Method for improving glucose acid conversion rate of glutamic acid fermentation through adding trehalase

A technology of trehalase and glutamic acid, applied in the field of corn deep processing, can solve the problems of undiscovered patent publications, unfavorable normal metabolism of glutamic acid bacteria, unnecessary consumption of sugar, etc., and achieves reduction of sugar concentration and improvement of utilization rate. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for increasing the sugar-acid conversion rate of glutamic acid fermentation by adding trehalase, the steps are as follows:

[0033] (1) Production equipment: 10L glutamic acid fermentation tank;

[0034] (2) Adding method of enzyme preparation: take the 28hr fermented liquid from the fermenter in the fermentation workshop (aseptic operation), and continue to ferment in the small-scale fermenter.

[0035] (3) Data comparison:

[0036] The average sugar-acid conversion rate of the fermenter with trehalase added is 69.5-71%, and the average acid production rate is 19-20.5%. The average sugar-acid conversion rate of the fermentation tank without adding trehalase is 68-69.5%, and the average acid production rate is 18-19.5%. . Through experimental comparison, it is found that the sugar-acid conversion rate of the experimental tank added with trehalase can be increased by 1-2%, and the acid production can be increased by 1-1.5%.

Embodiment 2

[0038] A method for increasing the sugar-acid conversion rate of glutamic acid fermentation by adding trehalase, the steps are as follows:

[0039] (1) Production equipment: 800m 3 Fermenter.

[0040] (2) Addition of enzyme preparation: add 0.1-100ppm trehalase in the late stage of glutamic acid fermentation process (20-32h), the temperature requirement for adding is 30-40°C, and the fermentation operating conditions before enzyme addition remain unchanged.

[0041] (3) Data comparison

[0042] The average sugar-acid conversion rate of the fermenter with trehalase added is 68-69.5%, and the average acid production rate is 18-19.5%. The average sugar-acid conversion rate of the fermentation tank without adding trehalase is 67-69%, and the average acid production rate is 17-19%. . Through experimental comparison, it is found that the sugar-acid conversion rate of the experimental tank added with trehalase can be increased by 1-1.5%, and the acid production can be increased by...

Embodiment 3

[0044] A method for increasing the sugar-acid conversion rate of glutamic acid fermentation by adding trehalase. Trehalase is added in the late stage of glutamic acid fermentation. The adding time is: 20-32 hours during the fermentation period, and the temperature when adding is required to be 30°C-40°C , Adding ratio: 0.1-100ppm, the fermentation operation conditions before inoculating the enzyme remain unchanged.

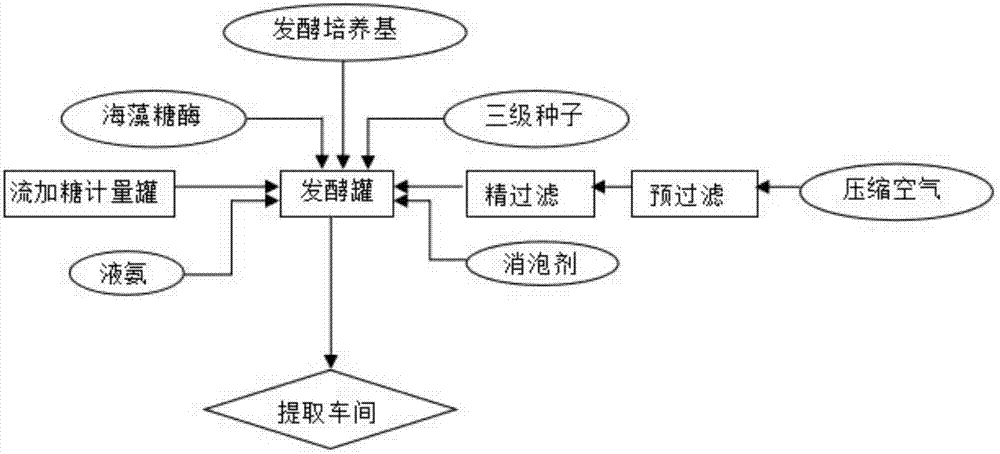

[0045] The specific steps can be as follows (such as figure 1 shown):

[0046] (1) Ingredients: According to the ratio of the conventional glutamic acid fermentation method, weigh the various raw materials of the fermentation medium and dissolve them completely to prepare the fermentation medium;

[0047] (2) Sterilization: Sterilize the prepared fermentation medium at a temperature of 108-110°C for 8-10 minutes, cool the sterilized medium to 33°C in the fermenter and wait for inoculation;

[0048] (3) Fermentation: Add the seed culture solution of temperature-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com