Patents

Literature

47results about How to "Short fermentation period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing typical Maotai-flavor liquor from Maotai-flavor distiller's grain

ActiveCN102618411AShort fermentation periodReduce manufacturing costAlcoholic beverage preparationBiotechnologyRed yeast rice

The invention discloses a method for producing typical Maotai-flavor liquor from Maotai-flavor distiller's grain. The method comprises the following steps of raw material preparation, distiller's yeast addition, pit entry and fermentation, secondary grain addition and liquor taking, and hot-pit fermentation. Auxiliary materials comprise edible alcohol, rhizopus bran-koji, esterified red yeast rice, TH-AADY, glucoamylase, yellow water of Maotai-flavor liquor, foreshot and distillation tails. In the secondary grain addition and liquor taking, moistened sorghum having a fragmentation degree of 30% and fermented grains taken from a pit are mixed into fermented sorghum; a mixed liquid of alcohol, yellow water, foreshot and distillation tails is put into a distillation bottom pot; and the fermented sorghum is subjected to boiling gelatinization and then first liquor is taken from boiling gelatinization products. In the hot-pit fermentation, distiller's grain obtained after grain boiling andliquor taking is supplied with water; a composite starter is prepared; the fermented grains supplied with water is mixed with distiller's yeast and then the mixture is put into the pit and is fermented; the mixed liquid of alcohol, yellow water, foreshot and distillation tails is put into the distillation bottom pot; the fermented grains are subjected to distillation and then second liquor is taken from distillation products; and the processes of the hot-pit fermentation are repeated so that third liquor is obtained. The method provided by the invention is simple, has a low cost, and can obviously improve a utilization rate of Maotai-flavor distiller's grain. The style of Maotai-flavor liquor obtained by the method is the same as that of the existing Maotai-flavor liquor.

Owner:SICHUAN TUOPAI SHEDE WINE

Active protein feed and its preparing method

InactiveCN1899080ALoose texturePromote digestion and absorptionFood processingAnimal feeding stuffActive proteinBiotin

The present invention discloses a kind of active protein feed and its preparation process. The active protein feed is prepared with the materials comprising fresh solid fermented distiller's grains 96-98 wt%, urea 0.5-1 wt%, ammonium sulfate 1-3 wt% and koji tray strain 0.1-0.6 wt%, and the preparation process is simple, low in labor strength and low in cost. The said process can eliminate the pollution caused by distiller's grains while producing loose feed with special fragrance, rich protein, vitamins, amino acid, biotin mineral and nutritious elements essential for animal growth.

Owner:李同军

Method for cultivating mushroom

InactiveCN101496486AIncrease productivityAvoid pollutionHorticultureFertilizer mixturesAgricultural scienceDisinfectant

The invention relates to a mushroom culture method. The culture materials used in the method is prepared from cotton seed hulls or saw dust or crop stalks, cattle manure, urea, concentrated superphosphate, calcium sulphate and calcium carbonate. The method comprises the following steps: firstly prewetting the cotton seed hulls or the saw dust or the crop stalks and the cattle manure, then evenly mixing the cotton seed hulls or the saw dust or the crop stalks, the cattle manure, urea, concentrated superphosphate, calcium sulphate and calcium carbonate, packaging the mixture in a bag, filling the fermentation material in the two ends of the bag, heating up the bag, replacing the non-cotton cover bodies on the two ends of the fungus bag with mushroom emergency rings, then carrying out the inoculation under the opening condition, carrying out the fungus fermentation and culture, and finally planting the mushroom indoors and outdoors. The method is characterized in that: the method overcomes the defects that: the conventional round mushroom culture is limited indoors; in addition, a disinfectant and a fungicide are used from the stock production, production seed propagation to culture production; and the conventional culture method has fussy operation, a long production cycle, high cost, and the like. The mushroom culture method needs neither the disinfectant nor the fungicide, and has simple operation, a short production cycle and low cost. Moreover, the method is also suitable for the production of the mushroom stock and the production seeds, and for any crop stalk as the culture material.

Owner:新疆巴音郭楞蒙古自治州农业科学研究院

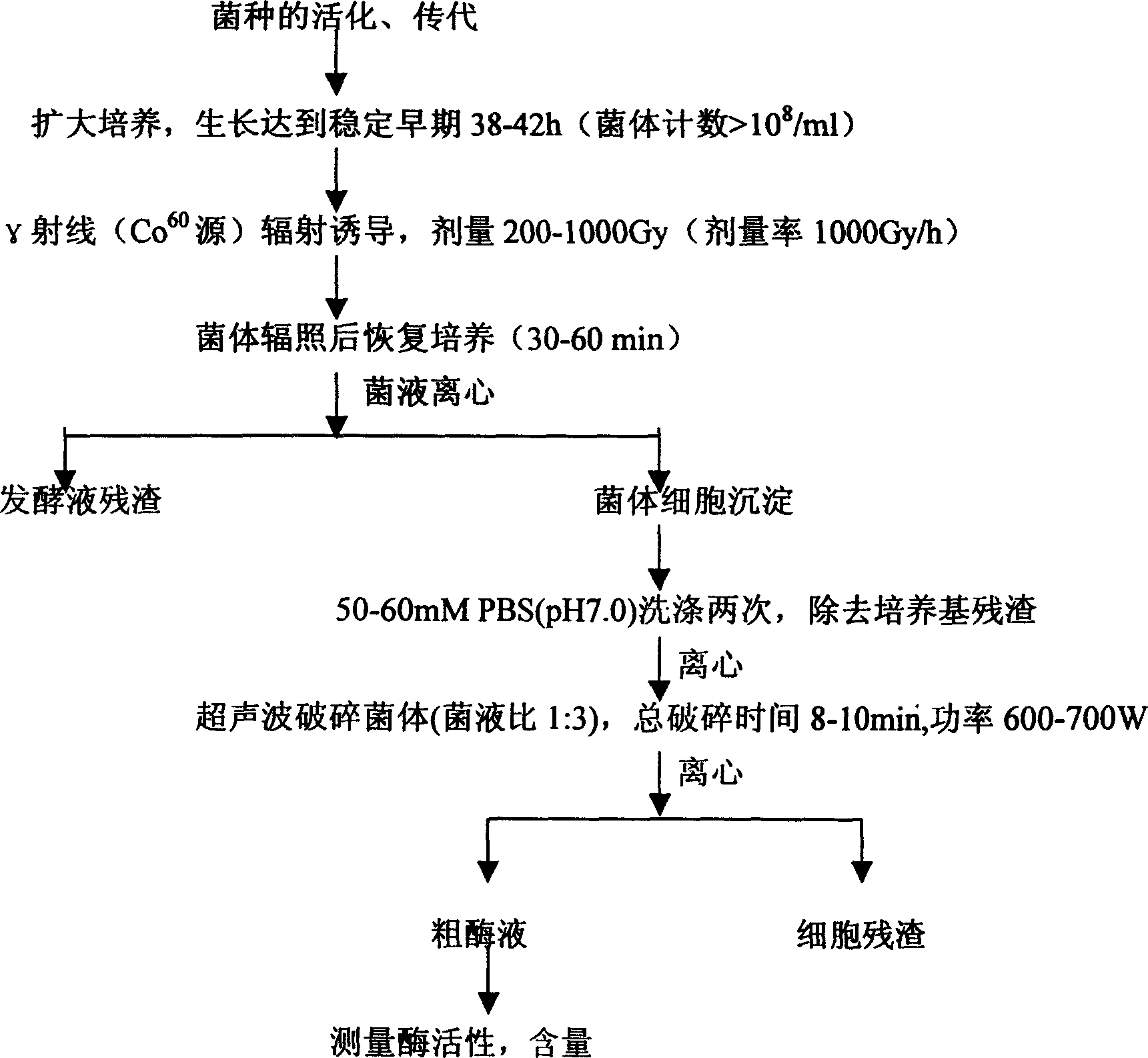

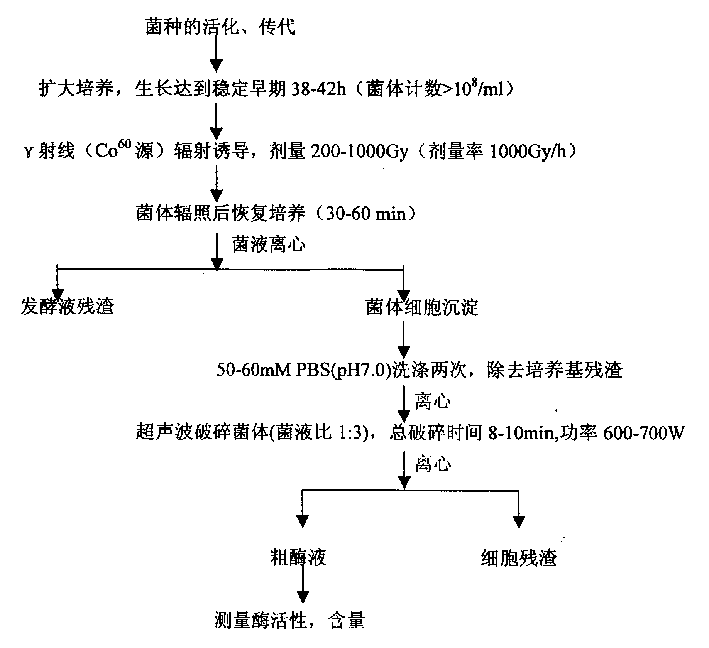

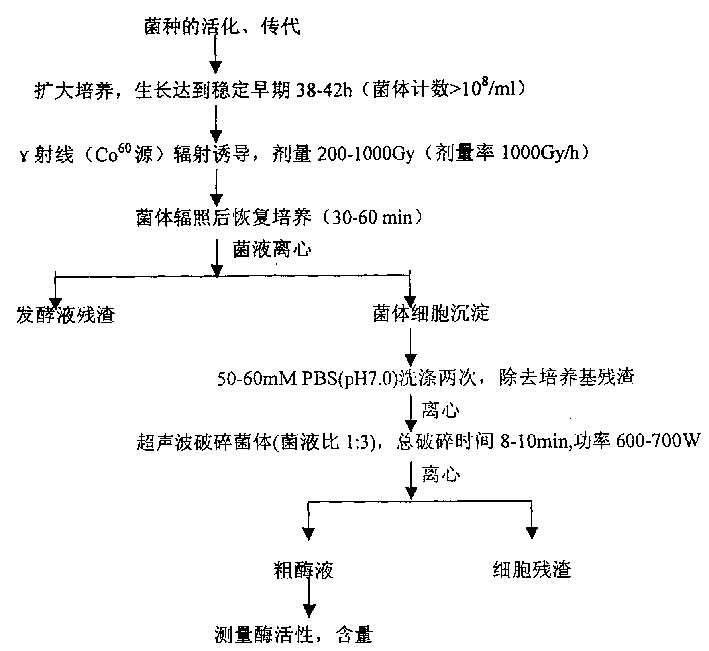

Method for increasing yield of superoxide dismutase of radioresistant coccus by radiation induction

Owner:ZHEJIANG UNIV

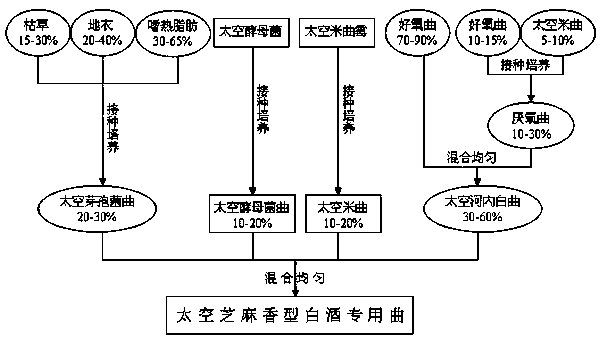

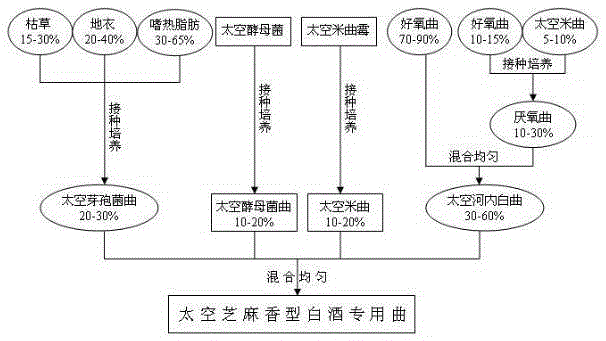

Preparation method for special wine-making starter for space sesame-fragrance type wine

ActiveCN103865725AQuality assuranceGuaranteed stabilityAlcoholic beverage preparationAspergillusMutation breeding

The invention discloses a preparation method for a special wine-making starter for space sesame-fragrance type wine. According to the preparation method disclosed by the invention, space bacillus, space saccharomycetes, space aspergillus oryzae and space Hanoi aspergillus which are subjected to space mutation breeding are used for preparing a space bacillus starter, a space saccharomycetes starter, a space aspergillus oryzae starter and a space Hanoi aspergillus starter according to processes respectively, and then the space bacillus starter, the space saccharomycetes starter, the space aspergillus oryzae starter and the space Hanoi aspergillus starter are mixed according to a ratio of 20-30%: 10-20%: 10-20%: 30-60% to prepare the special starter for space sesame-fragrance type wine, wherein the space bacillus starter is prepared by a zymomonas fermentation and compounding process; the space Hanoi aspergillus starter is prepared by a two-step fermentation method; starter pool culture for space bacillus is carried out by a method of sterilizing raw materials, then cooled to 60-70 DEG C, and replenished with saccharifying enzyme to increase reducing sugar; and meanwhile, space aspergillus oryzae is added, thus further improving the quality of the special starter for space sesame-fragrance type wine. The special starter for space sesame-fragrance type wine produced by the method is stable in quality, capable of increasing wine yield by 3-5%, reducing fermentation period by 3-5 days, increasing the content of the characteristic constituents of the sesame-fragrance type wine by 5-10%, and reducing the dosage of the starter by 2-7%; and the produced raw wine is full in body, gentle in fragrance and with a typical sesame-fragrance style.

Owner:泰山酒业集团股份有限公司 +1

Biological organic fertilizer and preparation method thereof

ActiveCN103992181ALow bulk densityImprove water retentionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyOrganic manure

The invention relates to fertilizer and a preparation method thereof and in particular relates to a biological organic fertilizer and a preparation method thereof. The biological organic fertilizer comprises the following raw materials in percentage by weight: 55-65% of withered tung tree, 15-25% of straw coal, 13-18% of tobacco juice, 3-5% of flower residue and 0.8-1.5% of bacteria, wherein the total percentage by weight of all the raw material components is 100%. The biological organic fertilizer has the effect of inhibiting and killing insect pests and harmful bacteria in soil, has long-lasting fertilizer efficiency (12 months) and has the functions of improving soil and increasing granular structures; a fermentation period is short (15 days), fine particles can be obtained without smashing, reprocessing is not needed; and the biological organic fertilizer can be prepared after fermentation is directly carried out for 10-15 days, thereby reducing the production cost.

Owner:QIUBEI COUNTY SHUANGLONG GREASE

Lyche yeast and lychee dry red dry white spirit produced by fermentation using lychee yeast

A litchi yeast is prepared from ordinary yeast through culturing in the culture medium prepared from litchi juice, sugar and malt juice and natural fermenting in litchi juice at 20-25 deg.c for 9-11 days. A dry red or dry white litchi wine is prepared from said litchi yeast and litchi juice through fermenting, filtering, clarifying, distilling and ageing. Its advantages are low content of alcohol and sugar, and pure wine and litchi taste.

Owner:吴琳娟

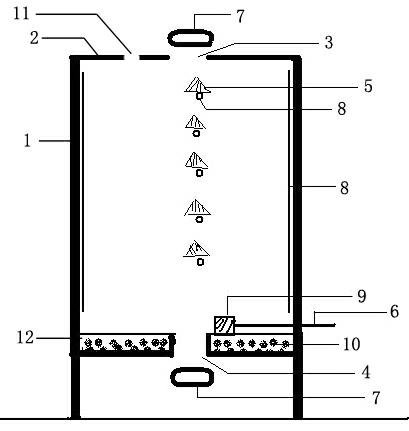

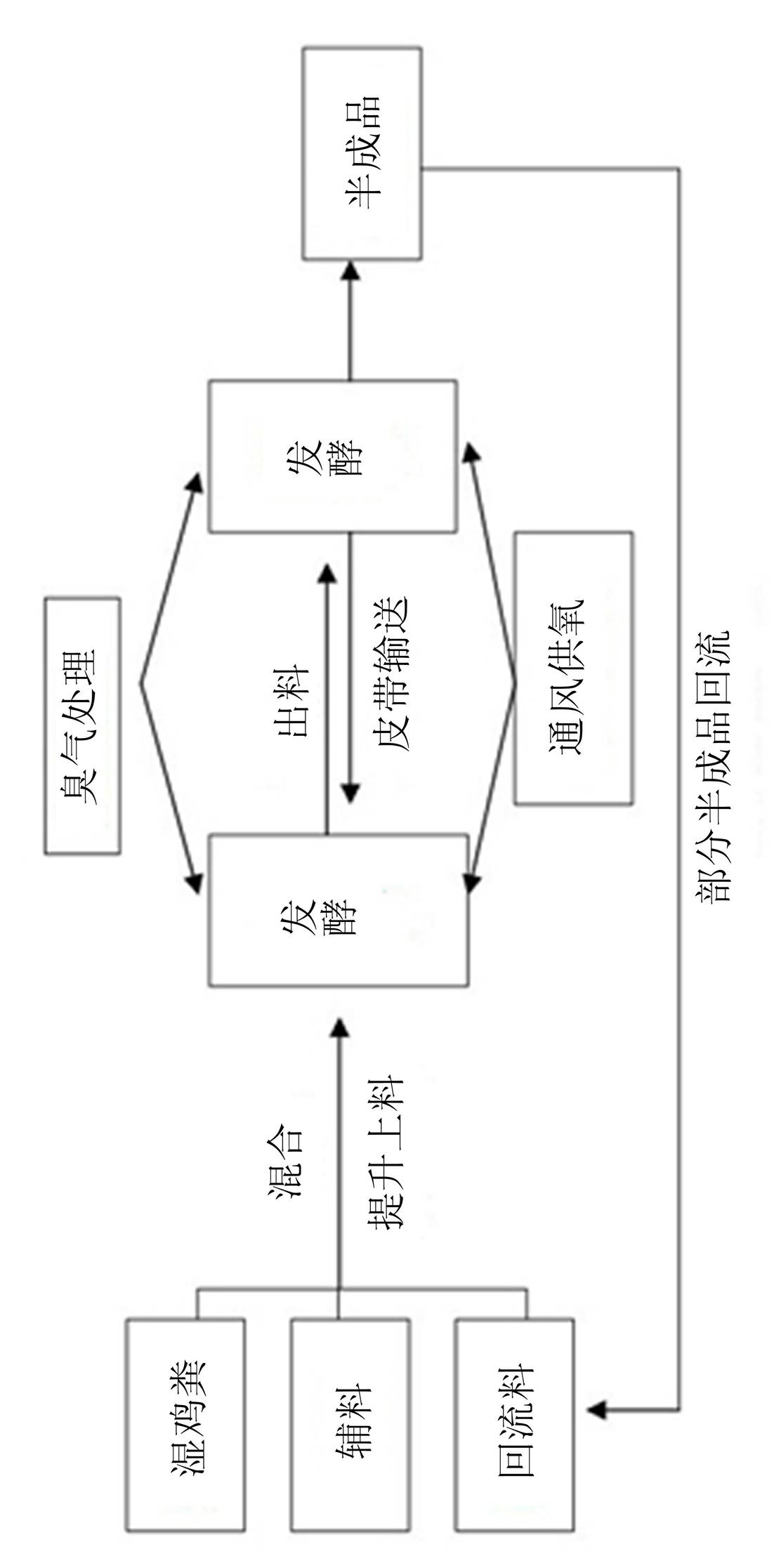

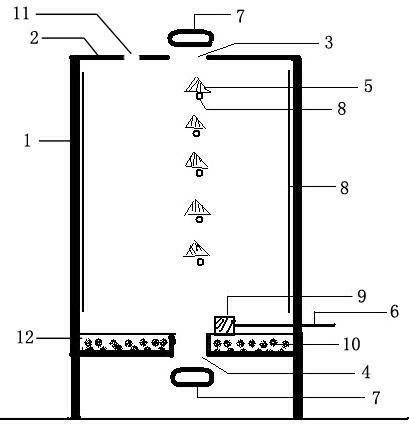

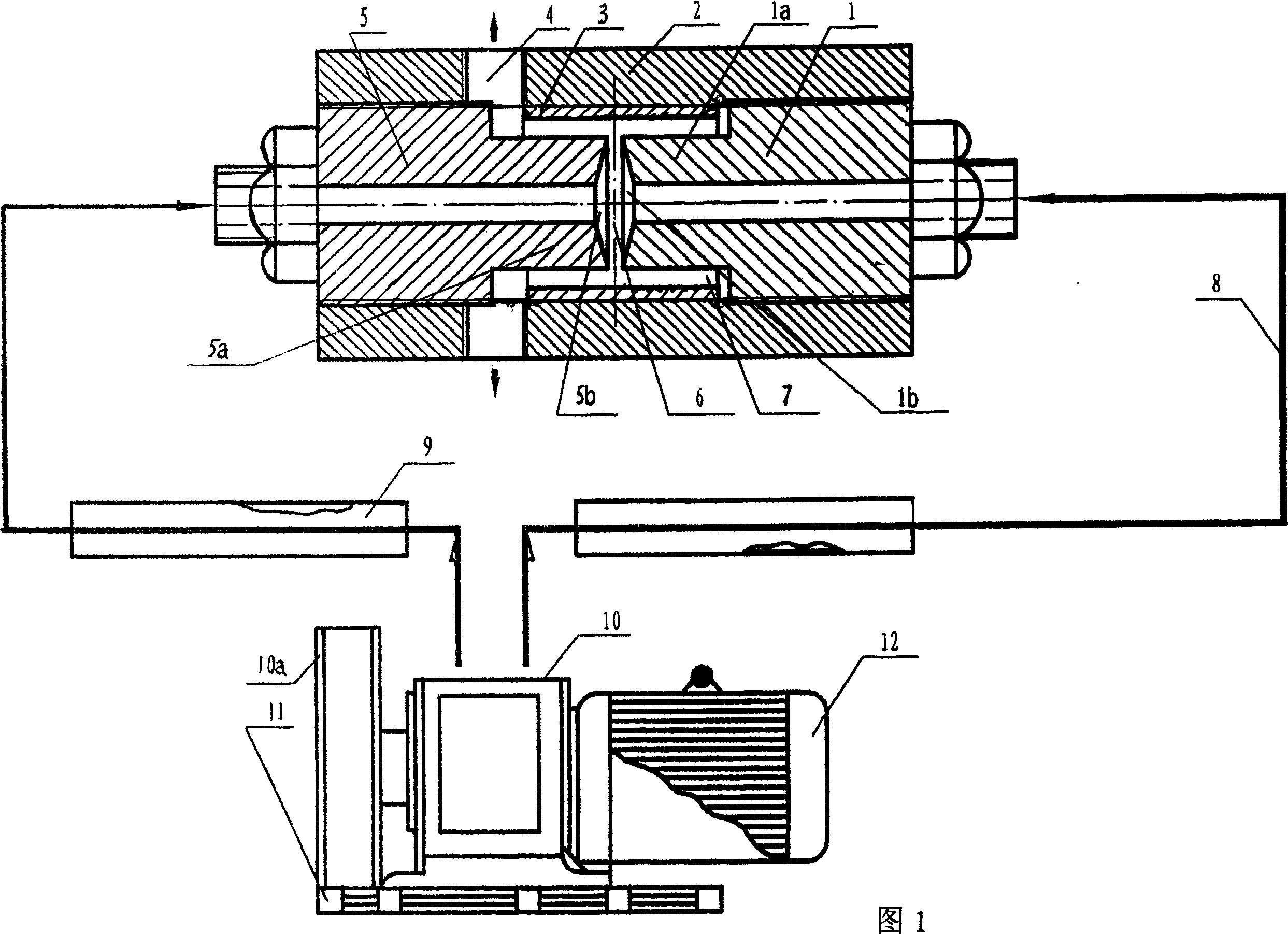

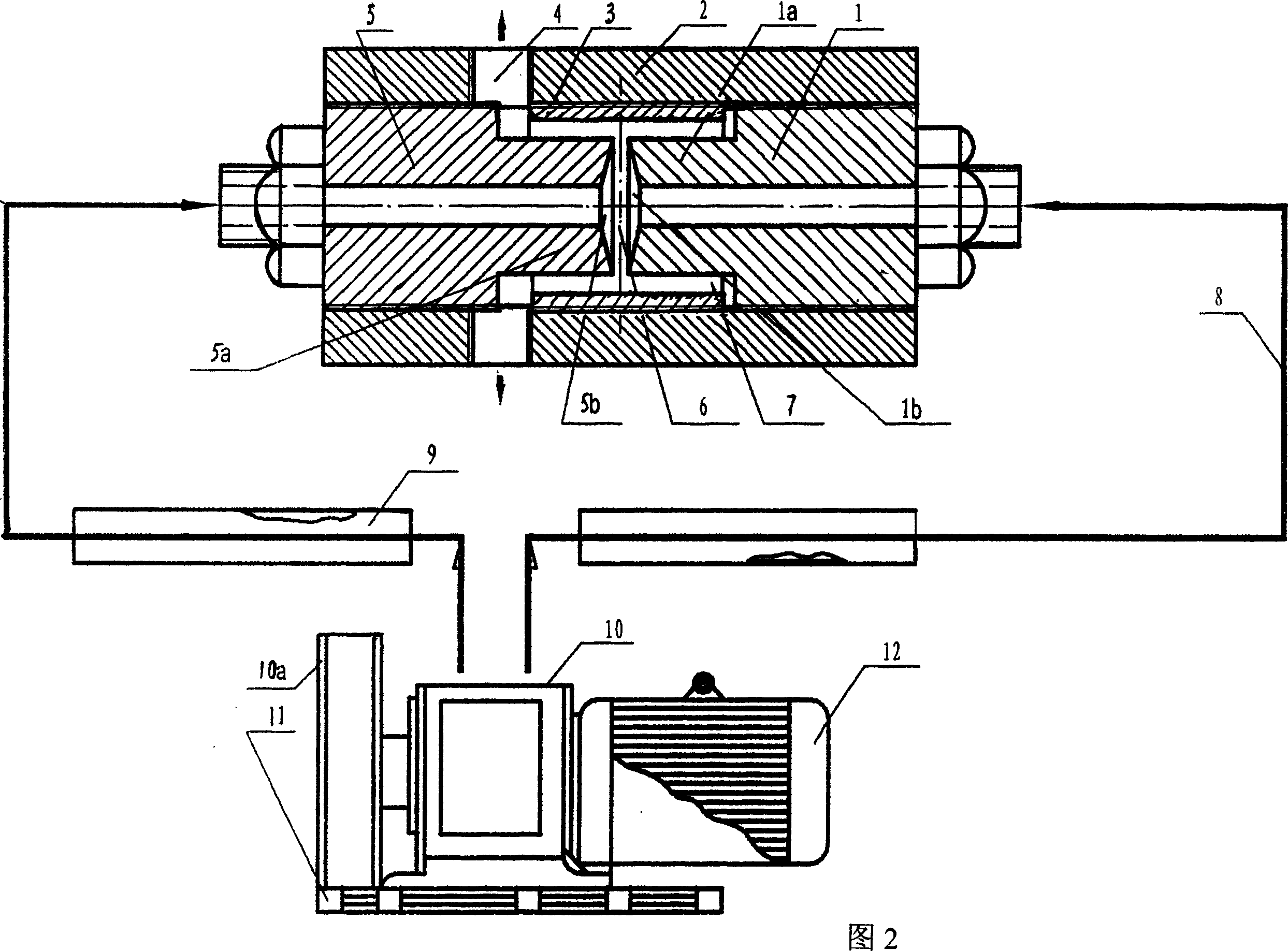

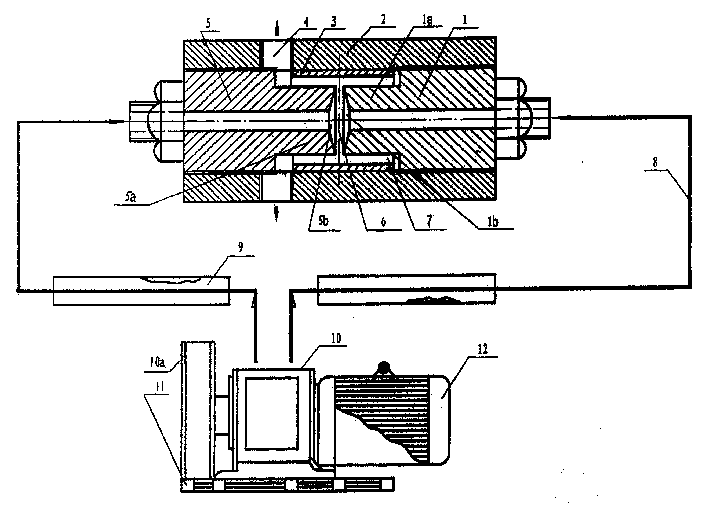

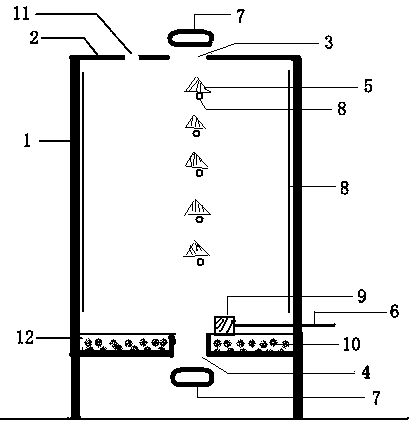

Vertical fermentation bin and fermentation process thereof

ActiveCN102603385AReduce weightCause hypoxiaBio-organic fraction processingOrganic fertiliser preparationPulp and paper industryCompost

The invention relates to a vertical fermentation bin and a fermentation process thereof. The vertical fermentation bin comprises a bin wall, a bin top, an air suction opening, a feed inlet, a discharge outlet, transverse beams, a hydraulic system, a belt conveying system and an air supply system. The fermentation process comprises the steps of material mixing, inoculation, lifting, fermentation and discharging. Since the transverse beams are arranged in the fermentation bin at intervals and are used for reducing the weight of materials during falling from the top, the materials are prevented from being compacted and the situation of oxygen deficit of compost is avoided; and since the hydraulic system is combined with a scraping plate for discharging, the materials are not apt to form material arches, the discharged materials are even, the equipment is not apt to be corroded, the maintenance cost is low, the production process is easy to control, the fermentation period is short and the product quality is stable.

Owner:GUANGDONG RUNTIAN FERTILIZER CO LTD

Nano biological particles made of waste thallus, and production method and use thereof, and nano-level thallus crusher

InactiveCN1528526ASave foodEliminate environmental pollution from waste bacteriaGrain treatmentsFood preparationChemistryAverage diameter

The invention provides a nano bio-particle made of waste thallus as well as its producing method and application together with the nano-level thallus crusher. The weight ratio of its raw material: waste thallus 1 share, and clear water 2-9 shares, and its average diameter is not greater than 100 nano, where the waste thallus is the waste microbe produced when producing antibiotic and fermenting food products. If the waste thallus is the one used in flavoring industry for producing, the above formula should be added with the 5'-phosphodiesterase containing clear liquid made of malt root 1 share and clear water 6-8 shares. During fermenting, it can replace grain as raw material, eliminating the environmental pollution and the harm to human beings caused by the waste thallus.

Owner:姚洪文

Fine efficient wine brewing technology of raw grains

InactiveCN105802786AComprehensive fermentation and brewing technology is feasibleEasy to operateAlcoholic beverage preparationYield (wine)Mentha spicata

The invention relates to a fine efficient wine brewing technology of raw rice. The technology consists of: screening, cleaning and purifying rice, adding clove, star anise or mint according to a raw grain / spice weight ratio of 100:1 and performing crushing grinding, pouring the crushed raw material into a fermentation vat, and adding koji for uncooked materials and purified water into the vat in order according to a weight ratio of the raw material, the koji and purified water of 100:6-8:290-300, stirring the materials evenly and performing sealing, stirring the substances once every 2-3 days, about 9 days later when the mash liquid turns into dark brown and is fermented well, putting the product into wine steaming equipment to perform wine steaming. The low alcohol mash liquid left after wine steaming can be used for rice vinegar and sauce production or re-fermentation, and the leftovers can be used for feed processing and livestock feeding, etc. The method provided by the invention has the advantages of practicability, exquisite process and easy operation, strong practicability and easy popularization, raw grain refinement, short fermentation period and excellent mash material quality, high yield, high quality and energy-saving, mellow wine quality and excellent aroma.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

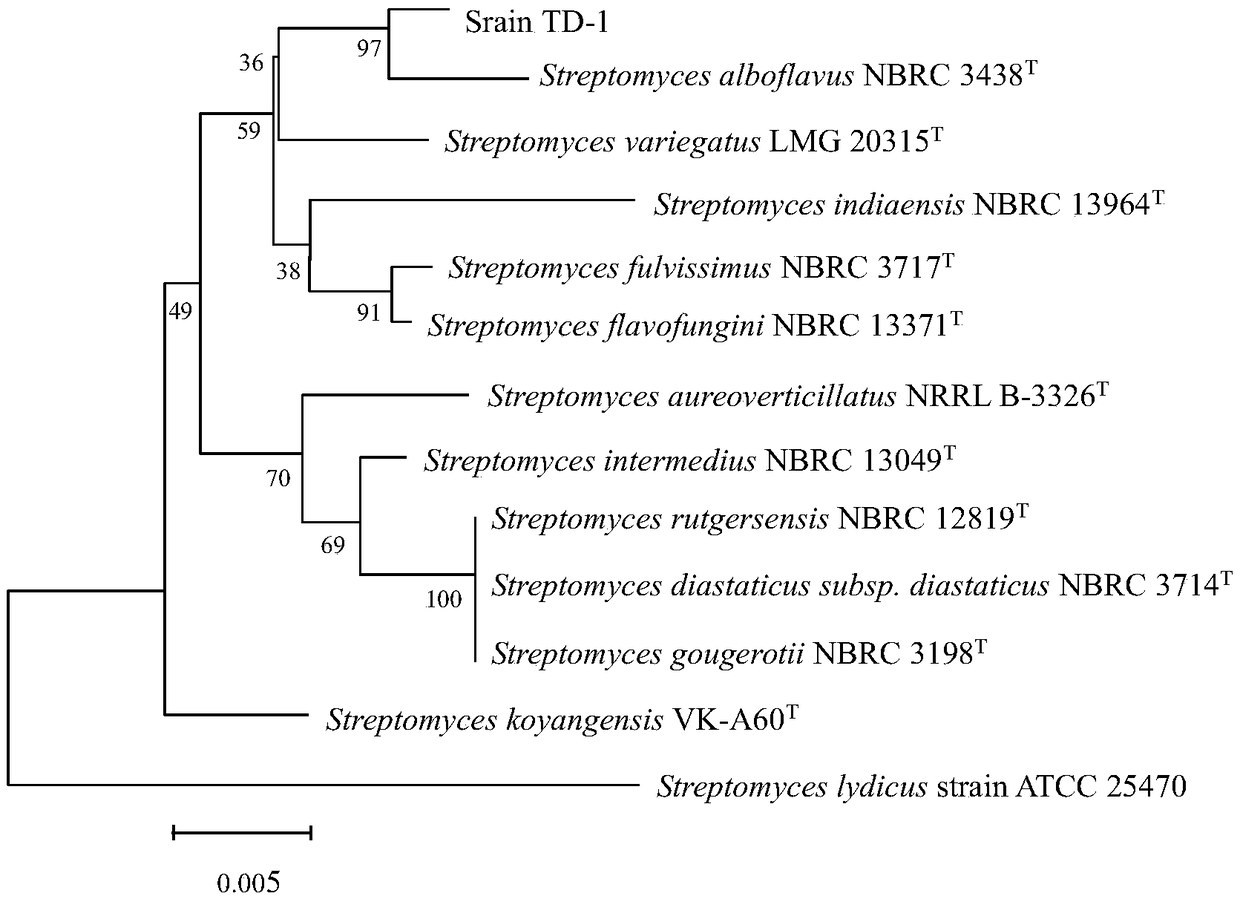

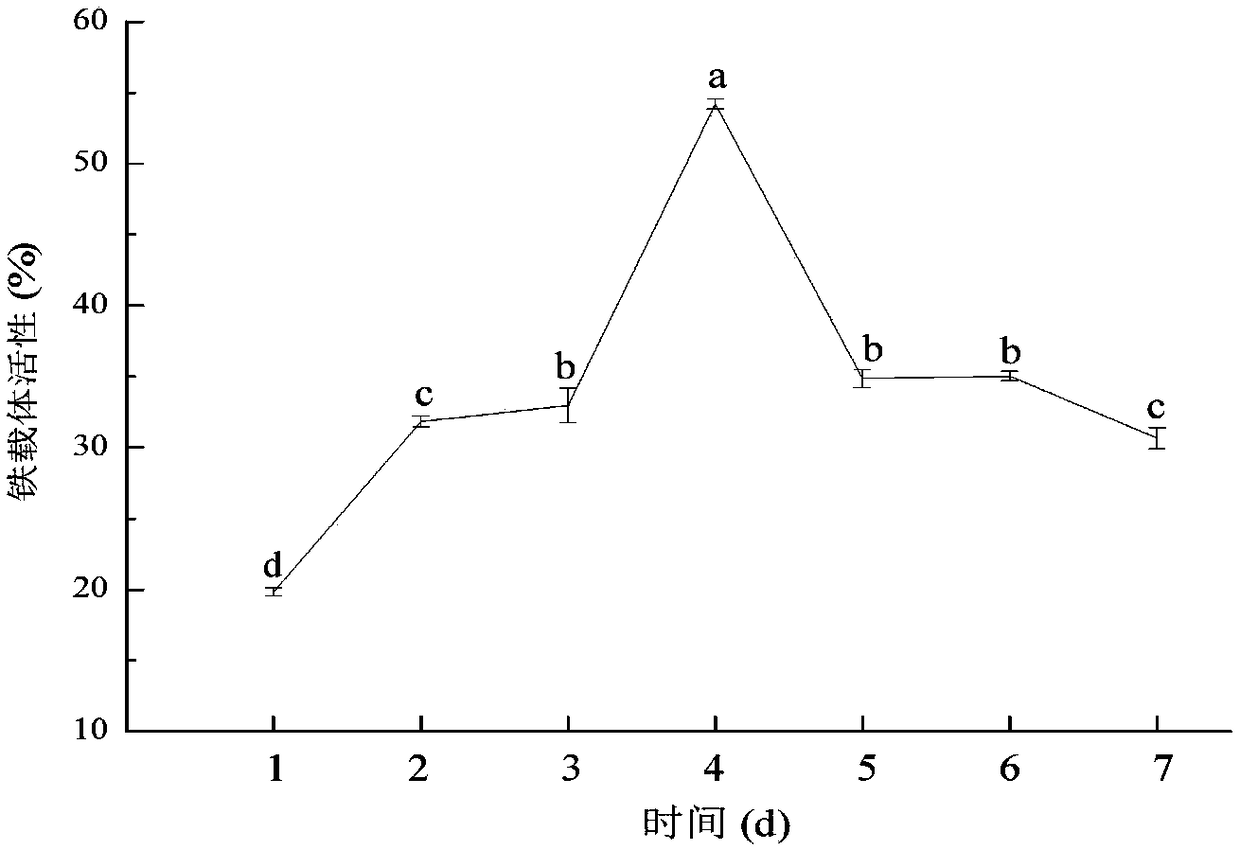

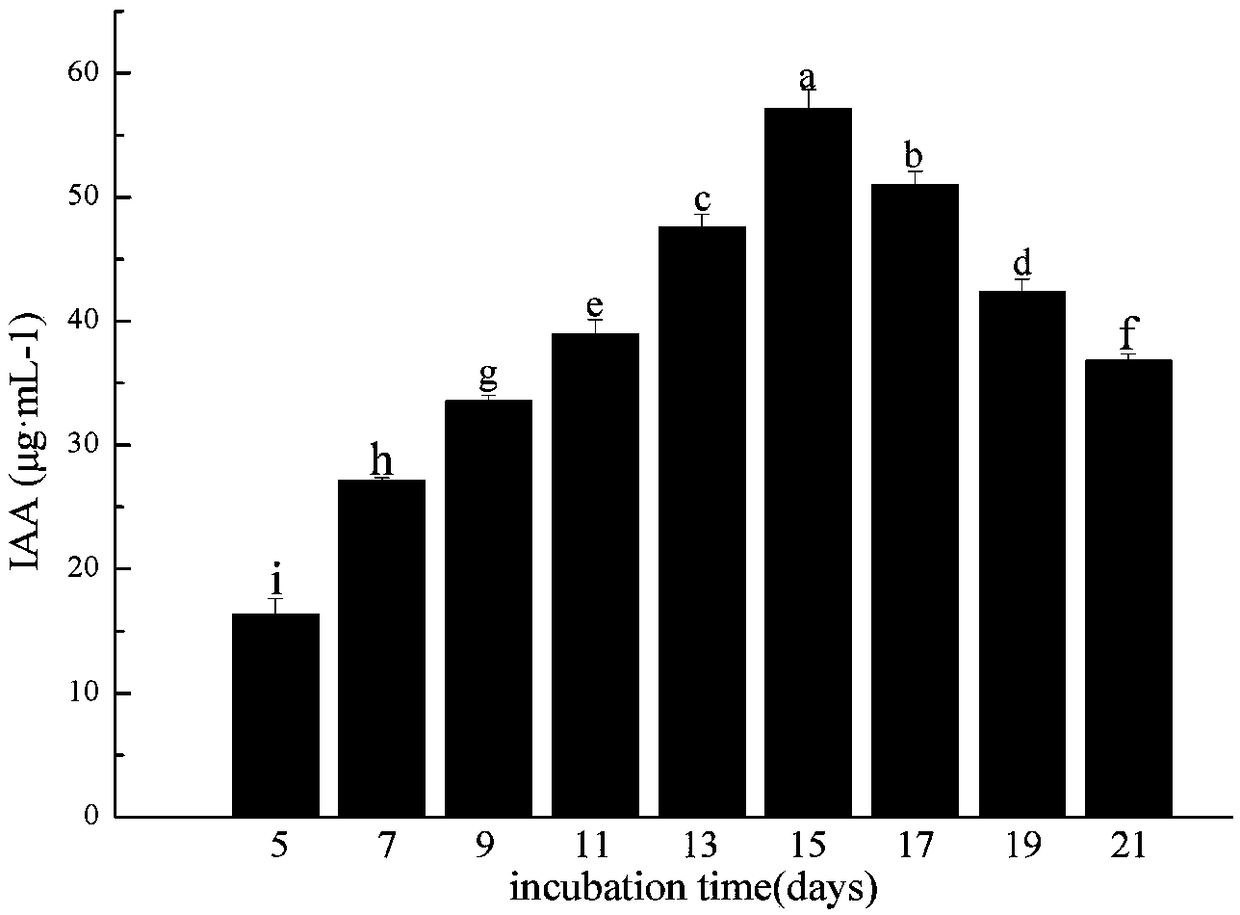

Streptomyces alboflavus, method using Streptomyces alboflavus to prepare biocontrol microbial agent and application

ActiveCN109136142ASimple preparation processShort fermentation periodBiocidePlant growth regulatorsBiotechnologyMicroorganism

The invention relates to Streptomyces alboflavus, a method using the Streptomyces alboflavus to prepare a biocontrol microbial agent and application. The method includes: placing the Streptomyces alboflavus into a preservation culture medium, activating at 28-32 DEG C for 5-7 days, placing into a seed culture medium, and culturing at 30 DEG C and 160-180r / min for 36-48 hours to obtain a seed bacterium solution; inoculating the seed bacterium solution into a fermentation culture medium, performing fermentation culture in a constant-temperature culture tank of 30 DEG C for 7 days, placing the matrix obtained after the fermentation culture into a ventilation drying oven of 25-35 DEG C or an air energy heat pump drying machine for drying or subjecting the matrix to natural drying under normaltemperature, and crushing to obtain the biocontrol microbial agent. The prepared biocontrol microbial agent is applicable to ralatonia solanacearum antagonism, applicable to salt resistance, drought resistance and soil inorganic phosphorus dissolving, applicable to siderophore and growth hormone heteroauxin synthesis, and applicable to tomato seed germination promotion and growth promotion.

Owner:TIANJIN UNIV OF SCI & TECH

Method for cultivating mushroom

InactiveCN101496486BIncrease productivityAvoid pollutionHorticultureFertilizer mixturesAgricultural scienceDisinfectant

Owner:新疆巴音郭楞蒙古自治州农业科学研究院

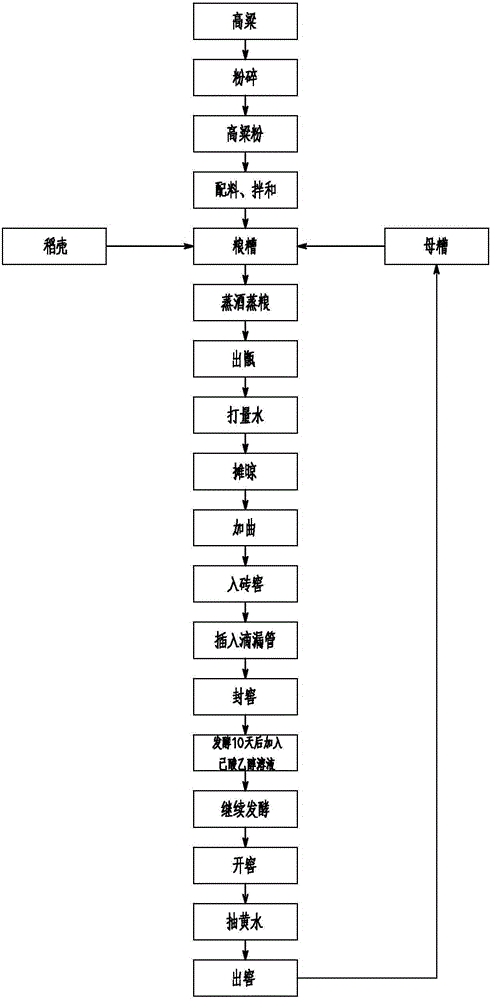

Pit-mud free strong-flavor liquor preparation method

InactiveCN106190742AAvoid direct contactReduce processing costsAlcoholic beverage preparationAlcoholTime cost

The invention relates to a pit-mud free strong-flavor liquor preparation method and belongs to the field of liquor preparation methods. In the preparation method, economic costs in building mud fermentation pits in traditional strong-flavor liquor fermentation pits and economic cost in use and maintenance of the mud fermentation pits are saved, and meanwhile, a great deal of manpower is saved; for example, costs in cultivation, maturation and maintenance of artificial pit mud and replacement of the artificial pit mud aging every other 3-5 years are saved. Compared with the prior art, the pit-mud free strong-flavor liquor preparation method had the advantages that fermentation period is shortened, a caproic acid ethanol solution is prepared by using caproic acid and ethyl alcohol directly, time for caproic acid bateria to be fermented to generate the caproic acid in the pit mud is saved, the fermentation period is shortened by 20-30 days as compared with that of a traditional strong-flavor liquor production process of the Bandaojing, and time cost and conversion cost of grain and raw liquor are saved.

Owner:SHANDONG BANDAOJING

Preparation method for persimmon wine

InactiveCN103361226AGreat tasteFully fermentedMicroorganism based processesAlcoholic beverage preparationAgeingBrewing

The invention discloses a preparation method for a persimmon wine. The preparation method comprises 1) a step of selecting fruits and juicing; 2) a step of sterilizing; 3) a step of color-protecting; 4) a step of performing initial fermentation; 5) a step of performing secondary fermentation for 5-15 d; and 6) a step of ageing, filtering, disinfecting and canning to obtain finished products. The preparation method adopts sweet persimmons to prepare the persimmon wine, and therefore time and cost for removing astringent taste are reduced, and the wine prepared by brewing is mellower and tastes better.

Owner:黄馨莹

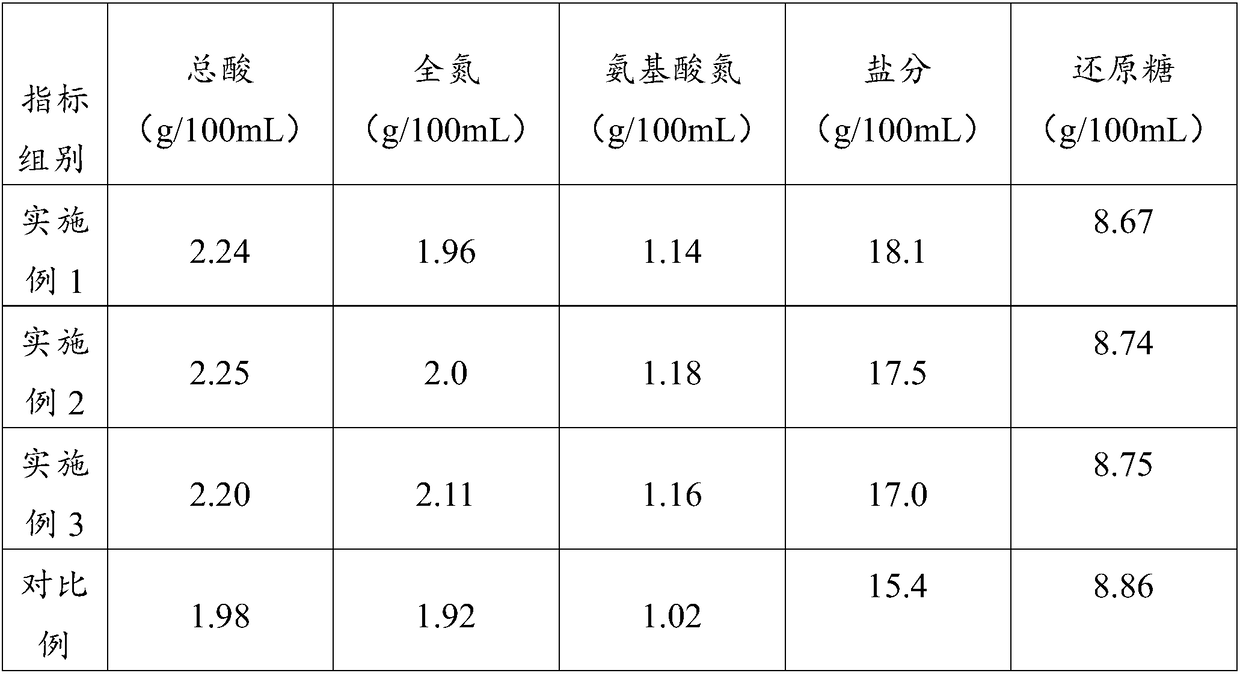

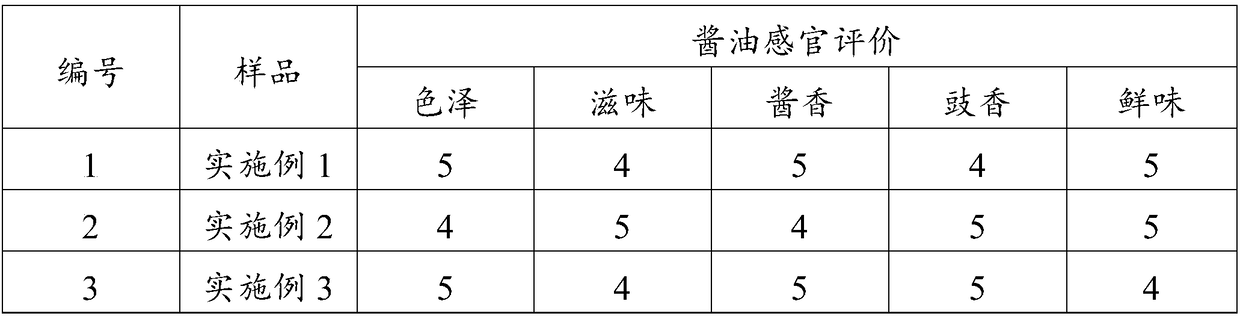

Preparation technology for improving quality of large-tank fermented soy sauce

The present invention discloses a preparation technology for improving quality of large-tank fermented soy sauce. The preparation technology comprises the following steps: (1) a soy sauce stock solution is manufactured by a traditional natural air-drying fermentation method; (2) a qualified soy sauce stock solution is screened: the soy sauce stock solution with sum amount of weissella, staphylococcus and salt-tolerant pediococcus pentosaceus accounting for 85-98% of the total amount of bacteria is used as the qualified soy sauce stock solution; (3) a koji material is prepared; and salt is added into the koji material to obtain soy sauce mash; (4) the qualified soy sauce stock solution is inoculated into the soy sauce mash; and the soy sauce mash is placed in a large tank to be subjected toa temperature-controlled compound fermentation to obtain first filtered sauce; and (5) the first filtered sauce is subjected to sterilizing, precipitating, filtering and blending to obtain the soy sauce. The manufactured soy sauce stock solution by using the natural air-drying fermentation method is inoculated into the soy sauce mash by a large-tank technology for the fermentation; and the preparation technology enriches types of microbial floras in the large-tank technology, improves the quality of the soy sauce, shortens fermentation period, better forms complete soy sauce flavor of traditionally brewed soy sauce, and improves nutrient production rate.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

Novel liquid-state wine distillation method using multiple potato raw materials

InactiveCN104745359AAdvanced technologyCraftsmanshipAlcoholic beverage preparationFlavorLiquid state

The invention relates to a novel liquid-state wine distillation method using multiple potato raw materials. The method comprises the processes of equipment preparation, refinement and proportion optimization, liquid-state fermentation and high-efficiency wine distillation. Concretely, the method comprises the steps: raw and dry cassava and sweet potatoes are cleaned and weighed according to a ratio of 6-5:3-4, and spice is mixed into the raw and dry cassava and the sweet potatoes according to a potato-to-spice ratio of 6-5:0.3-0.2; the raw materials is pulverized into spiced paste raw material and powder material that can pass a sieve of 38-40 meshes by a pulverizer; the paste raw material, the powder material, distiller's yeast and clean water are weighed in a manner that the ratio of the paste raw material to the distiller's yeast to the clean water is 100:0.7-0.8:260-280, and the ratio of the powder raw material to the distiller's yeast to the clean water is 100:0.6-0.8:280-300; the mixture is put into a fermentation tank or pool and stirred, and is subjected to anaerobic fermentation for 12 days; when mash liquid turns brown and is fully fermented, the fermented mash is put into wine distillation equipment for distillation, and the obtained wine is poured into dedicated bottles and is sealed for 13-15 days for quality improvement. Therefore, potato wine with a strong potato flavor and a mellow and sweet taste is obtained.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Chilli sauce soycheese and preparation method thereof

InactiveCN102742668BGreat tasteImprove technical indicatorsCheese manufactureFood scienceTrace elementBiological activation

The invention relates to chilli sauce soycheese. 20wt% of chilli freshly-pressed normal juice is added in raw material soya-bean milk in a preparation process of the soycheese to be used for making the soycheese after evenly stirring. The chilli sauce soycheese uses fresh chilli to make the chilli sauce soycheese through a scientific formula and modern equipment and contains abundant protein of soybeans and a large quantity of vitamins, carbohydrates and a plurality of mineral substances and trace elements of the chilli. The chilli sauce soycheese has special sweet smell of the soycheese and vegetables and excellent flora activation, increases taste and savor of the soycheese, and is abundant in nourishment.

Owner:HUAINAN BAGONGSHAN XINGXING BEAN PRODS

Efficient high-yield distiller's yeast for ripe and unripe materials

InactiveCN102876538AAdvanced technical formulaImprove performanceWine preparationVinegar preparationBiotechnologyAir temperature

The invention provides efficient high-yield distiller's yeast for ripe and unripe materials, and relates to a fermenting yeast. By mainly comprehensively analyzing advantages and disadvantages of the prior art, rejecting, combining, optimizing, improving and creating, the efficient high-yield distiller's yeast is optimized, refined and finely mixed to be universal by main components including biological enzyme yeast, active dried yeast, novel protease and auxiliary components of green natural creatures including anticorrosive herbs and natural perfumes. The efficient high-yield distiller's yeast is applicable to the technical requirements of efficient, high-yield and high-quality beer brewing and vinegar making relevant to production of alcohol, millet wine, fruit wine, wine, sauce and vinegar and the like by fermenting various ripe and unripe materials such as rice, potatoes, fruits, vegetables and grapes in a semi-liquid state or a liquid state at the temperature of 5-45 DEG C. Accordingly, the efficient high-yield distiller's yeast for ripe and unripe materials is advanced in formula, high in performance, wide in application range, universal for ripe and unripe materials, short in fermenting period, excellent in effect, high in yield and quality, energy-saving, fragrant in beer brewing and vinegar making, high in comprehensive cost performance and quite evident in comprehensive economic benefits of popularization and use, and is prepared by natural creatures.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Efficient compounded microbial feces treatment agent and preparation method thereof

InactiveCN106145585AReduce manufacturing costFast fermentationWater treatment compoundsWaste water treatment from animal husbandryLactic acid bacteriumMicroorganism

The invention discloses an efficient compounded microbial feces treatment agent and a preparation method thereof. The preparation method comprises the steps that 1, a saccharomycetes mixture is prepared; 2, a lactic acid bacterium mixture is prepared; 3, a bacillus natto mixture is prepared; 4, a microbial body to be used is prepared. The efficient compounded microbial feces treatment agent is prepared from, by weight, 6% of saccharomycetes mixture, 4% of lactic acid bacterium mixture, 10% of bacillus natto mixture and 80% of porous powdery carrier. According to the characteristics of organic dirt, the biological nature of bacillus natto is combined, the special feces treatment agent is prepared, the treatment agent can carry out a fermentation reaction according to the special process, that is, anaerobic fermentation and aerobic fermentation are carried out in sequence, meanwhile, the fermentation temperature is raised gradually, water evaporates gradually to increase air permeability in the fermentation process, and feces residues can be at the optimum fermentation temperature in the whole fermentation process.

Owner:HUNAN YUNFEN NETWORK TECH CO LTD

High-efficiency wine distillation method using refined old grain raw materials

InactiveCN104745357AComprehensive fermentation and brewing technology is feasibleEasy to operateAlcoholic beverage preparationYeastEnergy preservation

The invention relates to a high-efficiency wine distillation method using refined old grain raw materials. The method comprises: old grains including rice, wheat and sorghum are screened, cleaned and purified; spices, including clove, star anise or mint, are added into the old grains, wherein the ratio of the old grains to the spices is 100:1; the raw materials are ground and refined, and the ground raw materials are poured into a fermentation tank; raw distiller's yeast and clean water are added into the tank in sequence, wherein the ratio of the raw materials to the distiller's yeast to the clean water is 100:6-8:290-300; the mixture is evenly stirred and sealed, and then is stirred every 2-3 days; and after 9 days, when mash liquid turns brown and is fully fermented, the mash liquid is put into wine distillation equipment for wine distillation. After wine distillation, the left mash liquid containing mild wine can be used for production of rice vinegar and sauce or used for refermentation, and the leftovers can be used for feed processing, livestock feeding and the like. The method provided by the present invention is practicable, sophisticated in technology and easy to operate, thereby being suitable for application and popularization. In the method, the old grain raw materials are refined, so that the fermentation time is short, and the mash has high quality. Thus, the method has the advantages of high yield, high-quality products and energy preservation, and wine produced by using the method is mellow and good in flavour. The method can provide obvious comprehensive economic benefits if wildly used.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

New old grain raw material liquid-state efficient high-quality wine brewing method

InactiveCN106854613AComprehensive fermentation and brewing technology is feasibleEasy to operateFood processingAlcoholic beverage preparationFlavorIllicium verum

The present invention relates to a new old grain raw material liquid-state efficient high-quality wine brewing method, which comprises: screening old grains such as rice, wheat and sorghum, washing, purifying, adding clove, Illicium verum Hook.f. or peppermint according to a weight ratio of the old grains to the spice of 100:1, carrying out crushing thinning, pouring the crushed raw materials into a fermentation jar, sequentially adding a raw material koji and purified water to the jar according to a weight ratio of the raw materials to the koji to the water of 100:6-8:290-300, uniformly stirring, sealing, performing flipped stirring every 2-3 days within about 9 days, and pouring into a wine distillation device after the mash water becomes the tea color and the fermenting achieves the mature state so as to distill the wine, wherein the mash water containing low alcoholicity wine after the wine distillation can be used for rice vinegar and sauces production or re-fermentation, and the offcuts can be used for feed processing, livestock feeding, and the like. According to the present invention, the method has advantages of practicable feasibility, fine and easy-performing process, strong practicality, easy promotion, old grain raw material thinning, short fermentation period, excellent mash, high yield, high quality product production, energy saving, mellow wine product, excellent aroma of the product, promotion application, and significant comprehensive economic benefits.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

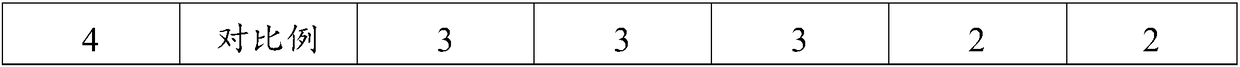

Method for increasing yield of superoxide dismutase of radioresistant coccus by radiation induction

InactiveCN1200099CIncrease SOD enzyme activitySimple processBacteriaOxidoreductasesYeastMicrobiology

The invention discloses a method for increasing the superoxide dismutase production of Radiation Coccus radiodurans induced by radiation, inducing the bacterial superoxide dismutase SOD by irradiating and post-culturing the radioresistant coccus radiodurans cultured to the stable early stage through gamma ray irradiation Synthesis, increase the production of bacterial enzymes. The bacterial cells of the present invention are separated, ultrasonically treated and extracted, and the obtained SOD enzyme activity is increased by more than 75% compared with that before irradiation treatment, which is 3 times that of the SOD-producing yeast enzyme activity. At the same time, the process flow is simple and the cost is low. The advantages.

Owner:ZHEJIANG UNIV

Liquid-state high-quality new wine brewing technology using potatoes

InactiveCN103773644AShort fermentation periodGood wine quality and aromaAlcoholic beverage preparationYeastFlavor

The invention discloses a liquid-state high-quality new wine brewing technology using potatoes, the liquid-state high-quality new wine brewing technology includes equipment allocation, refinement and optimal allocation, liquid fermentation, efficient wine distillation and other process steps, the liquid-state high-quality new wine brewing technology is as follows: weighing and mixing cleaned raw cassava and dry cassava and sweet potato according to the ratio of 6-5:3-4, weighing spices according to the ratio of the raw and dry cassava and sweet potato to the spices of 6-5:0.3-0.2 for mixing, respectively using a crusher for crushing into a 38-40 mesh fragrant paste raw material and a fragrant powdery raw material, weighing the paste raw material, distiller's yeast and clean water according to the ratio of 100:0.7-0.8:260-280, weighing the powdery raw material, the distiller's yeast and the clean water according to the ratio of 100: 0.6-0.8:280-300, respectively adding into a fermentation tank or pool for stirring evenly for anaerobic fermentation for 12 days, when the mash liquid becomes dark brown, the mash liquid is fermented maturely; adding the mature material into wine distillation equipment for distillation, filling the obtained wine matter into a special bottle for sealed storage for upgrading for 13-15 days to obtain the mellow sweet potato wine rich in potato flavor.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

New efficient energy-saving wine brewing process using yam-based raw materials

InactiveCN106867748AAdvanced technologyCraftsmanshipAlcoholic beverage preparationDistillationManihot esculenta

The invention relates t a new efficient energy-saving wine brewing process using yam-based raw materials. The new efficient energy-saving wine brewing process comprises technical processes such as equipment arrangement, thinning and matching optimization, liquid-state fermentation, efficient wine distillation and the like, and specially comprises: respectively adding washed raw manihot esculenta crantz and washed dried manihot esculenta crantz to sweet potato according to the same ratio of 6-5:3-4, respectively carrying out weighing mixing on the obtained materials and a spice according to a ratio of 6-5:0.3-0.2, respectively crushing with a crusher to obtain a 38-40 mesh fragrant slurry-like raw material and a powdery raw material, weighing the slurry-like raw material, koji and purified water according to a ratio of 100:0.7-0.8:260-280 and the powdery raw material, koji and purified water according to a ratio of 100:0.6-0.8:280-300, respectively pouring into a fermentation tank or pool, uniformly stirring, carrying out anaerobic fermentation for 12 days, pouring the mature mash into wine distilling equipment after the mash has a dark brown color and the fermentation achieves a mature state, distilling, filling the obtained wine into a special bottle, and carrying out sealed storage and quality improvement for 13-15 days so as to obtain the yam-based wine with characteristics of rich yam flavor and mellow, fragrant and sweet taste.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

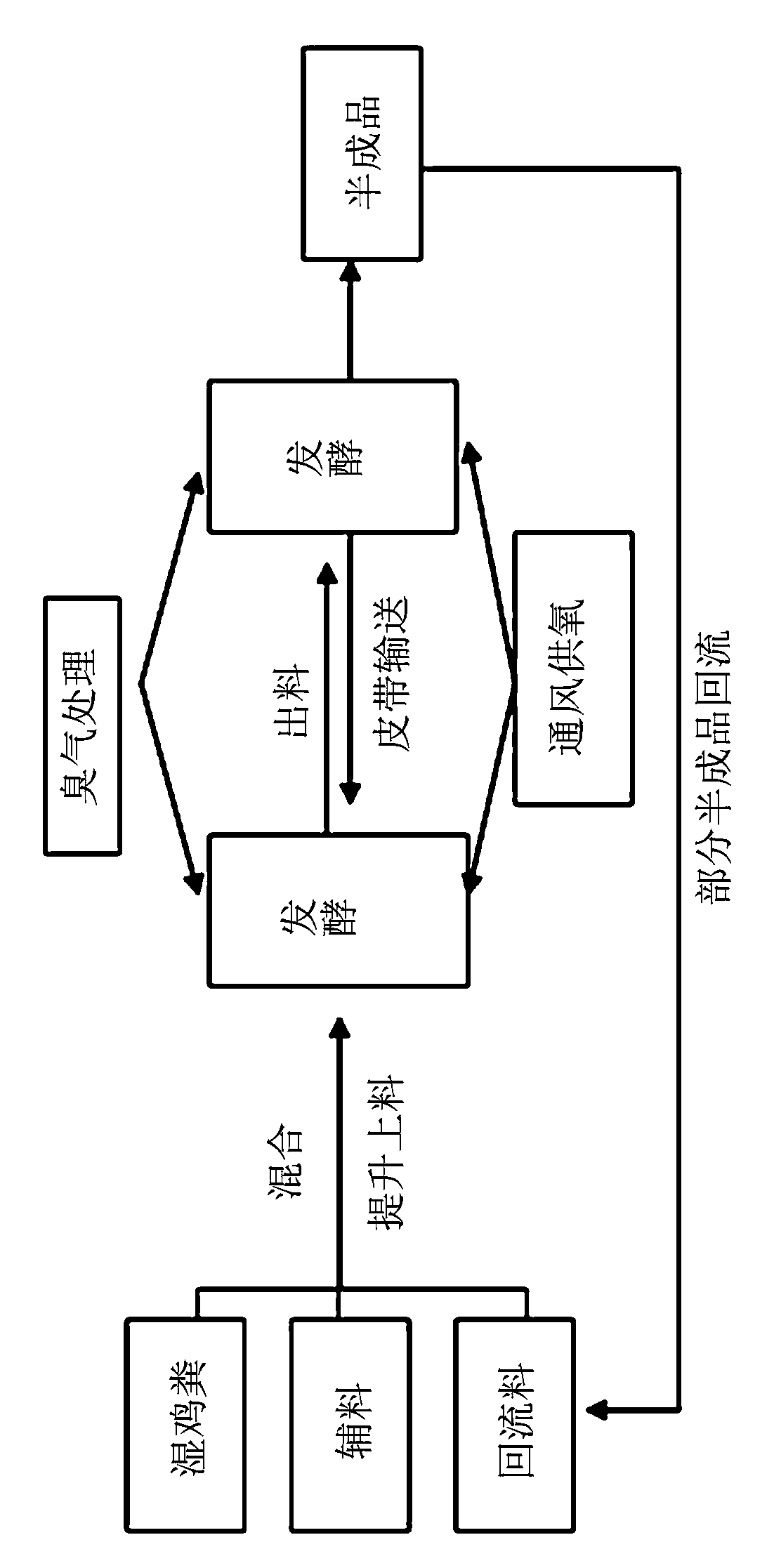

Kitchen waste treatment and resource utilization method

InactiveCN113172080AAvoid Resource Utilization ImpactsWell mixedTransportation and packagingSolid waste disposalResource utilizationEnvironmental engineering

The invention belongs to the technical field of garbage recycling, and particularly relates to a kitchen waste treatment and resource utilization method, which comprises the following steps: step 1, collecting and sorting: a worker collects kitchen waste through a garbage truck and conveys the kitchen waste to a garbage treatment plant, then the collected garbage is manually sorted and mechanically sorted, unrecyclable garbage is separated from recyclable garbage during sorting, and sanitary landfill treatment is carried out on the unrecyclable garbage after separation; and step 2, primary disinfection and drying are carried out, the recyclable garbage is injected into a disinfection tank, a disinfectant is heated, positive steam is atomized and injected into the disinfection tank to carry out primary disinfection on the garbage, the garbage is dried in a dryer after being disinfected for 8-10 minutes, and moisture in the garbage is reduced. According to the kitchen waste treatment and resource utilization method provided by the invention, through the arrangement of an extrusion dehydrator, oil and water in the garbage can be extruded and separated, and the situation that oil and water are mixed in the garbage to affect later resource utilization is avoided.

Owner:四川琳宸生物能源科技有限公司

Simple acid-resistant new technology of rice wine

InactiveCN105802782AGood wine quality and aromaProtect your healthAlcoholic beverage preparationStemona japonicaMentha spicata

The invention relates to a simple acid-resistant new technology of rice wine. The technology comprises purification grinding processing, quick-result raw material fermentation, timely distillation for wine production, rice wine quality standard, vinasse and raffinate treatment and other technological steps. The technology consists of: weighing pine needle leaf, mint stem leaf and Stemona japonica according to a ratio of 0.6-0.5:0.5-0.6:0.4-0.5 in acid-resistant and quality guarantee Chinese herbal medicines, and performing crushing to obtain a mixed raw material, then weighing wet or dry rice and the mixed raw material according to a ratio of 9-8:0.02-0.01 and conducting crushing to obtain a 35-45mesh pulp raw material or powder raw material, then weighing the pulp raw material, a distiller's yeast and purified water according to a ratio of 100:0.7-0.9:270-260 and weighing the powder raw materials, the distiller's yeast and purified water according to a ratio of 100:0.7-0.9:300-280, and putting the mixtures into a fermentation vat respectively, stirring the substances evenly, and performing sealed fermentation till the mash liquid turns into dark brown and is fermented well, and then putting the material into wine steaming equipment, thus obtaining the high quality green rice wine with acid-resistant and quality guaranteeing durability and mellow and excellent taste. The method provided by the invention has the advantages of practicability, fine process and easy operation, strong utility and easy promotion, rice raw material refining, short fermentation period and excellent mash material, high yield, high quality and energy-saving, and the rice wine has long shelf life, mellow quality and excellent taste.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Potato refinement raw material liquid efficient liquor brewing method

InactiveCN105802787AAdvanced technologyCraftsmanshipAlcoholic beverage preparationPulp and paper industryBrewing

A potato refinement raw material liquid efficient liquor brewing method comprises device configuration, refinement and optimized matching, liquid fermentation and efficient liquor steaming, and concretely comprises the following steps: weighing and mixing cleaned raw and dry cassava and sweet potato according to a ratio of 6-5:3-4, weighing and blending the obtained mixture and a perfume according to a ratio of 6-5:0.3-0.2, respectively crushing the mixture and the perfume through a crusher to form a 38-40 mesh flavor raw material slurry-shaped and powdery raw material, weighing the slurry-shaped raw material, distiller's yeast and purified water according to a ratio of 100:0.7-0.8:260-280, weighing the powdery raw material, distiller's yeast and purified water according to a ratio of 100:0.6-0.8:280-300, respectively adding all obtained materials to a fermentation tank or pool, uniformly stirring the materials, and carrying out anaerobic fermentation for 12d until the obtained undecanted liquor is tawny and mature. The potato refinement raw material liquid efficient liquor brewing method has the advantages of advanced technology, fine process, easy operation, strong practicality, easy promotion, coarse cereal raw material refinement, short fermentation period, good undecanted liquor, high yield, high quality, energy saving, mellowness and good taste of obtained liquor, high safety, environmental protection, and obvious comprehensive economy benefit in promotion and use.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

A kind of preparation method of space sesame-flavored liquor special koji for brewing

ActiveCN103865725BQuality assuranceGuaranteed stabilityAlcoholic beverage preparationFlavorAspergillus

The invention discloses a preparation method for a special wine-making starter for space sesame-fragrance type wine. According to the preparation method disclosed by the invention, space bacillus, space saccharomycetes, space aspergillus oryzae and space Hanoi aspergillus which are subjected to space mutation breeding are used for preparing a space bacillus starter, a space saccharomycetes starter, a space aspergillus oryzae starter and a space Hanoi aspergillus starter according to processes respectively, and then the space bacillus starter, the space saccharomycetes starter, the space aspergillus oryzae starter and the space Hanoi aspergillus starter are mixed according to a ratio of 20-30%: 10-20%: 10-20%: 30-60% to prepare the special starter for space sesame-fragrance type wine, wherein the space bacillus starter is prepared by a zymomonas fermentation and compounding process; the space Hanoi aspergillus starter is prepared by a two-step fermentation method; starter pool culture for space bacillus is carried out by a method of sterilizing raw materials, then cooled to 60-70 DEG C, and replenished with saccharifying enzyme to increase reducing sugar; and meanwhile, space aspergillus oryzae is added, thus further improving the quality of the special starter for space sesame-fragrance type wine. The special starter for space sesame-fragrance type wine produced by the method is stable in quality, capable of increasing wine yield by 3-5%, reducing fermentation period by 3-5 days, increasing the content of the characteristic constituents of the sesame-fragrance type wine by 5-10%, and reducing the dosage of the starter by 2-7%; and the produced raw wine is full in body, gentle in fragrance and with a typical sesame-fragrance style.

Owner:泰山酒业集团股份有限公司 +1

Vertical fermentation bin and fermentation process thereof

ActiveCN102603385BReduce weightCause hypoxiaBio-organic fraction processingOrganic fertiliser preparationProcess engineeringEngineering

The invention relates to a vertical fermentation bin and a fermentation process thereof. The vertical fermentation bin comprises a bin wall, a bin top, an air suction opening, a feed inlet, a discharge outlet, transverse beams, a hydraulic system, a belt conveying system and an air supply system. The fermentation process comprises the steps of material mixing, inoculation, lifting, fermentation and discharging. Since the transverse beams are arranged in the fermentation bin at intervals and are used for reducing the weight of materials during falling from the top, the materials are prevented from being compacted and the situation of oxygen deficit of compost is avoided; and since the hydraulic system is combined with a scraping plate for discharging, the materials are not apt to form material arches, the discharged materials are even, the equipment is not apt to be corroded, the maintenance cost is low, the production process is easy to control, the fermentation period is short and the product quality is stable.

Owner:GUANGDONG RUNTIAN FERTILIZER CO LTD

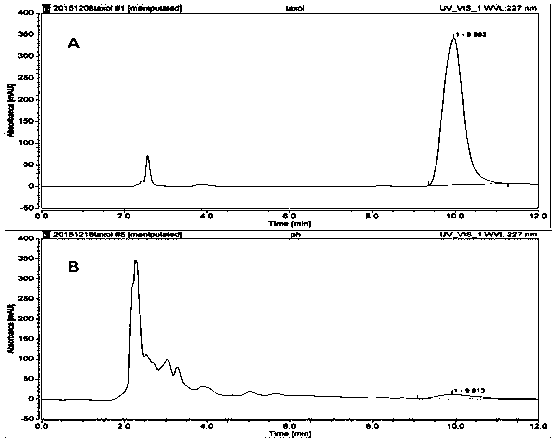

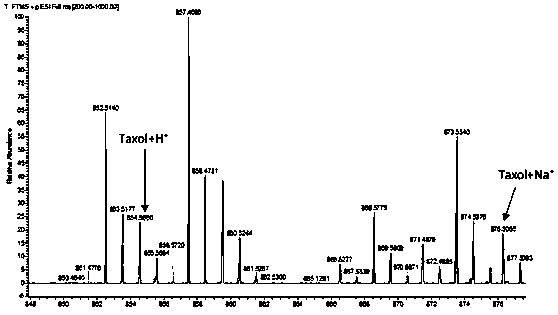

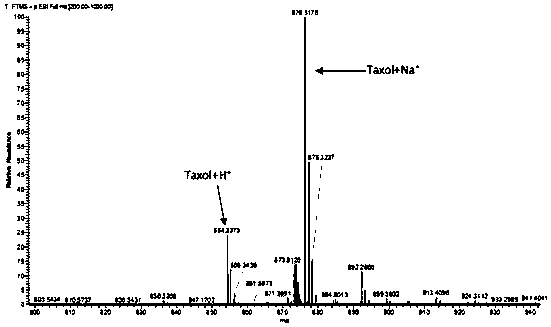

A taxol-producing endophytic fungus Aspergillus aculeatus tax-6 and its application

ActiveCN107058118BIncrease productionShort fermentation periodFungiMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a high-efficiency paclitaxel-producing fungus Aspergillus aculeatus Tax-6 and its application. The high-efficiency paclitaxel-producing fungus is named Aspergillus aculeatus ( Aspergillus aculeatinus ) Tax‑6, deposited in the China Center for Type Culture Collection, the deposit number is CCTCC M 2016614, the deposit date is November 3, 2016, and the deposit address is Wuhan University, Wuhan, China. The present invention cultivates Tax‑6 through a liquid fermentation process and then extracts paclitaxel in the fermentation broth, the highest content reaches 334.92 µg / L and the culture time only needs 7 days. The present invention utilizes the endophytic fungus of yew bark to ferment paclitaxel to produce paclitaxel, which not only produces paclitaxel, a high-efficiency anticancer drug, but also protects the rare species of yew.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com