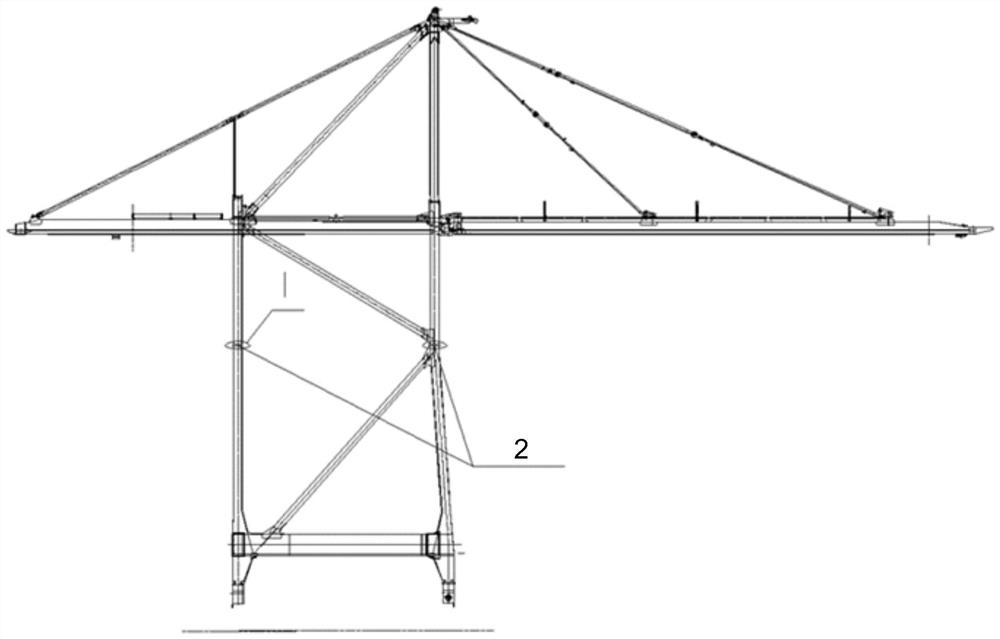

Machining method for stand column flange of quayside container crane

A technology of container crane and processing method, applied in the direction of manufacturing tools, workshop equipment, etc., can solve the problems of cumbersome processes, increased difficulty of marking and workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the above-mentioned technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

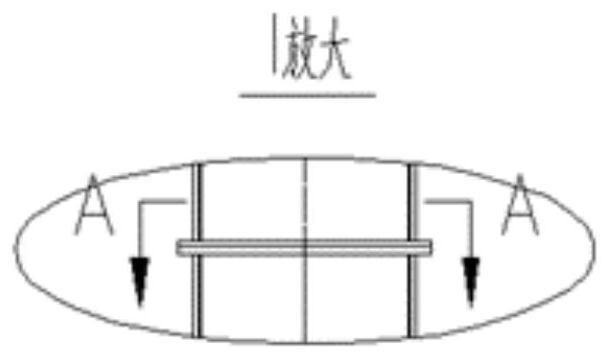

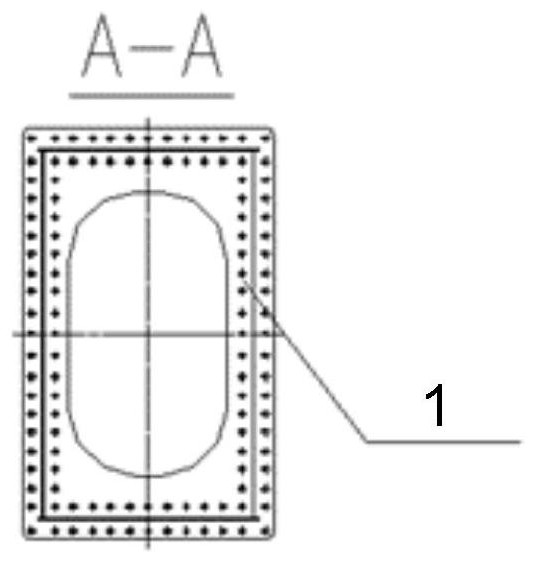

[0032] combine Figure 6 to Figure 9 As shown, a column flange processing method of a shore container crane provided by the present invention comprises the following steps:

[0033] S1. The upper and lower sections 5 and 6 of the column are made separately, and the two flange plates 7 are blanked and scraped, and then drilled in pairs, and fixed with bolts to form a flange assembly;

[0034] S2. The upper and lower sections 5 and 6 of the column are assembled with the flange components and passed the inspection. Three scoring plates 8 are respectively installed on the webs on the upper and lower sides of the flange plate 7. The marking plates 8 need to be Arranged at a position convenient for measurement, wherein two scribed plates 8 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com