Manipulator for cloth feeding

A technology of manipulators and fabrics, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of backward technology in the feeding process, conveying equipment that cannot meet production needs, and labor-consuming problems, so as to reduce the birth rate of defective products and waste products , The probability of waste products is reduced, and the effect of solving the difference in fabric size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

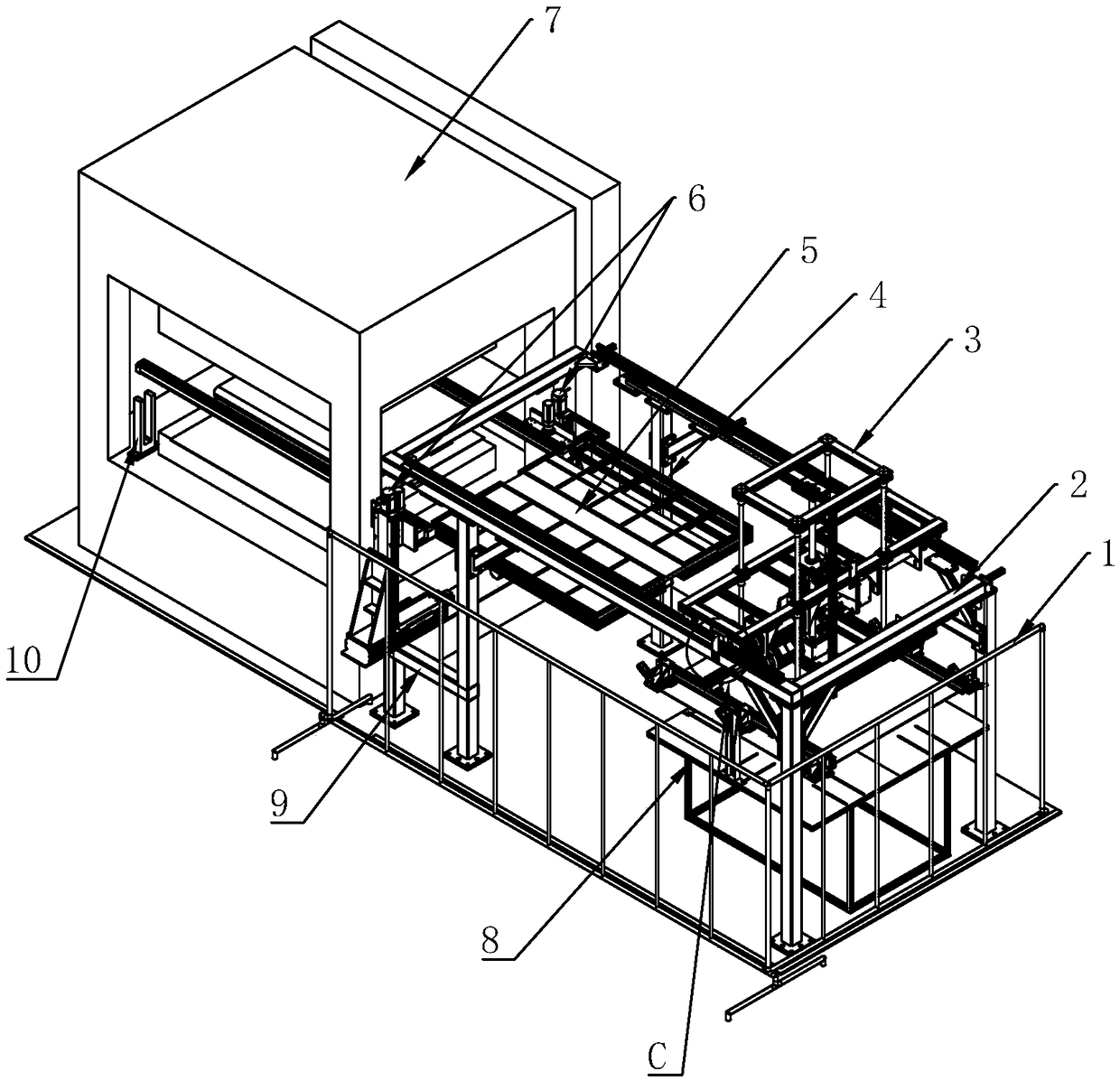

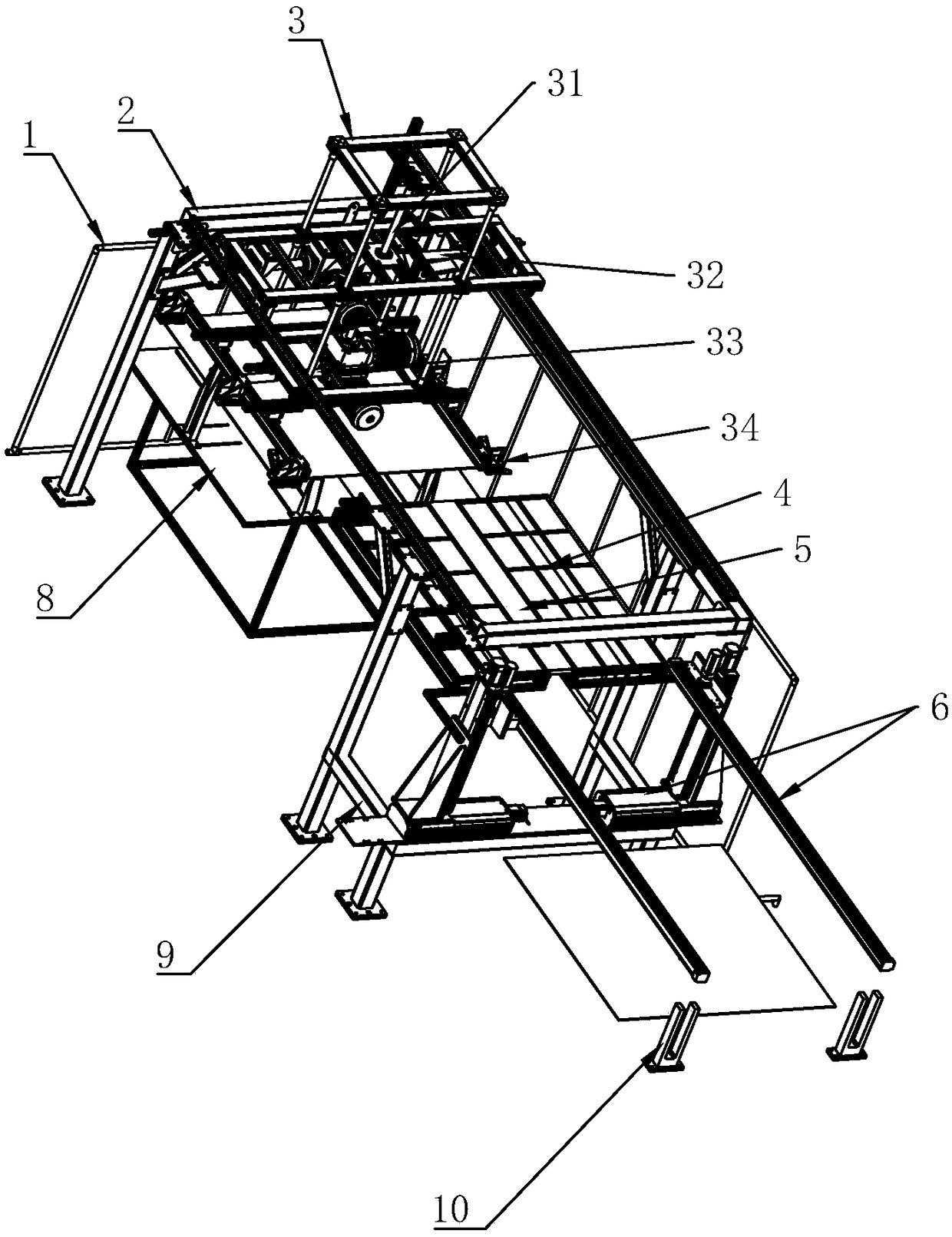

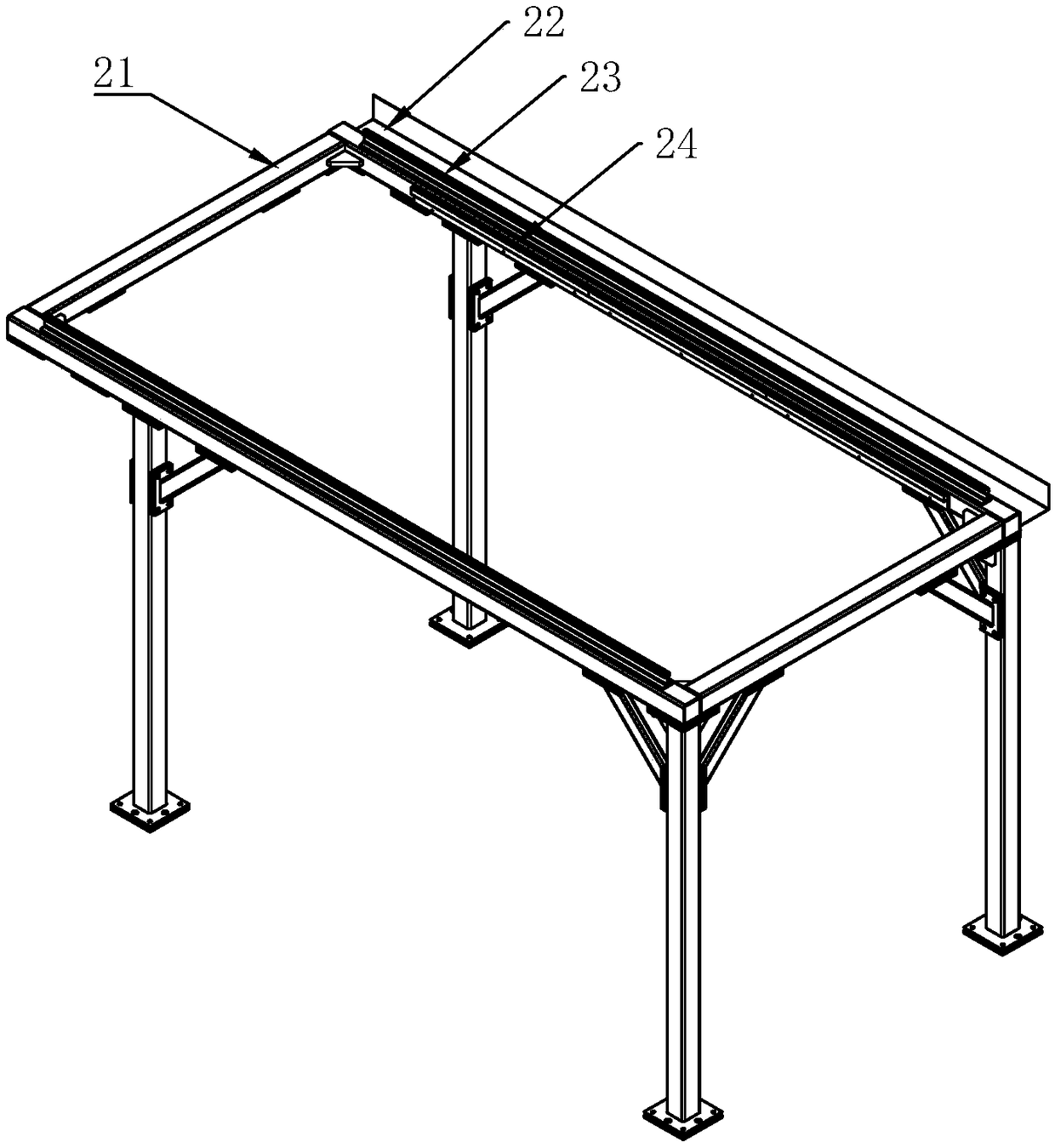

[0053] The reason for the wrinkles in the forming process of the car roof is that the fabric is not supported during the pressing process of the hydraulic mechanism 7, and when the hydraulic mechanism 7 receives the downward pressure, the fabric shrinks inward, and the uneven shrinkage of the fabric causes some fabrics to overlap or Rolled up, creating creases. Moreover, the existing conveying equipment on the market can only do a single fabric or a single action, cannot be flexibly adjusted, and cannot meet the production of various fabrics, resulting in low production efficiency. Compared with manual operation, the production efficiency improvement is small and cannot reflect It has the advantages of high efficiency, high precision, low cost and less defective products in the mechanical transportation process. Therefore, in view of the above problems, the present invention designs and produces a six-axis linkage cloth feeding manipulator, which improves the feeding efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com