Escherichia coli genetically engineered bacterium and method for producing L-theanine by fermenting escherichia coli genetically engineered bacterium

A technology of genetically engineered bacteria and theanine, applied in the field of bioengineering, can solve the problems of low yield and product purity, and achieve the effects of improving product yield and product quality, reducing pollution risks, and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

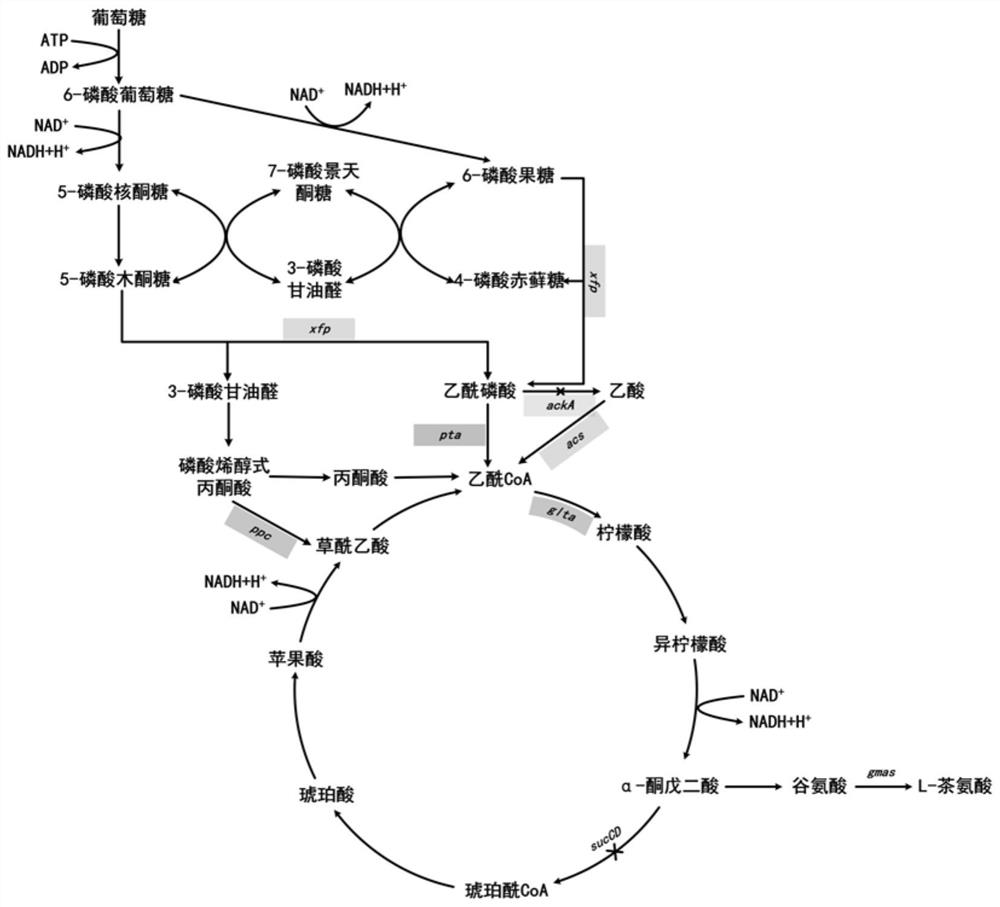

[0072] Embodiment 1: the construction of genetically engineered bacterial strain Escherichia coli E.coli THEE (transformation strategy sees figure 1 ):

[0073] 1. Methods of gene editing

[0074] In the present invention, the gene editing method mediated by CRISPR / Cas 9 is carried out with reference to literature (Metabolic Engineering, 2015, 31:13-21.), and the two plasmids used in this method are pGRB and pREDCas9 respectively. Among them, pREDCas9 carries gRNA plasmid elimination system, Red recombination system of lambda phage and Cas9 protein expression system, spectinomycin resistance (working concentration: 100mg / L), cultured at 32°C; pGRB plasmid, with pUC18 as the backbone, including promoter J23100 , gRNA-Cas9 binding region sequence and terminator sequence, ampicillin resistance (working concentration: 100mg / L), cultured at 37°C.

[0075] 2. The specific process of strain construction

[0076] L-theanine-producing genetic engineering bacteria constructed with ZL...

Embodiment 2

[0095] Example 2: Fermentation of strain E.coli THEE 5L fermenter to produce L-theanine

[0096] The composition of the slant medium is: glucose 2g / L, peptone 6g / L, beef extract 6g / L, yeast powder 3g / L, sodium chloride 2g / L, agar 18g / L, pH 7.0.

[0097] The composition of the seed medium is: glucose 25g / L, yeast extract 6g / L, peptone 15g / L, sodium chloride 15g / L, the rest is water, pH 7.0.

[0098] The composition of the fermentation medium is: glucose 30g / L, yeast powder 6g / L, corn steep liquor 8ml / L, citric acid 1.5g / L, potassium dihydrogen phosphate 2.5g / L, dipotassium hydrogen phosphate 2.0g / L, magnesium sulfate 1.0g / L, the rest is water, pH 7.2.

[0099] (1) Incline culture: Scrape a ring of strains from the bacteria-preserving tube of the -80°C refrigerator, spread evenly on the activated slope, incubate at 37°C for 14 hours, transfer to an eggplant-shaped bottle and continue to cultivate for 14 hours;

[0100] (2) Seed culture: Take an appropriate amount of sterile wate...

Embodiment 3

[0107] Embodiment 3 Determination of OD linkage ethylamine supplementation strategy

[0108] Fermentation and production of L-theanine in a 5L fermenter, when OD 600nm When it reaches above 10, start to add ethylamine. According to the degree of glucose consumption by the bacteria, adjust the flow rate of ethylamine to different degrees every hour to ensure that the sugar consumption rate is maintained at 7-8g L -1 h -1 . Collect 50 batches of fermentation batches whose L-theanine yield reaches 80g / L, and calculate the average OD at different fermentation times 600nm Value, average fermentation broth volume, and average ethylamine flow acceleration rate are shown in the following table:

[0109]

[0110]

[0111] According to the data in the above table, use ORIGIN software to perform linear fitting, Y is the average ethylamine flow acceleration rate, and X is the average OD 600nm value / (average fermentation broth volume (L)×fermentation time (h). Fitting results are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com