Method for preparing high-purity titanium plate for use as target

A pure titanium plate and target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of difficult production and high technical requirements, and achieve the effect of reducing shrinkage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

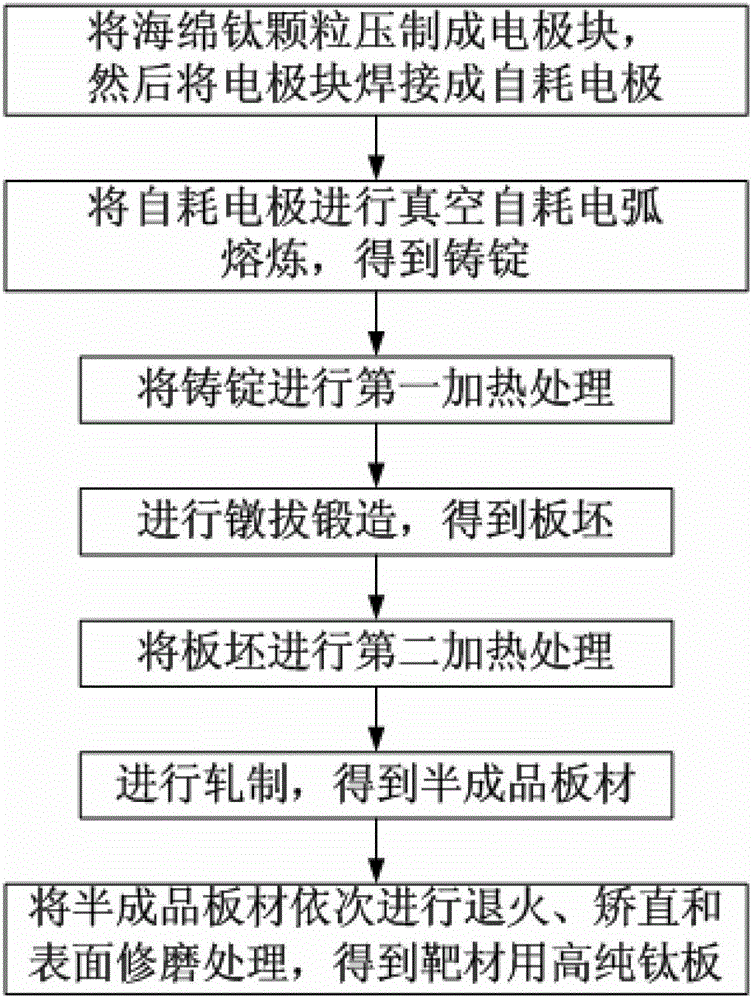

[0027] to combine figure 1 , the preparation method of the high-purity titanium plate for the target in this embodiment includes the following steps:

[0028] Step 1. Press the zero-grade sponge titanium particles with a particle size of 0.83mm to 12.7mm and meet the national standard GB / T2524-2002 into a density of 3.3g / cm 3 Then a plurality of the electrode blocks are vacuum plasma welded in a vacuum plasma welding box to obtain a consumable electrode; before pressing, the method of stirring can be used to make the size particles of zero-grade sponge titanium evenly distributed to ensure that the electrodes The density of the block is consistent; the pressed electrode block must be kept intact, without defects such as slag falling, delamination, and cracks;

[0029] Step 2, placing the consumable electrode described in step 1 in a vacuum consumable arc melting furnace, and performing vacuum consumable arc melting twice under the condition that the degree of vacuum is not gr...

Embodiment 2

[0037] to combinefigure 1 , the preparation method of the high-purity titanium plate for the target in this embodiment includes the following steps:

[0038] Step 1. Press the zero-grade sponge titanium particles with a particle size of 0.83 mm to 12.7 mm and meet the national standard GB / T2524-2002 into a density of 3.4 g / cm 3 Then a plurality of the electrode blocks are vacuum plasma welded in a vacuum plasma welding box to obtain a consumable electrode; before pressing, the method of stirring can be used to make the size particles of zero-grade sponge titanium evenly distributed to ensure that the electrodes The density of the block is consistent; the pressed electrode block must be kept intact, without defects such as slag falling, delamination, and cracks;

[0039] Step 2, placing the consumable electrode described in step 1 in a vacuum consumable arc melting furnace, and performing vacuum consumable arc melting twice under the condition that the degree of vacuum is not g...

Embodiment 3

[0047] to combine figure 1 , the preparation method of the high-purity titanium plate for the target in this embodiment includes the following steps:

[0048] Step 1. Press the zero-grade sponge titanium particles with a particle size of 0.83mm to 12.7mm and meet the national standard GB / T2524-2002 into a density of 3.5g / cm 3 Then a plurality of the electrode blocks are vacuum plasma welded in a vacuum plasma welding box to obtain a consumable electrode; before pressing, the method of stirring can be used to make the size particles of zero-grade sponge titanium evenly distributed to ensure that the electrodes The density of the block is consistent; the pressed electrode block must be kept intact, without defects such as slag falling, delamination, and cracks;

[0049] Step 2, placing the consumable electrode described in step 1 in a vacuum consumable arc melting furnace, and performing vacuum consumable arc melting twice under the condition that the degree of vacuum is not gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com