Nano biological particles made of waste thallus, and production method and use thereof, and nano-level thallus crusher

A technology of biological particles and production methods, applied in the fields of application, food preparation, grain processing, etc., to achieve the effect of saving food and eliminating environmental pollution from waste bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: utilize waste thalline to produce the method for nano biological particle, it may further comprise the steps:

[0023] ①Treat the waste cells: use the waste microorganisms produced at the end of fermentation by the microorganisms used in the production of antibiotics and food product fermentation as waste cells raw materials, take 10 kg of oxytetracycline waste mycelia (or penicillin waste mycelia, cephalosporins, etc.) Phalline waste thallus, streptomycin waste mycelia, Lin Ke waste thalline, gentamycin waste thalline, Pseudomonas, Bacillus cereus), add 80 kilograms of clear water, stir, be mixed with emulsion, pass 40-mesh sieve to remove large sundries, sand, stones, metal objects, etc., store at natural room temperature, and wait for use. ② Production of nano-biological particles: start the nano-scale cell crusher, pour the above-mentioned emulsion of waste cells into In the material port of the crusher, after the emulsion is cooled by the infusion tub...

Embodiment 2

[0024] Embodiment 2: utilize waste thalline to produce the method for nano biological particle, it may further comprise the steps:

[0025] ①Treat the waste cells: use the waste microorganisms produced by the microorganisms used in the production of antibiotics and food product fermentation at the end of the fermentation as the raw materials of the waste cells, take 10 kg of brewer's yeast (or short corynebacterium), add 75 kg of water, and stir , formulated into an emulsion, passed through a 40-mesh sieve to remove large debris, sand, stones, metal objects, etc., and stored at natural room temperature until use. The waste thallus used above is the waste thallus used in the production of the condiment industry, and further deep treatment is required: take another 1 part by weight of malt root, add 7 kg of clear water, and extract (leaching) at a temperature of 4°C After 20 hours, filter out the solids, take the clear liquid (containing 5'-phosphodiesterase) and pour it into th...

Embodiment 3

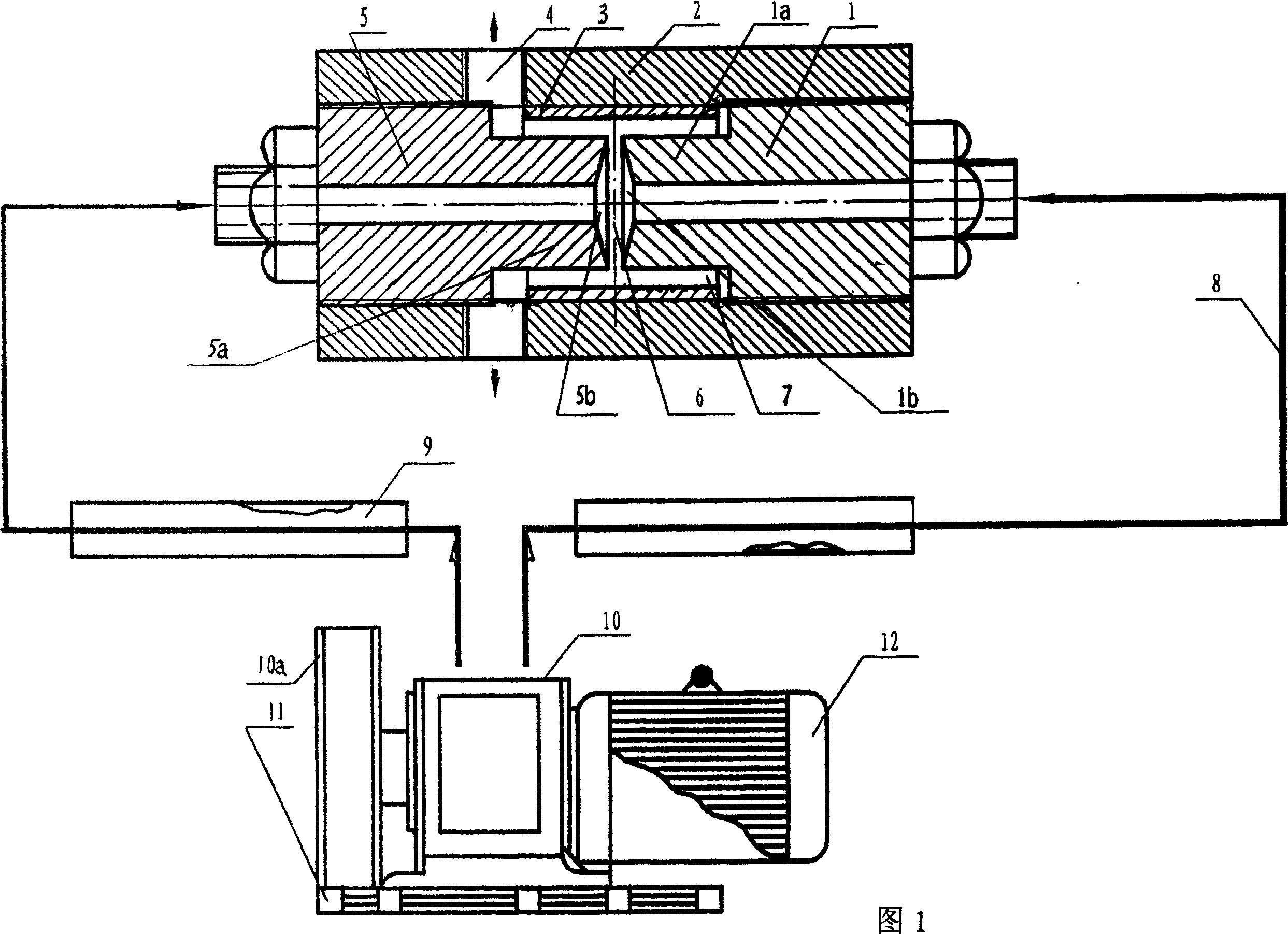

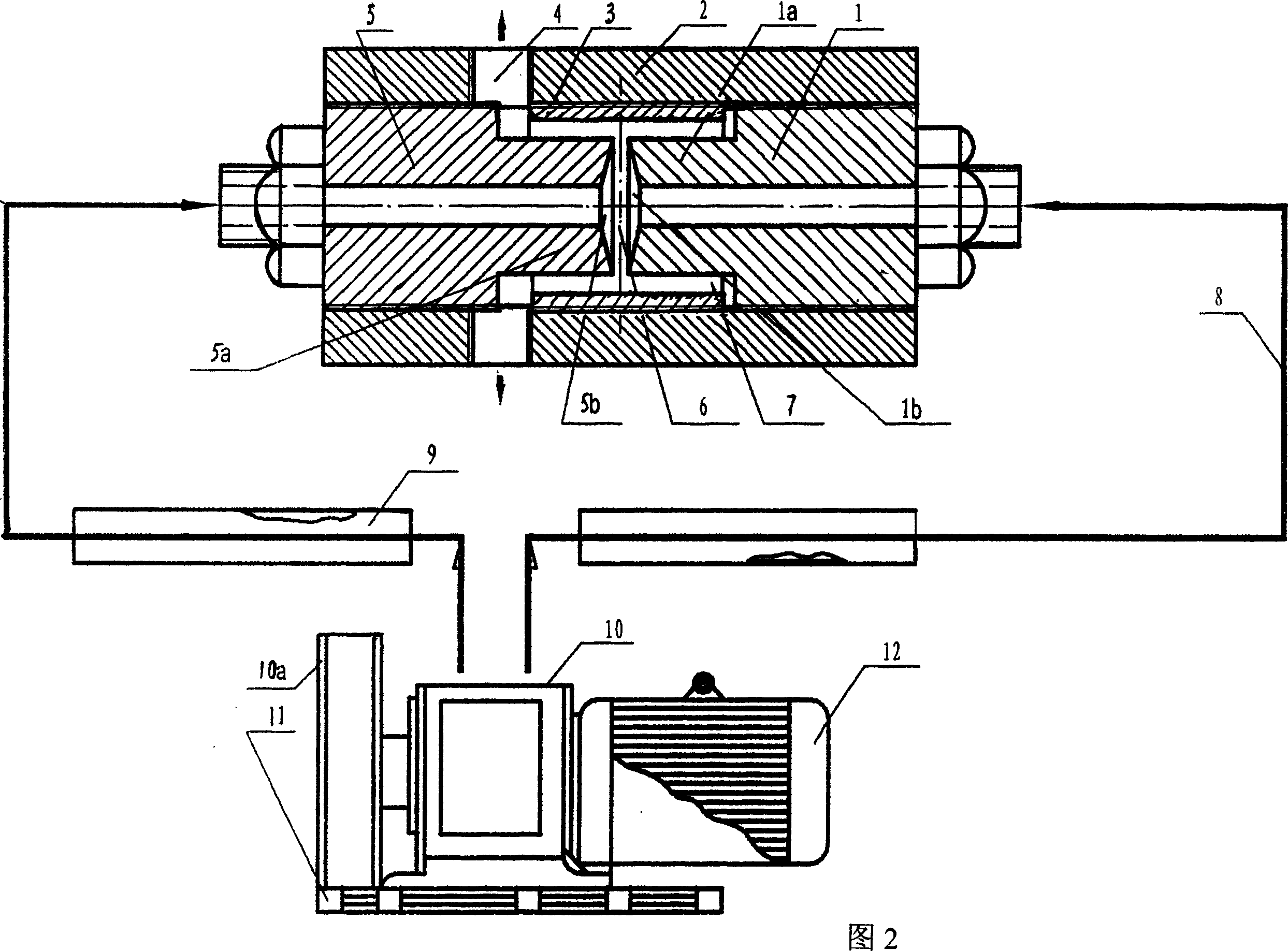

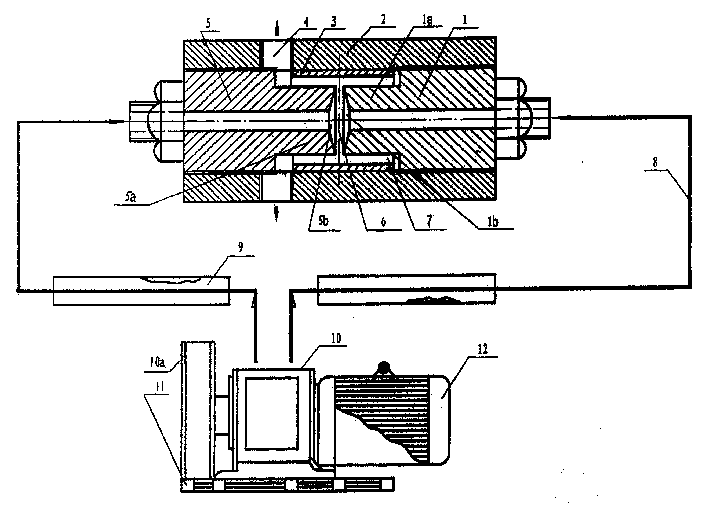

[0026] Embodiment 3: The technical scheme of the nanoscale bacterium disruptor is described in detail below. As shown in Figure 1, the nano-scale bacterium crusher has a base 11, a power source (motor) 12, a high-pressure pump 10, two infusion tubes 8, a casing 2, and an infusion tube that is sealed and fixedly connected with the casing. Two nozzle bodies 1 and 5, its inner wall as the cylinder body (cylinder) 3 of collision wall, two material coolers 9 that cool the material in the two infusion pipes respectively. The casing 2 has a circular through hole with internal threads at both ends, the nozzle body 1 (and the nozzle body 5) has a connecting part with the casing 2 (this part has external threads), the nozzle 1a (and the nozzle 5a ), the hexagonal screw head for installation on the other side of the spray head and the connector with external thread for connecting with the infusion tube. Both nozzle bodies 1, 5 have a circular axial through hole for jet delivery. The no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com