Production process for PSL-2 grade non-tempered N80 steel grade oil casing pipes

A PSL-2, production process technology, applied in the field of high-grade oil casing, can solve the problems of brittle cracks, unstable performance, etc., and achieve the effect of avoiding bending of the pipe body and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

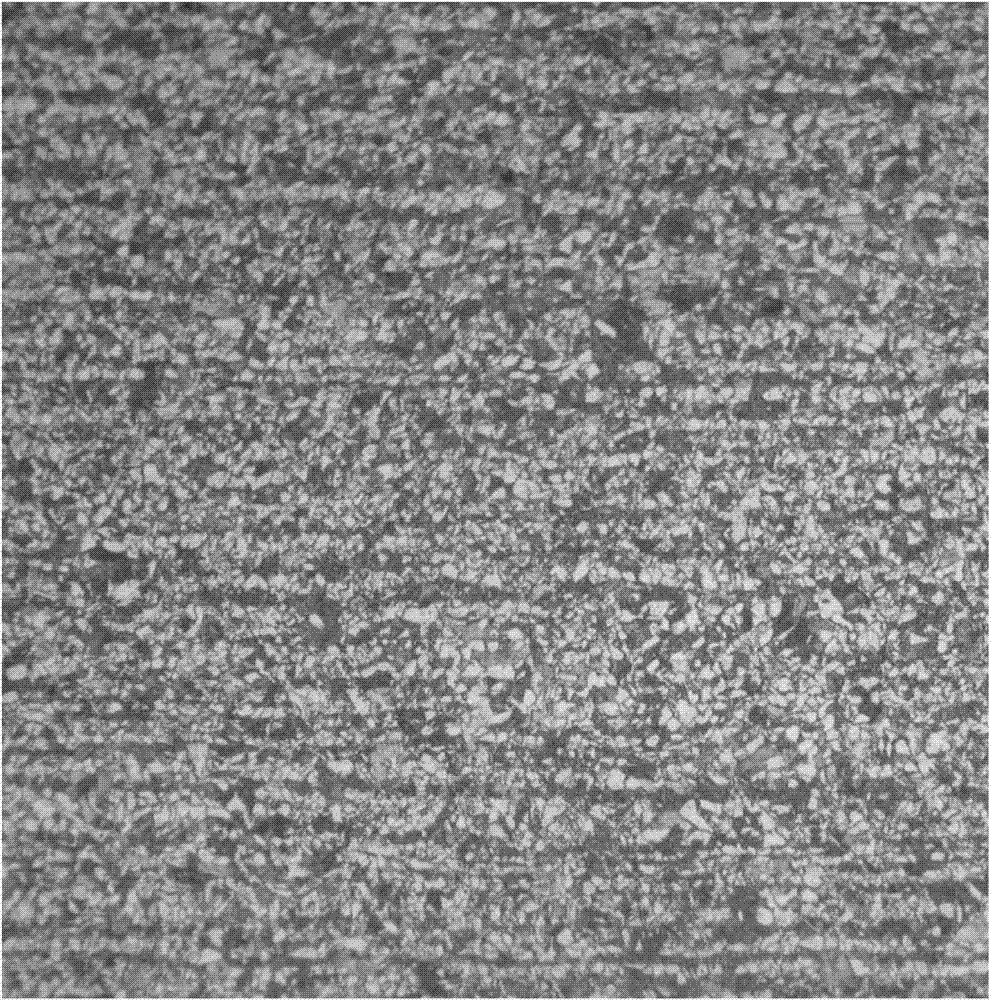

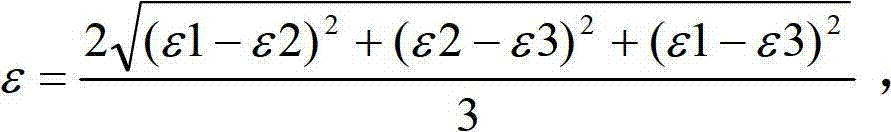

Image

Examples

Embodiment 1

[0021] Example 1: A PSL-2 grade non-quenched and tempered N80 steel grade tubing and casing (diameter 177.8mm×wall thickness 9.19mm) production process, using the following process steps:

[0022] (1) Ring furnace heating: heat the tube blank in a ring furnace at 1280℃ for 3.5h;

[0023] (2) Piercing: The heated tube is pierced on a piercing machine and rolled to obtain a capillary of the required specifications, and the capillary temperature is 1150℃;

[0024] (3) Continuous rolling and tube stripping: the capillary tube obtained after piercing is rolled to the required specification on the constrained mandrel continuous rolling mill, the final rolling temperature of continuous rolling is 1000℃; the capillary tube after continuous rolling is placed on the tube stripping machine Separate the waste pipe from the core rod;

[0025] (4) Sizing: The waste pipe obtained by stripping the continuous rolling is passed through a sizing machine to obtain the required outer diameter. The inlet t...

Embodiment 2

[0028] Example 2: A PSL-2 grade non-quenched and tempered N80 steel grade tubing and casing (diameter 177.8mm×wall thickness 9.19mm) production process, using the following process steps:

[0029] (1) Ring furnace heating: heat the tube blank in a 1200℃ ring furnace for 3 hours;

[0030] (2) Piercing: The heated tube blank is pierced on a piercing machine and rolled to obtain a capillary of the required specifications, and the capillary temperature is 1160℃;

[0031] (3) Continuous rolling and tube stripping: the capillary tube obtained after piercing is rolled to the required specification on the constrained mandrel continuous rolling mill, the final rolling temperature of continuous rolling is 1010℃; the capillary tube after continuous rolling is placed on the tube stripping machine Separate the waste pipe from the core rod;

[0032] (4) Sizing: The waste pipe obtained by stripping the continuous rolling is passed through a sizing machine to obtain the required outer diameter. The i...

Embodiment 3

[0035] Example 3: A PSL-2 grade non-quenched and tempered N80 steel grade tubing and casing (diameter 177.8mm×wall thickness 9.19mm) production process, using the following process steps:

[0036] (1) Ring furnace heating: heat the tube blank in a 1250℃ ring furnace for 3.2h;

[0037] (2) Piercing: The heated tube blank is pierced on a piercing machine and rolled to obtain a capillary of the required specification, and the capillary temperature is 1170℃;

[0038] (3) Continuous rolling and tube stripping: the capillary tube obtained after piercing is rolled to the required specification on the constrained mandrel continuous rolling mill, and the final rolling temperature of continuous rolling is 1020℃; the capillary tube after continuous rolling is placed on the tube stripping machine Separate the waste pipe from the core rod;

[0039] (4) Sizing: The waste pipe obtained by stripping the continuous rolling is passed through a sizing machine to obtain the required outer diameter. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com