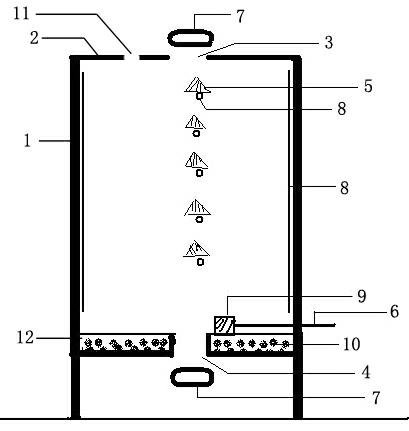

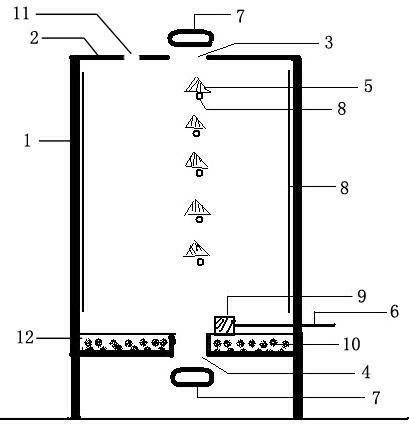

Vertical fermentation bin and fermentation process thereof

A fermentation process and fermentation chamber technology, applied to organic fertilizers, preparation of organic fertilizers, treatment of bio-organic parts, etc., can solve problems such as easy corrosion of flaps or spirals, easy arching of materials, high equipment maintenance costs, etc., to achieve product quality The effect of stable quality, uniform discharge and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

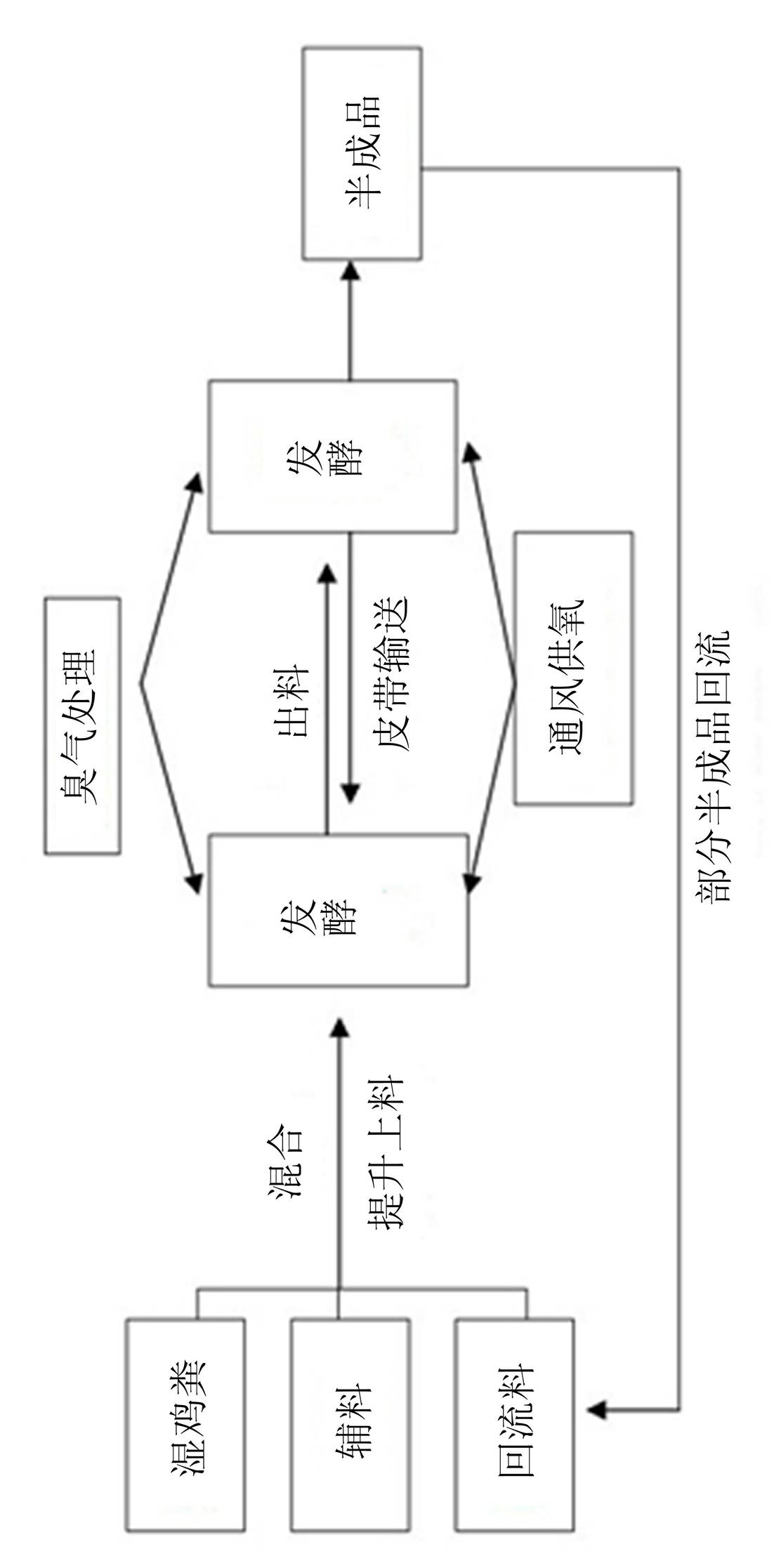

Method used

Image

Examples

Embodiment 1

[0046]Take the daily treatment of 10 tons of wet chicken manure as an example. The initial moisture of wet chicken manure is 80%. Need to add 5 tons of bran and 5 tons of peat soil for seasoning. After mixing, the moisture content of the material is about 50%. According to the method of direct inoculation of biological bacteria at a ratio of 1 / 1000, the bacteria are purchased commercial bacteria, mainly composite bacteria containing yeast, Bacillus megaterium and lactic acid bacteria. After the three materials are evenly transported and mixed together by the speed-adjusting auger, the liquid compound bacterial agent is sprayed. The spraying amount is 1 / 1000 of the total weight of the organic material. The inoculated organic material is lifted to the conveyor belt at the top of the fermentation bin by the elevator. On the top, enter the fermentation chamber through the feed port. From the second day after feeding the material for fermentation, the fermentation temperature ha...

example 2

[0048] Take the daily treatment of 10 tons of wet chicken manure as an example. The initial moisture of wet chicken manure is 80%. Need to add 5 tons of dry organic materials and 5 tons of fermented clinker. After mixing, the moisture content of the material is about 50%. After the three kinds of materials are evenly transported and mixed together by the speed-adjusting auger, they are lifted to the conveyor belt on the top of the fermentation bin by the hoist, and enter the fermentation bin through the feeding port. During the period, due to the use of recycled material as inoculation, the inoculation amount was about 25%. From the second day after feeding the material for fermentation, the fermentation temperature has reached above 60°C, and it only takes about 15 hours for the fermentation temperature of the material to rise from the initial temperature of 40-45°C to 60°C. During the entire fermentation period, the material temperature is mostly above 70°C, and the highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com