Method for extracting L-phenylalanine from fermentation liquid

A technology of phenylalanine and fermented liquid, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of low first pass rate of finished product quality, low acid production rate of phenylalanine, low yield low cost, high yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For the preparation of L-phenylalanine fermentation broth, refer to patent 201010135604.9, published on April 13, 2011.

[0027] (1) Seed medium:

[0028] Use LB medium (peptone 10g / L, yeast powder 5g / L, NaCl 10g / L), pH 7.0, solid culture

[0029] Add 2% agar to the base.

[0030] (2) Fermentation medium (g / L):

[0031] Glucose 25, L-Tyrosine 0.4, Calcium Carbonate 12.5, Magnesium Sulfate Heptahydrate 3.0, Calcium Chloride Dihydrate 0.015, Potassium Dihydrogen Phosphate 3.0, Sodium Chloride 1.0, Ammonium Sulfate 5.0, Ferrous Sulfate Heptahydrate 0.075, Lemon sodium sulfate 1.0, thiamine 0.075, kanamycin sulfate 0.04, trace element solution (TES) 1.5mL / L, pH 7.0.

[0032] TES solution (g / L): Al2(SO4)3·18H 2 O 2.0, CoSO4 7H 2 O 0.75, CuSO4 5H 2 O 2.5, H3BO30.5, MnSO4·H 2 O24, NaMoO4 2H 2 O 3.0, NiSO4 6H 2 O2.5, ZnSO4 7H 2 O 15, dissolved with 1N HCl.

[0033] The volume of the fermentation medium in the 3L fermenter is 1.5L, the ventilation rate is 1vvm, and th...

Embodiment 2

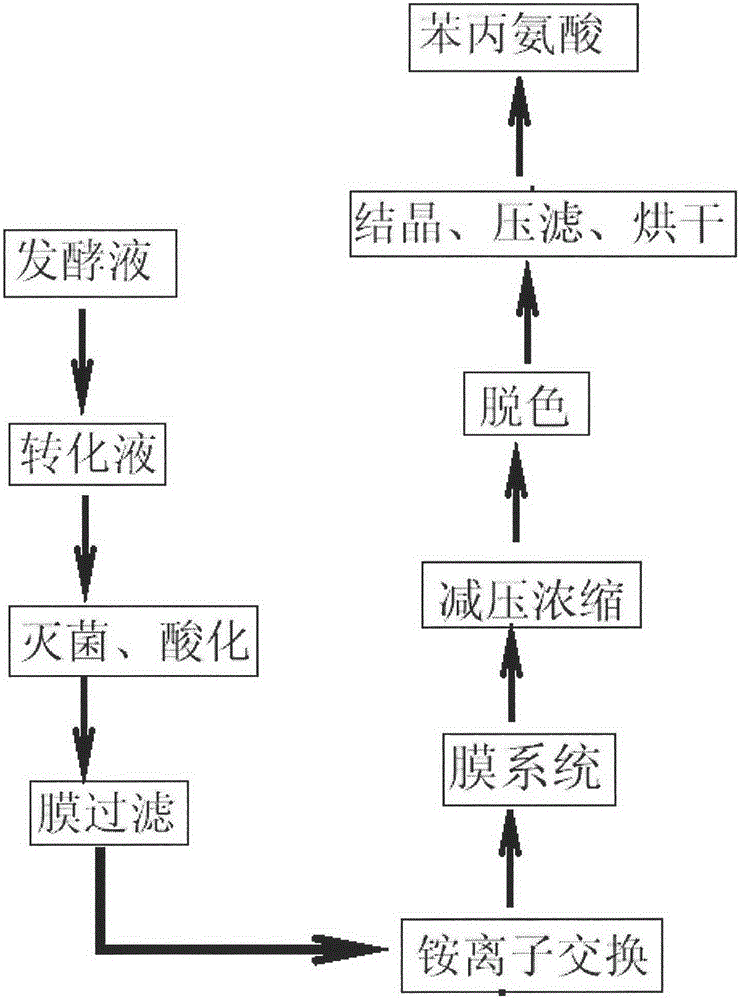

[0035] A method for extracting L-phenylalanine from fermentation broth, comprising:

[0036] (1) The fermentation broth of L-tyrosine-deficient Escherichia coli (obtained in Example 1) was subjected to a temperature of 32.5-36.5°C and a pH of 6 for 40 hours to obtain a transformation fluid;

[0037] (2) Acidify (98% sulfuric acid) above-mentioned conversion liquid under the condition of pH 1.5, sterilize, carry out membrane filtration (water), ammonium ion exchange (liquid ammonia water) afterwards, membrane system, decompression concentration; membrane system includes Ultrafiltration, decolorization and concentration, among which ultrafiltration is to remove the protein with a molecular weight above 6000, and decolorization is to remove the protein with a molecular weight above 300; after decompression and concentration, the ammonia is reused to save costs;

[0038] (3) decolorize the plate and frame of the substance after the step (2) is concentrated under reduced pressure, ...

Embodiment 3

[0042] A method for extracting L-phenylalanine from fermentation broth, comprising:

[0043] (1) The fermentation broth of L-tyrosine-deficient Escherichia coli (obtained in Example 1) was subjected to a temperature of 32.5-36.5° C. and a pH of 8 for 55 hours to obtain a transformation fluid;

[0044] (2) The above-mentioned conversion solution is acidified under the condition of pH 2.5, sterilized, then membrane filtration, ammonium ion exchange, membrane system, and concentration under reduced pressure; the membrane system includes ultrafiltration, decolorization and concentration, wherein ultrafiltration is to remove For proteins with a molecular weight above 6000, the decolorization is to remove the protein with a molecular weight above 300; after decompression and concentration, the ammonia is reused to save costs;

[0045] (3) Decolorize the material plate and frame after step (2) decompression and concentration, the conditions: pH is 4.5, temperature is 62-65 ° C, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com