Bean pulp hydrolysis technology

A soybean meal and process technology, applied in the field of soybean meal hydrolysis technology based on graphite reaction kettle, can solve the problems of lack of suitable, enamel reaction kettle is easy to collapse, and the hydrolysis process is long, so as to reduce production costs, reduce damage and return to the factory, improve Effect of acid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

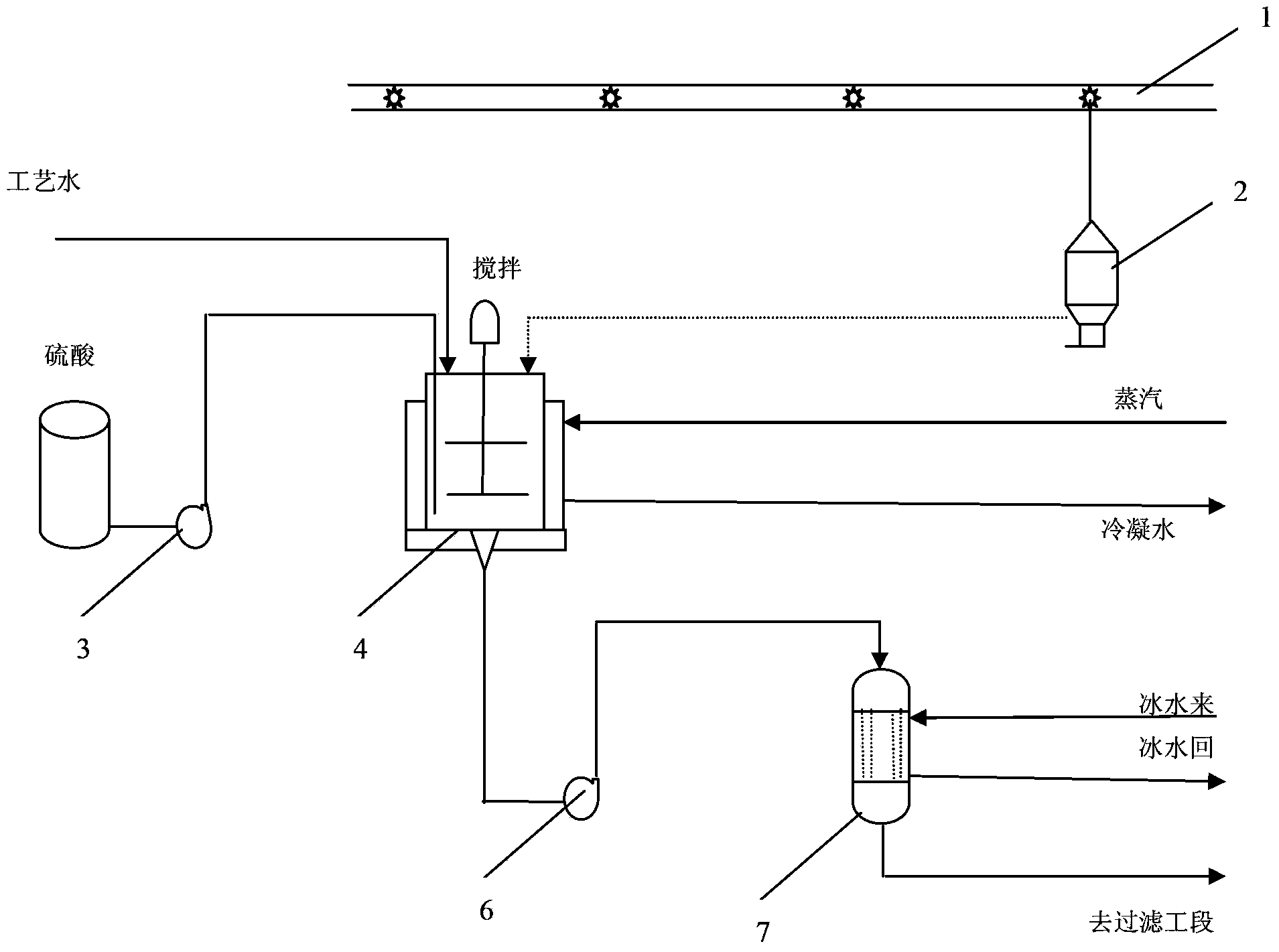

[0014] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, the equipment used in the soybean meal hydrolysis process includes guide rail 1, soybean meal bucket 2, sulfuric acid pump 3, graphite reactor 4, soybean meal hydrolyzate pump 5, and cooler 6. The soybean meal is installed in the soybean meal bucket, and the soybean meal bucket adopts electric The gourd is hoisted on the guide rail. The process includes the following steps: First, add water and 98% concentrated sulfuric acid into the graphite reactor according to the proportion and stir evenly, and set the temperature of the mixture of water and sulfuric acid to 90°C; then, according to the proportion Add bean curds to the graphite reactor at one time, heat to 95°C and keep for two hours; after that, add bean curds to the graphite reactor for the second time according to the proportion, heat to 116°C, and keep for 22 hours to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com