Carbon dioxide-slickwater intermittent mixed-fracturing design method

A design method, carbon dioxide technology, applied in the field of fracturing of unconventional reservoirs, reservoir stimulation and transformation, can solve the problem of less carbon dioxide composite fracturing, and achieve improved fracturing effect, development effect, and fracturing transformation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

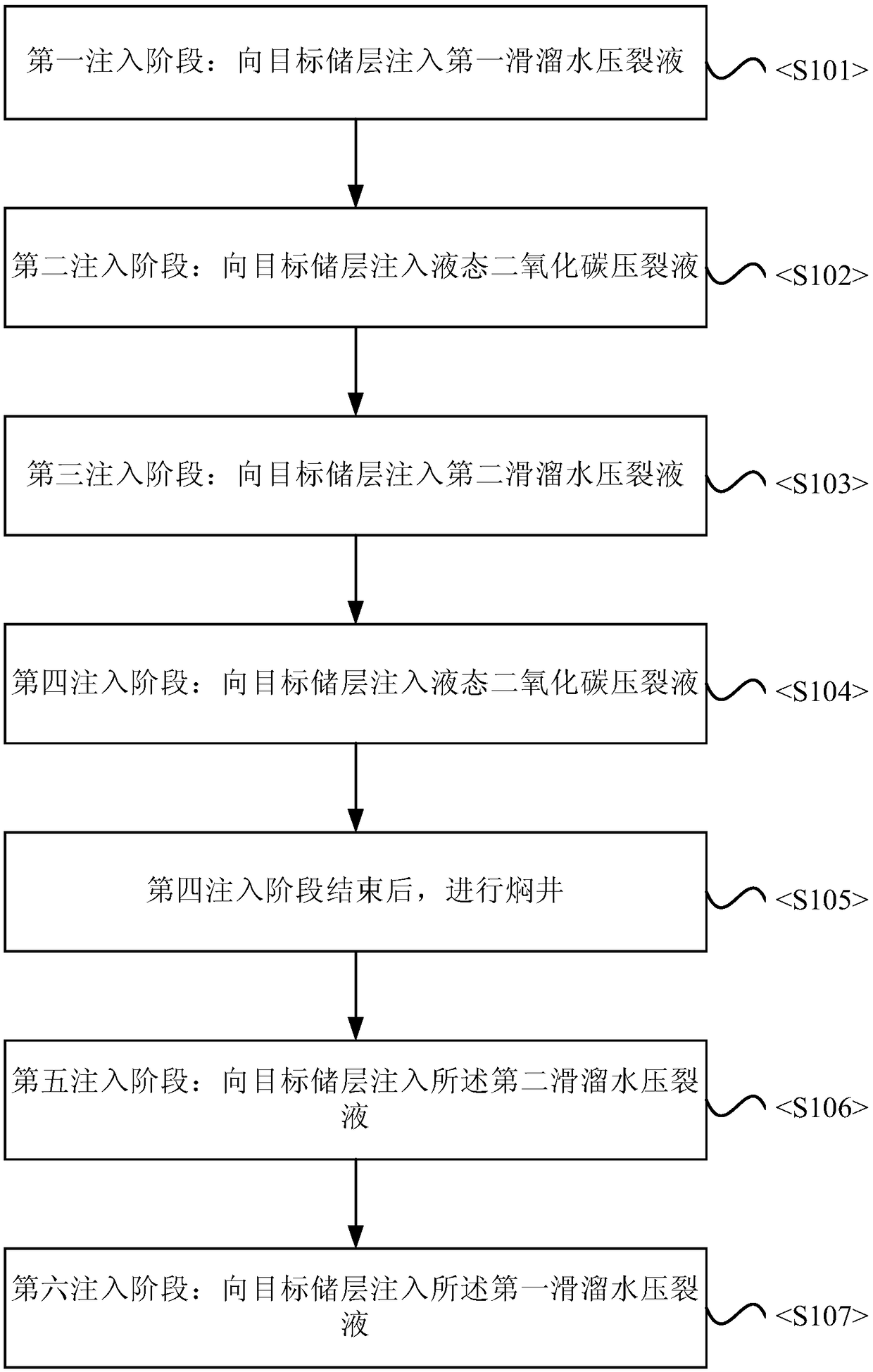

[0095] In this example, the carbon dioxide-slick water intermittent composite fracturing design method provided by the present invention is used to perform fracturing and exploitation of unconventional oil and gas reservoirs.

[0096] In this example, liquid carbon dioxide fracturing fluid without any additives, the first slickwater fracturing fluid (slickwater fracturing fluid without proppant added) and the second slickwater fracturing fluid (proppant added slick water fracturing fluid) as the working fluid.

[0097] Among them, the second slickwater fracturing fluid is prepared from the first slickwater fracturing fluid, proppant and fiber, the proppant is coated sand, and the proppant concentration is 250kg / m 3 , the fiber concentration is 1kg / m 3 .

[0098] The design method specifically includes the following steps:

[0099] 1. The first injection stage

[0100] First use 8~10m 3 / min to inject 30m into the target reservoir 3 The first slick water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com