A kind of preparation method of bionic intelligent flexible actuator

A flexible drive, bionic technology, applied in the field of materials, to achieve the effect of low preparation cost, high-efficiency movement form, and rapid swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

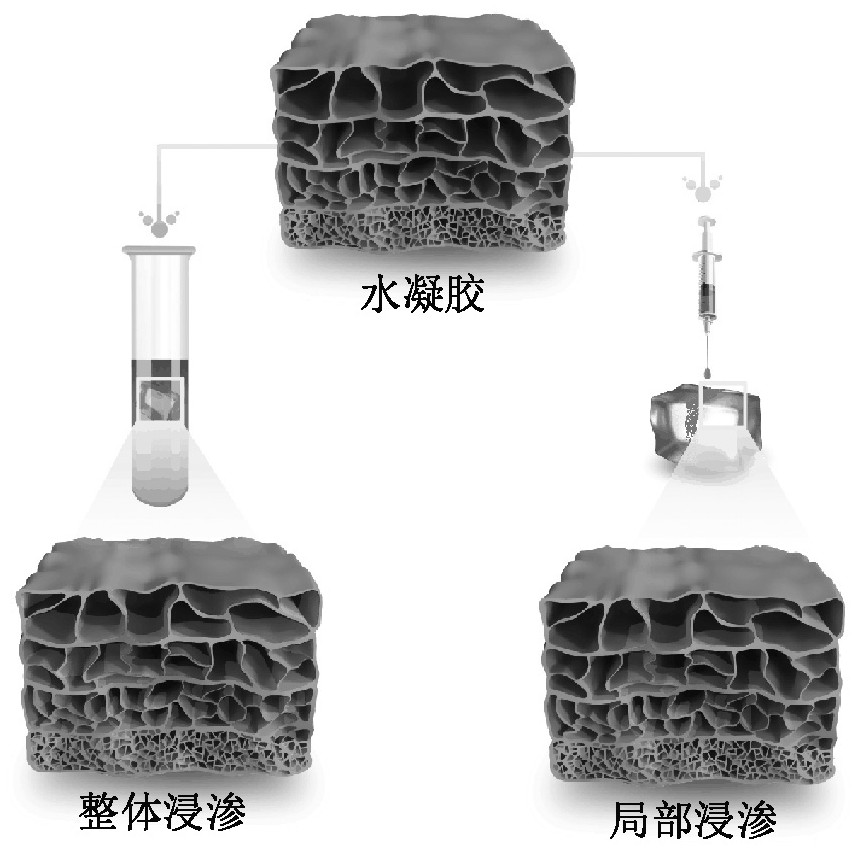

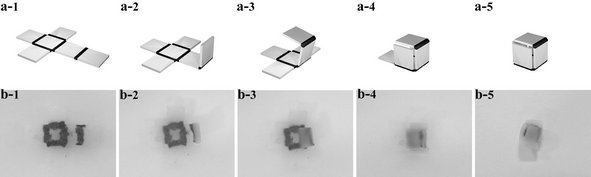

[0022] see figure 1 and figure 2 As shown, the "carton" type bionic intelligent flexible actuator is prepared by "partial impregnation" method:

[0023] N-isopropylacrylamide was selected as the monomer, 4-hydroxybutyl acrylate was used as the crosslinking agent, ammonium persulfate was used as the initiator, graphene oxide was used as the photothermal conversion agent, and 808nm near-infrared laser was used as the control source. The mass of the monomer is 1g-2g; the volume of the cross-linking agent is 200μL-400μL; the quality of ammonium persulfate is 10mg-20mg, and the concentration of the graphene oxide aqueous solution is 4mg / mL-5mg / mL. Add the monomer and initiator into distilled water, and fully dissolve under the stirring action of a magnetic stirrer, then add the crosslinking agent, then stir for 5min~6min, filter, put it into the reaction kettle, and react under the condition of 190℃~200℃ After 5-6 hours, cut the prepared hydrogel into a cross shape, and use filt...

Embodiment 2

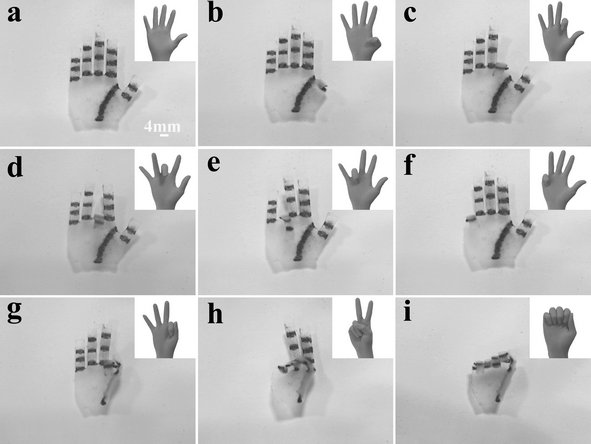

[0025] see figure 1 and image 3 As shown, the "palm" type bionic intelligent flexible actuator was prepared by the "partial impregnation" method

[0026] N-isopropylacrylamide was selected as the monomer, 4-hydroxybutyl acrylate was used as the crosslinking agent, ammonium persulfate was used as the initiator, graphene oxide was used as the photothermal conversion agent, and 808nm near-infrared laser was used as the control source. The mass of the monomer is 1g-2g; the volume of the cross-linking agent is 200μL-400μL; the quality of ammonium persulfate is 10mg-20mg, and the concentration of the graphene oxide aqueous solution is 4mg / mL-5mg / mL. Add the monomer and initiator into distilled water, and fully dissolve under the stirring action of a magnetic stirrer, then add the crosslinking agent, then stir for 5min~6min, filter, put it into the reaction kettle, and react under the condition of 190℃~200℃ After 5-6 hours, cut the prepared hydrogel into the shape of a palm, fully...

Embodiment 3

[0028] see figure 1 and Figure 4As shown, the "chrysanthemum" type bionic intelligent flexible actuator was prepared by the "integral impregnation" method

[0029] N-isopropylacrylamide was selected as the monomer, 4-hydroxybutyl acrylate was used as the crosslinking agent, ammonium persulfate was used as the initiator, graphene oxide was used as the photothermal conversion agent, and 808nm near-infrared laser was used as the control source. The mass of the monomer is 1g-2g; the volume of the cross-linking agent is 200μL-400μL; the quality of ammonium persulfate is 10mg-20mg, and the concentration of the graphene oxide aqueous solution is 4mg / mL-5mg / mL. Add the monomer and initiator into distilled water, and fully dissolve under the stirring action of a magnetic stirrer, then add the crosslinking agent, then stir for 5min~6min, filter, put it into the reaction kettle, and react under the condition of 190℃~200℃ After 5-6 hours, the prepared hydrogel sheet is fully absorbed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com