Preparation method of beer dreg and apple cider vinegar raw stock and apple cider vinegar beverage

A technology of brewer's grains and apple cider vinegar, which is applied in the preparation of vinegar, biochemical equipment and methods, and methods based on microorganisms. It can solve the problems of easy oxidation of active substances and dark color of fruit vinegar products, and achieve beneficial reproduction and metabolism. , Conducive to long-term storage, the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of brewer's grain apple cider vinegar, comprising the following steps:

[0035] (1) Pre-treatment of brewer's grains: Put the collected fresh brewer's grains into a dryer at 80°C for 5 hours to dry, then crush them into fine powder at ultra-high speed, and sieve through a 100-mesh sieve.

[0036] (2) Apple pretreatment: Peel the apples, remove insects and rotten parts, put them in a juicer at a ratio of 1:1 with distilled water, and add 0.5% pectinase to decompose pectin into soluble components. Enzymolysis at 50°C for 2 hours, then filter the pulp twice with boiled two-layer gauze, let it stand for clarification, and then filter once with four-layer gauze to obtain clarified juice, which is sterilized in a constant temperature water bath at 90°C enzyme.

[0037] (3) Yeast activation: Add the weighed dry yeast into 5% sucrose solution, and activate it in a water bath at 37°C for 30 minutes.

[0038](4) Alcoholic fermentation stage: mix brewer's gr...

Embodiment 1

[0054] (1) Pre-treatment of brewer's grains: Put the collected fresh brewer's grains into a dryer at 80°C for 5 hours to dry, then crush them into fine powder at ultra-high speed, and sieve through a 100-mesh sieve.

[0055] (2) Apple pretreatment: Peel the apples, remove insects and rotten parts, put them in a juicer at a ratio of 1:1 with distilled water, and add 0.5% pectinase to decompose pectin into soluble components. Enzymolysis at 50°C for 2 hours, then filter the pulp twice with boiled two-layer gauze, let it stand for clarification, and then filter once with four-layer gauze to obtain clarified juice, which is sterilized in a constant temperature water bath at 90°C enzyme.

[0056] (3) Yeast activation: Add the weighed dry yeast into 5% sucrose solution, and activate it in a water bath at 37°C for 30 minutes.

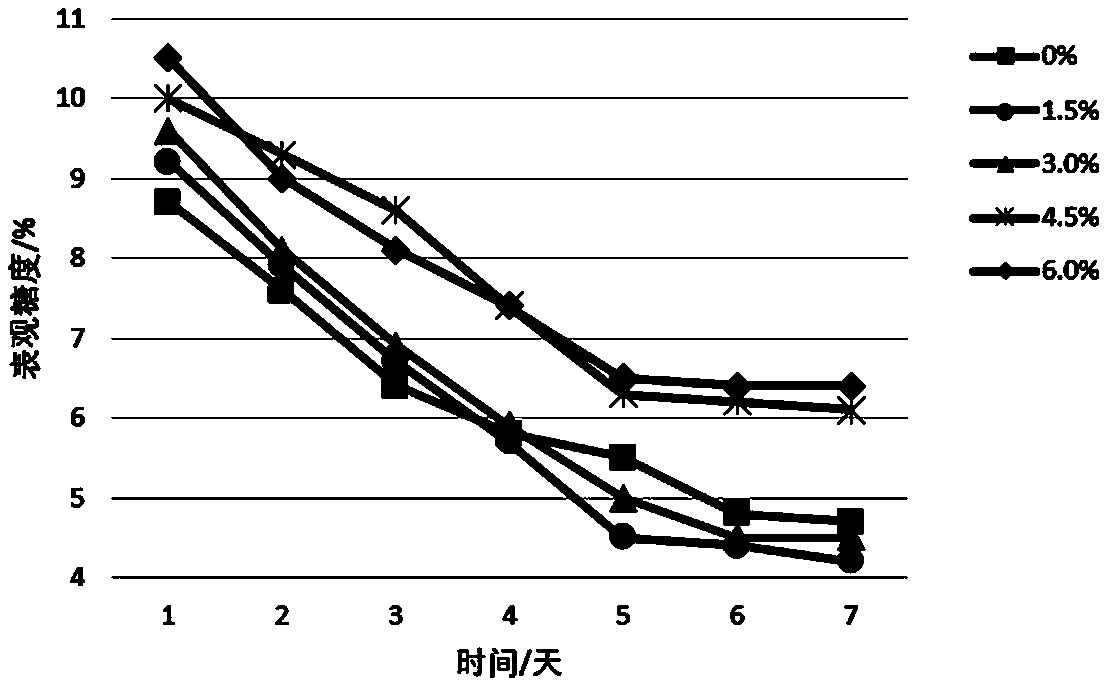

[0057] (4) Alcoholic fermentation stage: mix brewer's grains with fruit juice, add 1.5% brewer's grains, sterilize at 80 degrees for 30 minutes, add 0.6% yea...

Embodiment 13

[0084] (1) Pre-treatment of brewer's grains: Put the collected fresh brewer's grains into a dryer at 80°C for 5 hours to dry, then crush them into fine powder at ultra-high speed, and sieve through a 100-mesh sieve.

[0085] (2) Apple pretreatment: Peel the apples, remove insects and rotten parts, put them in a juicer at a ratio of 1:1 with distilled water, and add 0.5% pectinase to decompose pectin into soluble components. Enzymolysis at 50°C for 2 hours, then filter the pulp twice with boiled two-layer gauze, let it stand for clarification, and then filter once with four-layer gauze to obtain clarified juice, which is sterilized in a constant temperature water bath at 90°C enzyme.

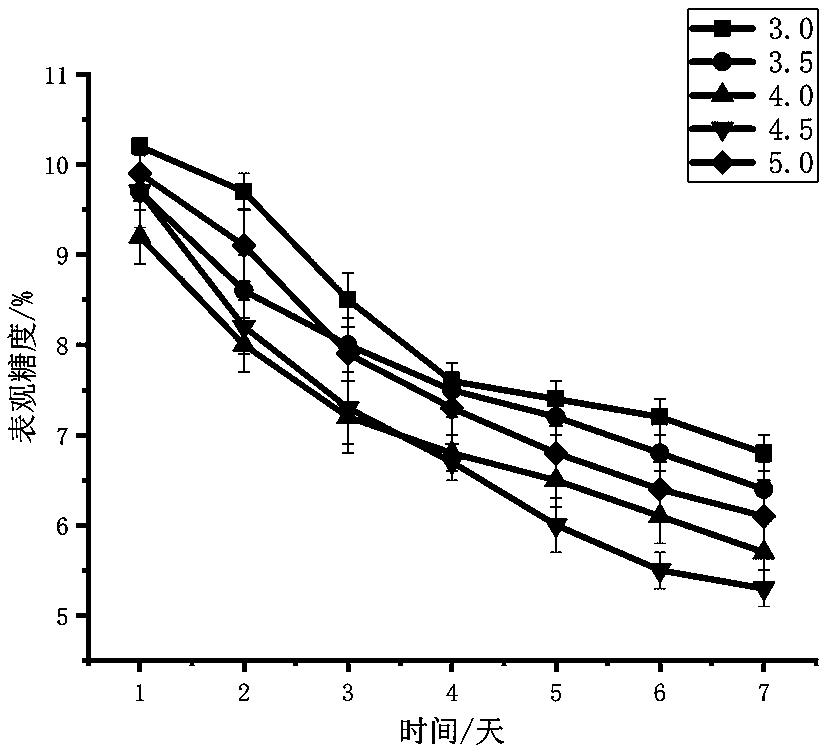

[0086] (3) Activate high temperature resistant yeast and lactic acid bacteria: the mass ratio of high temperature resistant yeast and lactic acid bacteria is 5:1, add the weighed high temperature resistant yeast into 5% sucrose solution, and activate it in a water bath at 37°C for 30 minutes ; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com