

54results about How to "Increase acid production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

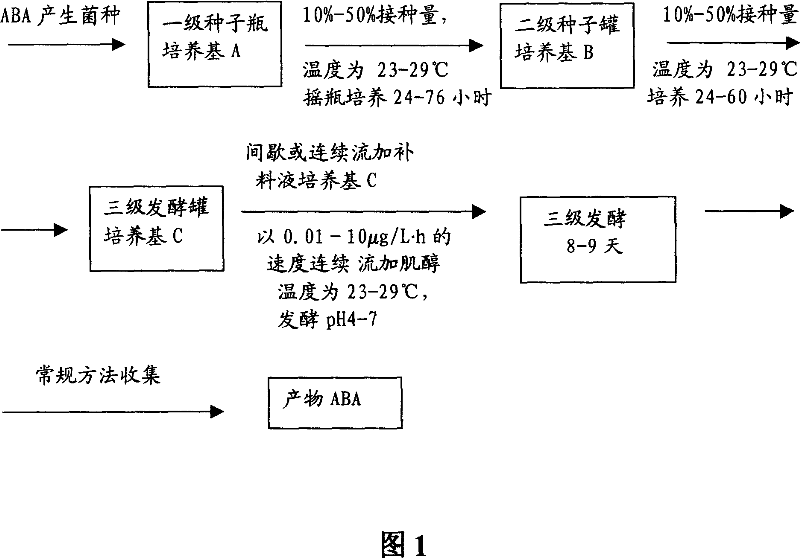

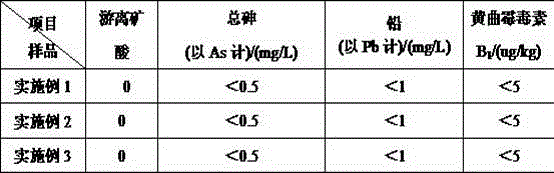

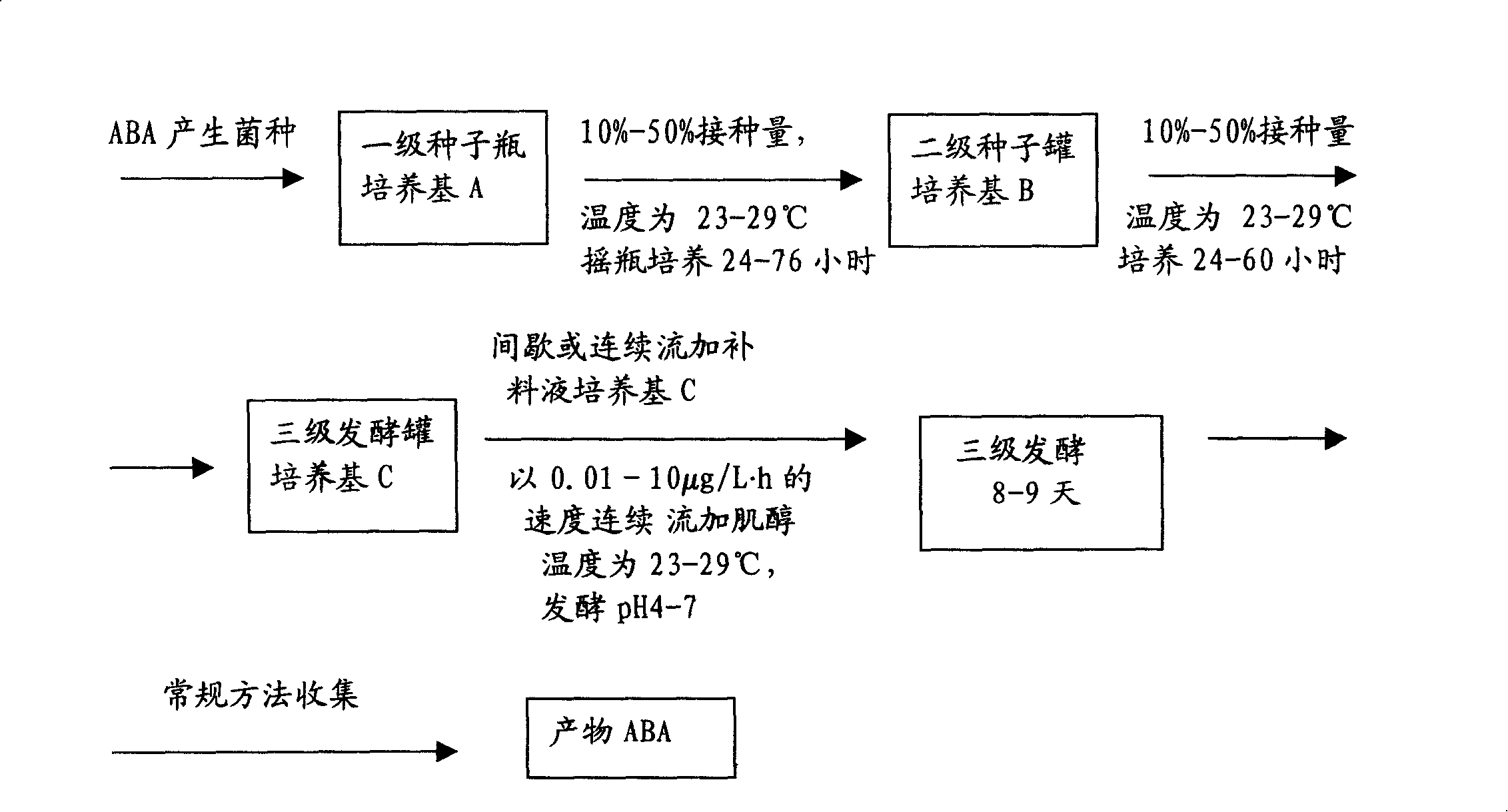

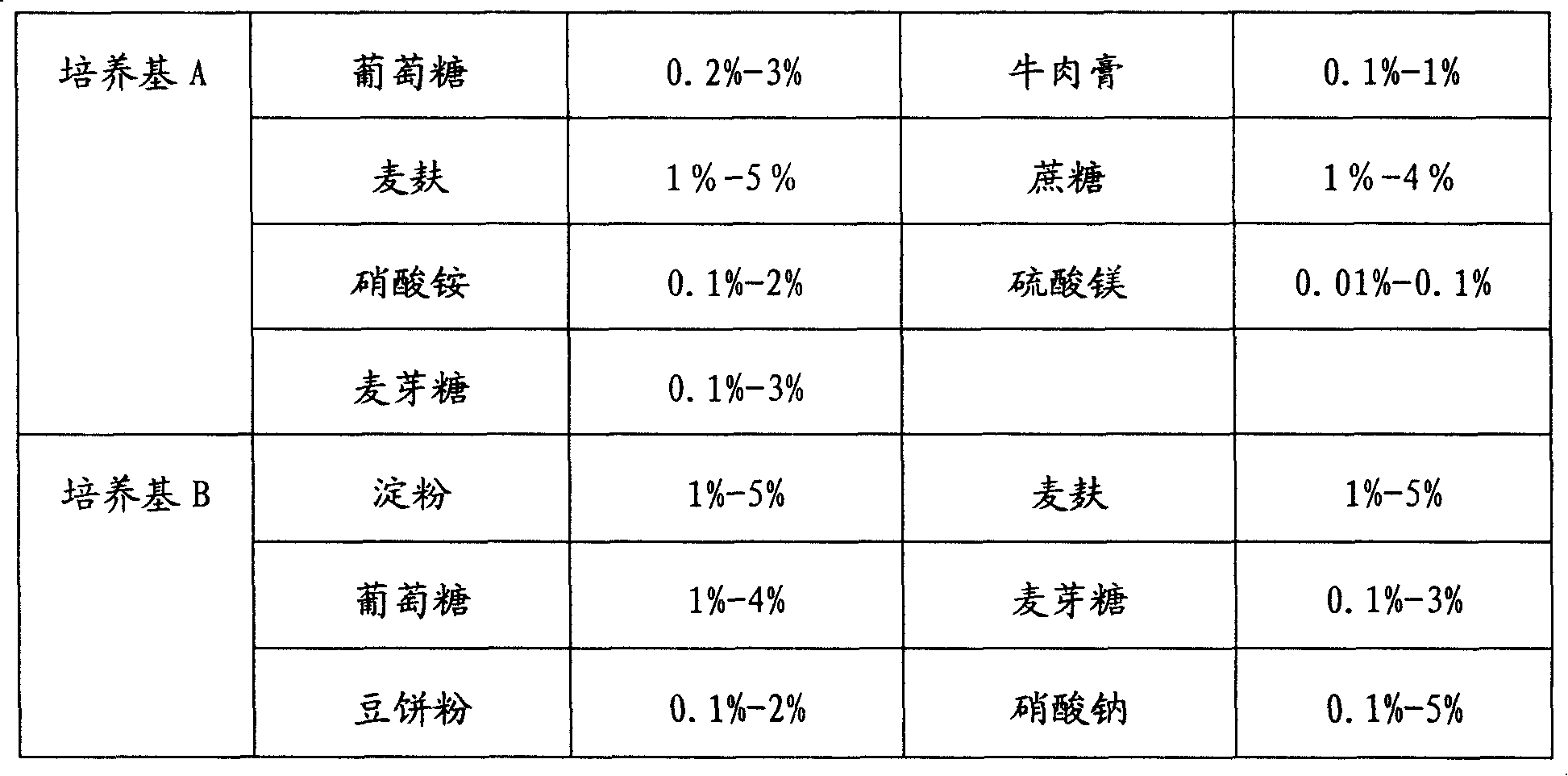

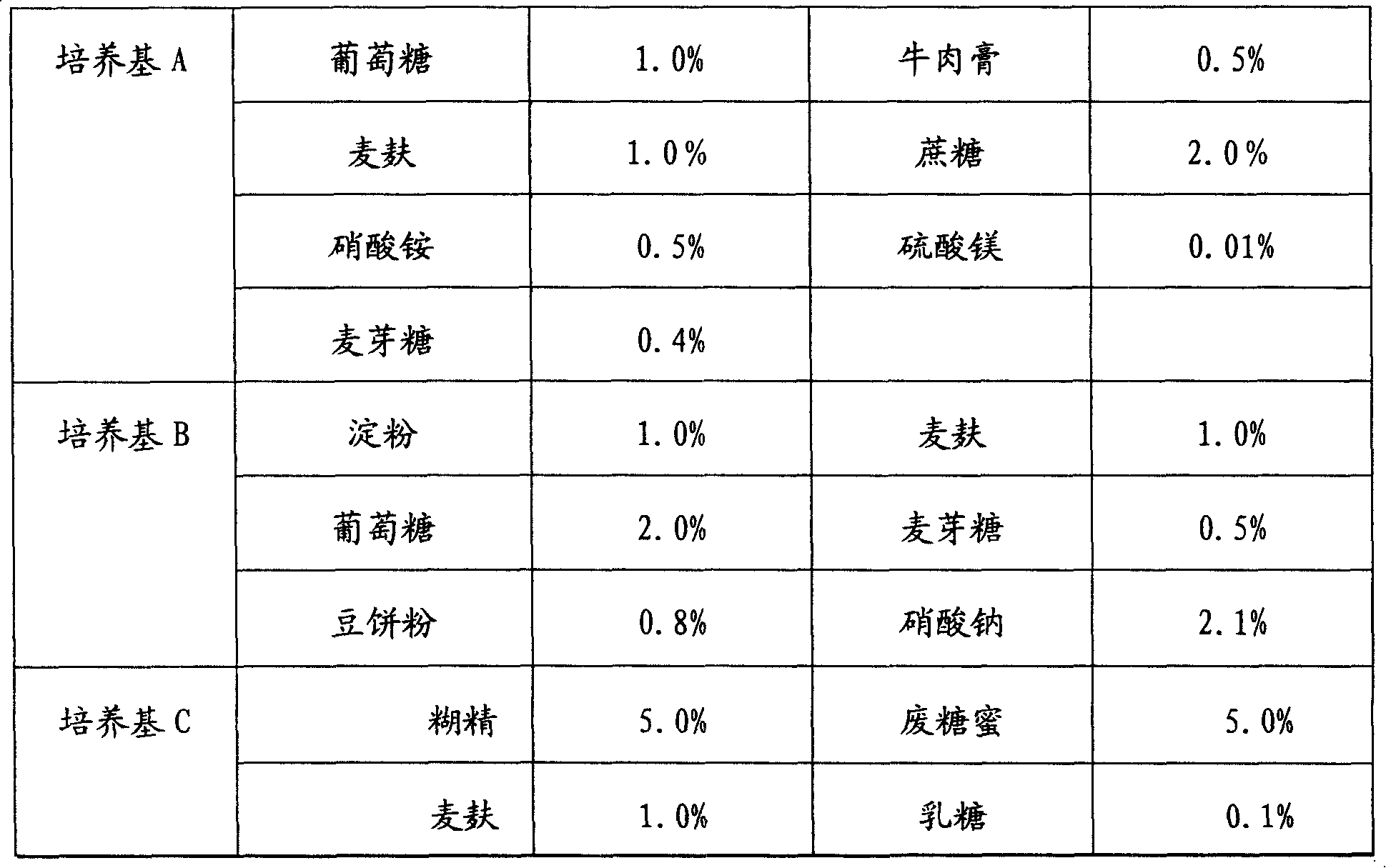

Preparation method of new natural abscisic acid

ActiveCN101041837ALower metabolismUnblockMicroorganism based processesFermentationYeastAbscisic acid

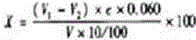

The invention discloses a preparing method of natural peel acid with flowing add muscle alcohol to absolve amylaceum repressible craft in ferment course and a new bacterial strain, which comprises the following steps: culturing fungus with generating natural abscisic acid in the first grade liquid culture medium; seeding the cultured first grade on the second liquid culture medium to culture; flowed-adding supplement material into the third grade liquid culture medium and muscle alcohol at the same time; proceeding yeast; collecting abscisic acid from the ferment culturing liquid.

Owner:江西新瑞丰生化股份有限公司

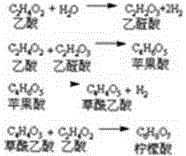

Multifunctional enzyme vinegar

InactiveCN106119055AHigh in nutrientsHigh in acetic acidMicroorganism based processesVinegar preparationRed yeast riceAspergillus niger

The invention relates to the technical field of food, and particularly relates to multifunctional enzyme vinegar. The multifunctional enzyme vinegar comprises the following raw materials in parts by weight: 10-50 parts of starch raw material, 20-60 parts of fruits, 20-60 parts of vegetable, 1-3 parts of aspergillus niger, 1-2 parts of aspergillus oryzae, 10-20 parts of Daqu, 5-10 parts of Chinese koji, 5-10 parts of red yeast rice, 2-4 parts of yeast, 0.15-0.4 part of lactic acid bacteria, and 4-7 parts of acetic acid bacteria. In the enzyme vinegar, total acid is greater than 11g / 100 mL, citric acid is greater than 2g / 100 mL, malic acid is greater than g / 100 mL, and lactic acid is greater than 1 g / 100 mL. the invention further relates to a preparation method of the enzyme vinegar. The enzyme vinegar is rich in nutrients, and mellow in mounthfeeling, the proportion of total acid to non-volatile acid is proper, and the enzyme vinegar has multiple nutritional health-care efficacies of strengthening the stomach, moistening intestine, calming down and relieving thirsty, reducing blood pressure and blood lipid, being anti-oxidant and anti-aging, and the like.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

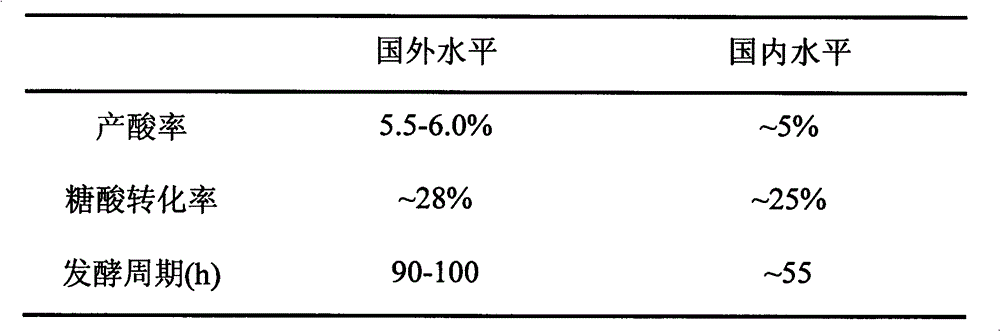

Fermentation medium for fermenting and producing glutamic acid from thermo-sensitive type strain and fermenting method for producing glutamic acid by using fermentation medium and application

The invention relates to a fermentation medium for fermenting and producing glutamic acid from a thermo-sensitive type strain. The components and the final concentration of the fermentation medium in the formula are as follows: 165-205g / L corn starch amylolysis, 15-30g / L maize slurry, 10-18g / L molasses, 0.5-1.5g / L glycine betaine, 5-10g / L bean pulp hydrolysate, 3-8g / L H3PO4, 1.25-1.75g / L MgSO4.7H2O, 0.064-0.084g / L MnSO4.7H2O, 0.055-0.085g / L FeSO4.7H2O, 3-6g / L KCl, 0.08-0.15g / L threonine, 0.8-1.2g / L succinic acid, and 0.1-0.3g / L defoamer, and the solvent is water, the pH value of the fermentation medium is 6.8-7.0 when the phosphoric acid is neutralized by alkali. Due to the appropriate carbon source, the nitrogen source, the carbon nitrogen ratio and the phosphorus content in the medium, the acid production rate is increased, the acid production of the thallus is promoted, the final acid production level is obviously improved by about 5.5% and the glutamic acid yield and the glucose acid conversion ratio are increased.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

Process for producing carbon source for processing wastewater

InactiveCN101219843AEasy to operateLess investment in infrastructureMultistage water/sewage treatmentSustainable biological treatmentAcetic acidPropanoic acid

The invention relates to a preparation method of carbon resource for treating wastewater, which belongs to the technical fields of environmental protection, the wastewater and sludge treatment.The invention is characterized in that the acidic fermentation preparation process is used for treating the carbon source of mine wastewater with sulfate and hydrochloric acid, which makes the sludge acidic fermentation products contain 42 percent-85 percent of propionic acid, 5 percent-18 percent of acetic acid and 10 percent-40 percent of butyrate, so the short chain fatty acid is unnecessary to be extracted from supernatant of acidic fermentation reactor; the supernatant of the acidic fermentation reactor is used as the carbon source of sulfate reducing bacteria and directly added into the mine wastewater with the sulfate and the hydrochloric acid and the obtained; the invention solves the key difficult problem that a biological method is used for treating the acidic mine wastewater. The sludge acidic fermentation process has simple operation and the fermentation products, propionic acid, acetic acid and butyrate, can be used as low cost carbon sources for treating acidic mine wastewater biologically; at the same time, the process achieves the quantity reduction, resource utilization and stabilization of the sludge.

Owner:TAIYUAN UNIV OF TECH

Peracid hawthorn vinegar as well as plant drink containing hawthorn vinegar and preparation method of peracid hawthorn vinegar

ActiveCN104328022AImprove conversion rateIncrease acid production rateMicroorganism based processesNatural extract food ingredientsBiotechnologyAcetobacter aceti

The invention discloses peracid hawthorn vinegar as well as a plant drink containing the hawthorn vinegar and a preparation method of the peracid hawthorn vinegar. The preparation method of the peracid hawthorn vinegar comprises the following step: by taking hawthorn juice as a raw material, fermenting with a high-yielding acetobacter aceti by using a super-fast hawthorn vinegar fermentation process. Therefore, stable automatic control of the acetic fermentation of the hawthorn vinegar is achieved, and the purpose of rapidly brewing the hawthorn vinegar is achieved. In addition, the peracid hawthorn vinegar and natural plant herbs such as the hawthorn juice, momordica grosvenori, lalang grass rhizome and mesona chinensis are scientifically combined and reasonably matched, so that the plant drink which has the effects of helping produce saliva and slaking thirst, removing summer heat and reducing the temperature, tonifying spleen and promoting the appetite as well as preventing heat and refreshing the mind can be developed. The plant drink prepared from the peracid hawthorn vinegar is sour and sweet and pure in flavor, has the specific fragrance of fermented hawthorn, and is natural and relatively healthy as no food preservative is added.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

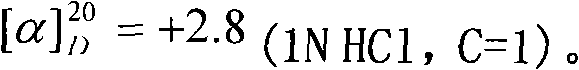

Method for preparing fermented liquid rich in L-tryptophan by utilizing rice

InactiveCN101550437APromote growthActivate Active IngredientsMicroorganism based processesFermentationEscherichia coliRecombinant escherichia coli

The invention relates to a method for preparing fermented liquid rich in L-tryptophan by utilizing rice, which is applied in the preparation of fermented liquid containing L-tryptophan. The method comprises the following steps of: (1) preparation of double enzyme glucose solution, which includes zymohydrolysis and saccharification of rice slurry by using high-temperature amylase and efficient saccharifying enzyme; (2) preparation of seed culture, which includes the steps of (2.1) dividing the double enzyme glucose solution obtained in (1) into three parts of X, Y and Z by weight according to the proportion that X : Y : Z is equal to 1 : 4 : 95, wherein X is used as sugar liquid needed by seed culture medium, Y is used as sugar liquid needed by fermentation medium and Z is used as sugar liquid needed by fed-batch sugar; and (2.2) preparing seed culture medium containing double enzyme glucose solution with the amount of X by using a conventional method and equally dividing the seed culture medium into two parts: one part is used as seed culture medium for recombinant Escherichia coli; and the other part is used as seed culture medium for corynebacterium glutamicum; and (3) fed-batch sugar fermentation by using the seed culture. The method has the advantages of improving the acid yield and the yield coefficient, shortening the fermentation period and saving the energy consumption.

Owner:福建省建阳武夷味精有限公司

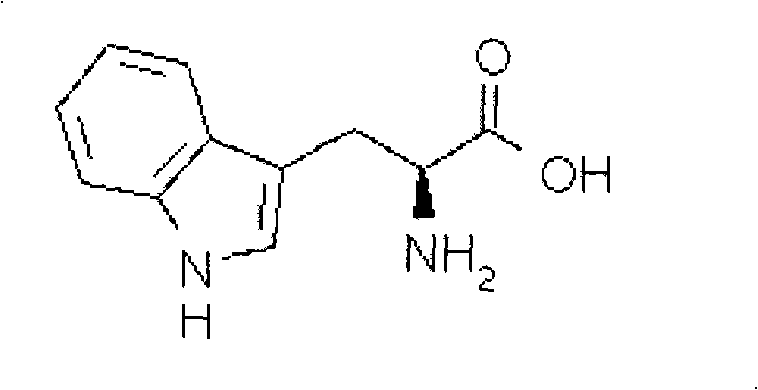

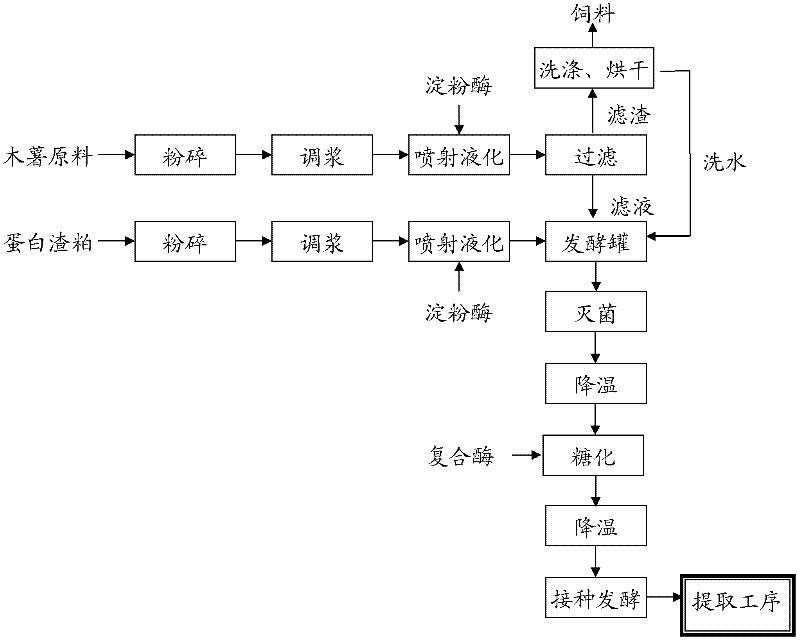

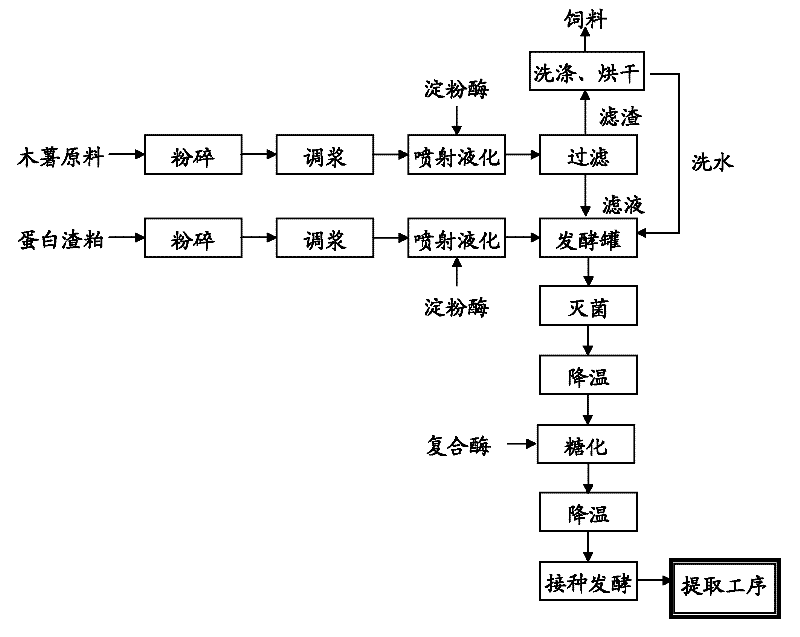

Method for producing citric acid through complete cassava fermentation

InactiveCN102399830AImprove fermentation conversion rateIncrease acid production rateMicroorganism based processesFermentationSlagFiltration

The invention relates to a method for producing citric acid through fermentation, in particular to a method for producing citric acid through complete cassava fermentation, which comprises work procedures of pulverization, size mixing, liquefaction, filtration and fermentation. Before the fermentation, acid compound enzyme is adopted for saccharifying raw materials; and during the fermentation, protein slag or protein meal is adopted as a nitrogen source. The protein slag or protein meal is added for supplementing the fermentation nitrogen source, the goal of complete non-grain fermentation is reached, the defect of poor oxygen dissolution effect in the fermentation process caused by too high cassava high-sugar fermentation material concentration can also be overcome through the addition of a filtration process, simultaneously, the residue carbon sources in the protein slag or the protein meal are utilized, the integral utilization of raw materials is realized, and the fermentation grain consumption is reduced.

Owner:RIZHAO LUXIN JINHE BIOCHEM

Genetically engineered bacterium for realizing high yield of L-isoleucine as well as construction method and application of genetically engineered bacterium

ActiveCN106701648AImprove abilitiesIncrease acid production rateBacteriaMicroorganism based processesAcetohydroxy Acid ReductoisomeraseAcetohydroxy acid isomeroreductase

The invention discloses a corynebacterium glutamicum genetically engineered bacterium for realizing high yield of L-isoleucine. The bacterium is obtained by knocking out argG genes of encoded argininosuccinate synthase and alaT genes of encoded aminotransferase from a corynebacterium glutamicum strain Corynebacterium glutamicum H5 and inserting an operon of ilvC genes of encoded acetohydroxy acid isomeroreductase into loci where the alaT genes are knocked out, wherein the corynebacterium glutamicum strain Corynebacterium glutamicum H5 is collected in China Center for Type Culture Collection (CCTCC) and has a collection number of CCTCC NO:M2016609. The invention further discloses a construction method and application of the genetically engineered bacterium. The genetically engineered bacterium provided by the invention is used for fermenting to produce L-isoleucine, and the yield and glucose acid conversion ratio can be improved.

Owner:WUHAN GRAND HOYO

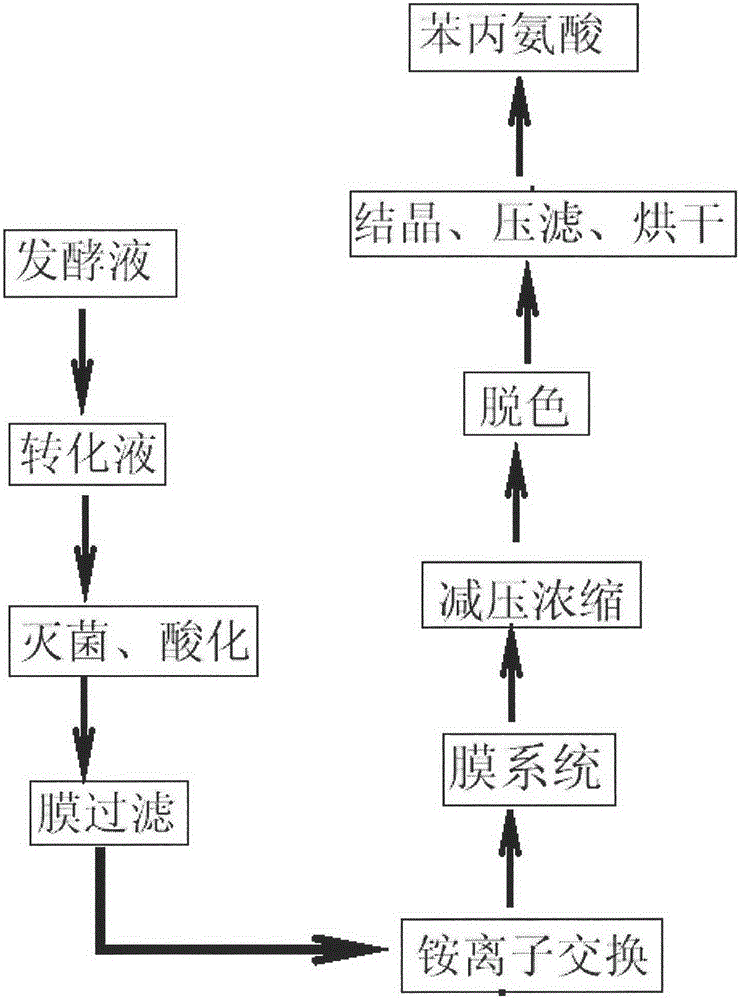

Method for extracting L-phenylalanine from fermentation liquid

InactiveCN102718671AIncrease acid production rateHigh yieldOrganic compound preparationAmino-carboxyl compound preparationEscherichia coliFiltration

The invention provides a method for extracting L-phenylalanine from fermentation liquid. The method for extracting the L-phenylalanine from the fermentation liquid comprises the following steps: (1) transforming the fermentation liquid of L-tyrosine defective type Escherichia coli under the conditions of the temperature of 32.5 to 36.5 DEG C and the pH value of 6 to 8 to obtain the transformation liquid; (2) acidizing and sterilizing the transformation liquid under the condition of the pH value of 1.5 to 2.5, performing membrane filtration and ammonium ion exchange, passing through a membrane system and concentrating under reduced pressure; and (3) decoloring a material plate frame concentrated under reduced pressure for 20 to 60 minutes under the conditions of the pH value of 3.0 to 4.5, the temperature of 62 to 65 DEG C and the mass content of active carbon of 4 to 8 percent, crystallizing, filtering and drying to obtain the L-phenylalanine. By the extraction process, the acid yield of the phenylalanine is increased from 6.0 percent to 7.0 percent, the yield of the phenylalanine is increased by 5 percent, and the first-pass yield of the finished products is increased from 96 percent to 99 percent.

Owner:JIANGSU HAN KUANG BIOLOGICAL ENG

Production of stabilized isotope 15N labelled L-valine

InactiveCN1982466AIncrease the amount of controlIncrease acid production rateMicroorganism based processesFermentationMicroorganismIsotope

Production of stable isotope 15N marked L-valine is carried out by selecting proper bacterium, slope preparing, culturing formula by fermentation, fermenting, separating and extracting. It can add micro-vitamin composite, improve growth and metabolism and decrease 15N utilization rate.

Owner:SHANGHAI RES INST OF CHEM IND

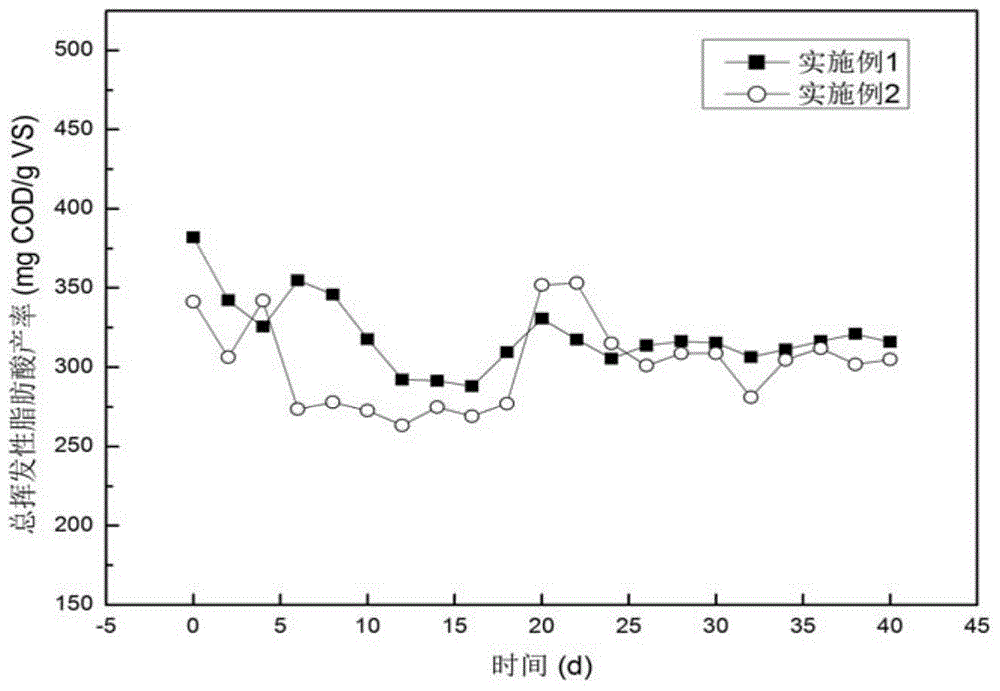

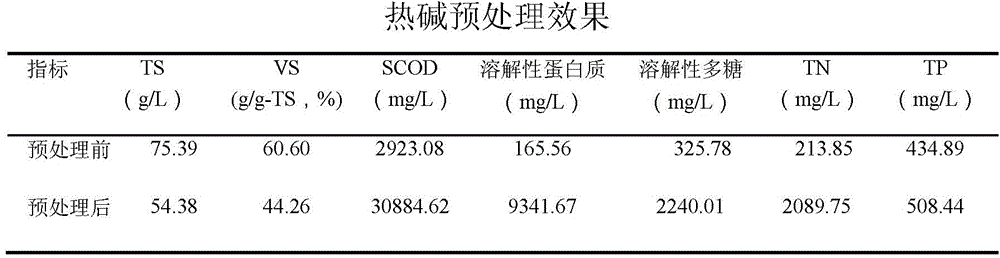

A sludge fermentation acid-producing method combining thermo-alkaline pretreatment and semi-continuous flow fermentation

InactiveCN105439407AIncrease acid production rateHas large-scale application prospectsBiological sludge treatmentContinuous fermentationContinuous flow

A sludge fermentation acid-producing method is disclosed. The method includes a step of preparing sludge to be treated into thick slurry having a concentration of 10-100 g-TS / L with water, a step of performing thermo-alkaline pretreatment and a step of subjecting the sludge subjected to the thermo-alkaline pretreatment to semi-continuous flow anaerobic fermentation, wherein the thermo-alkaline pretreatment includes adjusting the pH of the thick sludge slurry to be alkaline and heating the sludge the pH of which is adjusted.

Owner:JIANGNAN UNIV

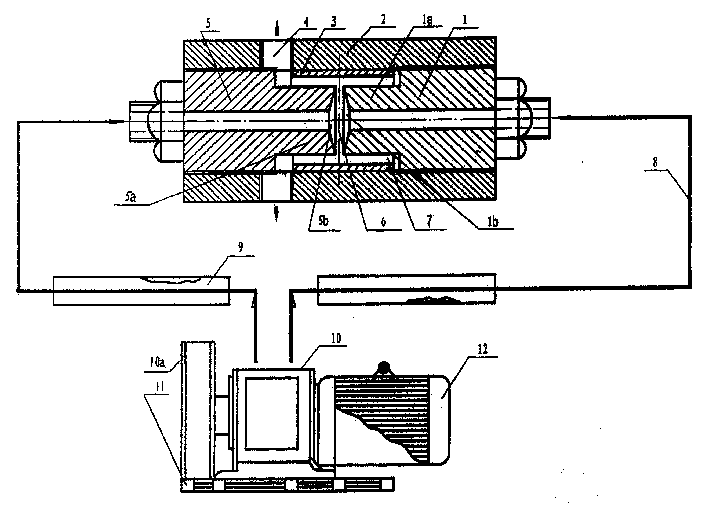

Nano biological particles made of waste thallus, and production method and use thereof, and nano-level thallus crusher

InactiveCN1528526ASave foodEliminate environmental pollution from waste bacteriaGrain treatmentsFood preparationChemistryAverage diameter

The invention provides a nano bio-particle made of waste thallus as well as its producing method and application together with the nano-level thallus crusher. The weight ratio of its raw material: waste thallus 1 share, and clear water 2-9 shares, and its average diameter is not greater than 100 nano, where the waste thallus is the waste microbe produced when producing antibiotic and fermenting food products. If the waste thallus is the one used in flavoring industry for producing, the above formula should be added with the 5'-phosphodiesterase containing clear liquid made of malt root 1 share and clear water 6-8 shares. During fermenting, it can replace grain as raw material, eliminating the environmental pollution and the harm to human beings caused by the waste thallus.

Owner:姚洪文

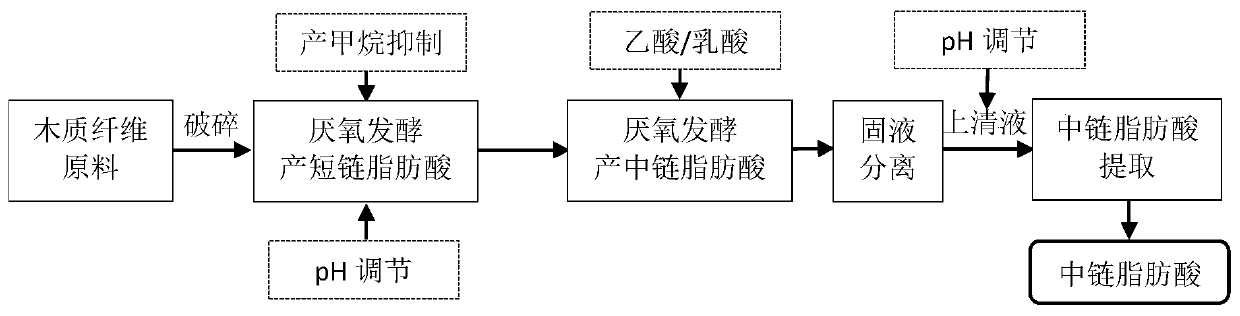

Method for producing medium-chain fatty acid through anaerobic fermentation of lignocellulosic material

The invention provides a method for producing a medium-chain fatty acid through anaerobic fermentation of a lignocellulosic material. The method for producing the medium-chain fatty acid through anaerobic fermentation of the lignocellulosic material comprises the following steps: (1) mixing the crushed lignocellulosic material and anaerobic digestion sludge according to a mass ratio ranging from 1:4 to 1:20, adjusting a pH value to be 9.0-11.0, adding a methanogenic inhibitor, and then conducting anaerobic fermentation to obtain first fermentation liquor containing a short-chain fatty acid; (2) continuing conducting anaerobic fermentation on the first fermentation liquor containing the short-chain fatty acid for 10-45 days at a fermentation temperature of 30-40 DEG C, and intermittently adding ethyl alcohol or lactic acid in the fermentation process to obtain second fermentation liquor containing the medium-chain fatty acid; and (3) conducting solid-liquid separation on the second fermentation liquor containing the medium-chain fatty acid to obtain supernate, adjusting a pH value of the supernate to be 3.0-6.0, and extracting the medium-chain fatty acid from the supernate. The method for producing the medium-chain fatty acid through anaerobic fermentation of the lignocellulosic material can not only consume the organic waste (lignocellulosic material), but also has a clean conversion process compared with a petrochemical-based technology, and thus is a clean green conversion technology.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

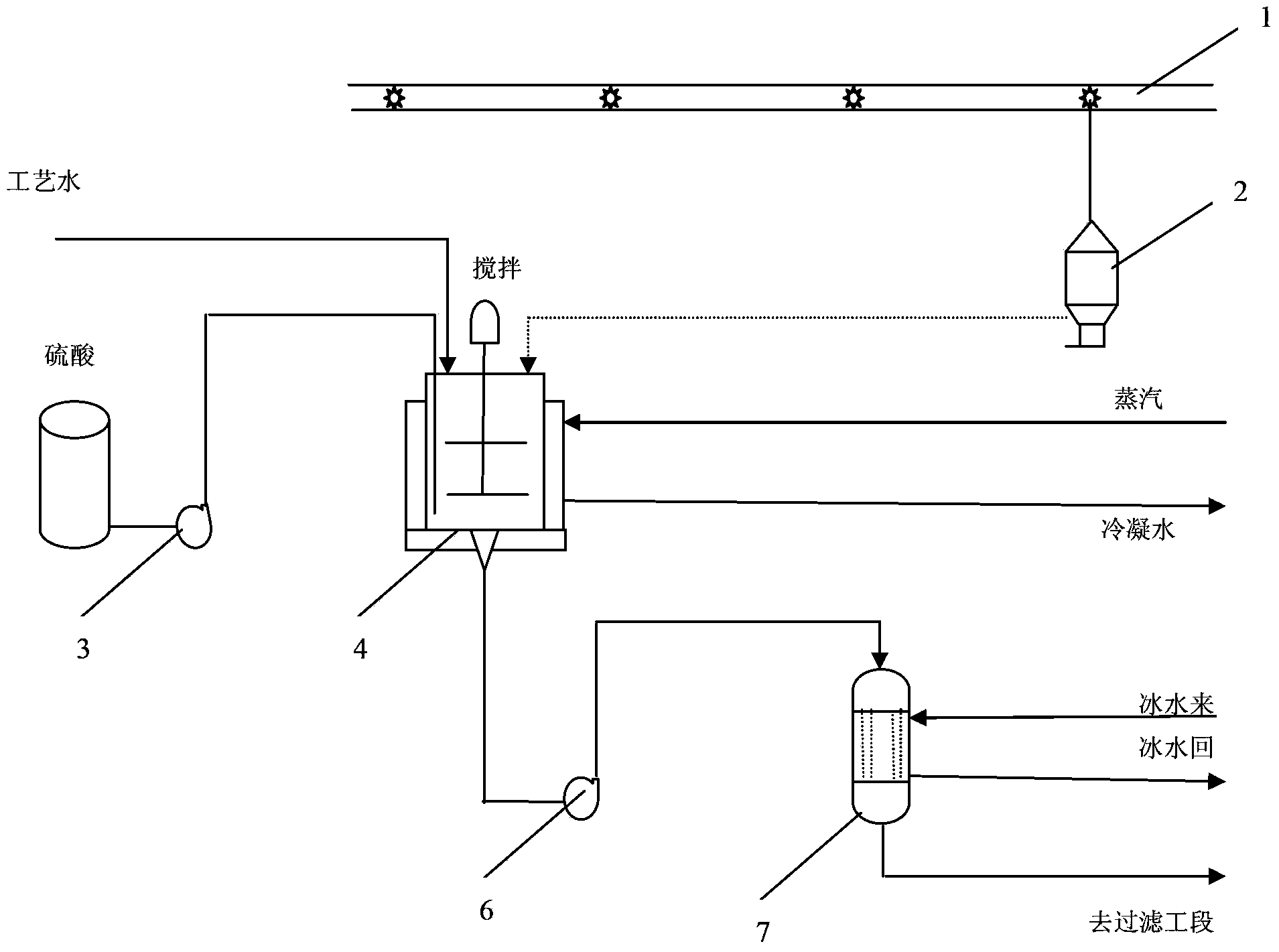

Bean pulp hydrolysis technology

InactiveCN103436566AIncrease acid production rateReduce damage to factoryFermentationHydrolysateGraphite

The invention discloses a bean pulp hydrolysis technology which comprises the steps that water and concentrated sulfuric acid are added to a graphite reaction kettle proportionally and stirred uniformly; the temperature of water and sulfuric acid mixed liquid is set; bean pulp is added to the graphite reaction kettle proportionally for the first time, heated and maintained; then the bean pulp is added to the graphite reaction kettle proportionally for the second time, heated and maintained to form bean pulp hydrolysate; and finally, the bean pulp hydrolysate is conveyed to a cooler by a bean pulp hydrolysate pump and cooled to accomplish bean pulp hydrolysis. The bean pulp hydrolysis technology increases an acid production rate of lysine fermentation in China at present, lowers the production cost overall, and greatly reduces a situation that the existing equipment is damaged in a short time and returned to a factory.

Owner:长治市金泽生物工程有限公司

Preparation method of 13C and 15N double labeled L-lysine hydrochloride

ActiveCN102174603AEfficient use ofIncrease acid production rateMicroorganism based processesFermentationBiotinCorn steep liquor

The invention relates to a preparation method of 13C and 15N double labeled L-lysine hydrochloride, comprising the following steps: (1) fermenting strain selection; (2) fermenting culture formulation; (3) fermentation process; and (4) separation and extraction. The fermentation process adopted by the invention is suitable for preparing the 13C and 15N double labeled L-lysine hydrochloride; the acid yield under the process condition is improved by 40-60% compared with the acid yield by adopting a fully synthetic culture medium, and the effect is obvious; the substances, such as homoserine, biotin and vitamin B1 and the like are added through controlling the additive amount of carbon source glucose, and inorganic nitrogen sources, such as ammonium sulfate and the like, as well as organic nitrogen sources, such as corn steep liquor and the like, thus the fermenting formulation is improved, the isotope abundance is controlled, the risk of abundance reduction is reduced, the acid yield is ensured, the isotope raw material is effectively utilized, the production cost is lowered, and the raw materials with different abundance specifications can be utilized to prepare the products with different abundances, thus satisfying various abundance requirements.

Owner:SHANGHAI RES INST OF CHEM IND

Lysine fermentation waste water processing method, and method for preparing citric acid through fermentation

InactiveCN102390906AIncrease acid production rateThe promotion effect is obviousMultistage water/sewage treatmentFermentationAmylaseIon content

The invention provides a lysine fermentation waste water processing method. The method comprises steps that: lysine fermentation waste water contacts anion exchange resin, such that a contact liquid is obtained; with a contacting condition, the sulfate ion content in the contact liquid is lower than 0.05wt%; the obtained contact liquid is mixed with lysine wet sugar manufacturing waste water, such that the ammonium ion content in the obtained mixed liquid is 0.01-0.1wt%, and the protein content in the mixed liquid is 0.1-1.0wt%; the obtained mixed solution contacts a crushed starchiness material under the existence of amylase, such that an enzymolysis product is obtained. The invention also provides a method for preparing citric acid. According to the method, the enzymolysis product is adopted as a culture medium. With the methods provided by the invention, circular utilization of the lysine waste water is improved, waste water processing cost is effectively reduced, water adopted in citric acid production is saved, citric acid fermentation level is improved, and citric acid production cost is reduced.

Owner:COFCO BIOTECHNOLOGY CO LTD

Cultivating method for high-yield itaconic acid strain

InactiveCN101215524AHigh yieldIncrease profitFungiMicroorganism based processesSaccharic acidBiotechnology

The invention discloses a method for breeding strain with highly yield itaconic acid, wherein selecting strain with producing itaconic acid as depart strain, which is cultured in an incubator after culturing, separation and purification, selecting bacterial colony which has large color-changing loop, wherein the spores are picked on a test tube inclined-plane for culturing to obtain mature spores which have high-yield itaconic acid via shaking table. When producing itaconic acid which is produced by the strain utilizing the method, saccharic acid percent conversion is capable of achieving 65%, acid production via invoice method is capable of achieving 9.01g / 100ml, improving productivity of the itaconic acid, reducing residual sugar content of fermentation liquor, thereby facilitating the processing of subsequent abstraction process such as filtration of the fermentation liquor and the like, simultaneity, improvement of acid production ratio also increases availability ratio of raw materials, thereby reducing cost of production.

Owner:QINGDAO LANGYATAI GRP

Method for improving methane yield of primary sludge through utilizing expanded granular sludge bed

InactiveCN103172241APromote hydrolysisIncrease acid production rateWaste based fuelBiological sludge treatmentChemical oxygen demandSludge

The invention belongs to the technical field of environmental protection, and in particular relates to a method for improving the methane yield of primary sludge through utilizing an expanded granular sludge bed. The method comprises the specific steps of: firstly carrying out anaerobic hydrolysis acidification on the primary sludge under the alkaline condition so as to obtain supernatant liquor which contains a great quantity of short-chain fatty acids, and then, feeding the supernatant liquor into the expanded granular sludge bed (EGSB) to efficiently and continuously generate methane. The hydrolysis and acid production rate of non-soluble organic matters (such as protein and carbohydrate) in the primary sludge can be increased, so that more short-chain fatty acids are obtained, and moreover, the organic matters can be efficiently converted into the methane in the EGSB, thus the environmental pollution of the sludge is reduced. According to the method, the pH value of the primary sludge is regulated to be 8-12, the primary sludge is stirred at 30-40 DEG C for 6-10 days to be anaerobically fermented, the supernatant liquor of the primary sludge is collected, and the pH value of the supernatant liquor is regulated to be 6-8; and then, the supernatant liquor is filled into the EGSB to be fermented, the methane is anaerobically generated under the intermediate temperature anaerobic fermentation condition of 33-37 DEG C and the organic load (the organic matter removal amount in a unit time per unit volume of the bed) of 5-45kg COD (chemical oxygen demand) / m<3> / d.

Owner:TONGJI UNIV

Method for fermenting temperature-sensitive strains by phosphoric acid to produce glutamic acid

The invention relates to a method for fermenting temperature-sensitive strains by phosphoric acid to produce glutamic acid. In a fermentation production process, the phosphoric acid is used for replacing phosphate in a process for fermenting the temperature-sensitive strains to produce the glutamic acid to prepare a fermentation culture medium; the glutamic acid is produced through fermentation. In the fermentation process of the method provided by the invention, the equal mol equivalent of the phosphoric acid is used for replacing the phosphate of the fermentation culture medium, and then a pH (Potential of Hydrogen) value of fermentation culture is neutralized by utilizing an alkaline substance; on one hand, the disadvantages that the time for completely dissolving the phosphate into water is long so that the fermentation culture medium is not uniformly mixed easily can be overcome, the preparation time of the fermentation culture medium is shortened and the production efficiency is improved; on the other hand, the acid production speed can be improved, a fermentation period is shortened and acid production of thalli is facilitated, so that the production cost is reduced; the acid production ratio and the saccharic acid invert ratio are improved; finally, the acid production level is also remarkably improved and can be improved by about 15 percent; the yield of the glutamic acid and the saccharic acid invert ratio are improved; the method has a wide industrial application prospect.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

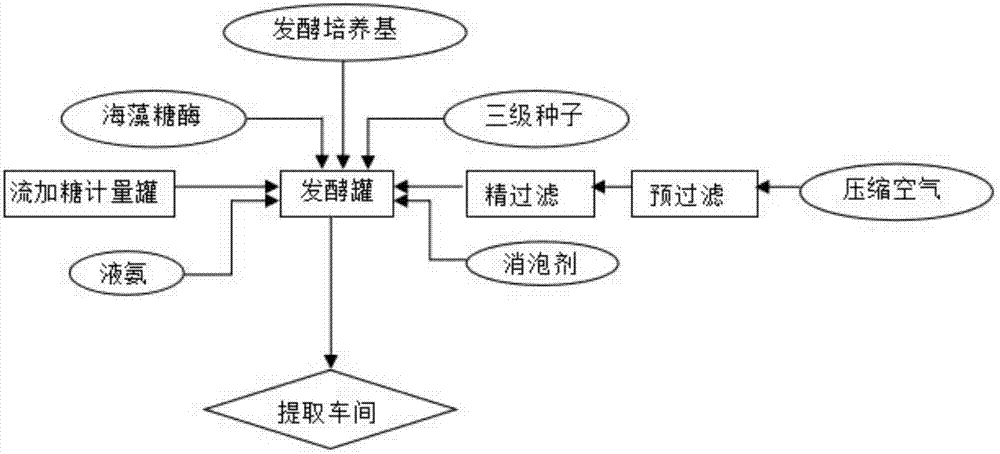

Method for improving glucose acid conversion rate of glutamic acid fermentation through adding trehalase

InactiveCN107058415AImprove conversion rateIncrease acid production rateFermentationTrehalaseD-Glucose

The invention relates to a method for improving the glucose acid conversion rate of glutamic acid fermentation through adding trehalase. The trehalase is added in a later period in the glutamic acid fermentation process, wherein the adding time is 20-32h during a fermentation period, the temperature is required to be 30-40 DEG C during addition and the adding ratio is 0.1-100ppm. The fermentation operation condition before enzyme connection is invariable. According to the method, the glucose acid conversion rate of glutamic acid fermentation can be improved, the acid yield can be improved, and meanwhile, the consumption of sugar can be reduced. Due to the method, the utilization rate of the fed sugar in the later fermentation period is improved, the consumption of the fed sugar is reduced, meanwhile, the sugar concentration in a fermentation liquid is reduced, electro-crystallization such as post-extraction of glutamic acid is facilitated, and thus, the method plays a great role in improvement of the quality of a glutamic acid product.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

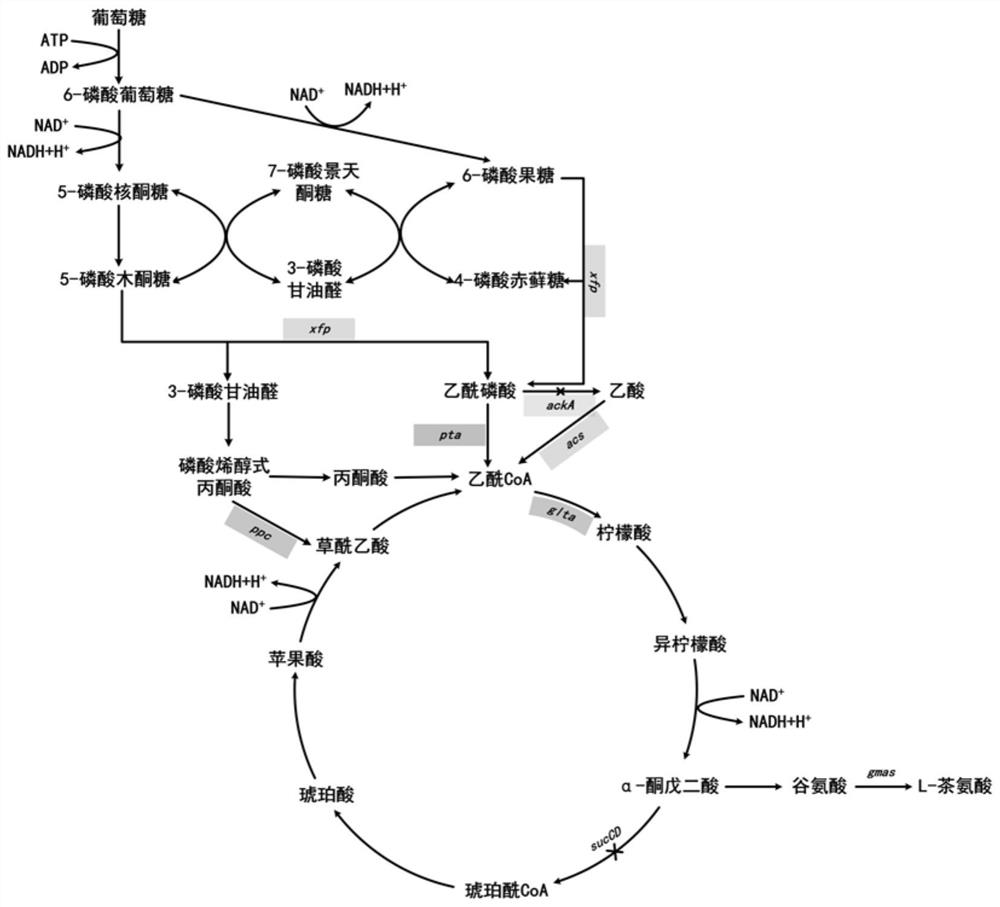

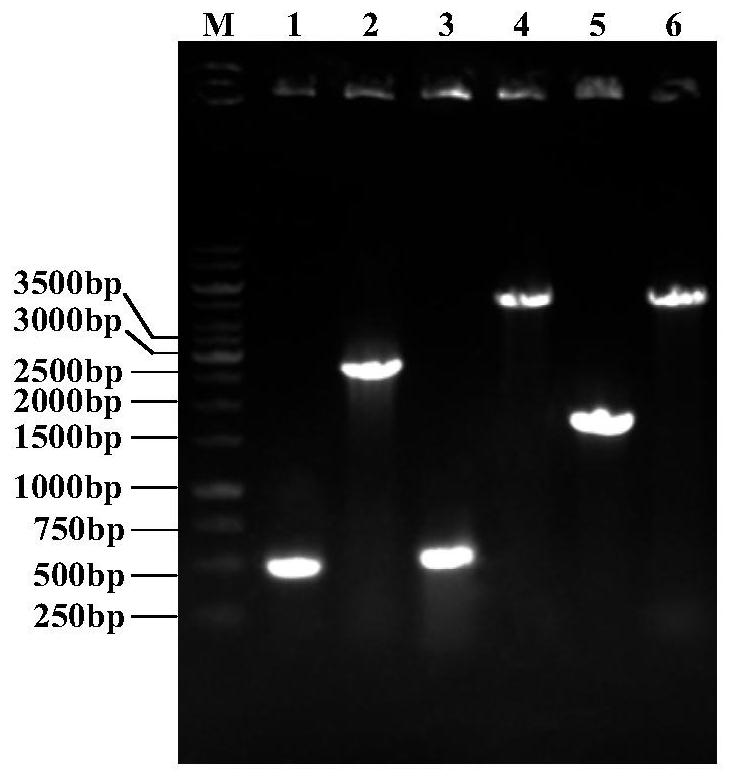

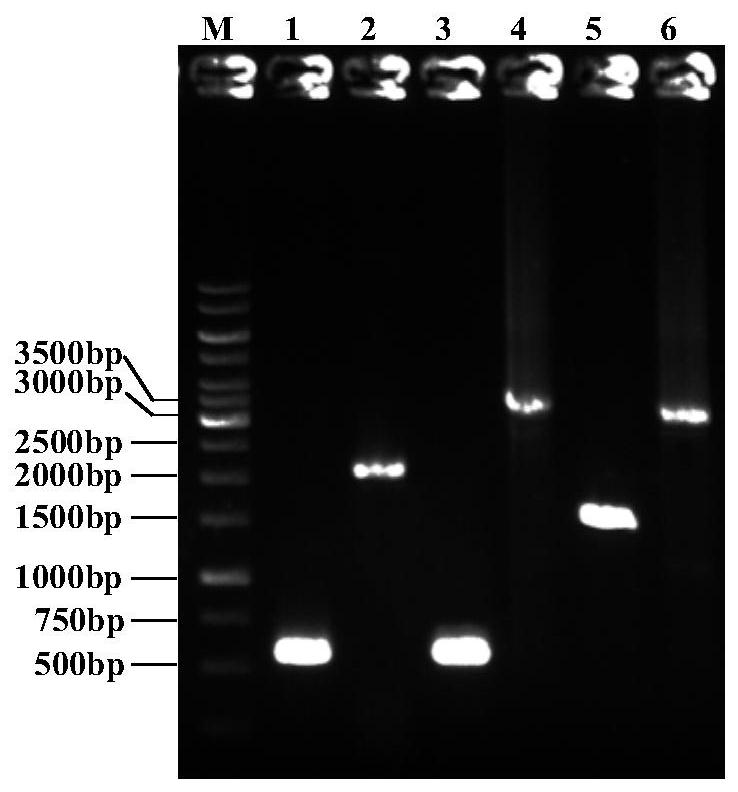

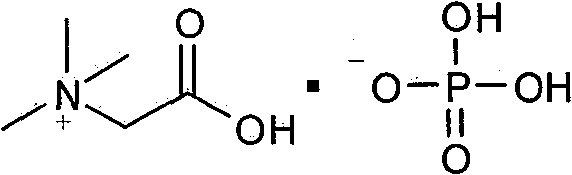

Escherichia coli genetically engineered bacterium and method for producing L-theanine by fermenting escherichia coli genetically engineered bacterium

PendingCN113774075AEffective control of concentrationStrong toxic effectBacteriaGenetically modified cellsEscherichia coliSaccharic acid

The invention belongs to the field of bioengineering, and particularly relates to a method for producing L-theanine by fermenting escherichia coli genetically engineered bacteria. The engineering bacterium is obtained by taking a strain obtained by single copy of T7RNAP, double copy of gmas, knockout of xylR and knockout of sucCD on an escherichia coli W3110 genome as a starting strain, integrating xfp, pta, acs, gltA and ppc on the genome and knockout of ackA. According to the present invention, the L-theanine is efficiently synthesized from the beginning by using the cheap carbon source such as glucose as the substrate by using the OD-linked ethylamine supplementing strategy, the saccharic acid conversion rate is high, the production performance is stable, the yield of the L-theanine can achieve 75-80 g / L after 20-25 h, and the saccharic acid conversion rate achieves 52-55%; the fermentation liquor is purified by adopting a membrane separation and anion-cation resin tandem technology, the primary crystallization yield is 72.3%, and the purity of the finished product of L-theanine reaches 99%.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fermentation method for preparing L-amino acid

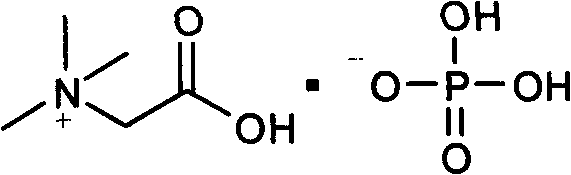

ActiveCN101235401BIncrease acid production rateEase of industrial productionMicroorganism based processesFermentationBetainePhosphate

The invention relates to a method for preparing L-amino acid through fermenting. The method of the invention uses fermentation additive betaine phosphate. With the method of the invention, the acid yield of the L-amino acid can be prominently increased, the cost of manufacture is lowered, and the method is suitable for large-scale industrial production.

Owner:山东祥维斯医药科技有限公司

Kojic acid producing process

The present invention relates to a production process of kojic acid and belongs to the preparation of oxygenous organic compound. The production process includes liquefying and saccharifying starch in a fermenting tank; inoculating to sterilized saccharide liquid to culture kojic acid via fermentation; and refining kojic acid through concentration and crystallization of kojic acid liquid, dissolving crystallized product, decoloring, cooling and crystallization to obtain kojic crystal. The product is homogeneous crystal with purity over 98%.

Owner:山东中舜科技发展有限公司

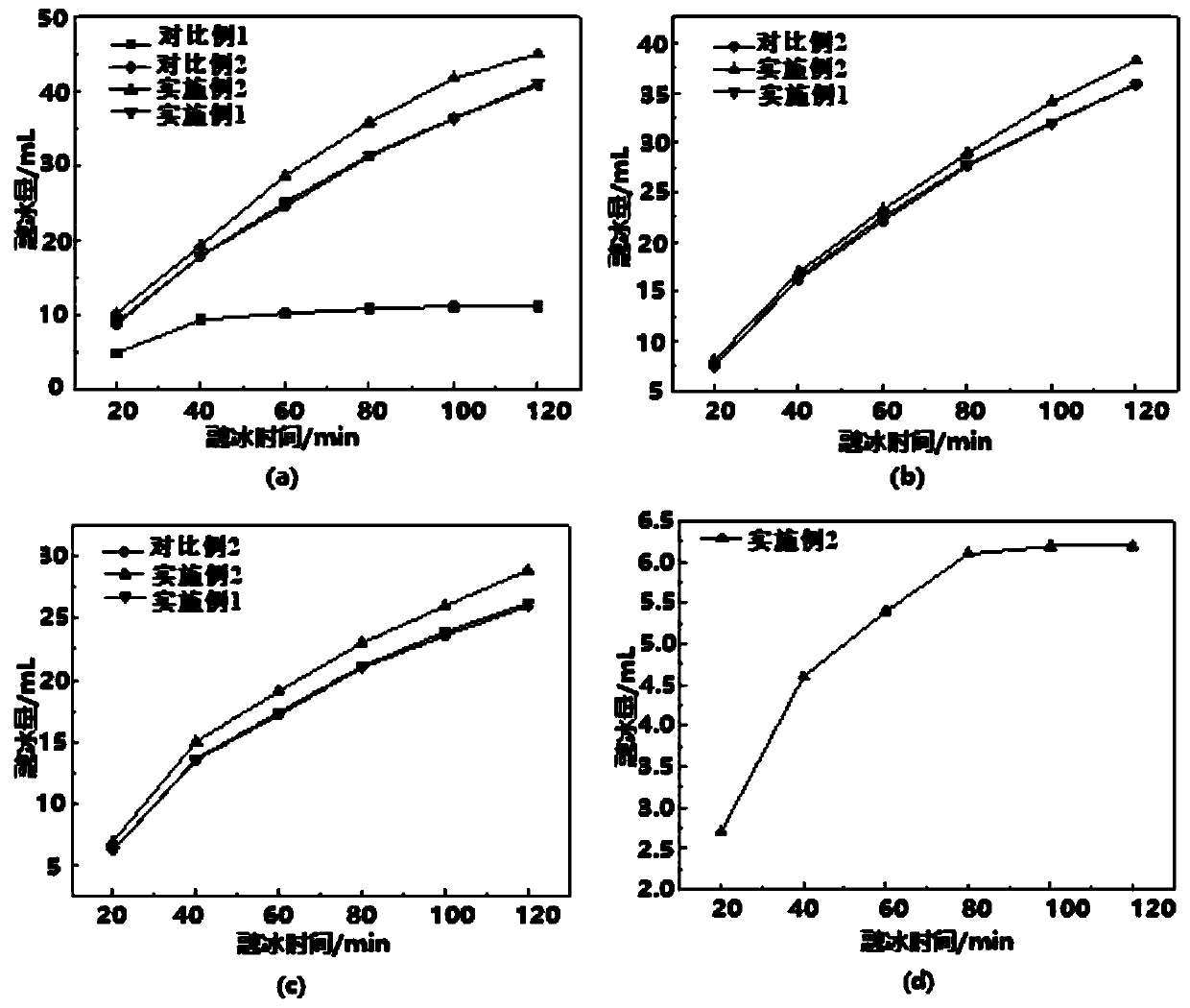

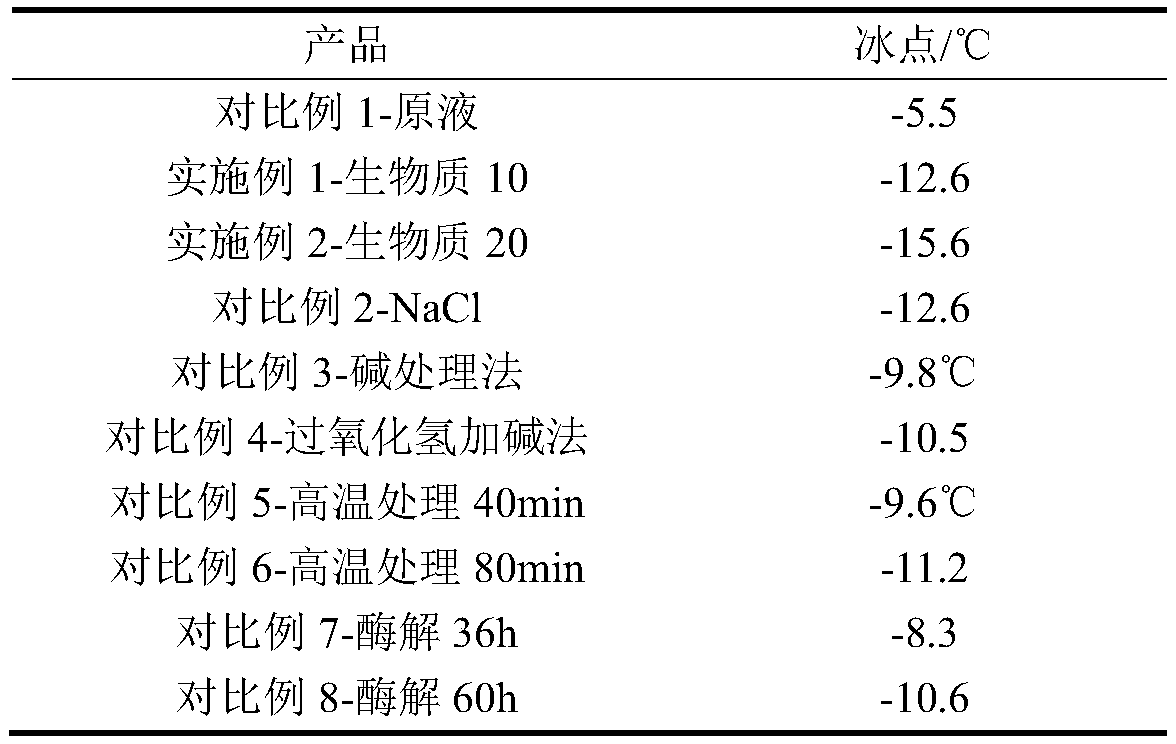

Ice melting agent raw liquor, method for preparing ice melting agent raw liquor through straw powder and application of ice melting agent raw liquor

PendingCN110241139AAchieve recyclingRealization of generationOther chemical processesMicroorganismsSolventNo production

The invention discloses ice melting agent raw liquor, a method for preparing the ice melting agent raw liquor through straw powder and an application of the ice melting agent raw liquor. The method comprises the following steps of performing potato-straw fermentation circulation for many times, collecting potato fermentation filtrate obtained through the potato-straw fermentation circulation each time for mixing to obtain filtrate a, collecting straw fermentation first filtrate obtained through the potato-straw fermentation circulation each time for mixing to obtain filtrate A, mixing the filtrate a with the filtrate A in the equal volume, and adjusting pH to neutral so as to obtain the ice melting agent raw liquor; and adding a solubilizer and a stabilizing agent to the ice melting agent raw liquor to obtain an environmental-friendly type ice melting agent. According to the ice melting agent raw liquor and the method for preparing the ice melting agent raw liquor disclosed by the invention, the potato-straw fermentation circulation is performed for many times, two stages of potato enzymolysis fermentation and straw enzymolysis fermentation are integrated, the freezing point and the ice melting rate of obtained products are both close to those of a sodium chloride solution having the same concentration, no production of waste water and waste materials in the production procedure is realized, trash is utilized, the raw material cost of new products is greatly reduced, influence to environment is small, and the application range is wide.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Glutamic acid preparation method

InactiveCN102925507AShorten the fermentation cycleIncrease acid production rateFermentationEcologyBiotin

The invention discloses a glutamic acid preparation method. The preparation method which adopts comprises the following steps: inoculating bacterial strains into an inclined surface; carrying out primary shake flask seed culture; utilizing a secondary seed tank to carry out the enlarged culture of nutrition cells; utilizing a tertiary seed tank to carry out primary transition cell culture; carrying out fermentation culture through using a super-suboptimal improving technology; carrying out secondary transition in a fermentation tank; and carrying out a high-biotin tween-60 technology. The method has the advantages of effective shortening of the fermentation time, acid production improvement, discharge reduction, and generation of great influences to the improvement of economic benefits, and social benefits comprising environmental protection and the like.

Owner:SHANGHAI GUANSHENGYUAN TIANCHU FLAVORING

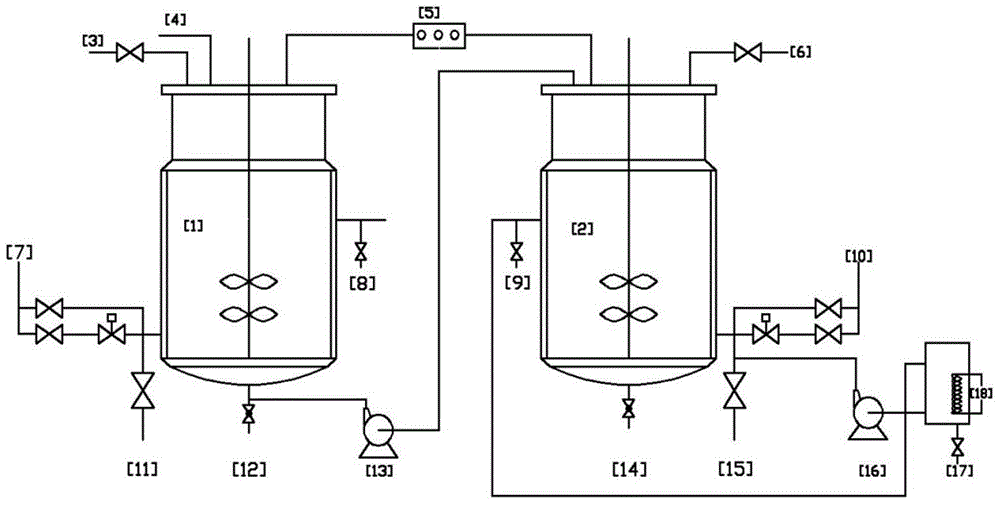

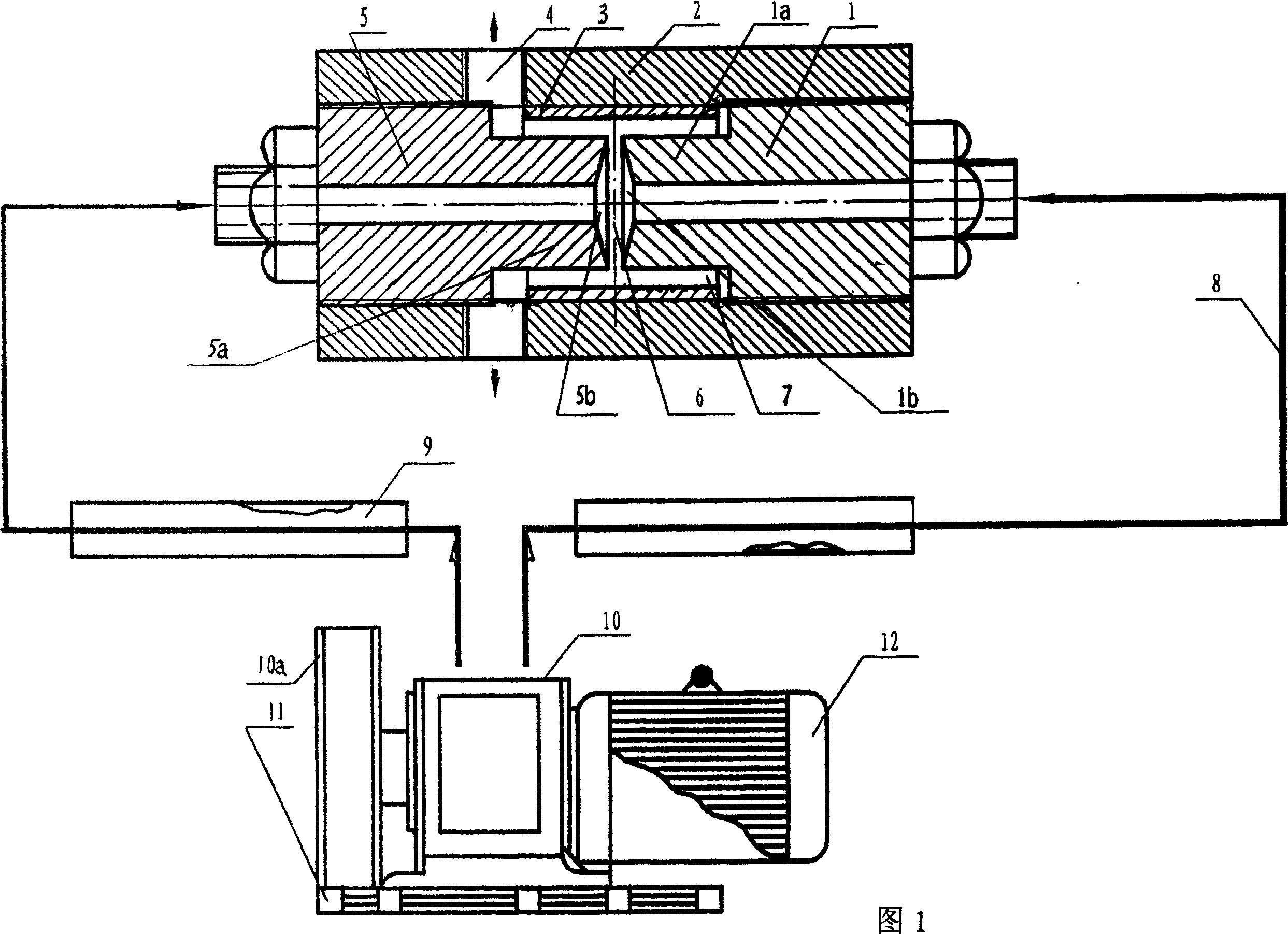

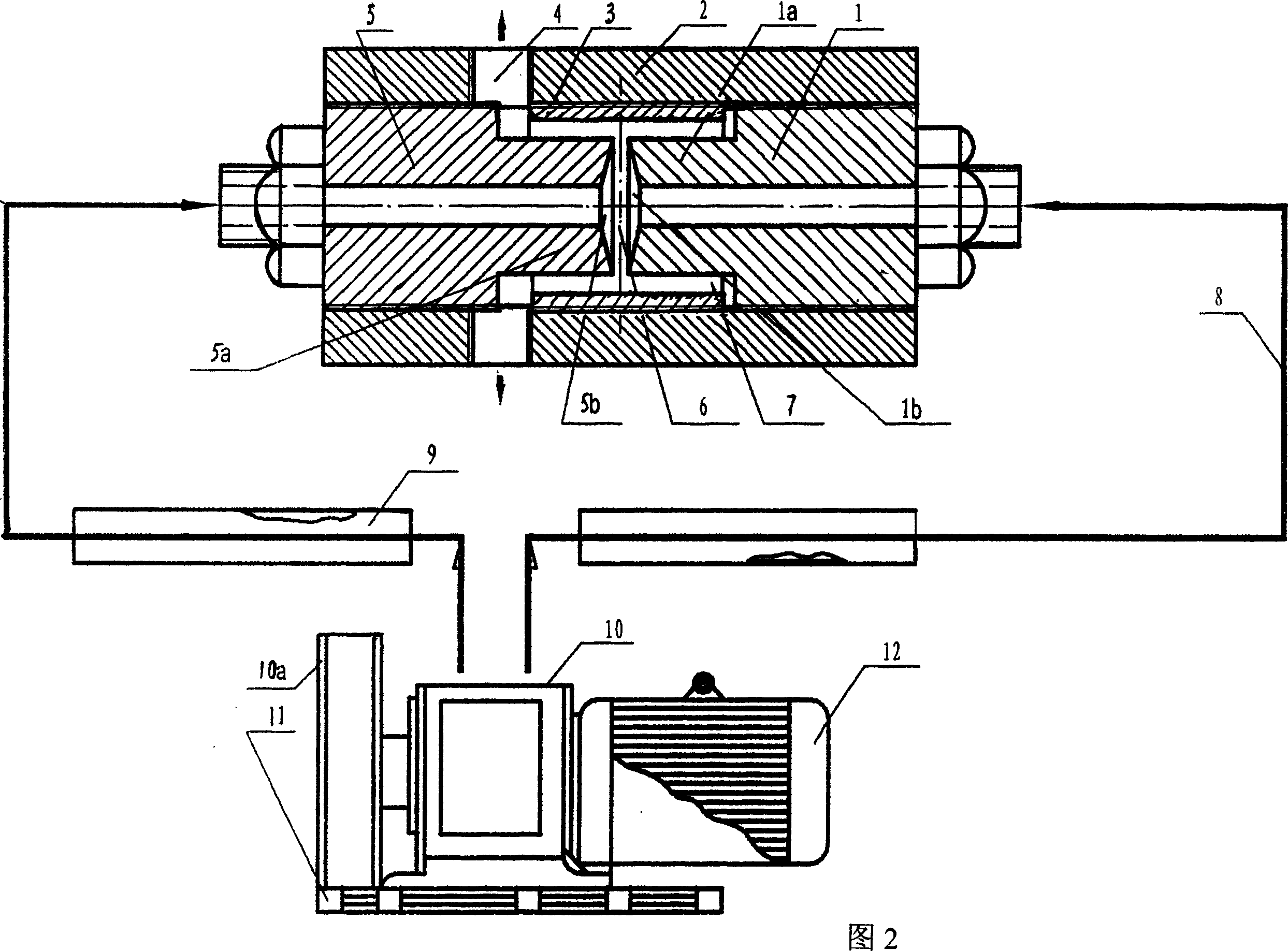

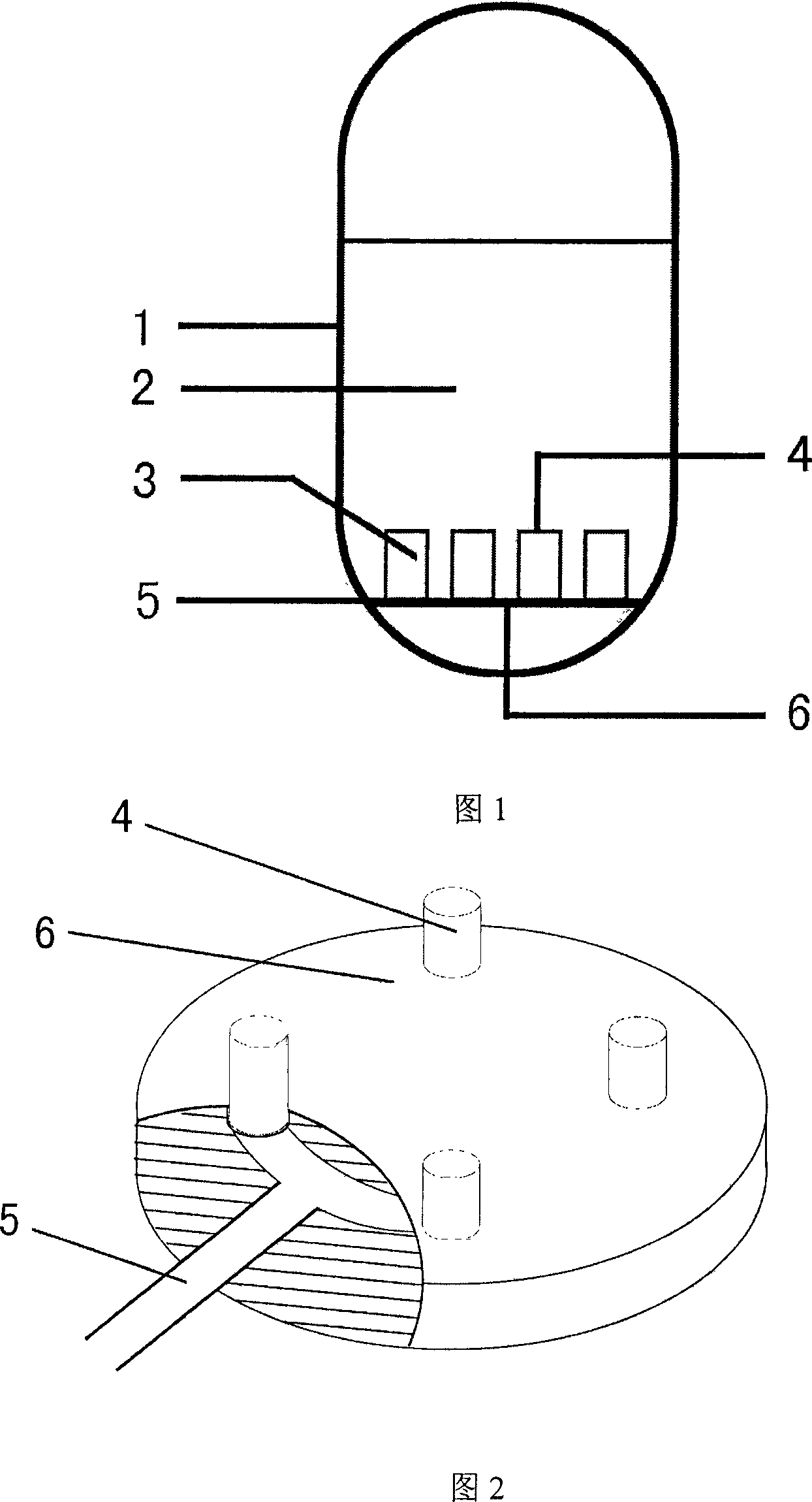

Preparation method of liquid edible vinegar and special reactor

InactiveCN1904028AImprove oxygen transfer coefficientMeet growthVinegar preparationProduction rateLiquid state

The present invention relates to a preparation method of liquid edible vinegar and its special-purpose reactor. Said preparation method includes the following steps: adding fermenting mash liquor into a fermentation cylinder, introducing air into a reactor positioned in the bottom portion of said fermentation cylinder, making the air be uniformly escaped from said reactor and penetrated into fermenting mash liquor to make the gas and liquid in fermenting mash liquor be fully atomized continuously for 25-30 hr so as to obtain liquid edible vinegar. Said invention also provides the concrete structure of its special-purpose reactor.

Owner:山东云德食品有限公司

Preparation method of beer dreg and apple cider vinegar raw stock and apple cider vinegar beverage

InactiveCN110713894AStrong anti-corrosion and fresh-keeping effectHigh alcohol contentMicroorganism based processesVinegar preparationBiotechnologyMicroorganism

The invention discloses a preparation method of beer dreg and apple cider vinegar raw stock. Beer dregs and apple pulp are mixed and fermented together, so that additional values of the beer dregs canbe sufficiently utilized; since a proper amount of lactic acid is added to adjust the pH value when beer is brewed, the lactic acid can be retained in the beer dregs, the lactic acid is capable of promoting the progress of yeast fermentation at an alcohol fermentation stage, after the beer dregs are added, the alcoholic strength of a fermentation liquor after 7 days of fermentation is higher thanthat of a fermentation liquor which is made by fermenting apple pulp for 7 days independently, desired alcoholic strength can be rapidly achieved with the beer dregs, and the fermentation time can beshortened; in addition, the lactic acid has a very good preservation and fresh-keeping effect, is capable of inhibiting growth of microorganisms, is beneficial to long-term preservation of apple cider vinegar, is capable of prolonging the shelf life, maintaining the stability of active substances in the apple cider vinegar and apple cider and has functions of bacteriostasis, flavoring and maintenance of the color of an apple cider vinegar beverage; in addition, because of the unique sour taste of the lactic acid, the delicious taste of the apple cider vinegar beverage can be enhanced, the sour taste of the apple cider vinegar beverage can be good and soft, and the taste quality of a fruit vinegar beverage can be improved.

Owner:JINLIN MEDICAL COLLEGE

New lactic acid fermentation technology

InactiveCN104328146AShort fermentation cycleIncrease acid production rateFermentationCarbon steelHigh rate

The invention relates to a new lactic acid fermentation technology which is suitable for the fermentation of fruits of plants, and belongs to the technical field of biological chemical engineering. The new lactic acid fermentation technology is as follows: grinding rice, liquefying the rice, saccharifying the rice, adding trace amino acids into a carbon steel tank for fermentation, and is characterized in that: proper amount of calcium hydroxide is added online in the fermentation process, the pH value of the proper amount of calcium hydroxide solution is 6-7, and a reaction container is the carbon steel tank. The new lactic acid fermentation technology has the advantages of short fermentation period, high rate of lactic acid production, good purity and the like.

Owner:陈丽

Method for preparing citric acid by fermenting cassava raw material residue-removed clear solution with aspergillus niger

InactiveCN102864183ARaise the level of fermentationIncrease acid production rateMicroorganism based processesFermentationSporelingSterile water

The invention provides a method for preparing citric acid by fermenting a cassava raw material residue-removed clear solution with aspergillus niger. Citric acid fermentation conditions are researched by taking the aspergillus niger as a starting strain and taking a cassava raw material clear solution as a raw material. The method comprises the following steps of: filling 50mL of fermentation culture medium into a triangular flask of 250mL; inoculating by adopting spores; eluting a fresh inclined surface, which is cultured for seven days, with sterile water; preparing a spore suspension in a volumetric flask of 50mL; sucking a certain amount of spore liquid with a sterile suction tube for inoculating; tying with a layer of flannel; putting onto a rotary shaking table; and culturing on the shaking table at the rotating speed of 300 revolutions per minute and at the temperature of 39+ / -1 DEG C for 72-96 hours.

Owner:太仓市茂通化建有限公司

Preparation method of new natural abscisic acid

Owner:江西新瑞丰生化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com