Permanent magnetic ferrite wet forming magnetic shoe carrying device

A permanent magnet ferrite and handling device technology, applied in the direction of unloading device, transportation and packaging, conveyor objects, etc., can solve the problems of high manual handling cost, low efficiency, poor palletizing effect, etc., and achieve high precision and operation Smooth, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

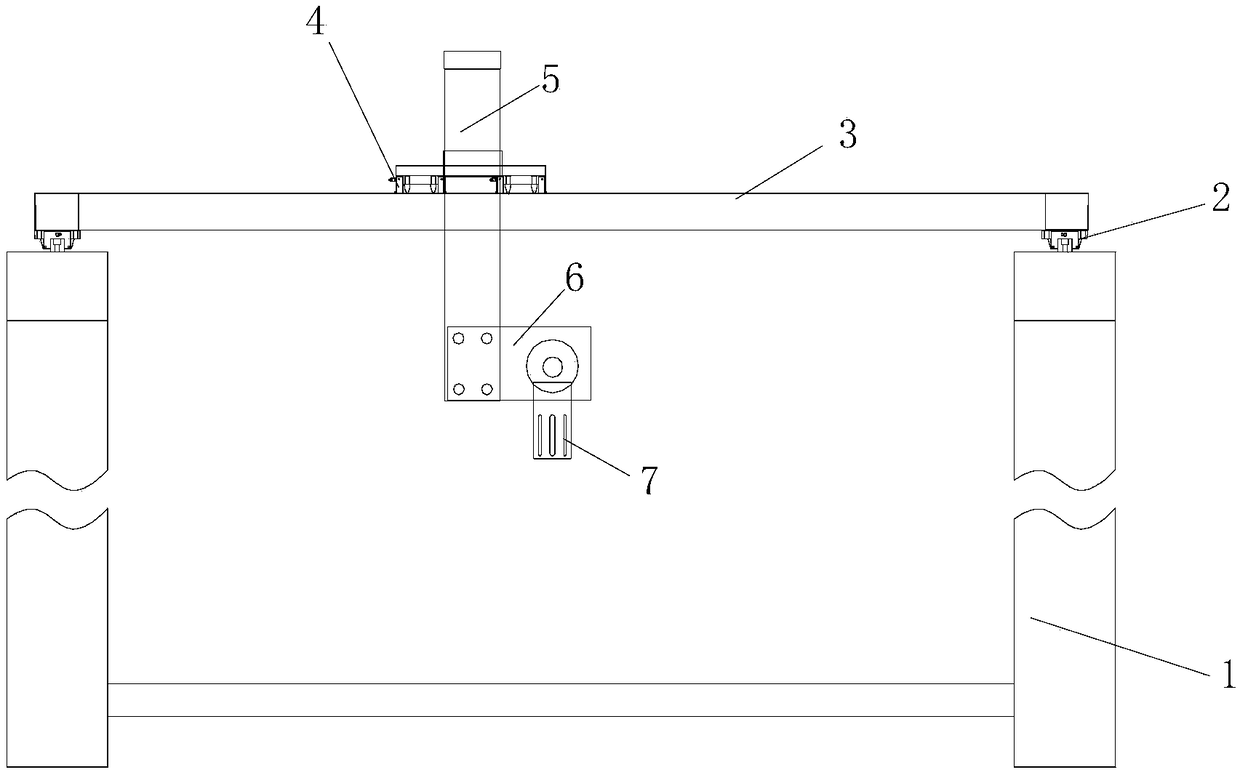

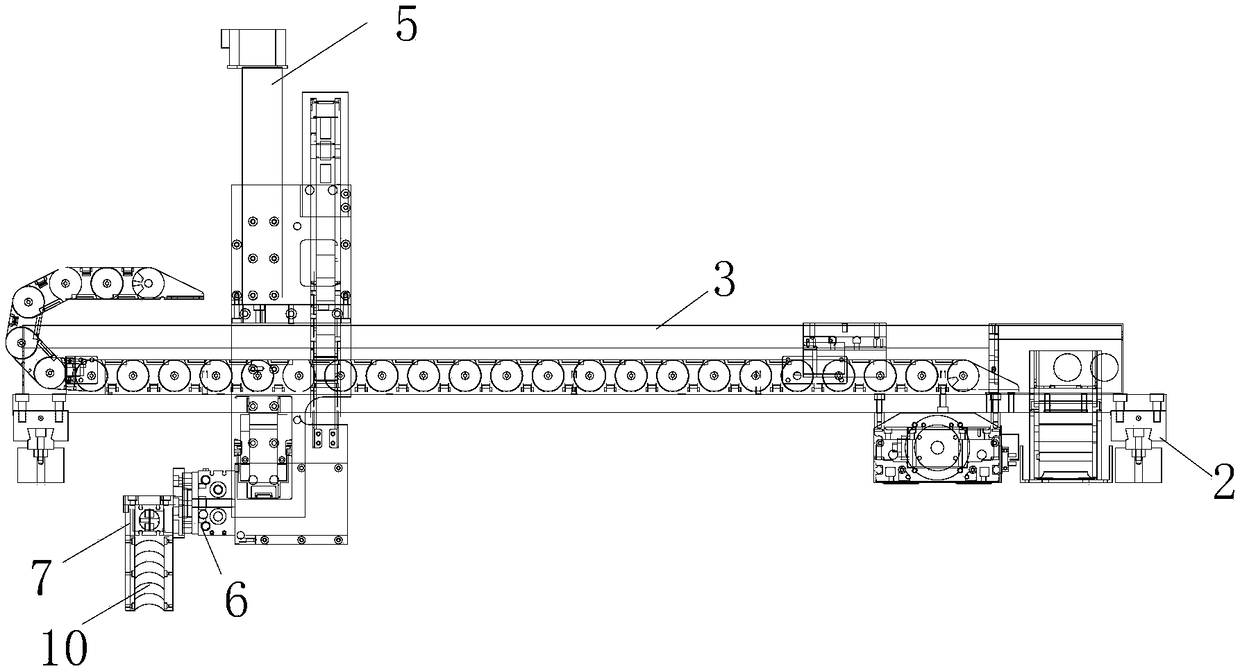

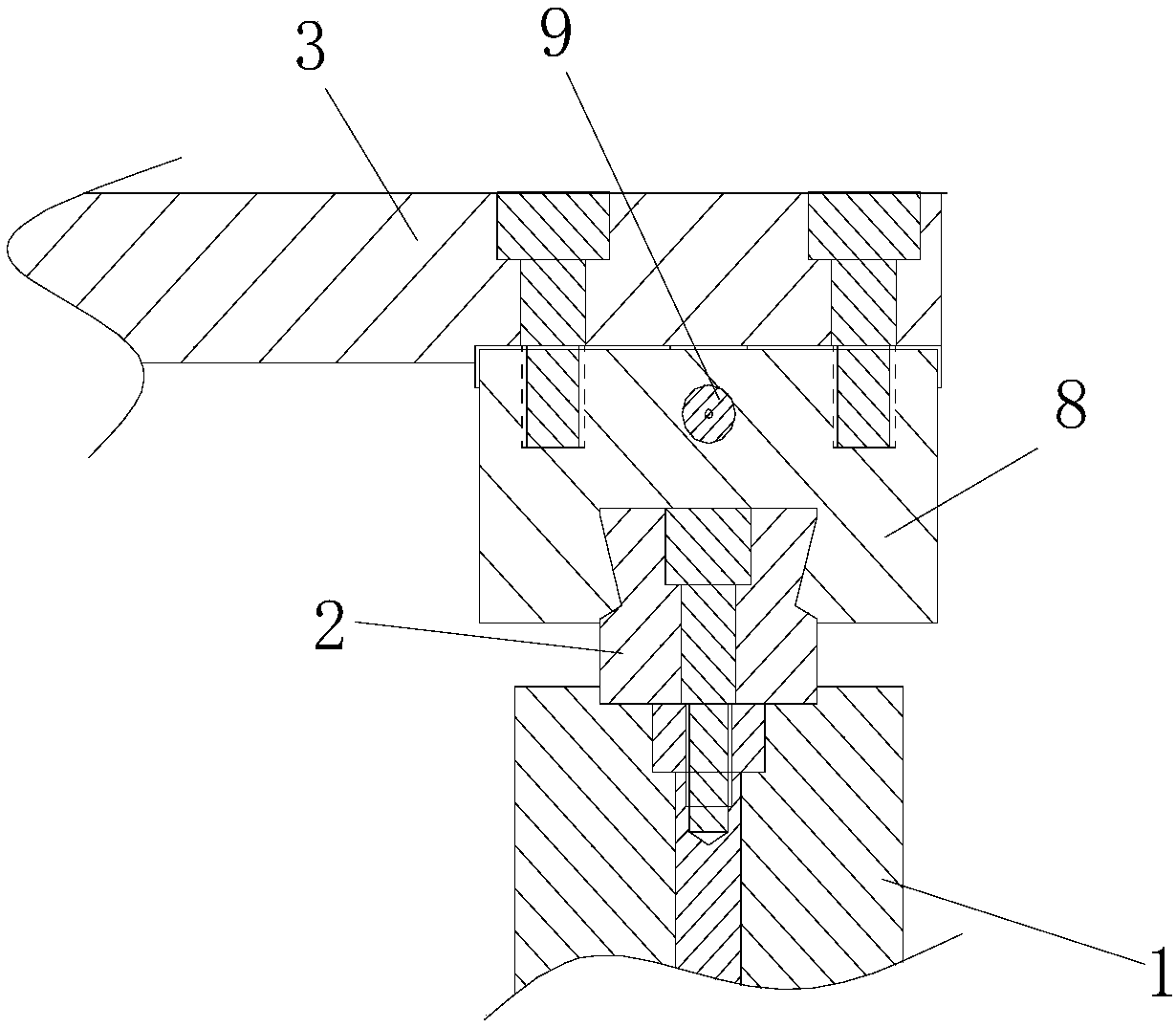

[0030] Such as Figure 1-4 As shown, the permanent magnet ferrite wet-pressed magnetic tile handling device includes a bracket 1, and two parallel X-guiding rails 2 are horizontally arranged on the bracket 1, and the two X-guiding rails 2 are arranged at the same height.

[0031] Each X guide rail 2 is slidably provided with a first slider 8, and the two first sliders 8 are respectively fixedly connected with the two ends of the Y guide rail 3, and the Y guide rail 3 is horizontally arranged, and the Y guide rail 3 and the X direction The guide rails 2 are arranged vertically, and each X-direction guide rail is fixedly provided with a first driving device for driving the first slider to slide.

[0032] The Y guide rail is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com