Prefabricated concrete main beam and cast-in-place secondary beam connecting structure and construction method thereof

A prefabricated concrete and connection structure technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problem of low node strength at the junction of prefabricated main beams and cast-in-place secondary beams, which cannot effectively prevent the stress concentration of cast-in-place secondary beams, The low structural strength of the primary and secondary beam joints achieves the effect of convenient and quick binding, which is conducive to hoisting operations and reduces the difficulty of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

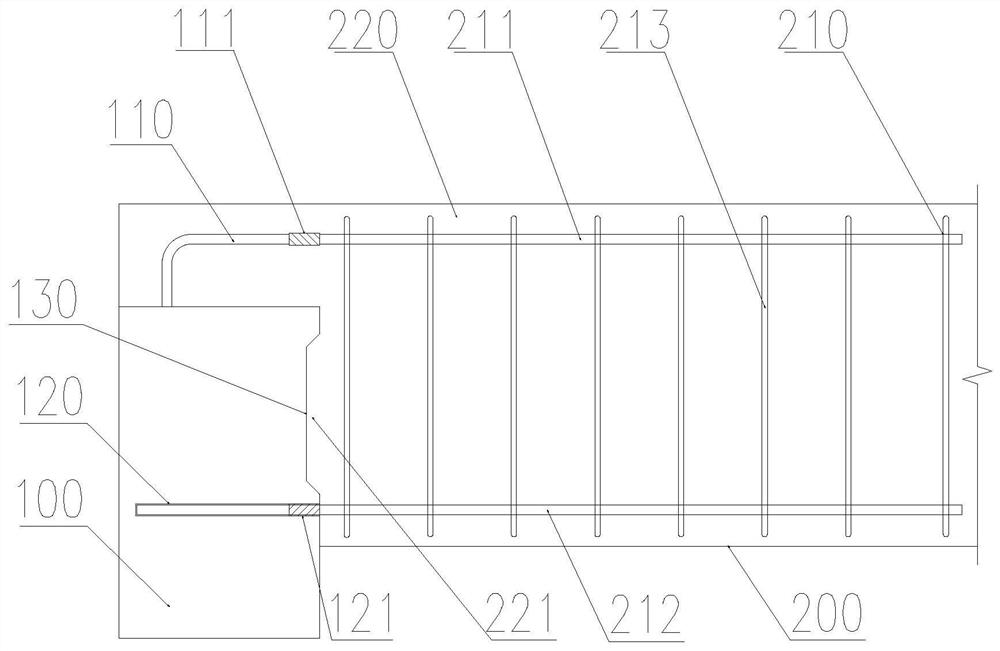

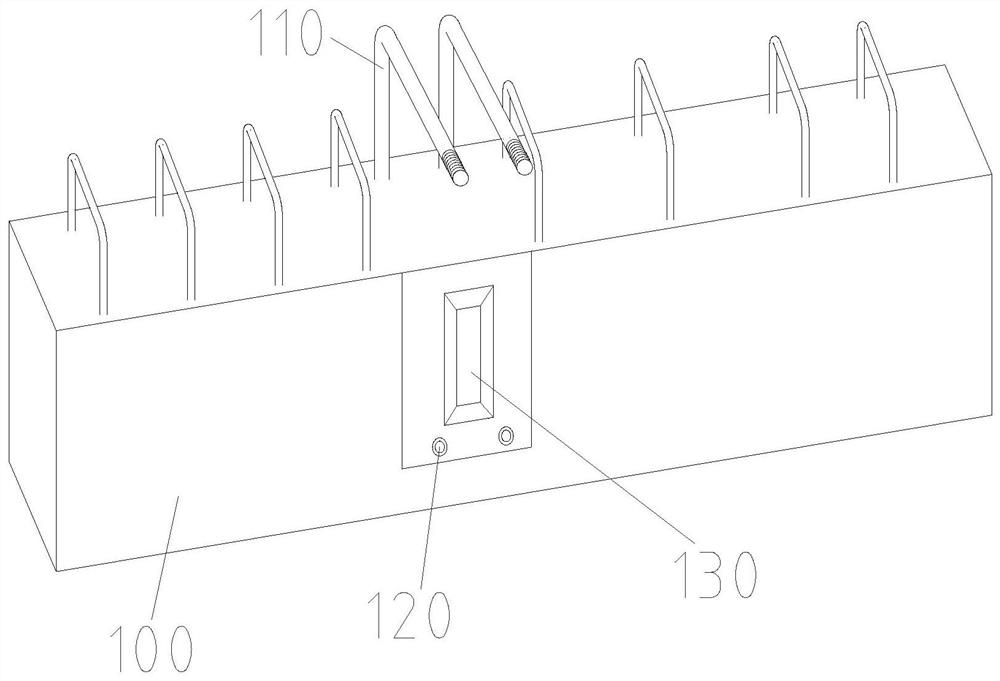

[0032] as attached figure 1 , figure 2 As shown, a prefabricated concrete main beam and cast-in-place secondary beam connection structure, including:

[0033] The prefabricated concrete main beam 100 has an installation position on it, a bent anchor steel bar 110 is installed on the top wall of the installation position, and a pre-embedded hole 120 is opened on the side wall of the installation position, and a pre-embedded hole 120 is provided in the pre-embedded hole 120. Straight thread sleeve 121;

[0034] The cast-in-place secondary beam 200, which is installed at the installation position, the cast-in-place secondary beam 200 includes a steel bar skeleton 210 and cast-in-place concrete 220, and the upper longitudinal reinforcement 211 connection end of the steel bar skeleton 210 is connected to the bent anchor bar 110 , the connection end of the lower longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com