A Diesel Engine Fuel Injector Fuel Injection Advance Angle Assembly Tool

A technology of advancing angles and assembling tools, which is applied in the direction of machines/engines, fuel injection devices, and charging systems, and can solve problems such as economic losses, difficult assembly, and heavy workload, so as to reduce production costs and solve low production efficiency , Improve the effect of consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

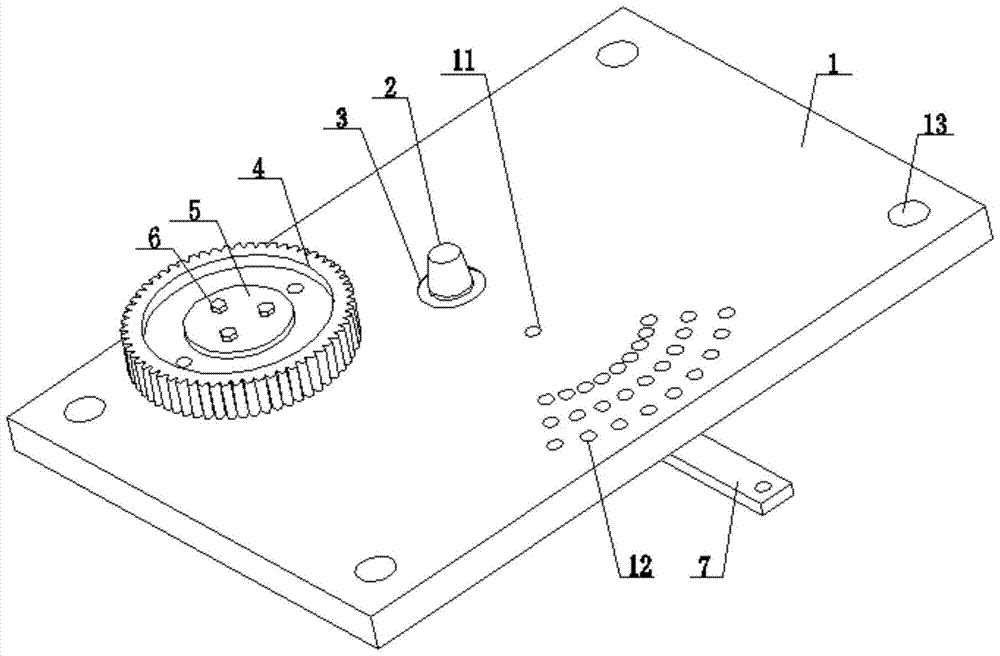

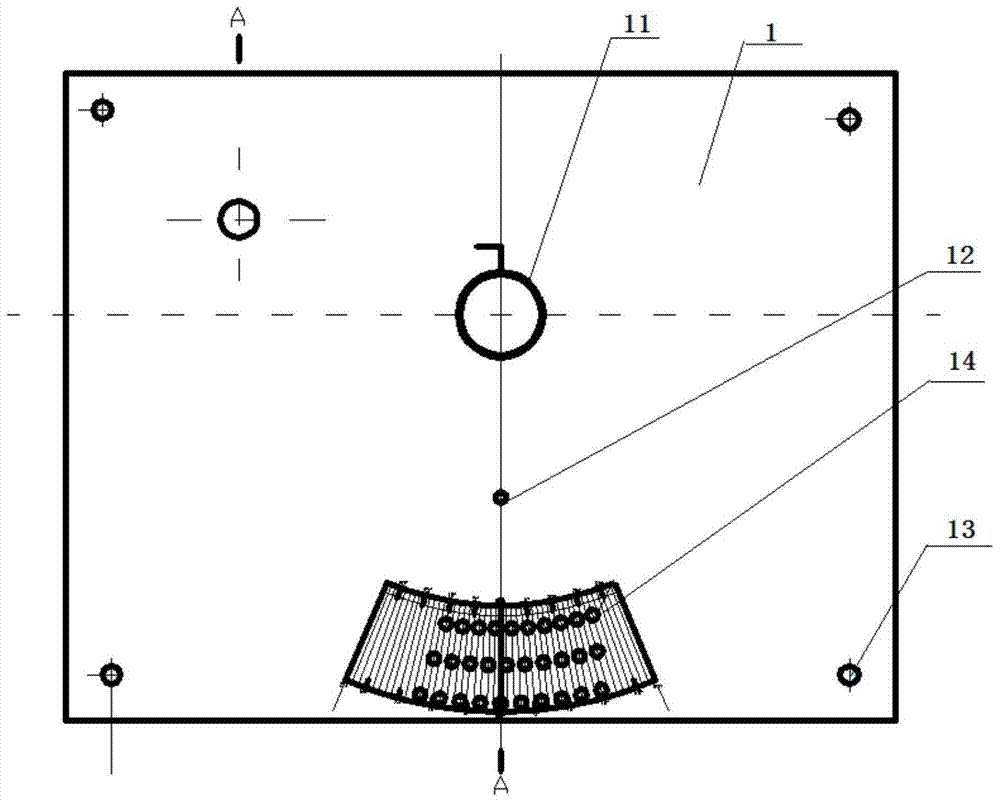

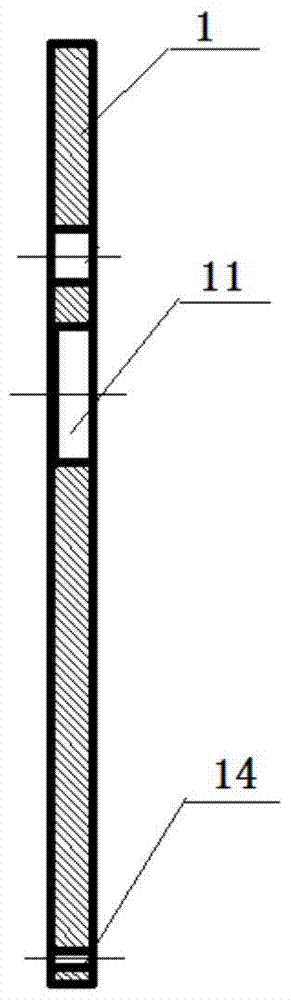

[0019] Such as Figure 1 to Figure 5 As shown, the diesel fuel injector fuel injection advance angle assembly tool includes a bottom plate 1 , an idler gear 4 and an adjustment handle 7 .

[0020] Wherein the bottom plate 1 is provided with a positioning shaft 2 for installing the oil pump gear connector, and the positioning shaft 2 is connected with the bottom plate 1 through a bearing 3, and is used for supporting and assembling the positioning connection operation of the oil pump gear connector and the oil pump gear.

[0021] The support screw holes 13 on the four sides of the base plate 1 are connected by bolts to fix and support the entire diesel injector fuel injection advance angle installation tool.

[0022] The reference hole 11 provided on the bottom plate 1 serves as a reference for the angle positioning holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com