Preparation method of new natural abscisic acid

A natural abscisic acid and seed technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of glucose repression, high production cost, and low fermentation yield, so as to reduce production cost and increase acid production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

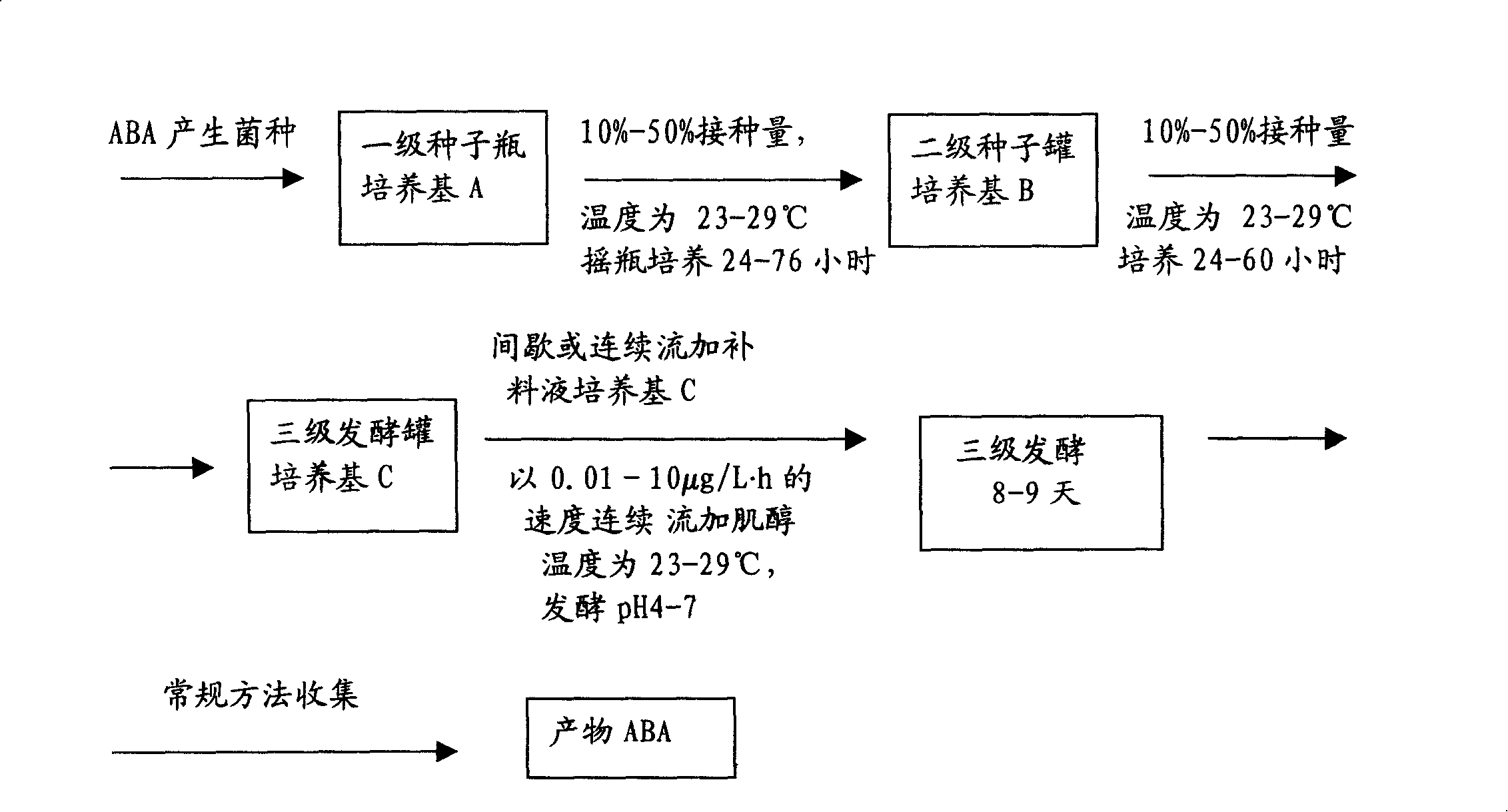

Method used

Image

Examples

Embodiment 1

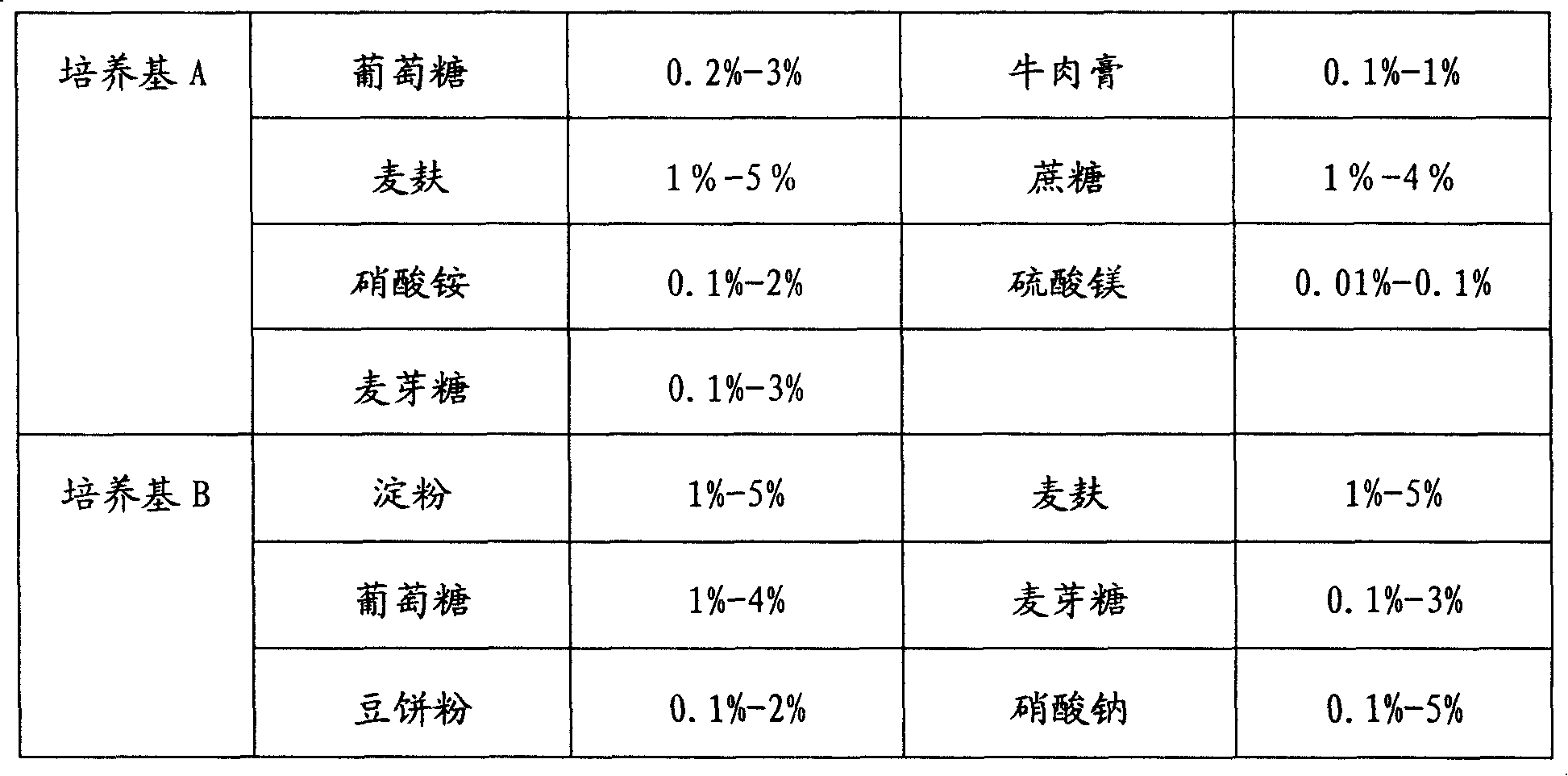

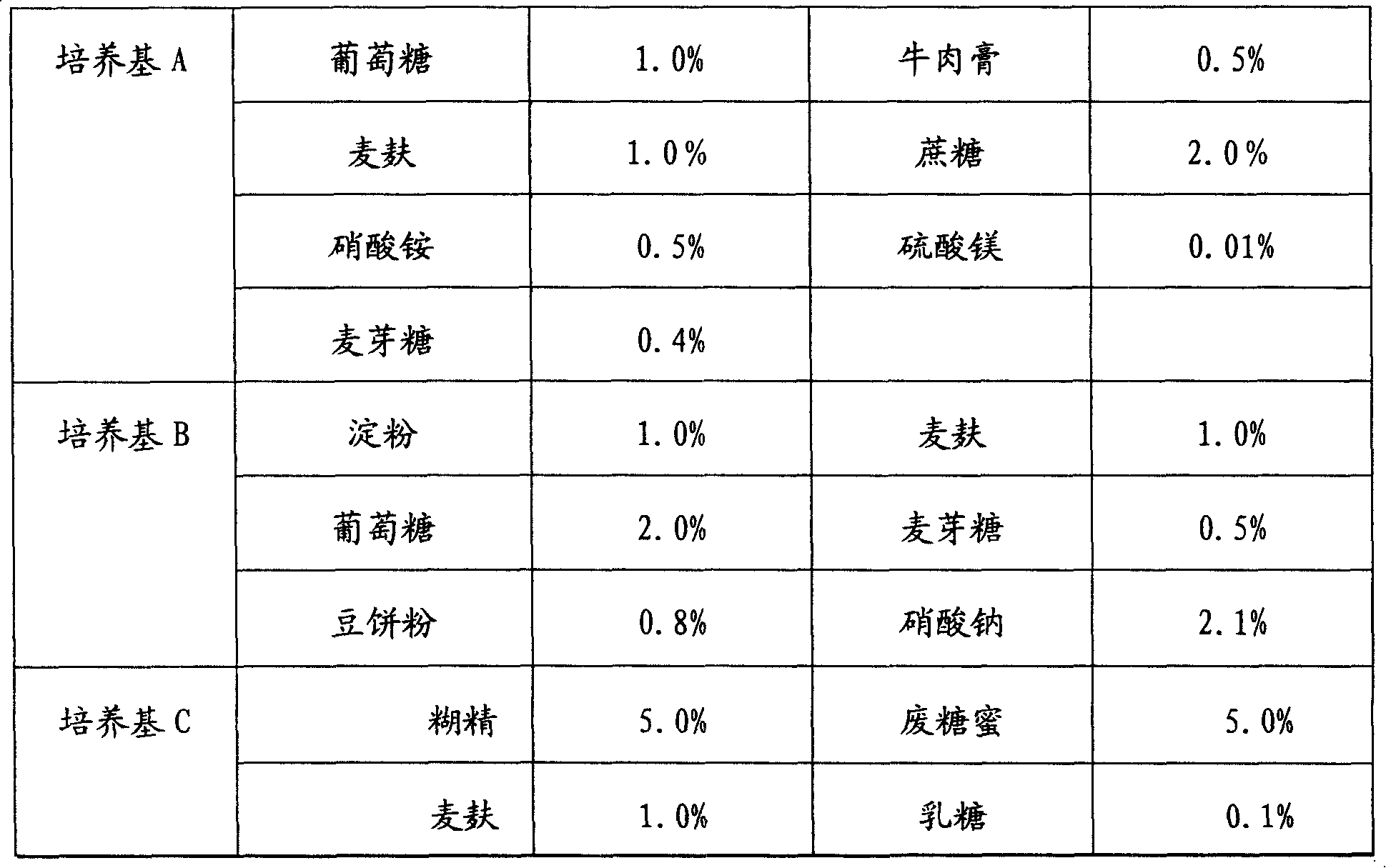

[0174] Use 25 1000ml Erlenmeyer flasks, each with 300ml medium A, sterilize at 120°C, inoculate the activated abscisic acid high-yielding strain Botrytis cinerea TBC-10 CGMCC No.1889 spore suspension after cooling, and place at 25°C , shake flasks for 24-46 hours. Inoculate the cultured primary seed liquid into a 100 liter fermenter (secondary seed tank) with 50 liters of medium B inside by 13%-15% inoculum, and cultivate it with aeration and stirring at a temperature of 26°C-28°C for 24 -40 hours.

[0175] Use a 1-ton fermenter for the third-stage tank fermentation, and the medium C in the tank is about 500L. After sterilizing with conventional high-pressure hot steam sterilization, inoculate the seed liquid of the second-stage tank according to the inoculation amount of 10%-15%, and ferment with aeration and stirring for 20 - After 40 hours, feed medium C is intermittently fed, the intermittent time is to feed once every 10-15 hours, and the amount of each feed is 0.1%-0.5%...

Embodiment 2

[0182] Use 50 1000ml Erlenmeyer flasks, each with 300ml medium A, sterilize at 120°C, inoculate the activated abscisic acid high-yielding strain Botrytis cinerea TBC-10 CGMCC No.1889 spore suspension after cooling, and place at 25°C , shake flasks for 24-33 hours. Inoculate the cultured primary seed solution into a 200-liter fermenter (secondary seed tank) with 100 liters of medium B inside according to the inoculum size of 15%-18%, and cultivate it with aeration and stirring at a temperature of about 26°C for 24-30 Hour.

[0183] Use a 1-ton fermenter for the third-stage fermentation. The medium C in the tank is about 500L. After sterilizing with conventional high-pressure hot steam sterilization, inoculate the seed liquid of the second-stage tank with 20%-25% of the inoculation amount, and ferment with aeration and stirring for 15 - After 24 hours, feed medium C is fed intermittently, the intermittent time is 1-3 times every 20-28 hours, and the amount of each feed is 0.05%...

Embodiment 3

[0189]Use 30 1000ml Erlenmeyer flasks, each containing 300ml medium A, sterilize at 120°C, inoculate the activated abscisic acid high-yielding strain Botrytis cinerea TBI-9 CGMCC No.0500 spore suspension after cooling, place at 27°C, Shake flasks were incubated for 24-33 hours. Inoculate the cultured primary seed liquid into a 100 liter fermenter (secondary seed tank) with 50 liters of medium B inside by 15%-20% inoculation amount, and cultivate it with aeration and stirring at a temperature of about 26°C for 24-30 Hour.

[0190] Use a 1-ton fermenter for the third-stage fermentation. The medium C in the tank is about 500L. After sterilizing with conventional high-pressure hot steam sterilization, inoculate the seed liquid of the second-stage tank with 10%-15% of the inoculation amount, and ferment with aeration and stirring for 15 - After 24 hours, continuously feed medium C at a rate of 0.1-5 L / h until 10 hours before stopping fermentation (lower tank). Add inositol contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com