Processing technology of copper strip for buzzing piece

A processing technology and buzzer technology, applied in metal material coating technology, metal rolling, etc., can solve the problems affecting the mechanical properties, strength, poor wear resistance, and wear of copper strips of copper strips, so as to protect the copper strip substrate , Improve the strength and electrical conductivity, and enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

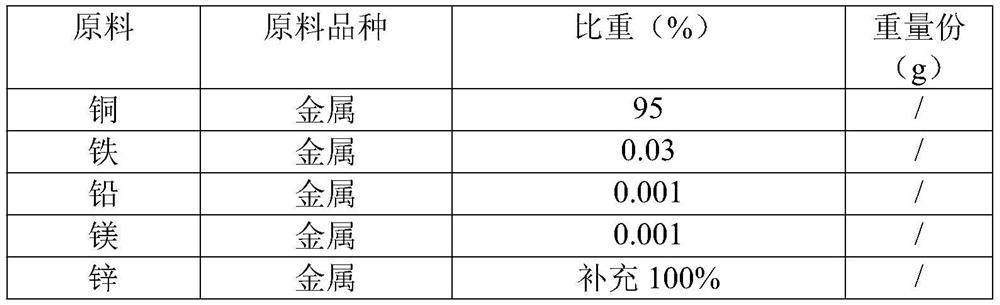

[0039] Embodiment 1, the preparation raw material A formula ratio 1 used in the preparation process is:

[0040]

Embodiment 2

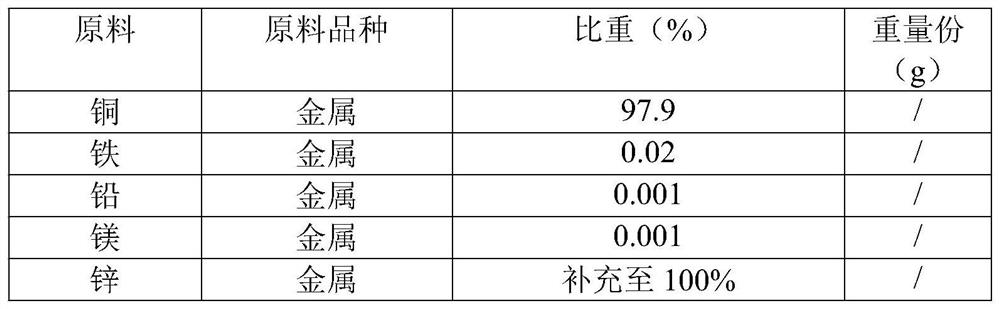

[0041] Embodiment 2, the preparation raw material A formula ratio 2 used in the preparation process is:

[0042]

[0043]

Embodiment 3

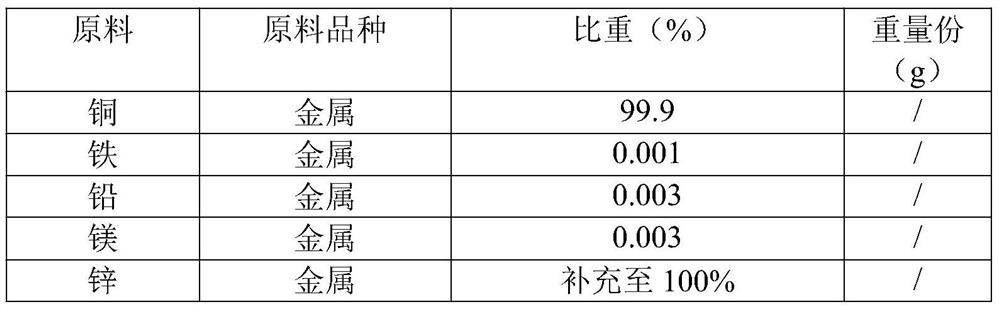

[0044] Embodiment 3, the preparation raw material A formula ratio 3 used in the preparation process is:

[0045]

[0046] In summary, the present invention provides a process for processing copper strips for buzzing chips. The present invention selects multi-group mixed raw materials of preparation raw material A, preparation raw material B and raw material C as the preparation raw materials of the copper strip, and simultaneously selects Proper proportion of copper, iron, magnesium and zinc is used as preparation raw material A, suitable proportion of copper, iron, tin, lead, phosphorus and zinc is selected as preparation raw material B, and zinc ingot is selected as preparation raw material C. The mixing of multiple raw materials can improve the The structural level of the copper strip enhances the mechanical properties and improves the strength and electrical conductivity of the copper strip. By effectively controlling the concentration of the acid solution during picklin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com