Glass-reinforced-plastic filter element framework and manufacture method thereof

A glass fiber reinforced plastic and filter element technology is applied in the field of glass fiber reinforced plastic filter element frame and its production, which can solve the problems of complicated processing, low porosity, and reduced frame strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

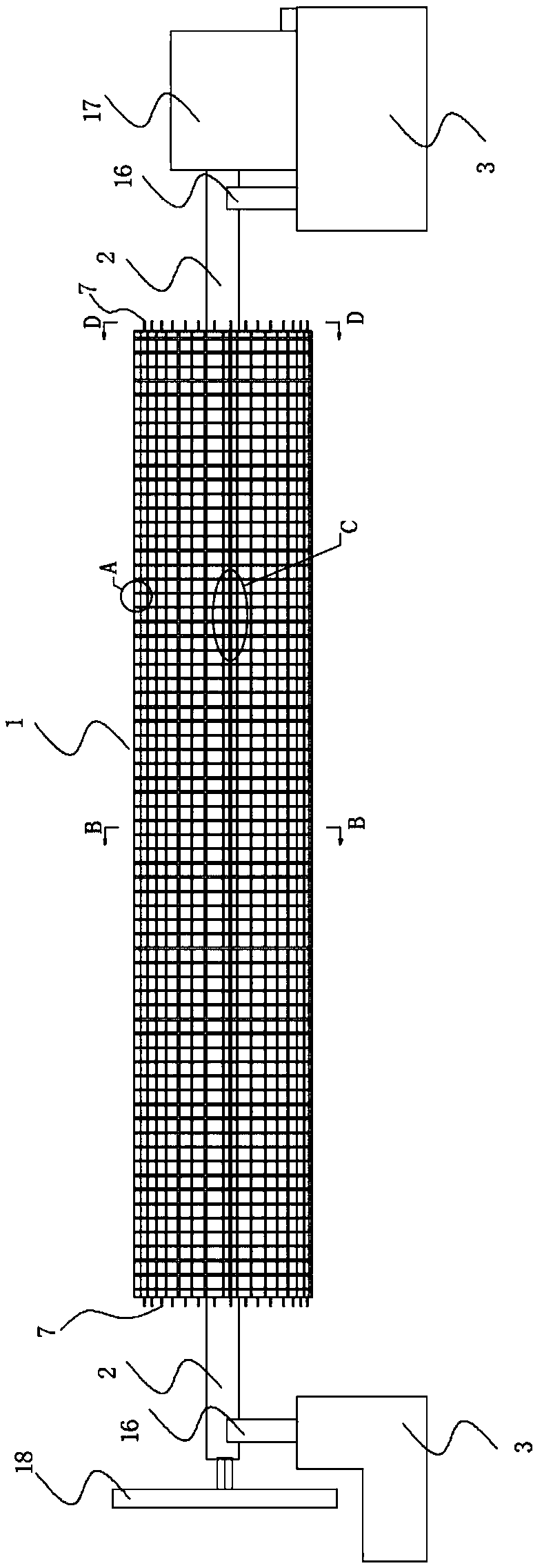

[0040] A method for preparing a fiberglass filter element skeleton, comprising the steps of:

[0041] In the first step, glass fiber filaments are soaked in resin, and then converged into glass fiber strips;

[0042] In the second step, the resin-soaked glass fiber strips are wound on the mold to form a fiberglass filter core skeleton, and the glass fiber strips are continuously staggered, and ports 22 are left;

[0043] The third step is to solidify the wound mesh FRP filter skeleton;

[0044] The fourth step is demoulding.

[0045] In Step 3, the curing is at natural temperature for 45-60 minutes; or hot air curing, the curing temperature is 50-55° C., and the curing time is 15-20 minutes.

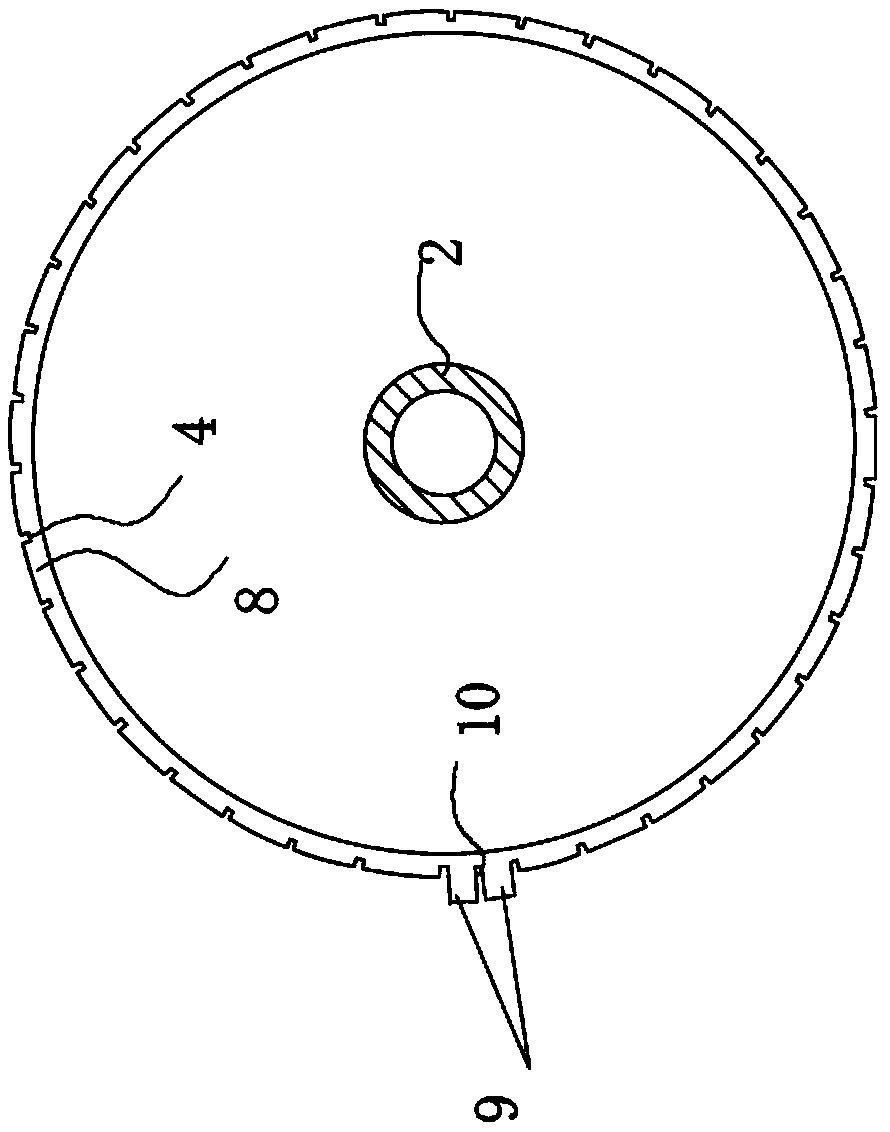

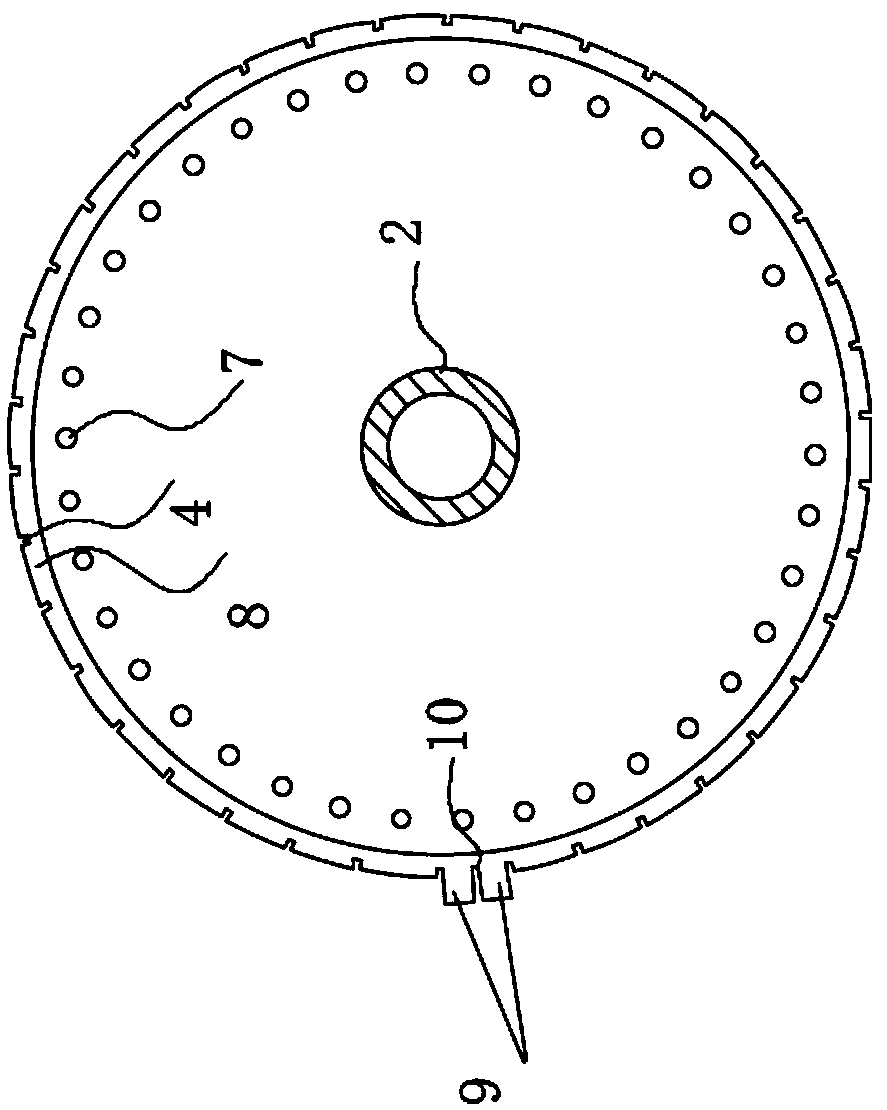

[0046]In step 2, the mold is a cylindrical mold 1, and the surface of the mold 1 is distributed with interlaced embedding grooves, the embedding grooves include axial grooves and circumferential grooves, and the axial grooves are evenly distributed around the mold 1, The circumferenti...

Embodiment 1

[0051] A glass fiber reinforced plastic filter skeleton, said glass fiber reinforced plastic filter skeleton is integrally cured and molded by continuous interlaced glass fiber solidified ribs, air vents 21 through which gas passes are formed between said interlaced glass fiber solidified ribs, said glass fiber reinforced plastic filter skeleton At least one port 22 is opened on the top to accommodate fluid entry or exit.

[0052] The whole frame of the FRP filter element is hollow columnar, and the upper end and / or lower end of the columnar FRP filter element frame is a port 22 .

[0053] The interlaced glass fiber cured ribs include axial glass fiber cured ribs 23 and circumferential glass fiber cured ribs 24 formed integrally with the axial glass fiber cured ribs 23, the axial glass fiber cured ribs The strips 23 are provided with multiple parallel to each other, and the circumferential glass fiber solidified ribs 24 are arranged with multiple ones along the axial direction...

Embodiment 2

[0077] Further optimization of embodiment 1, the upper end of the columnar fiberglass filter core skeleton is provided with an upper connecting plate 25, the inner edge of the upper connecting plate 25 is connected to the upper end of the fiberglass fiber reinforced plastic filter element skeleton through resin thermosetting, and the upper connecting plate 25 is A port 22 is provided; the lower end of the columnar fiberglass filter core frame is provided with a lower connection plate 26, and the outer edge of the lower connection plate 26 is connected with the inner edge of the lower end of the fiberglass filter core frame by resin thermosetting, and the lower connection plate 26 is provided with Filtrate collection port 27.

[0078] The lower connecting plate 26 is funnel-shaped with a wide top and a narrow bottom, and the filtrate collecting port 27 is at the bottom of the lower connecting plate 26 .

[0079] The two ports 22 of the fiberglass filter element skeleton are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com