Preparation method of liquid edible vinegar and special reactor

A reactor and vinegar technology, applied in the production process of liquid vinegar, can solve the problems of high power consumption, poor utilization of fermented mash, and air, and achieve low power consumption, low equipment cost, and increased dissolved oxygen volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

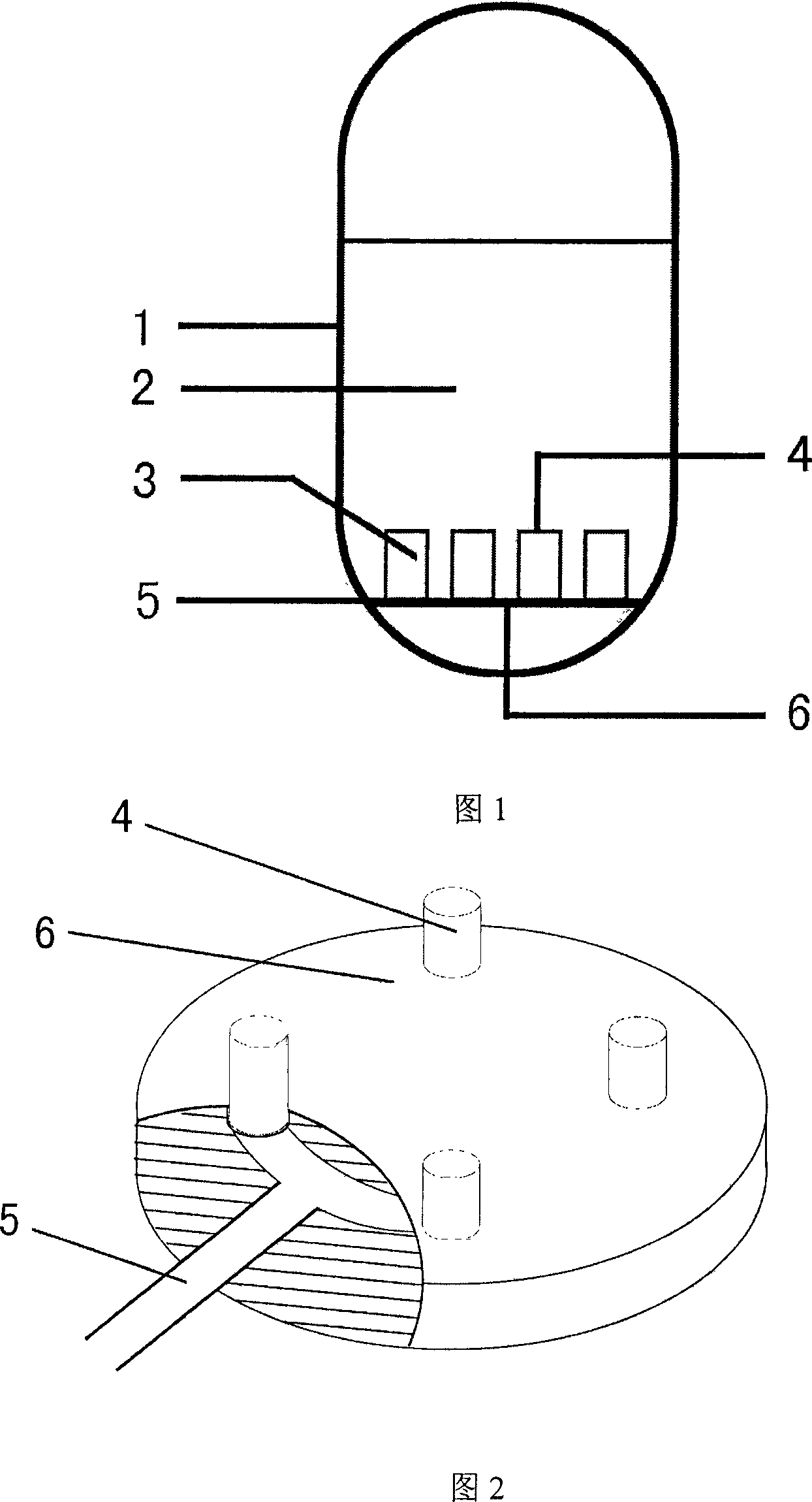

[0024] As shown in Figure 1, a special reactor 3 in the preparation method of liquid vinegar is installed at the bottom of 100 liters of fermentor 1, and the chassis 6 of reactor 3 matches with fermentor 1 bottom shape, drops into fermentor 1 After fermenting the mash 2, feed the compressed air of 0.3 MPa into the reactor 3 through the air inlet pipe 5, the volume ratio of feeding the compressed air and the fermenting mash is 1:0.08, and the air passes through the microporous tube of the reactor 3 4 evenly escapes and infiltrates into the fermented mash 2, fully atomizes the gas and liquid in the fermented mash 2, improves the oxygen transfer coefficient to the acetic acid bacteria, increases the amount of dissolved oxygen, and satisfies the aerobic microorganisms to the greatest extent. The needs of the growth, reproduction and metabolism of acetic acid bacteria continue to ferment the mash 2 maturation after 28 hours to obtain liquid vinegar.

[0025] As shown in Figure 2, a...

Embodiment 2

[0027] Same as Example 1, the difference is that a special reactor 3 in the preparation method of a liquid vinegar is installed at the bottom of the 3 cubic meter fermenter 1, and the chassis 6 of the reactor 3 matches the shape of the bottom of the fermenter 1, to After dropping into the fermented mash 2 in the fermenter 1, feed the compressed air of 0.2 MPa into the reactor 3 through the air inlet pipe 5, the volume ratio of the compressed air and the fermented mash is 1:0.1, and the air from the reactor The microporous tube 4 of 3 evenly escapes and infiltrates into the fermented mash 2, so that the gas and liquid in the fermented mash 2 are fully atomized, improve the oxygen transfer coefficient to the acetic acid bacteria, increase the amount of dissolved oxygen, and maximize the Satisfy the needs of the growth, reproduction and metabolism of the aerobic microorganism acetic acid bacteria, and mature after 29 hours to obtain liquid vinegar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com