All-steel radial truck tire structure

A radial tire and skeleton structure technology, applied in the direction of heavy-duty tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of no major technological innovation, single skeleton structure, and not much improvement in load capacity, etc., to achieve The effect of reducing material costs, improving safety performance, and improving load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings.

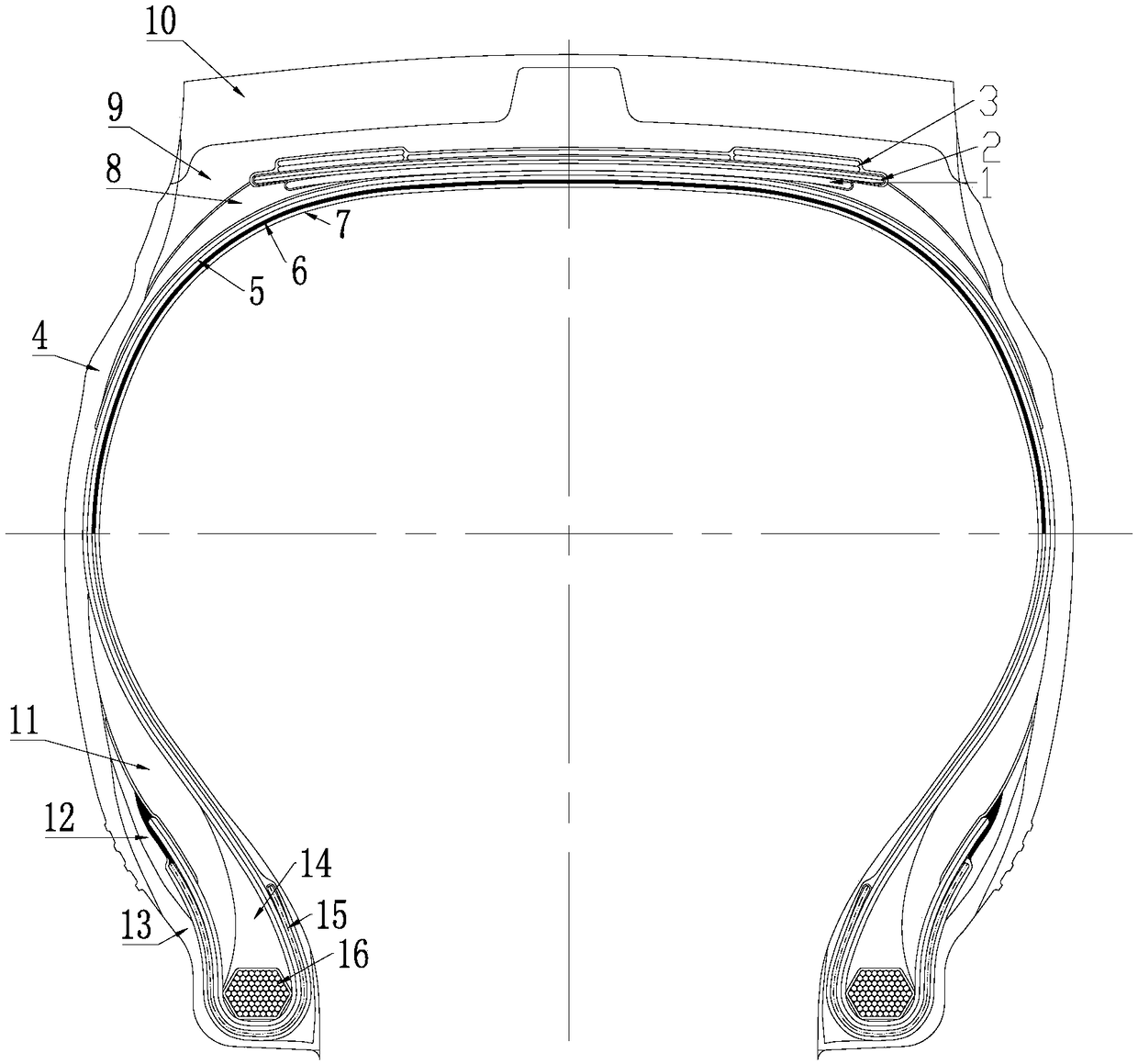

[0014] Such as figure 1 As shown, the structure of the all-steel radial truck tire of the present invention includes a tread, a sidewall 4, a shoulder connecting the tread and the sidewall 4, a bead connected to the lower part of the sidewall 4, and a skeleton structure, and the skeleton structure consists of A layer of steel wire carcass cord 5, a layer of nylon wrapping layer 6 and an airtight layer 7 are formed, and the nylon wrapping layer 6 is filled between the innerliner 7 and the steel wire carcass cord 5; the bead includes a steel traveler 16, The steel ring complex composed of the upper apex 11 and the lower apex 14, the outer surface of the steel ring complex is turned up to the steel wire carcass cord 5 and the steel wire slit cloth 15, and the steel wire carcass cord 5 is turned up to the steel wire slit cloth 15. About 15mm away from the end point of the turn-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com