A sludge fermentation acid-producing method combining thermo-alkaline pretreatment and semi-continuous flow fermentation

A hot alkali pretreatment, semi-continuous technology, applied in the direction of biological sludge treatment, etc., to achieve the effect of shortening the reaction time, increasing the acid production, and rapid acid production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

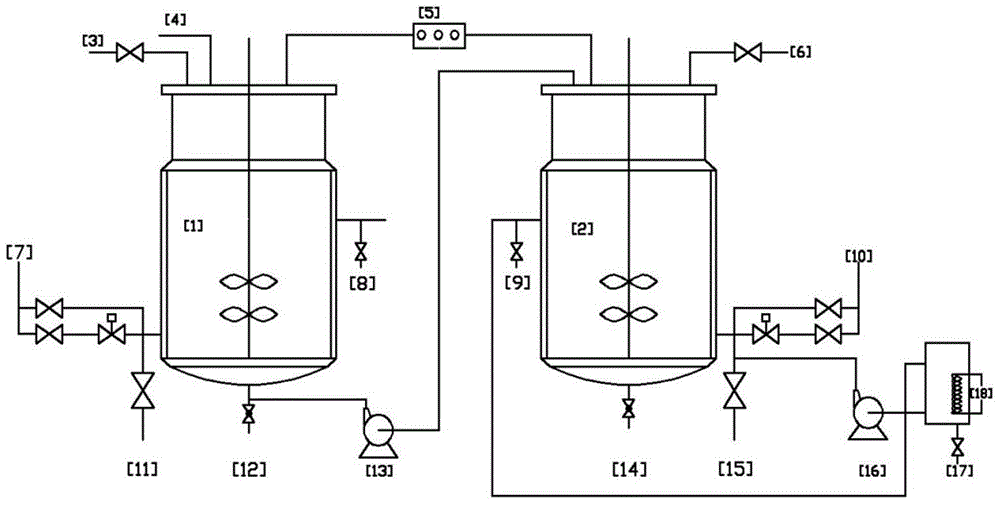

Method used

Image

Examples

Embodiment 1

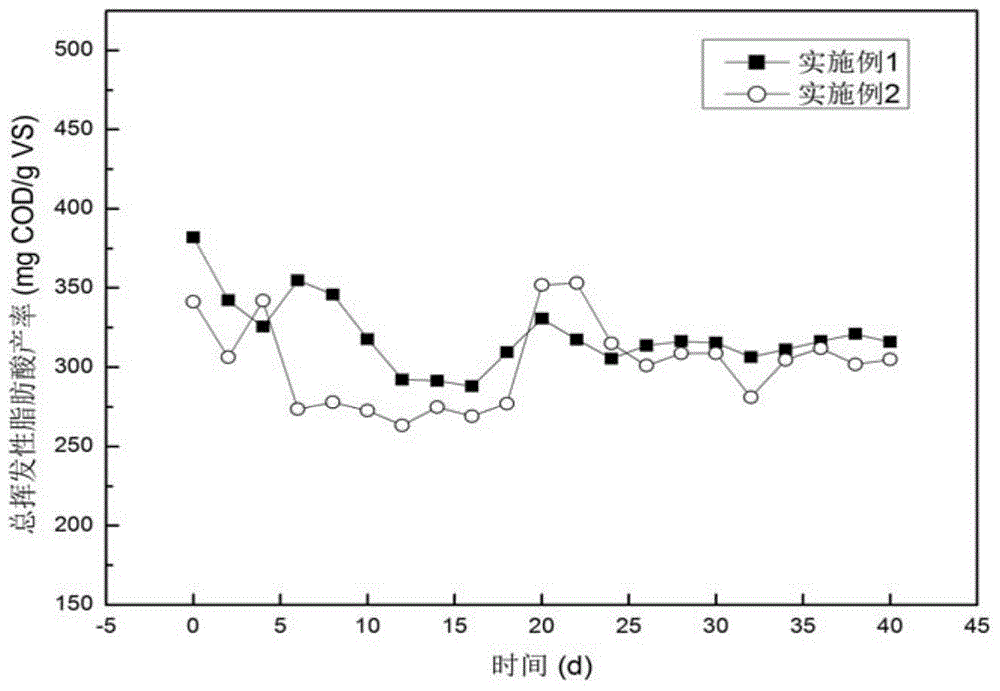

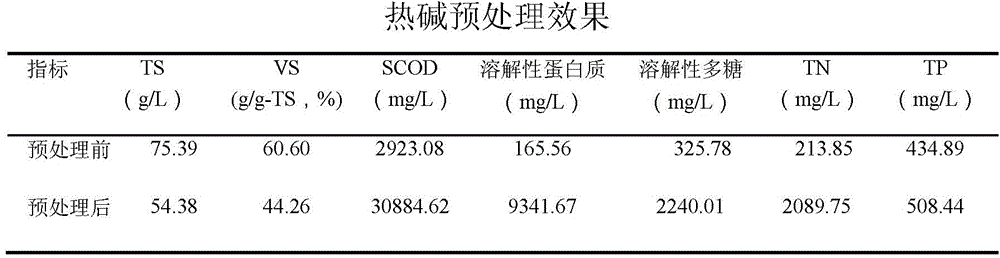

[0031] Sludge was collected from Taihu New Town Wastewater Treatment Plant in Wuxi City, and the total solids (TS, totalsolids) and volatile solids (VS, volatilesolid) of the sludge were 15.46g / g and 0.61g / g-TS, respectively. Adjust the sludge with water to a thick slurry of 75gTS / L, and then pump it into the pretreatment tank for hot alkali pretreatment. The pretreatment conditions are: temperature T=70-100° C., pH=10-12, and reaction time 2-3 hours. After hot alkali pretreatment, anaerobic fermentation was carried out in a 30L fermenter. The main technical parameters and operating parameters of the fermenter (1# is a pretreatment tank, and 2# is a fermentation reaction tank) are shown in Table 1 and Table 2. The liquid volume of the fermentation tank is 21L, the inoculation amount of the seed sludge is 10%, then add 90% of the volume of the pretreated sludge, and fill the 2# tank with nitrogen for more than 15 minutes to maintain the anaerobic condition (no need to fill the...

Embodiment 2

[0037] Collect concentrated sludge from Wuxi Lucun Wastewater Treatment Plant, the sludge TS and VS are 13.30g / L and 0.65g / g-TS respectively. The recovered sludge is directly subjected to thermal alkali pretreatment-semi-continuous flow fermentation reaction, and the main technical parameters and operating parameters of the fermenter (1# is the pretreatment tank, 2# is the fermentation reaction tank) are shown in Table 1 and Table 2 . The liquid volume of the fermentation tank is 21L, the inoculation amount of the seed sludge is 10%, then add 90% of the volume of the pretreated sludge, and fill the 2# tank with nitrogen for more than 15 minutes to maintain the anaerobic condition (no need to fill the nitrogen later, the whole system Good sealing), start the fermentation reaction. The hydraulic retention time is 10 days, and the feed and discharge are carried out every 2 days (that is, 4.2L of fermented sludge is discharged, and 4.2L of pretreated sludge is injected at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com