Bentonite lamella bridging cladded type slow release composite fertilizer and its preparation method

A technology of compound fertilizer and bentonite, applied in the direction of inorganic fertilizer, ammonium salt fertilizer, fertilizer mixture, etc., can solve the problems of low dosage, underutilization of bentonite structural characteristics and various properties, ineffective improvement of chemical structure and performance Processing and other issues to achieve the effect of improving soil, easy fertilization operation, and increasing application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

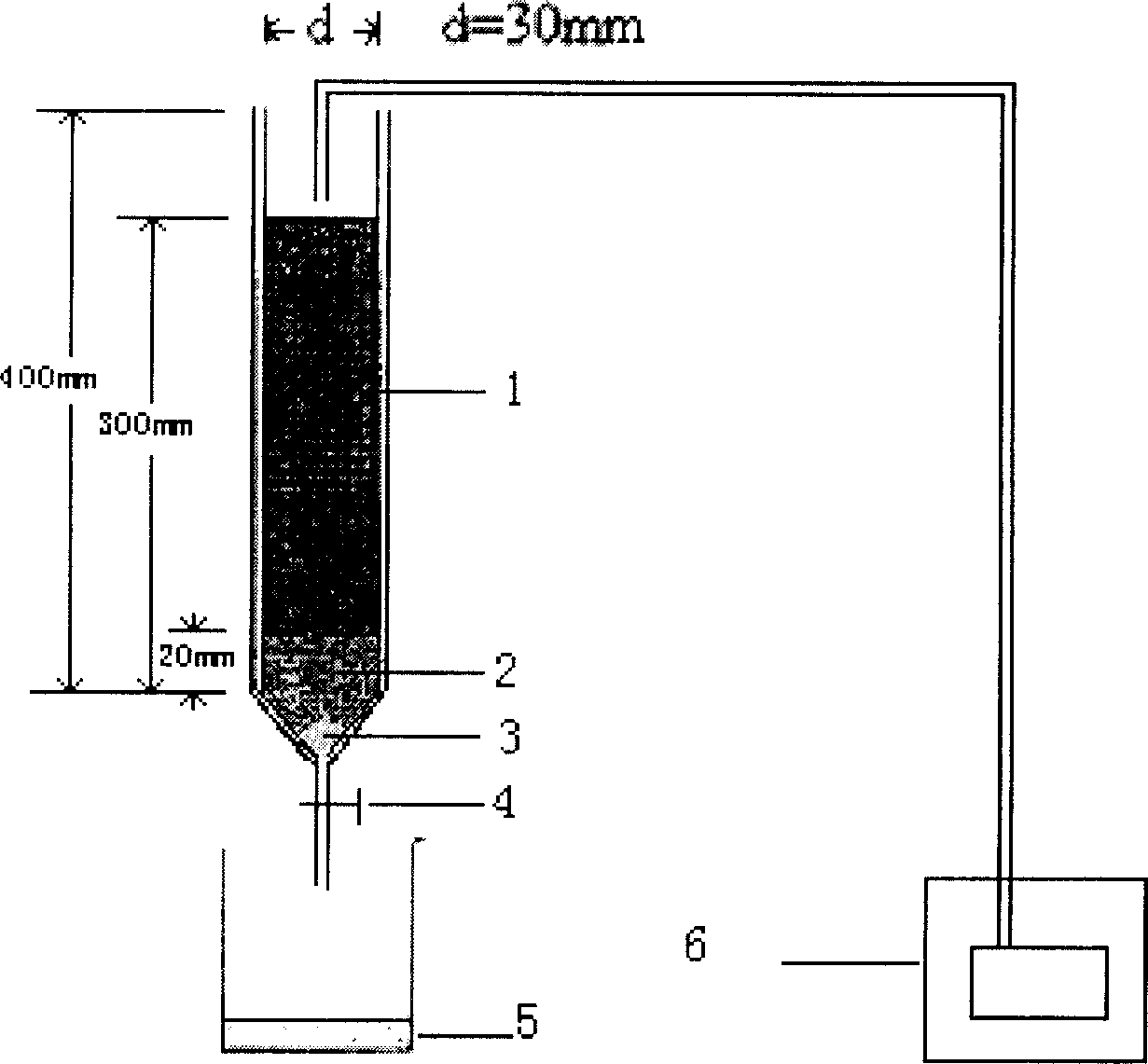

Image

Examples

Embodiment 1

[0064] (1) Pulverize 12kg of potassium chloride, 18kg of ammonium dihydrogen phosphate, 2kg of ammonium bicarbonate, 8kg of ammonium chloride, and 8kg of urea and mix evenly, then add 2kg of gypsum and 36.4kg of bentonite (sodium-based bentonite in Lin'an, Zhejiang), and continue Crush and mix well.

[0065] (2) (2) 15.6kg of bentonite is ground into powder to reach a 200-mesh sieve. Bentonite powder was added into 156kg water, stirred to form a suspension, and then 8.8kg bridging agent (CH 3 O) 3 Si-(CH 2 ) 6 -Si-(OCH 3 ) 3 Add, stir evenly, spray the suspension on the surface of the raw material obtained in step (1), age, the bridging agent reacts with the montmorillonite sheet to form a coating, which is all coated on the surface of the urea or nitrogen, phosphorus and potassium fertilizer particles .

[0066] (3) The above mixture is granulated to obtain a coated slow-release fertilizer. Nitrogen (N%), Phosphorus (P 2 o 5 %), Potassium (K 2 (2%) nutrient ratio i...

Embodiment 2

[0068] (1) Pulverize and mix 21kg of potassium chloride, 29kg of ammonium dihydrogen phosphate, 3kg of ammonium bicarbonate, 13kg of ammonium chloride, and 13kg of urea, and then add 3kg of gypsum and 14kg of bentonite, and continue to pulverize and mix evenly.

[0069] (2) Grind 6kg of bentonite into powder to pass through a 200-mesh sieve. Add bentonite powder to 60Kg of ethanol, stir to form a suspension, then add 6kg of bridging agent orthosilicate ethyl ester, stir evenly, spray the suspension on the surface of the raw material obtained in step (1), age, bridging agent It reacts with montmorillonite sheets to form a coating, which is all coated on the surface of urea or NPK fertilizer particles.

[0070] (3) The above mixture is granulated to obtain a coated slow-release fertilizer. Nitrogen (N%), Phosphorus (P 2 o 5 %), Potassium (K 2 (0%) nutrient ratio is approximately 13:13:13 (excluding bridging agent and solvent quality).

Embodiment 3

[0072] (1) Pulverize and mix 6kg of potassium chloride, 9kg of ammonium dihydrogen phosphate, 1kg of ammonium bicarbonate, 4kg of ammonium chloride, and 4kg of urea, and then add 1kg of gypsum and 60.8kg of bentonite, and continue to pulverize and mix evenly.

[0073] (2) Grind 15.2kg of bentonite into powder to pass through a 200-mesh sieve. Add bentonite powder into 76kg of ethanol and water (weight ratio: 3: 4) mixed solution, stir to form a suspension, and then 3.04kg of bridging agent (C 2 h 5 O) 3 Si-(CH 2 ) 3 -Si-NH 3 + Cl - Add, stir evenly, spray the suspension on the surface of the raw material in (1), age, the bridging agent reacts with the montmorillonite sheets to form a coating, which is completely coated on the surface of the urea or nitrogen, phosphorus and potassium fertilizer particles.

[0074] (3) The above mixture is granulated to obtain a coated slow-release fertilizer. Nitrogen (N%), Phosphorus (P 2 o 5 %), Potassium (K 2 (0%) nutrient ratio i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com